Preparation method of tailing micropowder portland cement

A technology of portland cement and tailings micropowder, which is applied in the direction of cement production, etc., can solve the problems of limitations, failure to stimulate and mobilize chemical and physical functions, etc., and achieve improved rheology, good micro-aggregate effect, good The effect of the shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

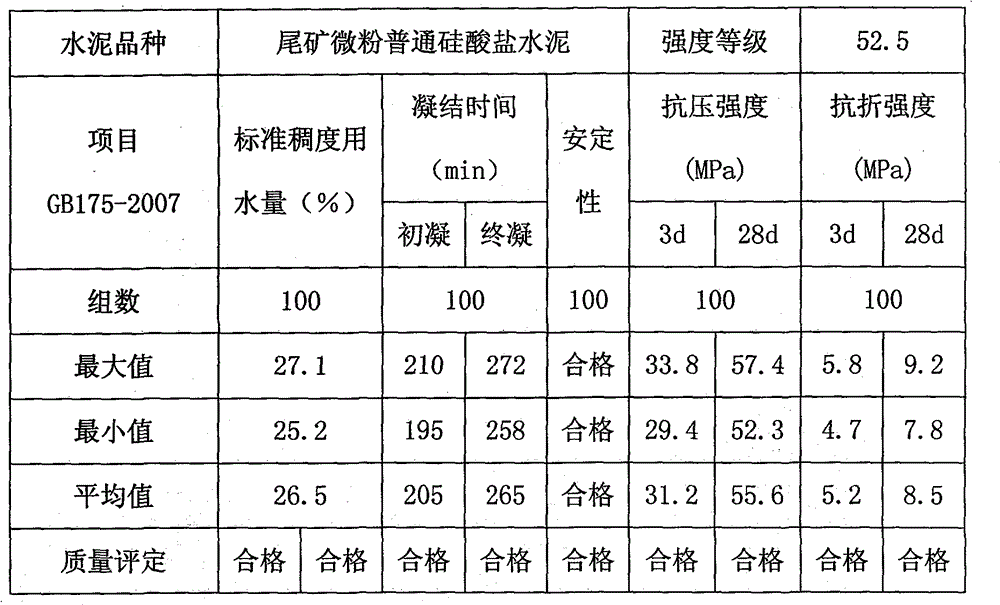

[0032] Tailings micropowder Portland cement provided by the present invention is used to prepare tailings micropowder ordinary Portland 52.5 cement:

[0033] In terms of mass percentage, clinker micropowder is 95%, tailings micropowder 5%, which is obtained by mixing and grinding.

[0034] Statistical Table 1 of Verification Test Results

[0035]

Embodiment 2

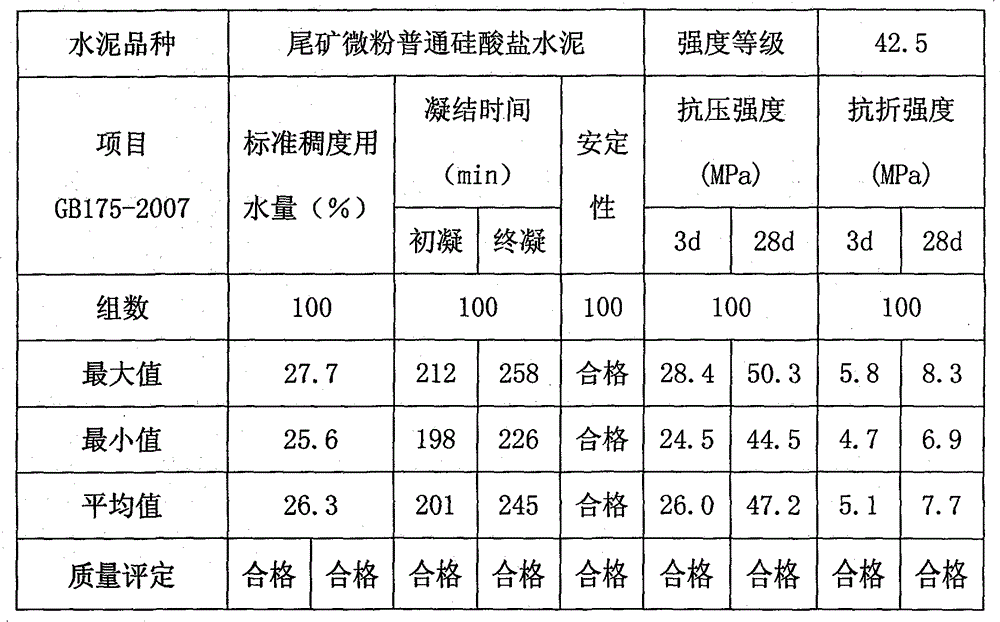

[0037] The micro-powdered tailings Portland cement provided by the invention is prepared from the micro-powdered tailings ordinary Portland 42.5 cement; in terms of mass percentage, 85% of clinker micro-powder and 15% of tailings micro-powder are mixed and ground to obtain the product.

[0038] Statistical Table 2 of Verification Test Results

[0039]

Embodiment 3

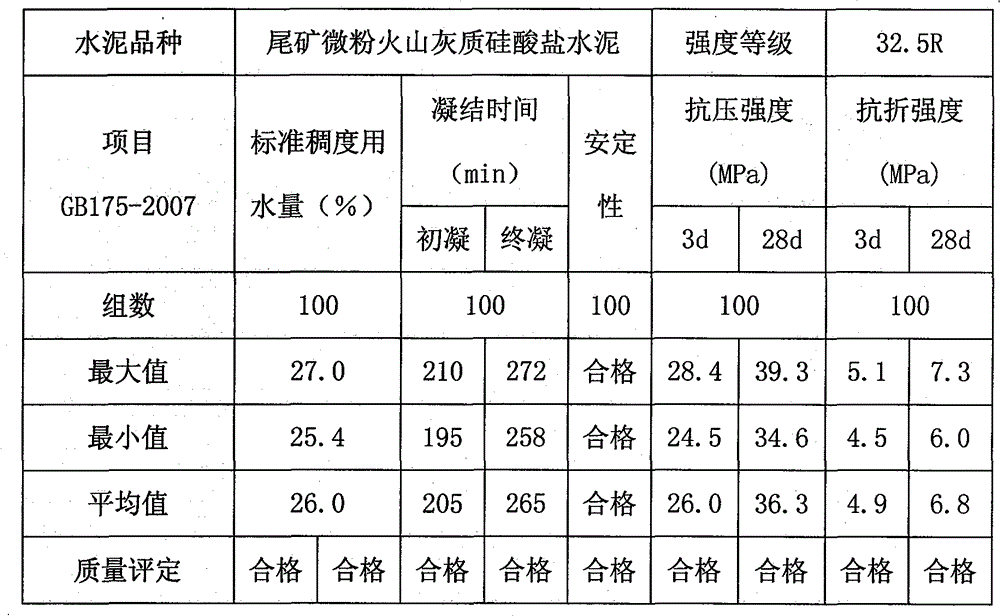

[0041] Tailings micropowder Portland cement provided by the present invention is used to prepare tailings micropowder pozzolanic Portland 32.5R cement:

[0042] In terms of mass percentage, clinker micropowder is 70%, tailings micropowder 30%, which is obtained by mixing and grinding.

[0043] Statistical Table 3 of Verification Test Results

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com