Heat treatment distortion control method for leaf spring parts

A technology of heat treatment deformation and control method, which is applied in the field of heat treatment of spring leaf parts and heat treatment deformation control of spring leaf parts. The effect is obvious, the rebound effect is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

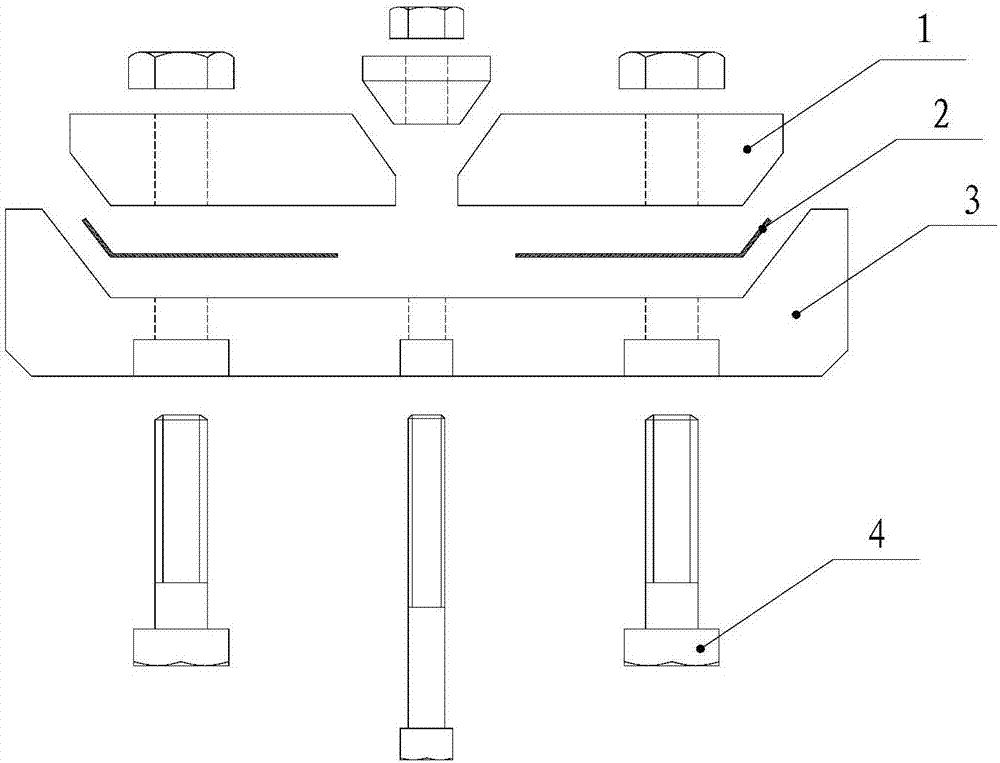

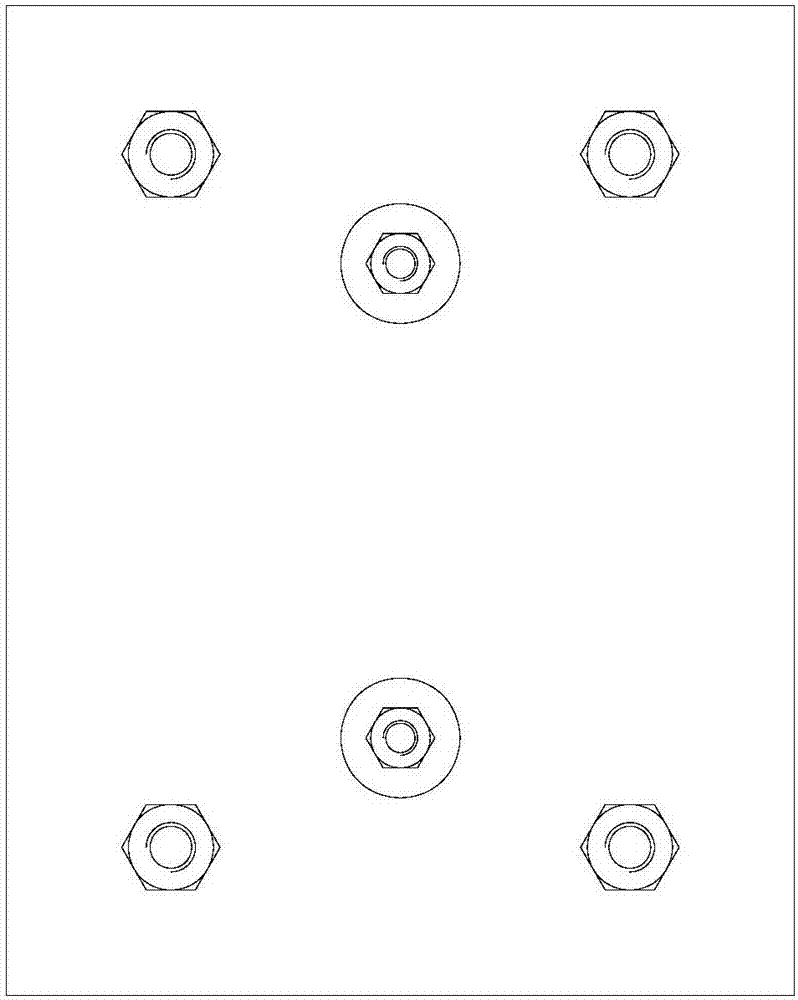

[0021] Such as figure 1 , 2 As shown in the figure, between the pressure plate and the base in the shape-correcting fixture, the bolts that apply pre-tightening force to the parts are arranged symmetrically.

[0022] The first step, quenching treatment: place the cold-formed 65Mn reed in a carbon box to reduce the high-temperature oxidation of the parts, put them into the furnace together and heat them at 800-820°C for quenching treatment;

[0023] The second step is pre-calibration: place the quenched spring in the shape-calibration fixture. Because the deformation of the reed is different and the hardness is high, you can moderately pre-tighten the bolts that fix the pressure plate and the base first, so that most of the reed will stick to the shape. Put it into the furnace and heat it at the specified tempering temperature, wherein the tempering temperature is 350 ° C ~ 400 ° C;

[0024] The third step is to finalize the shape: the total tempering time is h. When the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com