Insulating sleeve bulging tool

An insulating sleeve and expanding technology, which is applied to insulators, insulators, waveguide-type devices, etc., can solve the problems of increased structure, unstable electrical indicators, difficult to guarantee the size of the outer circle machining, affecting the overall performance of the filter, etc. To improve the efficiency and the quality of the shape, the effect of the shape is good, and the stability is enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

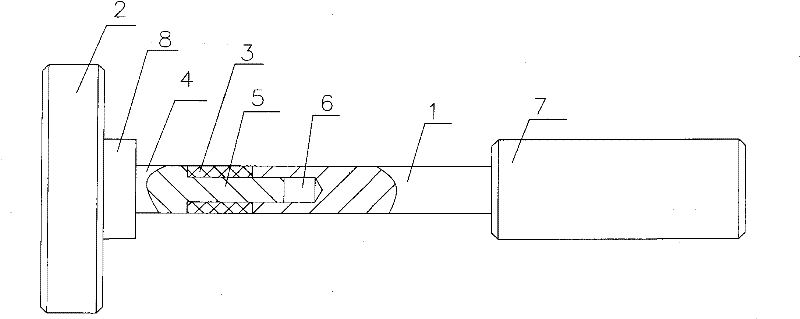

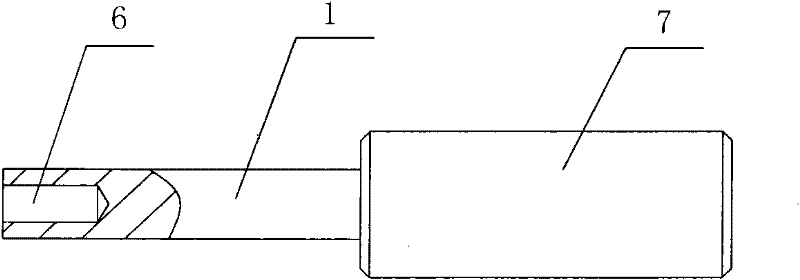

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

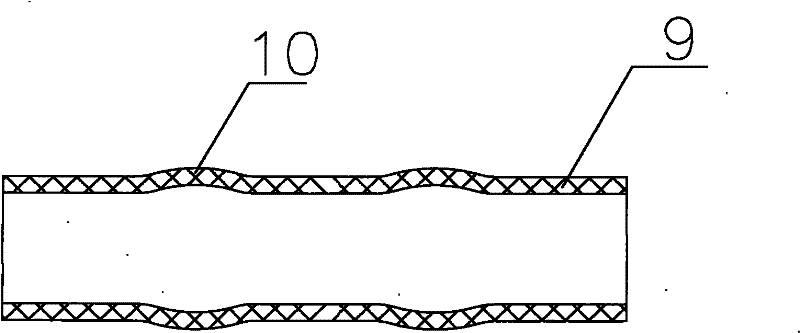

[0027] like figure 1 In the shown insulating sleeve, at least one ring of flanges 10 is provided on the insulating sleeve 9 along the circumferential direction of the insulating sleeve 9, and the protrusion height of the flanges 10 ranges from 0.5 to 0.8 mm. like Image 6 As shown, the flange 10 is used to closely fit the filter cavity 11 to prevent the insulating sleeve 9 from being displaced in the filter cavity 11 .

[0028] In the above technical solution, the insulating sleeve 9 is provided with two rings of flanges 10 along the circumferential direction of the insulating sleeve 9 . The distance between the flange 10 on the left side of the insulating sleeve 9 and the left end of the flange sleeve 9 is 10.5-11.5 mm, and the distance between the flange 10 on the right side of the insulating sleeve 9 and the right end of the flange sleeve 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com