A tool for correcting the shape of engine load-bearing struts matched with heat treatment

A technology of engine and heat treatment temperature, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., to achieve the effects of convenient operation, lower production costs, and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

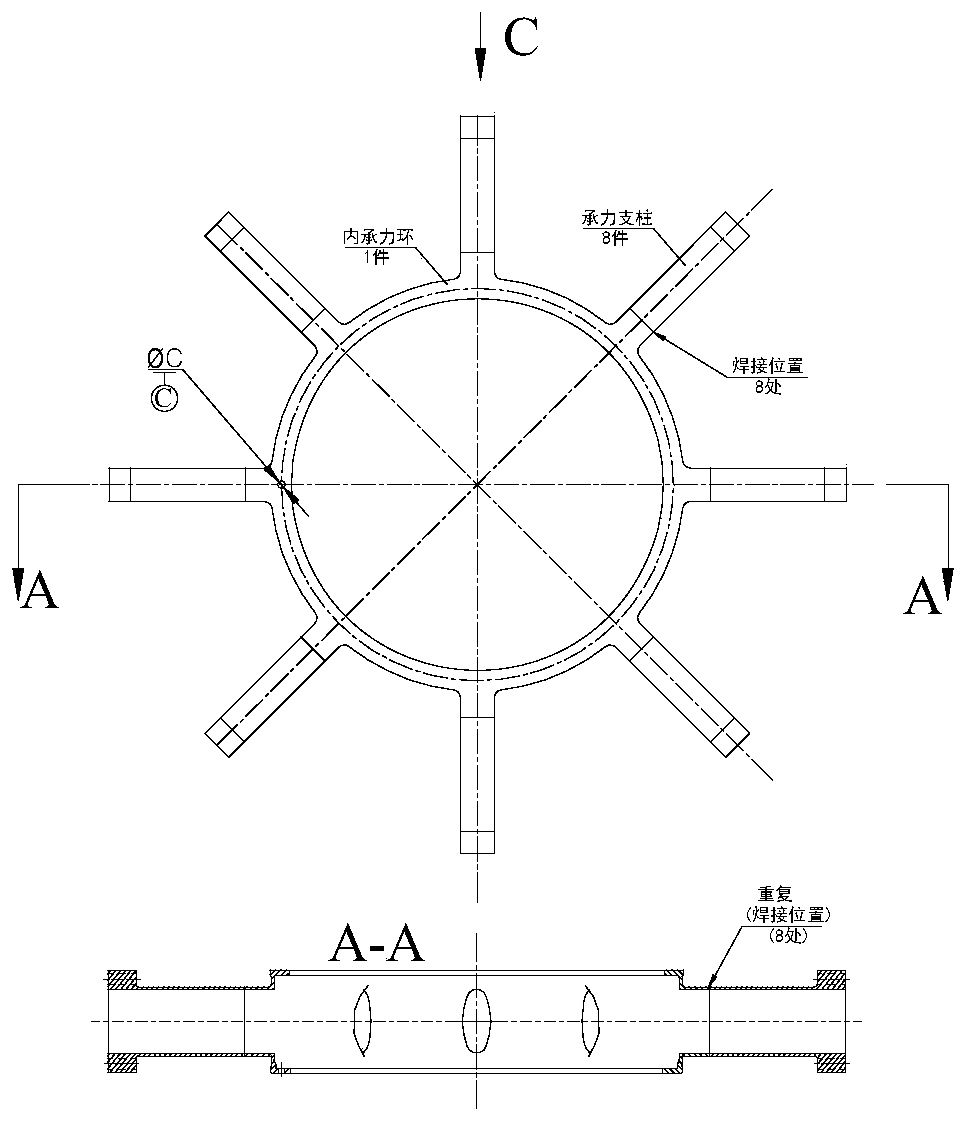

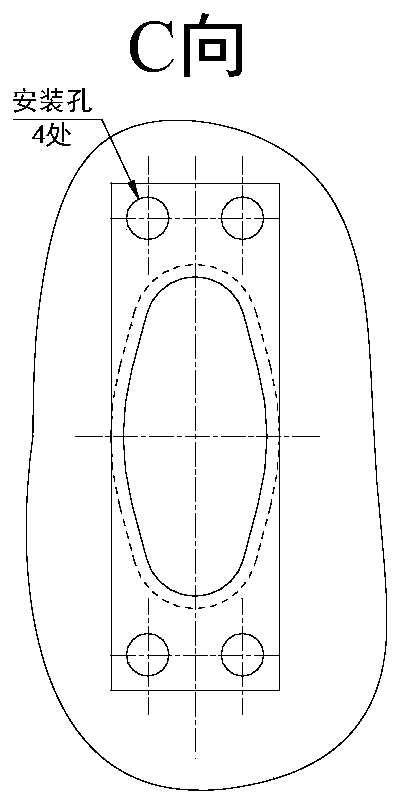

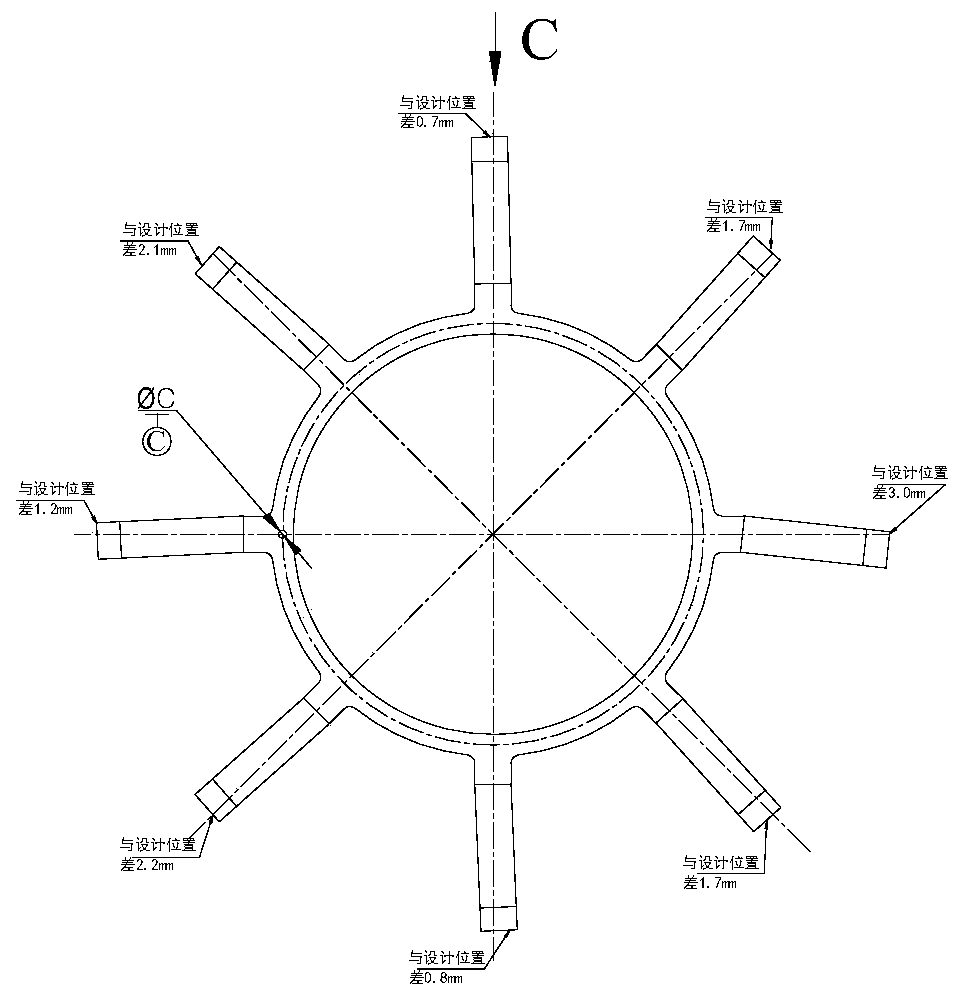

[0031] The shape-calibrating tooling of the engine load-bearing strut that matches the heat treatment provided in this embodiment is based on the welding between the inner load-bearing ring of a certain type of engine and 8 evenly distributed load-bearing struts, which need to be calibrated due to deformation. shape to design. Since there are 8 welding positions, such as figure 1 As shown, the structure of the designed correction tool is as follows Figure 5 As shown, it is specifically composed of a base 1 , a correction assembly, a pressing plate assembly and a positioning angle pin 22 .

[0032] Among them, the base 1 is a disc with a boss 2 in the middle, and an axial step through hole 3 is opened in the middle of the boss 2, and a pin hole 4 is opened on one side of the upper surface of the boss 2, and the pin hole is connected with the bottom surface of the inner bearing ring. The pin hole ΦC matches, and is connected and positioned by the positioning angle pin 22, se...

Embodiment 2

[0040] The structure of the correction tooling provided by this embodiment is basically the same as that of Embodiment 1, the difference is that: 1) there are 4 correction assemblies and pressure plate assemblies in this embodiment; 2) the inclination angle α of the inclined through hole is 30° , the angle α between the bevel at the front end of the wedge nail and the axis is also 30°; 3) The heat treatment temperature is 700°C, and the heat treatment time is 3 hours.

Embodiment 3

[0042] The structure of the correction tooling provided by this embodiment is basically the same as that of Embodiment 1, the difference is that: 1) there are 6 correction assemblies and platen assemblies in this embodiment; 2) the inclination angle α of the inclined through hole is 20° , the angle α between the bevel at the front end of the wedge nail and the axis is also 20°; 3) The heat treatment temperature is 750°C, and the heat treatment time is 1.5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com