Patents

Literature

111 results about "Distortion control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

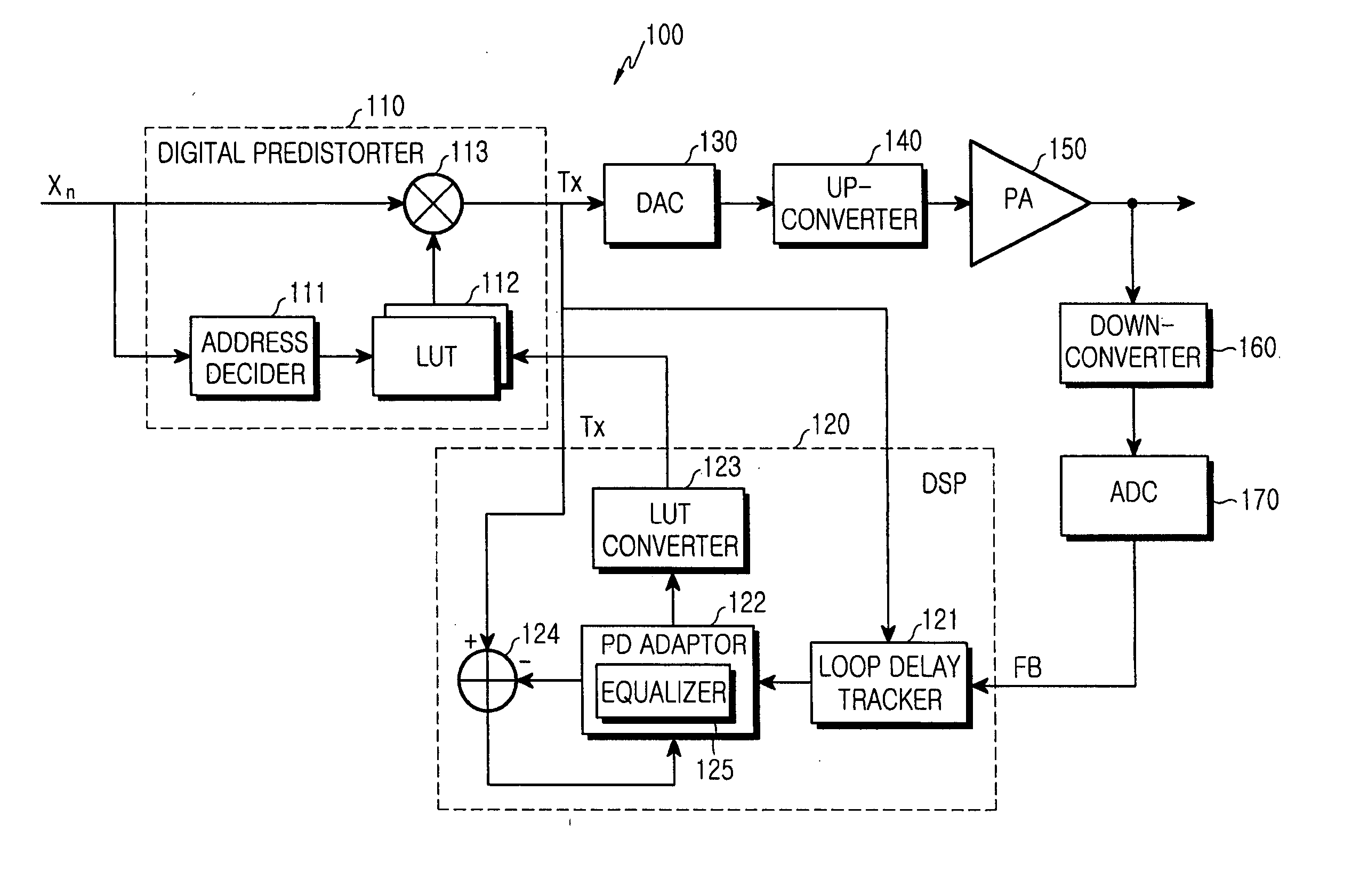

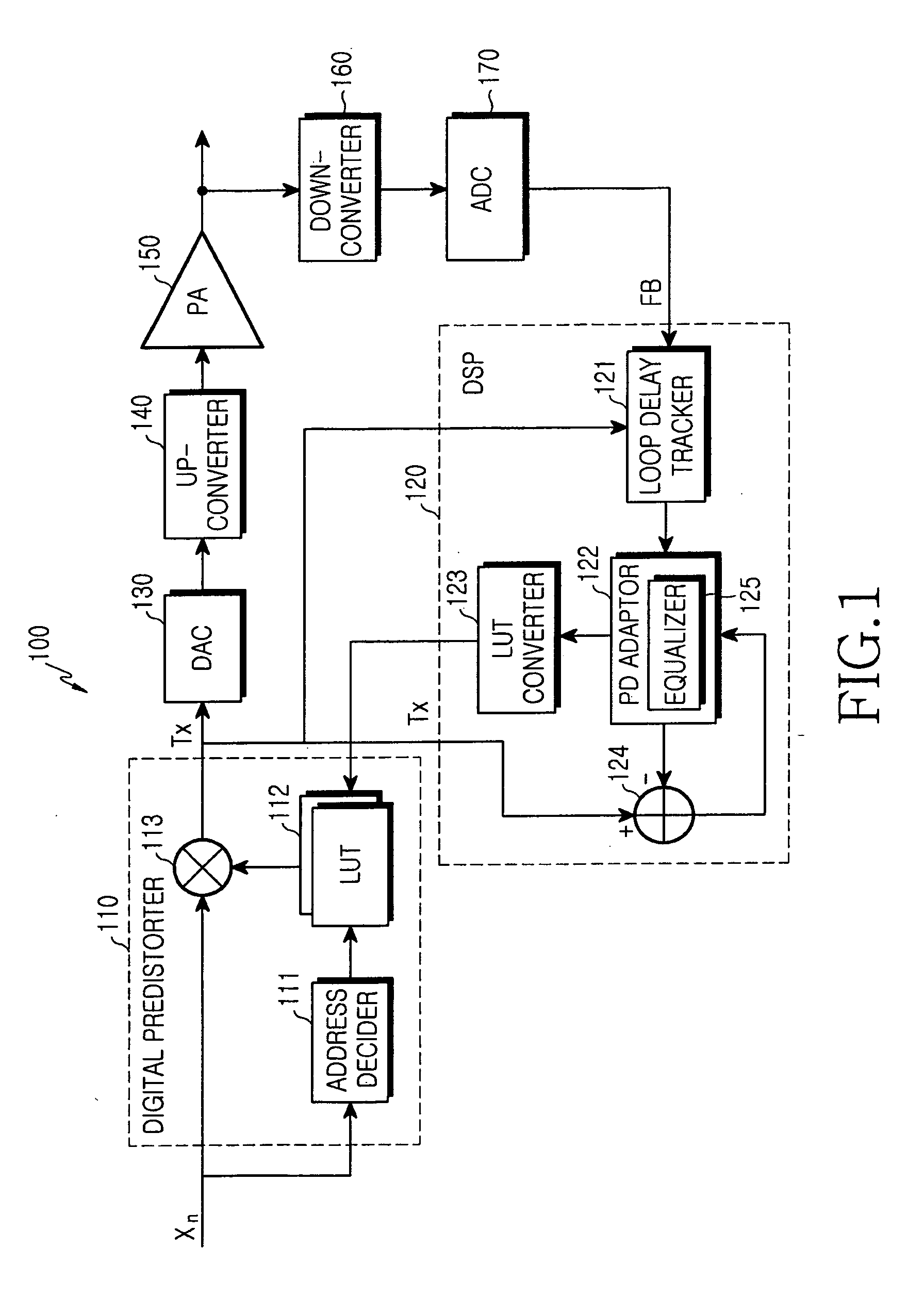

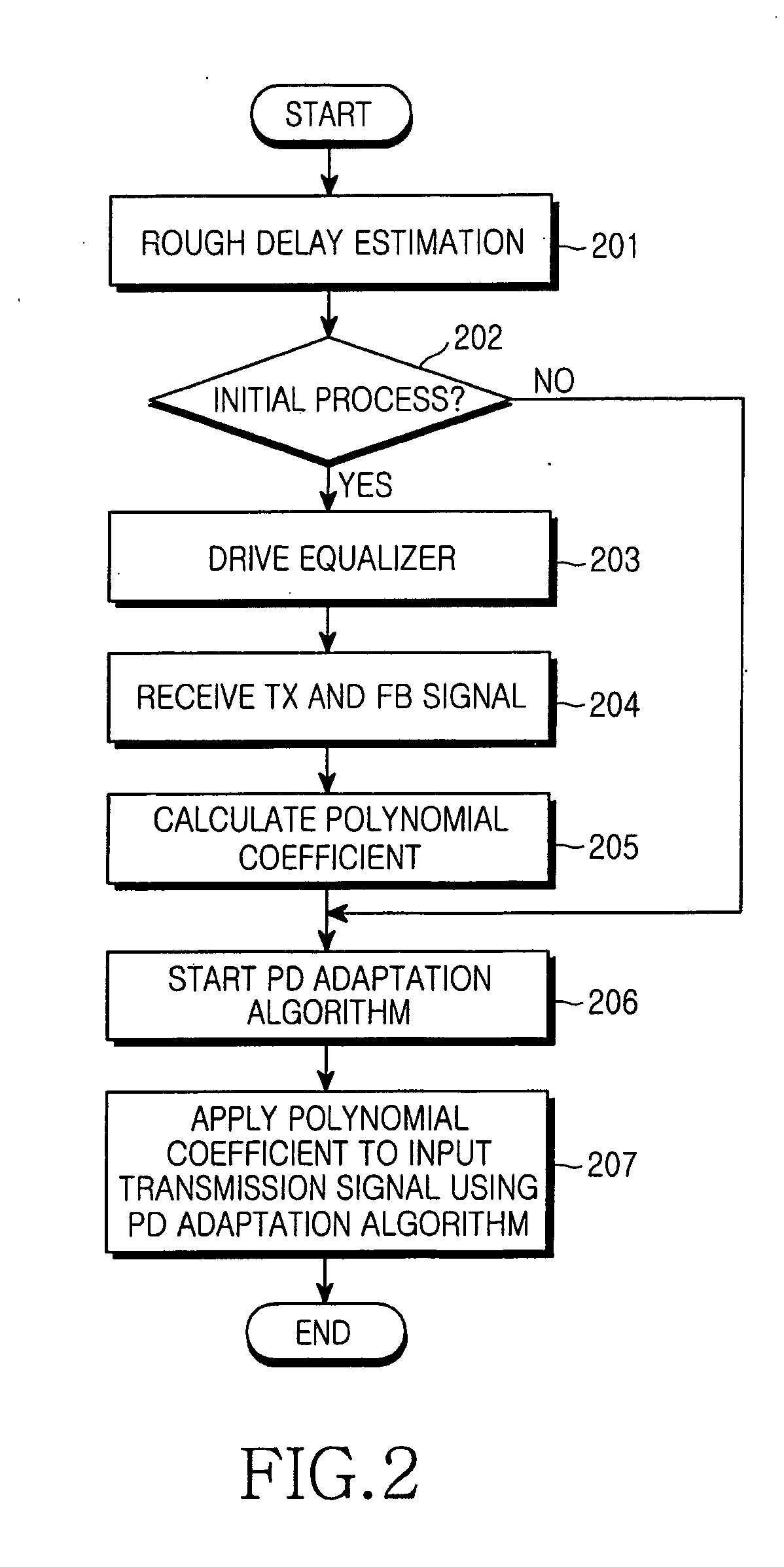

Digital predistortion apparatus and method for a wideband power amplifier

InactiveUS20050253745A1Performance maximizationShorten convergence timeAmplifier modifications to reduce non-linear distortionElectric signal transmission systemsCommunications systemAudio power amplifier

A method and apparatus compensate for a non-linear characteristic of a wideband power amplifier in a transmitter for a communication system, which has the wideband power amplifier for amplifying a digital input signal. The method involves the steps of (a) generating an address based on the digital input signal, reading a distortion control value corresponding to the address from a look-up table, and applying the read distortion control value to the digital input signal to predistort the digital input signal; (b) frequency up-converting the predistorted signal and amplifying the frequency up-converted signal; (c) frequency down-converting the amplified signal and compensating for a delay of the frequency down-converted signal; and (d) updating a predetermined distortion control value in the look-up table to compensate for an error value generated in the power amplifier and an analog path occurring in steps (b) and (c) based on the compensated signal.

Owner:SAMSUNG ELECTRONICS CO LTD

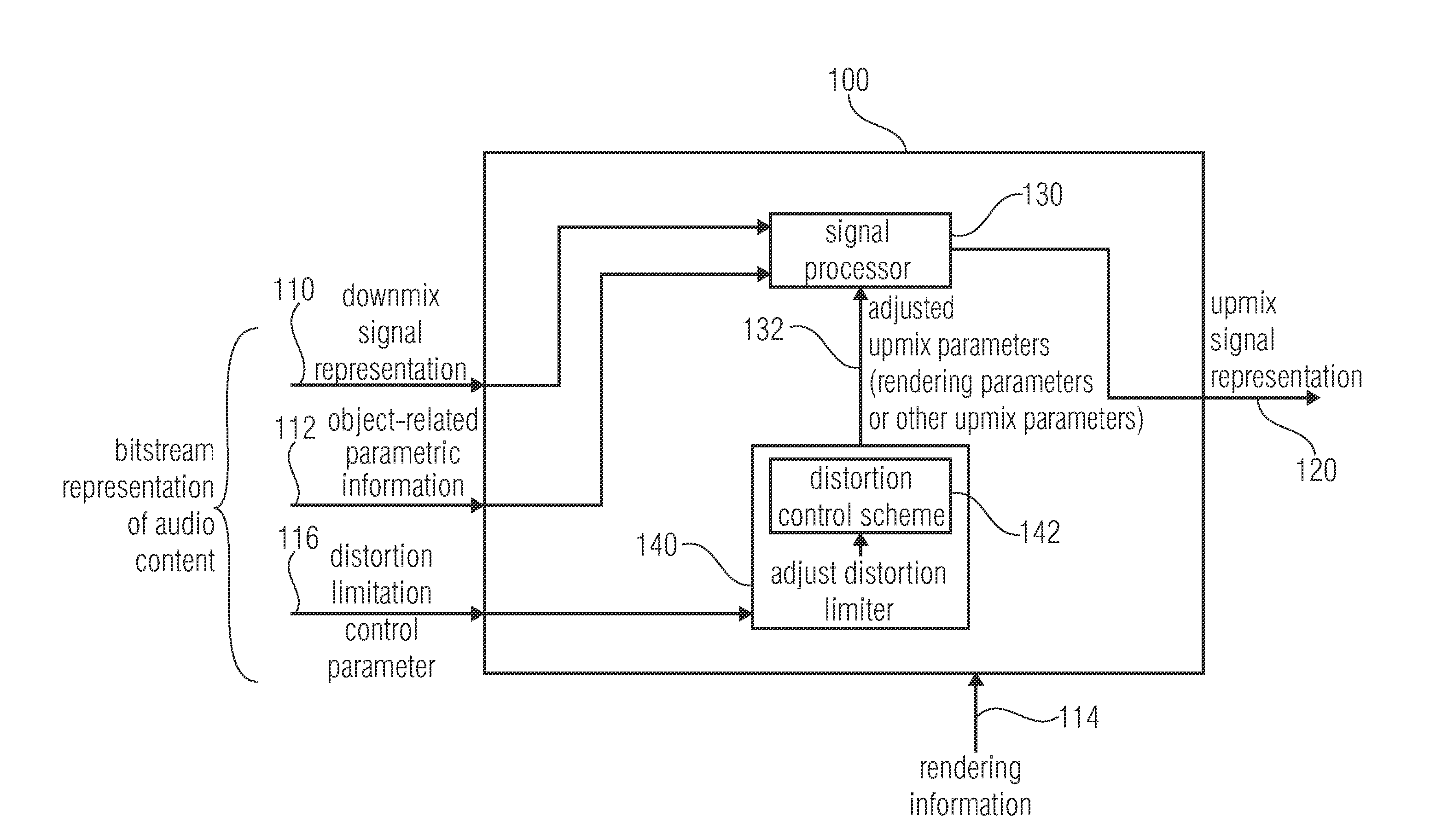

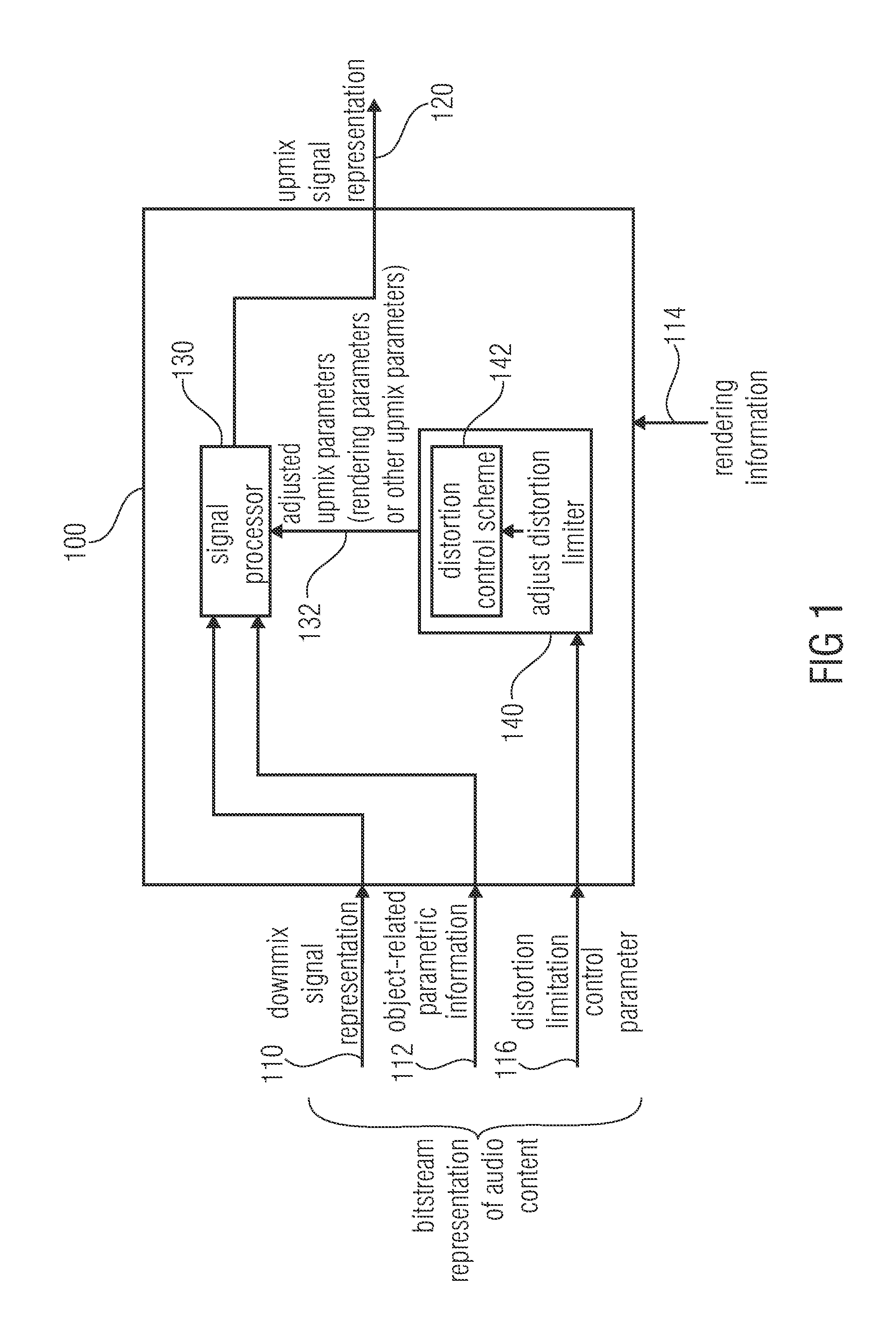

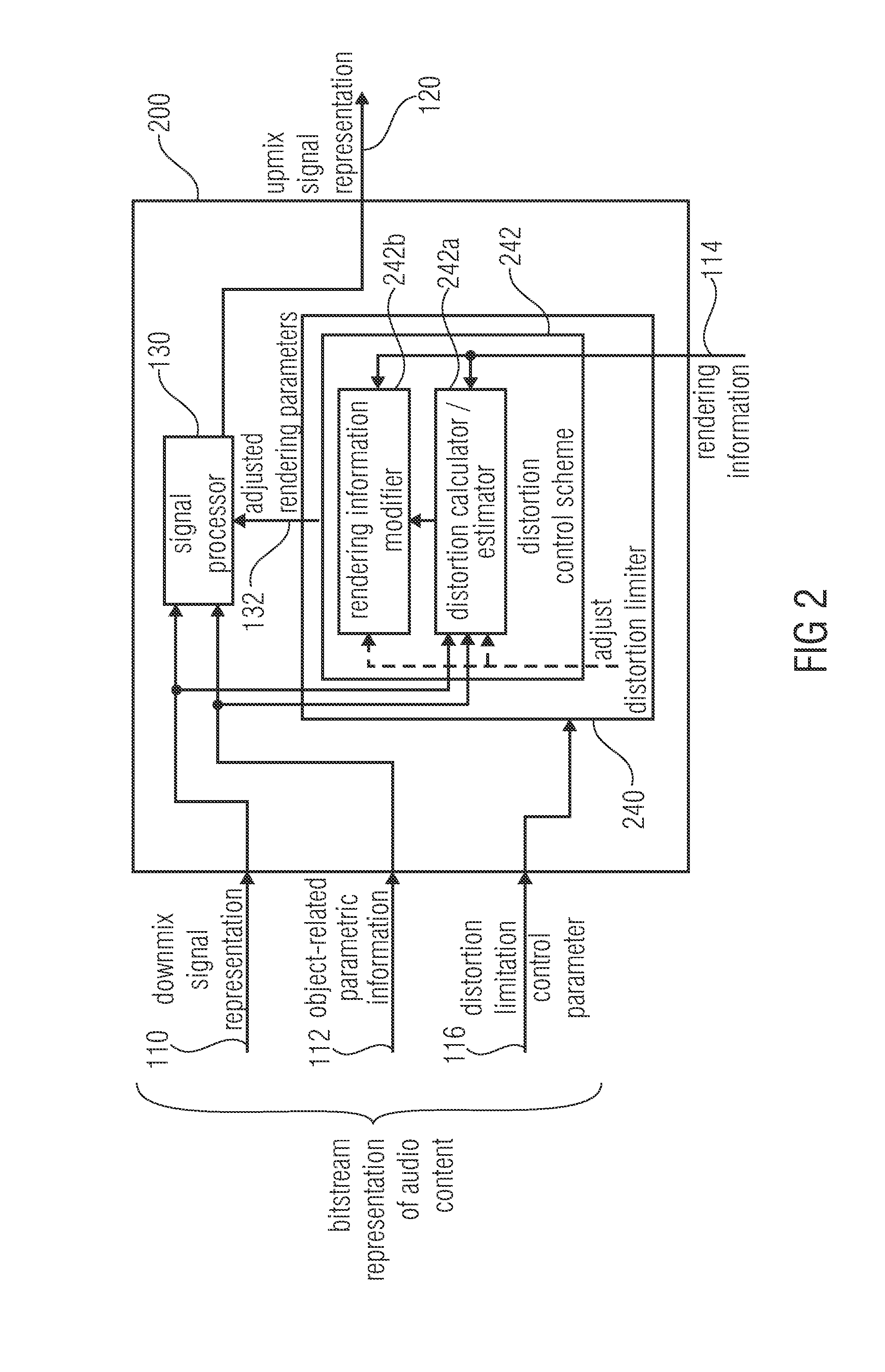

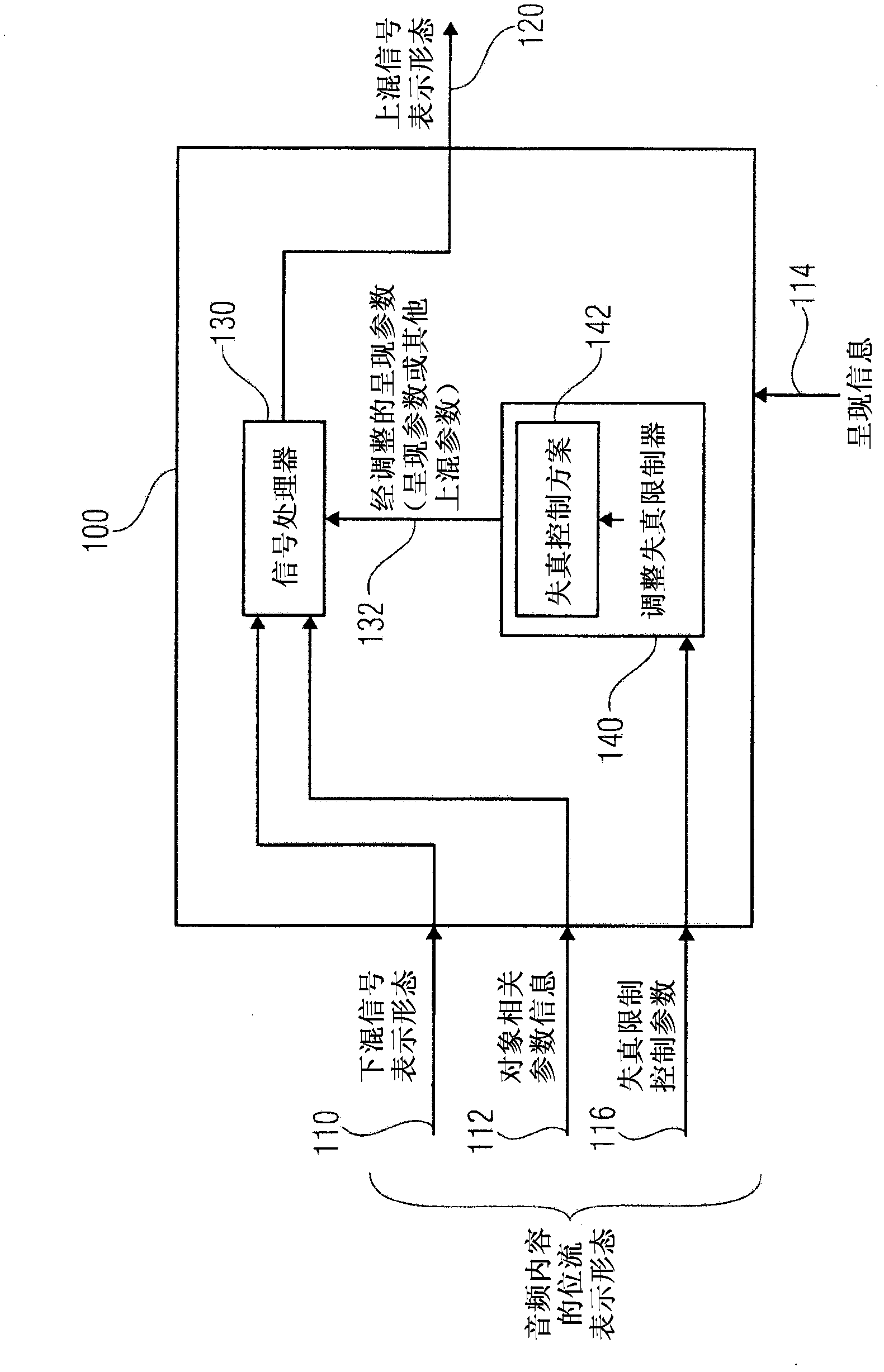

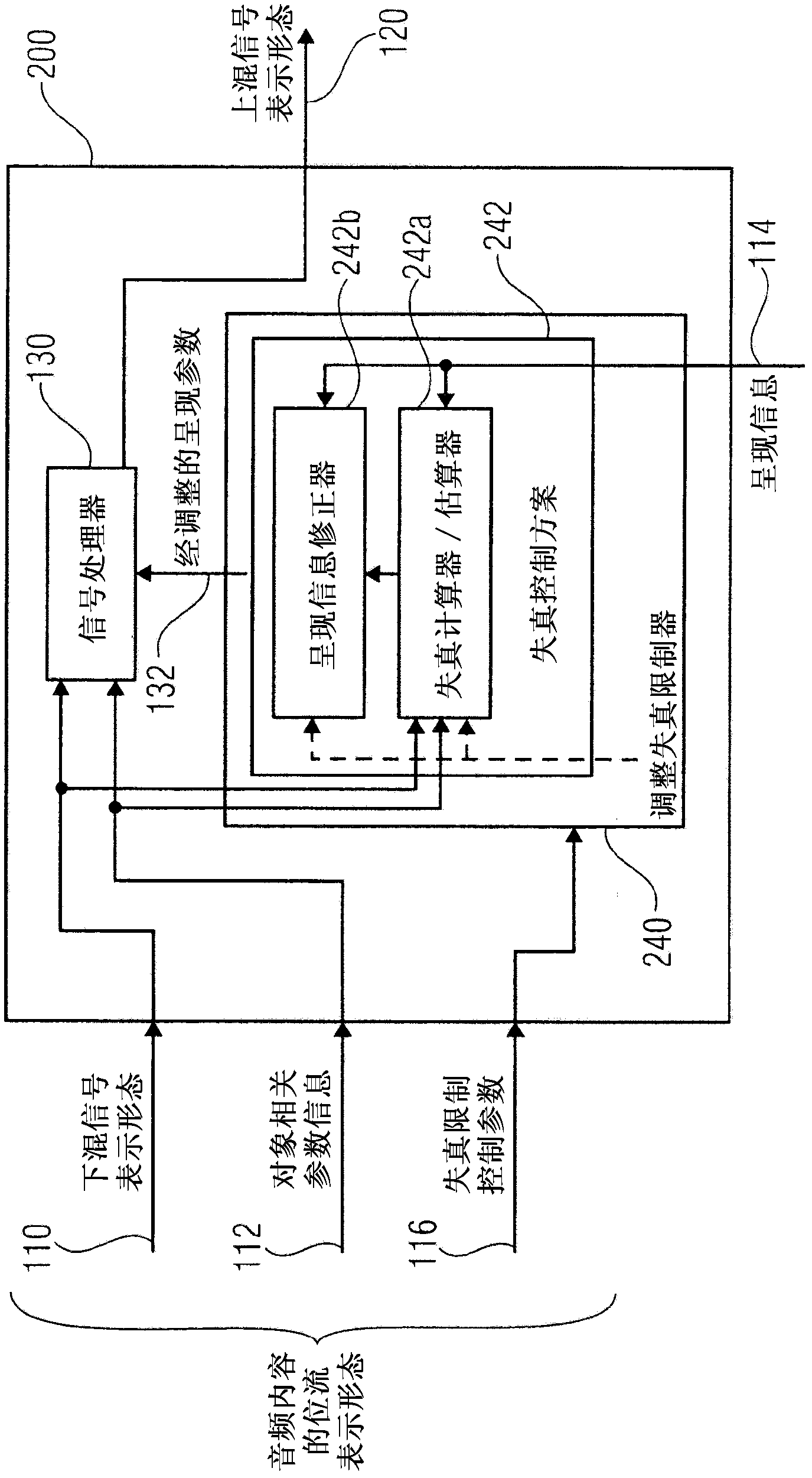

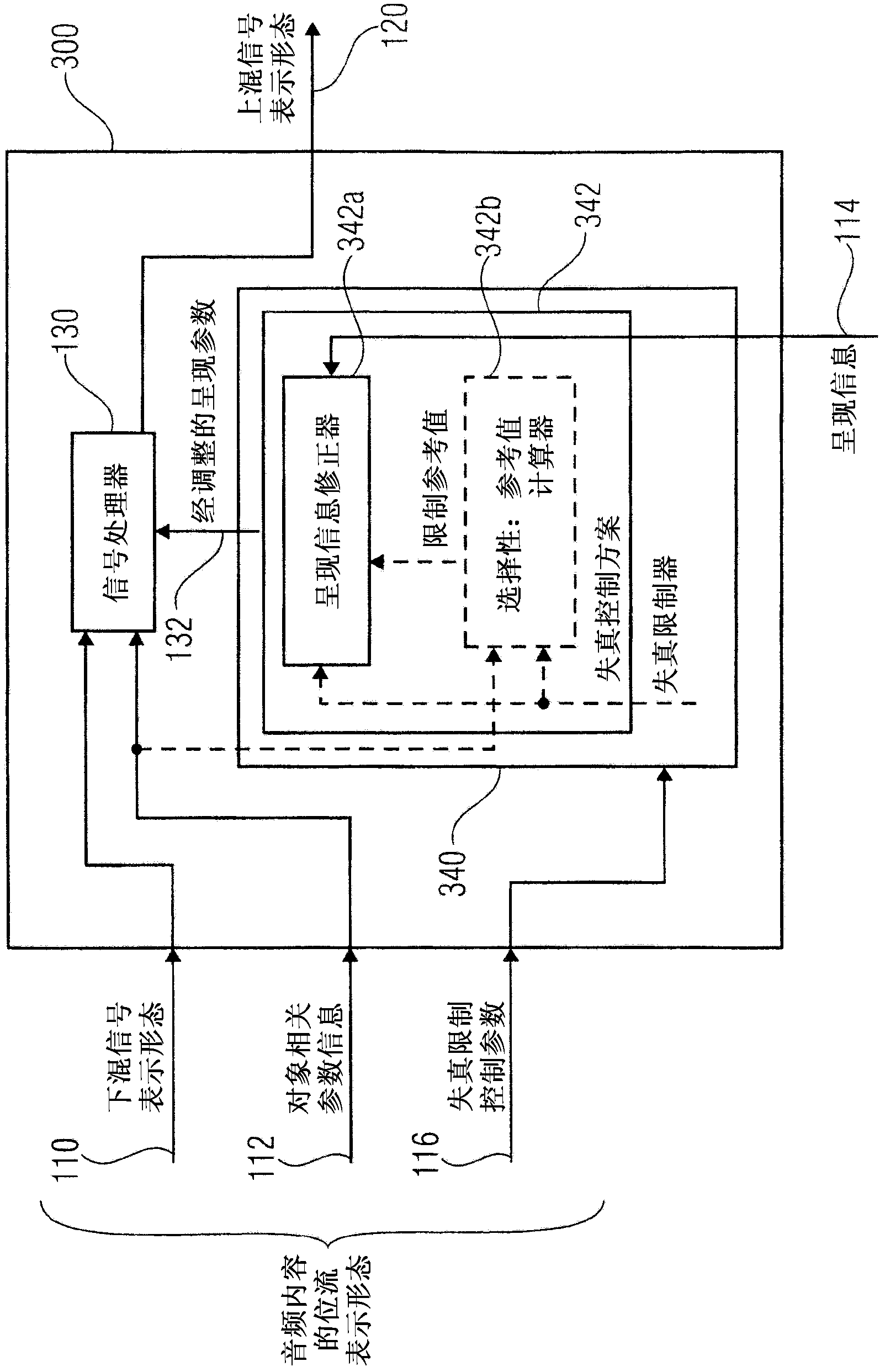

Apparatus for providing an upmix signal representation on the basis of a downmix signal representation, apparatus for providing a bitstream representing a multi-channel audio signal, methods, computer program and bitstream using a distortion control signaling

ActiveUS20120243690A1Avoid and limit audible distortionEffective regulationSpeech analysisTransmission noise suppressionVocal tractAudio frequency

An apparatus for providing an upmix signal representation on the basis of a downmix signal representation and an object-related parametric information, which are included in a bitstream representation of an audio content, and in dependence on a rendering information, has a distortion limiter configured to adjust upmix parameters using a distortion control scheme to avoid or limit audible distortions which are caused by an inappropriate choice of rendering parameters. The distortion limiter is configured to obtain a distortion limitation control parameter, which is included in the bitstream representation of the audio content, and to adjust a distortion control scheme in dependence on the distortion limitation control parameter.

Owner:DOLBY INT AB +1

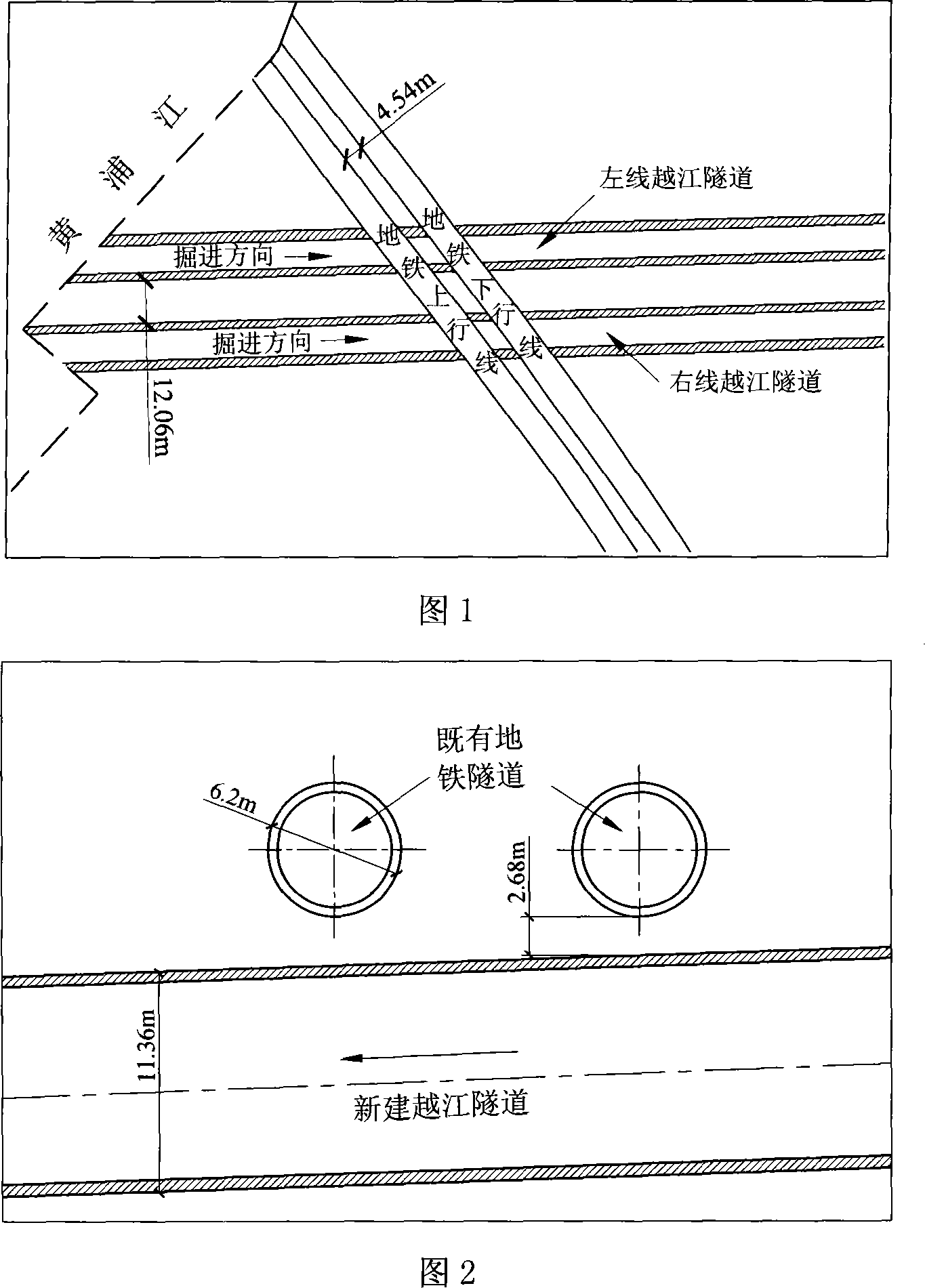

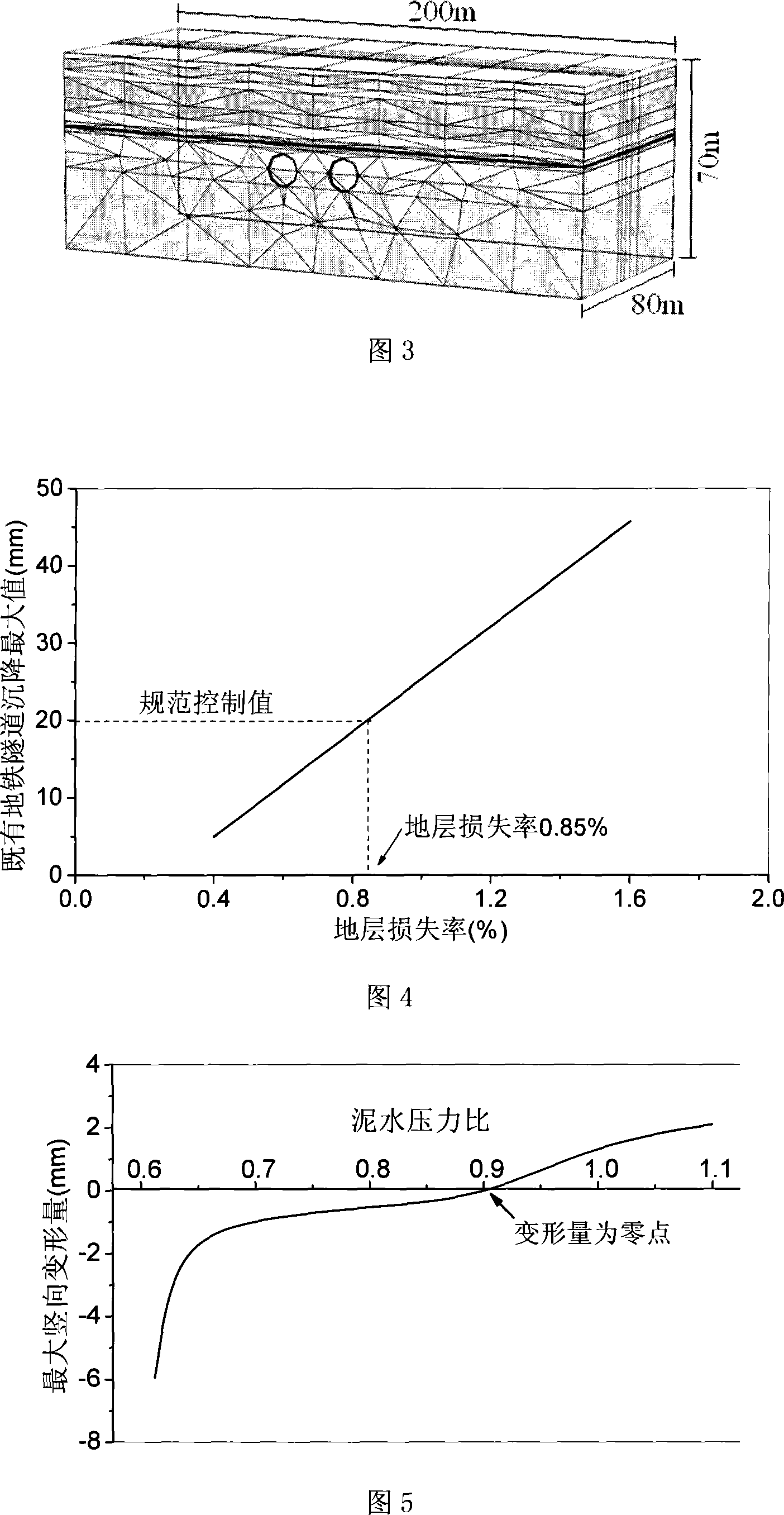

Large diameter tunneling close range down-traversing small diameter subway tunnel distortion control method

InactiveCN101215969AGuarantee smooth constructionEnsure safetyTunnelsUnderground tunnelFinite element method

The invention discloses a method for controlling distortion for deep large diameter shield tunnels to under-pass small diameter tunnels, which pertains to the technical field of tunnel engineering. According to the method, the control range of the stratum loss ratio of newly established tunnels and the optimum value of the support pressure of the shield cut surface are acquired by using the finite-element method; soil pressure in front of the shield cut surface is kept relatively balanced by setting the optimal value of the support pressure, and the support pressure fluctuation range of the cut surface is controlled to range from minus 10kPa to plus 10kPa; the stratum loss ratio of the newly established tunnels is controlled within the allowed range. According to the construction technique measures, a test propelling area is arranged before the shield reaches a cross position. In the area, construction is carried out according to the situation of the existing underground tunnels above; and construction parameters are controlled and regulated to adjust the support pressure, the propulsive velocity and the amount of the grout to be injected in time; the shield passes through the cross position in combination with the optimal values of the construction parameters of the test propelling area. The invention can not only ensure the construction of tunnels to be carried out safely and smoothly, but also minimize the influence of construction on ambient environment.

Owner:SHANGHAI JIAO TONG UNIV

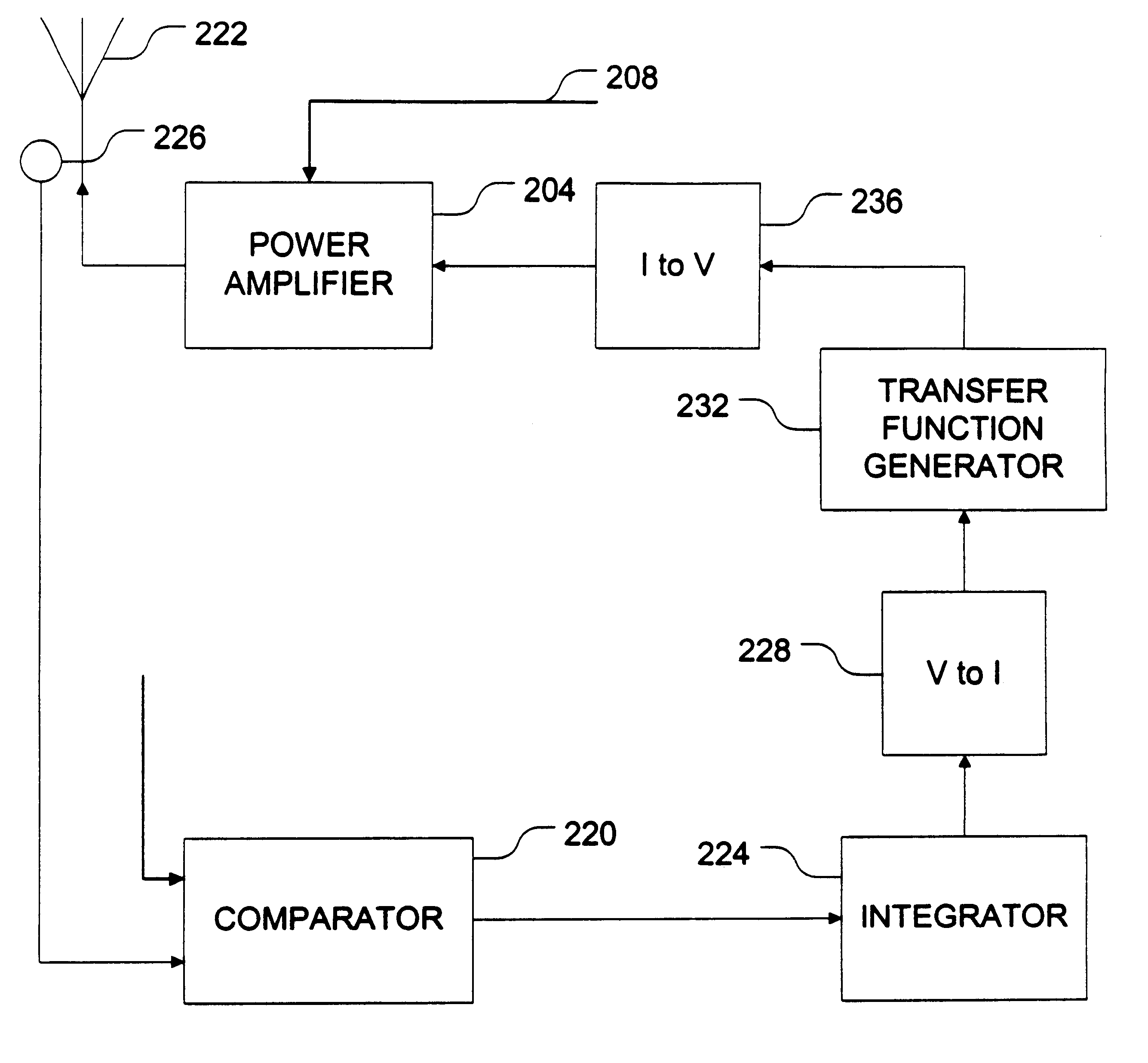

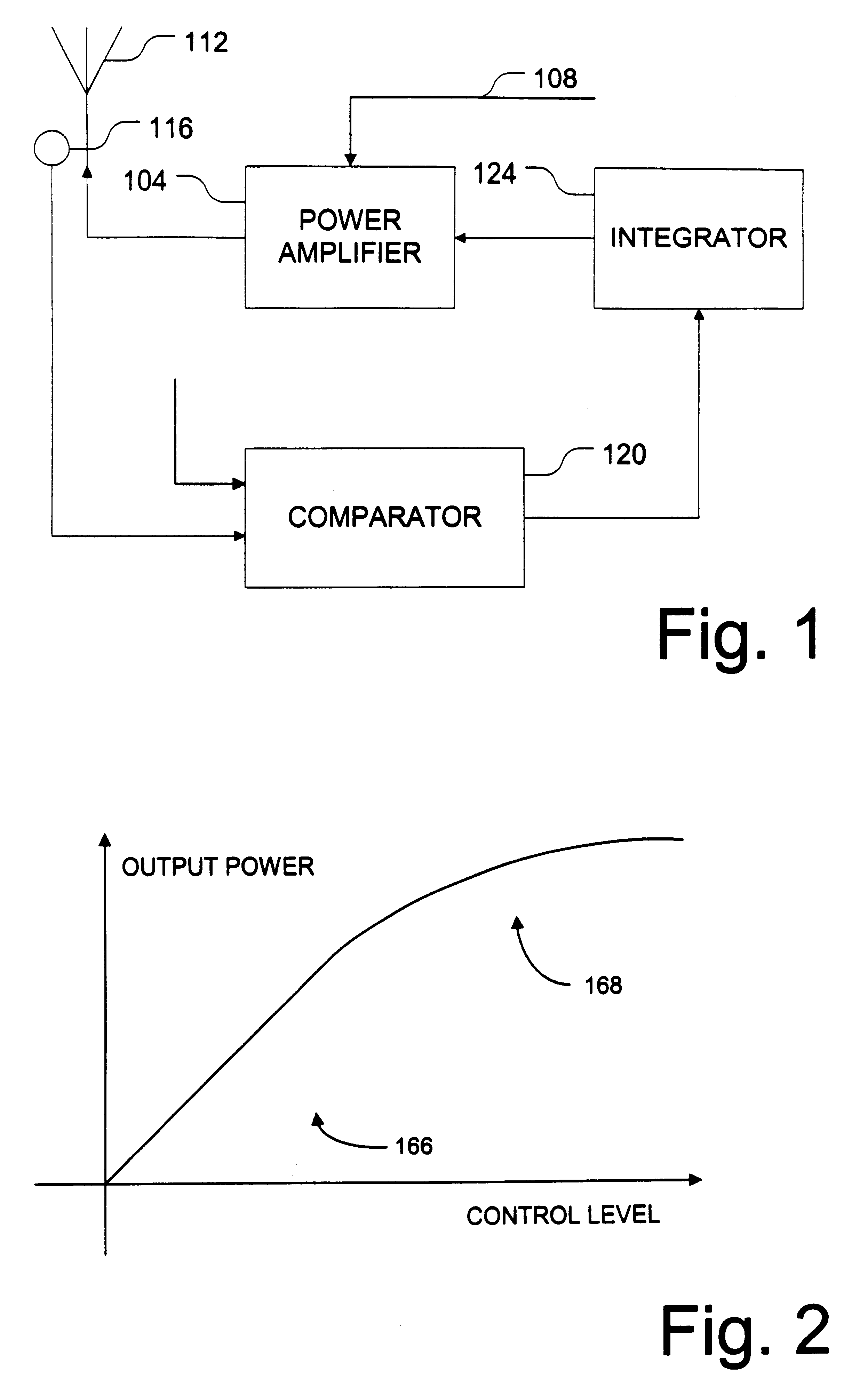

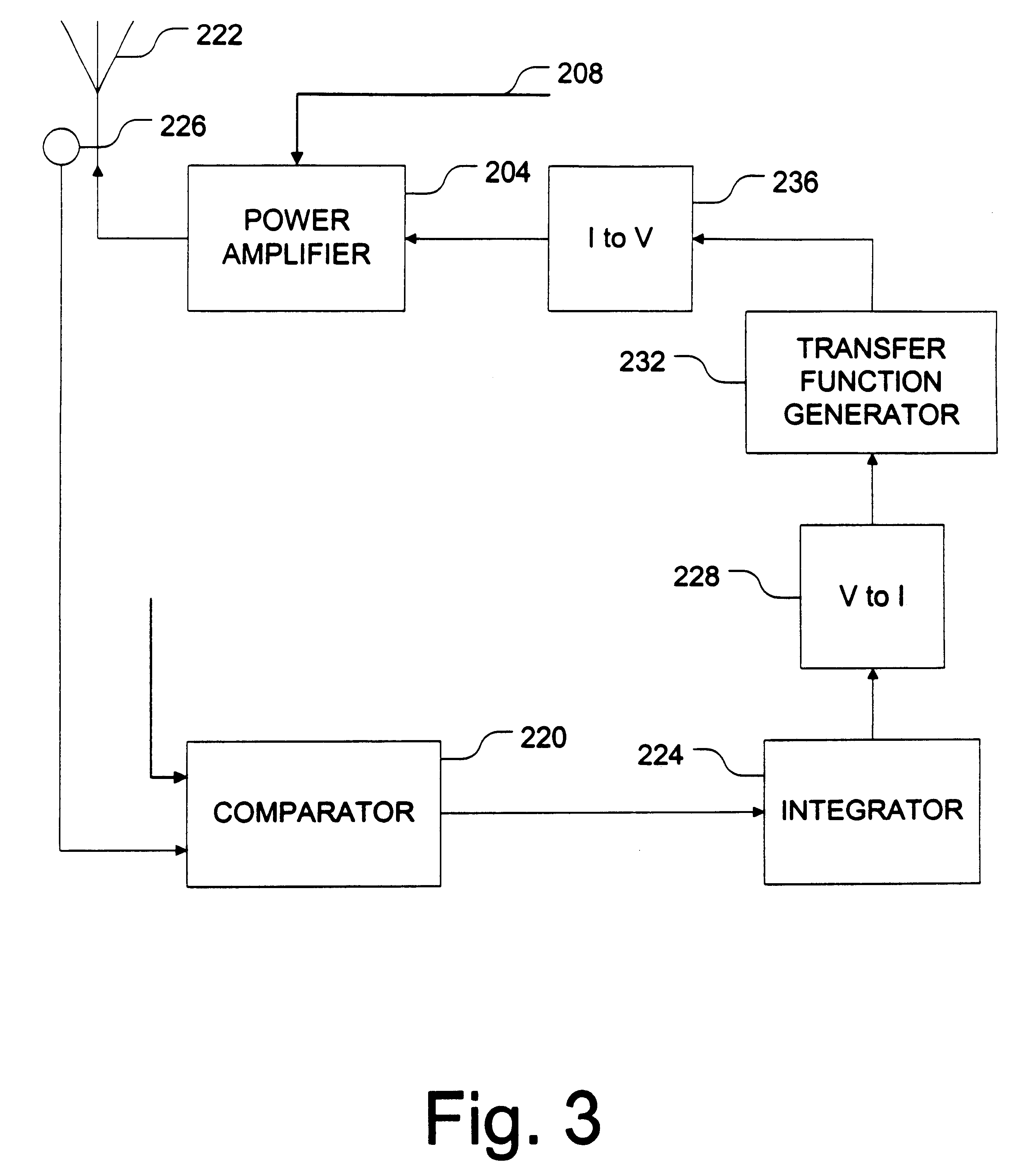

Distortion control feedback loop utilizing a non-linear transfer function generator to compensate for non-linearities in a transmitter circuit

InactiveUS6321072B1Adjustable outputLimiting output levelAmplifier modifications to reduce non-linear distortionResonant long antennasFunction generatorTransmitter

A transfer function generator provides the ability to provide a non-linear response in a feedback loop to compensate for non-linearities introduced elsewhere in the system. The transfer function generator includes a non-linear function generator configured to provide an output current that is a non-linear function of an input signal representing an error to be corrected. The transfer function generator can also include a linear function generator configure to provide a linear output current as a function of an input current representing the error corrected. Tuning devices can be provided to adjust the turn-on level of the non-linear function generator and the output level of the linear function generator to allow the transfer function generator flexibility in implementation.

Owner:SKYWORKS SOLUTIONS INC

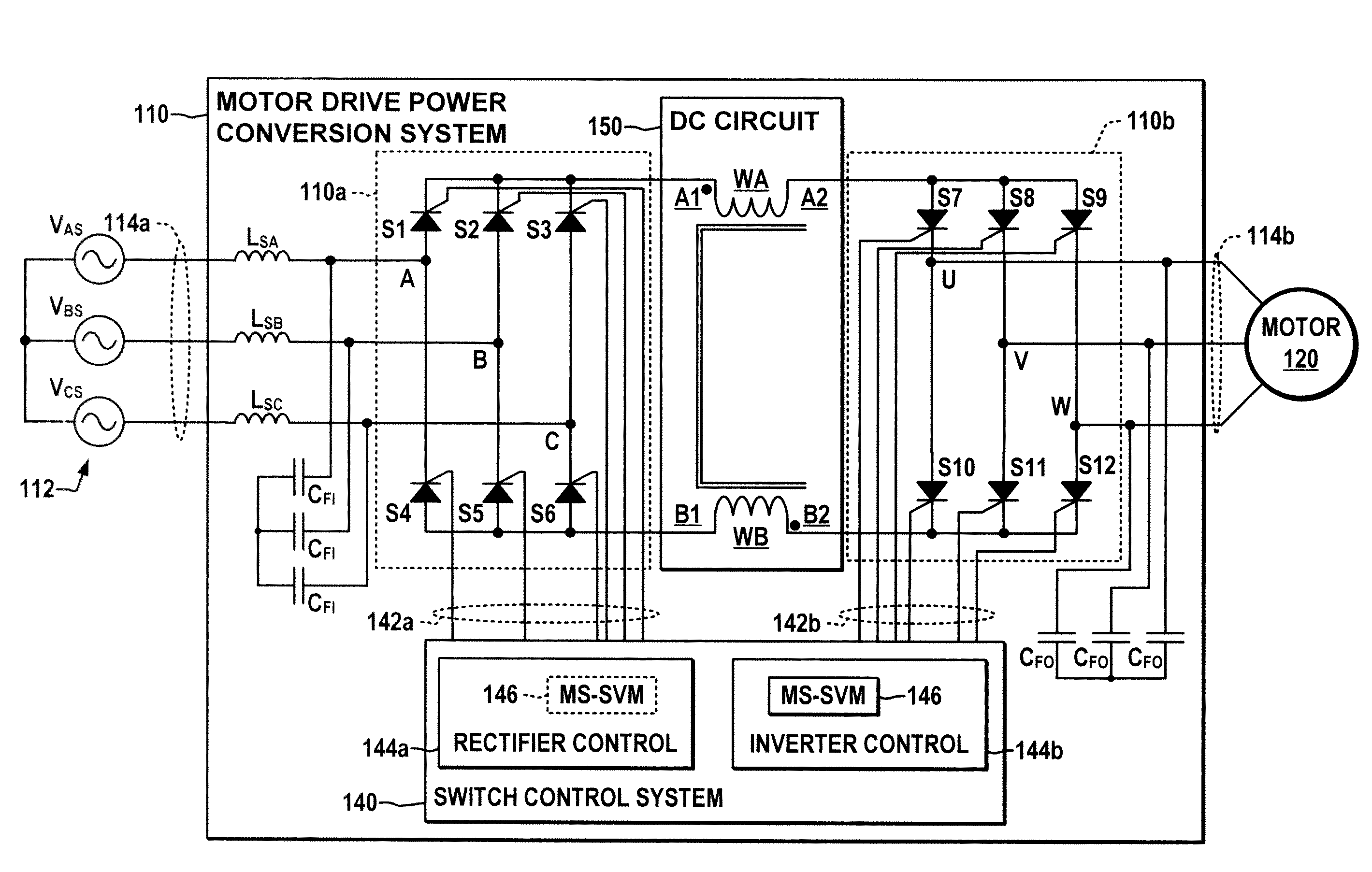

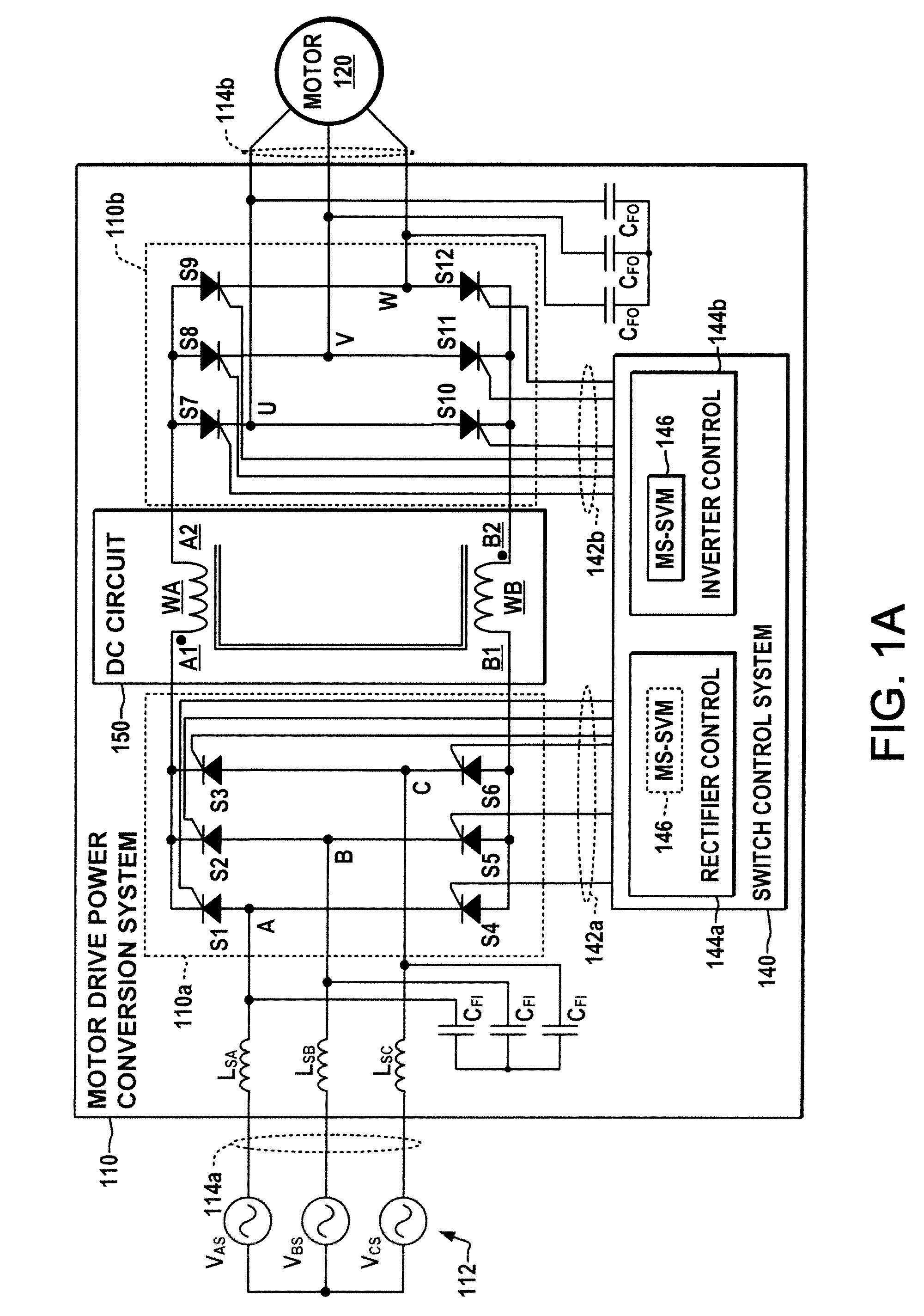

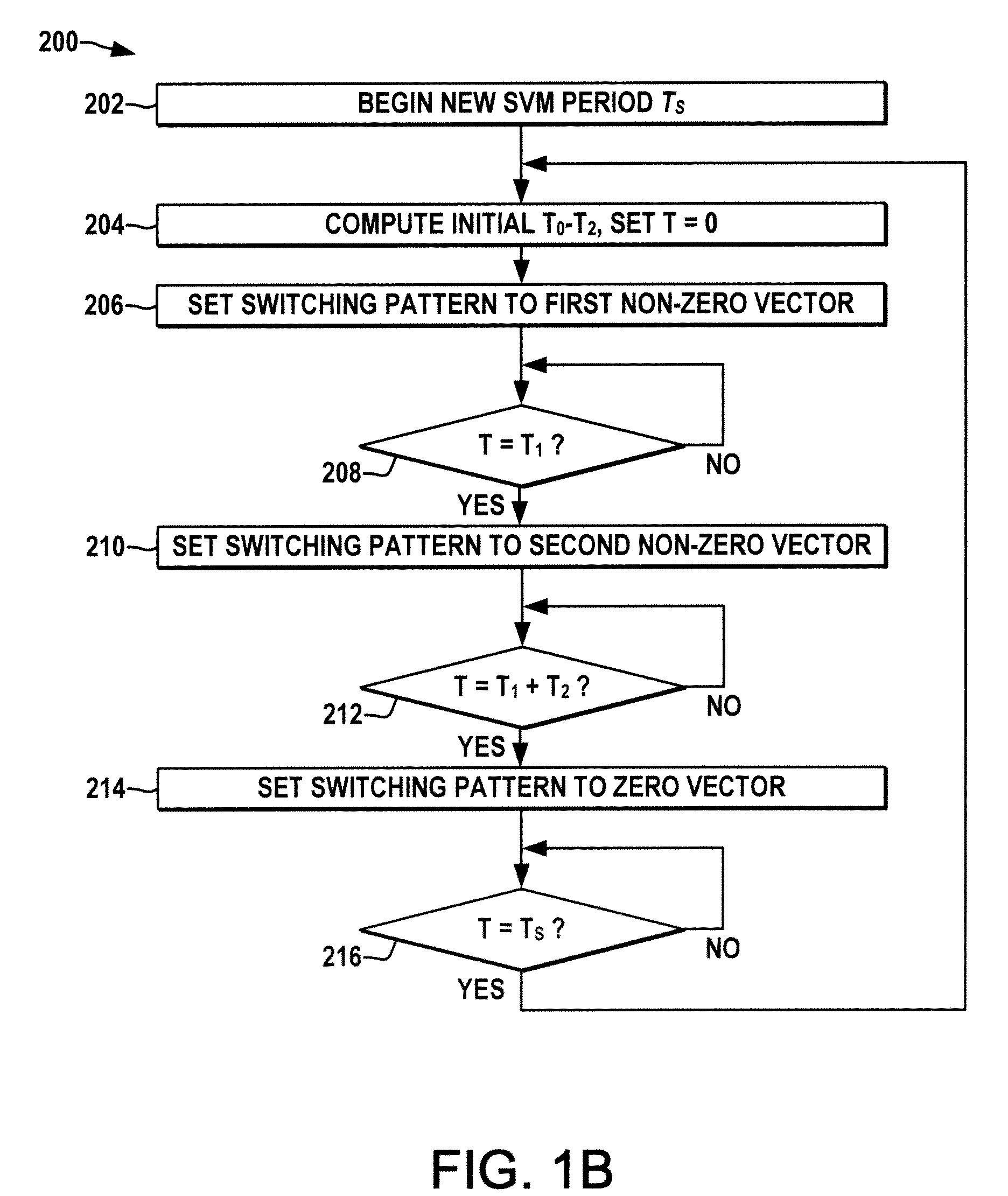

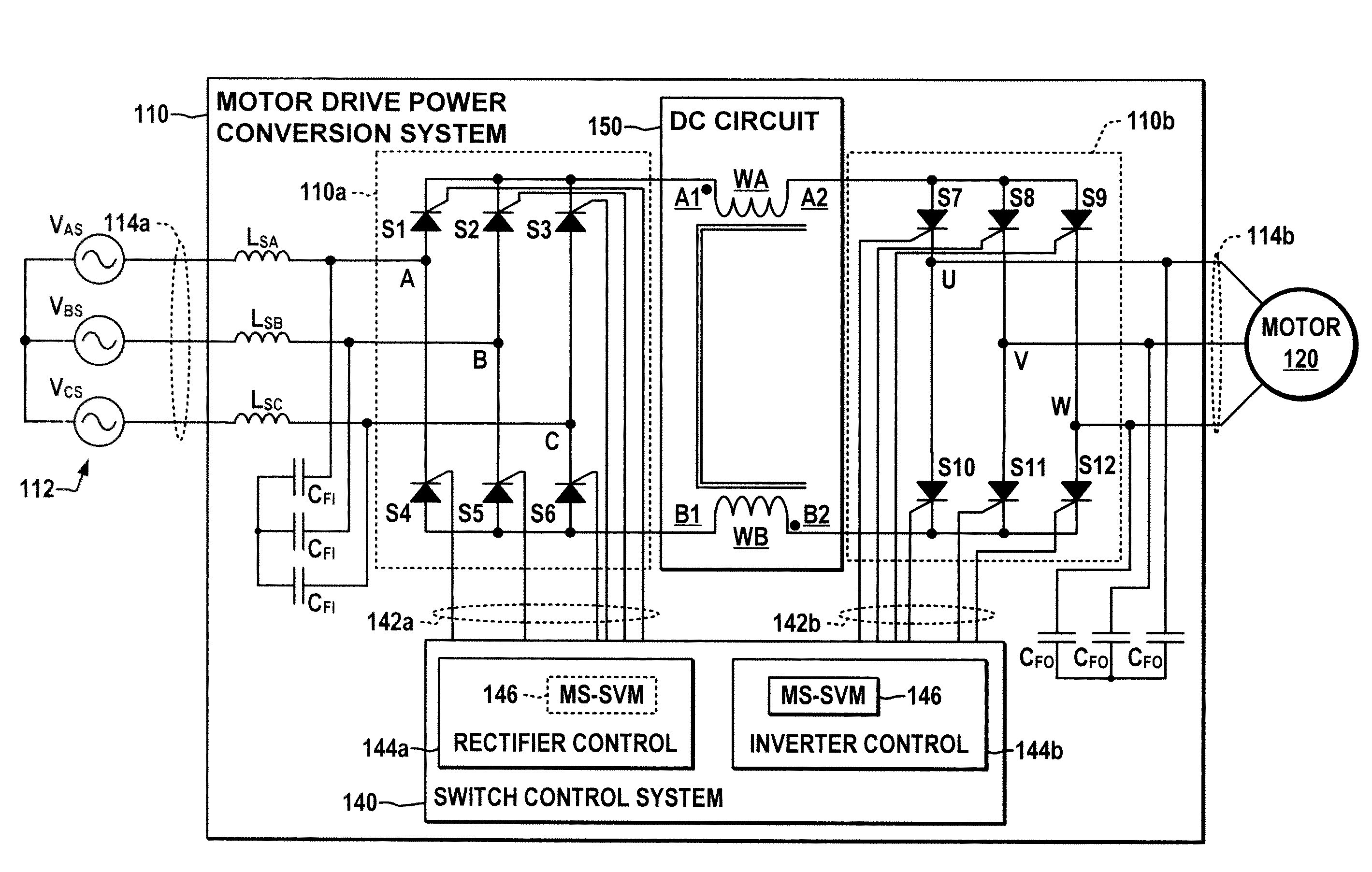

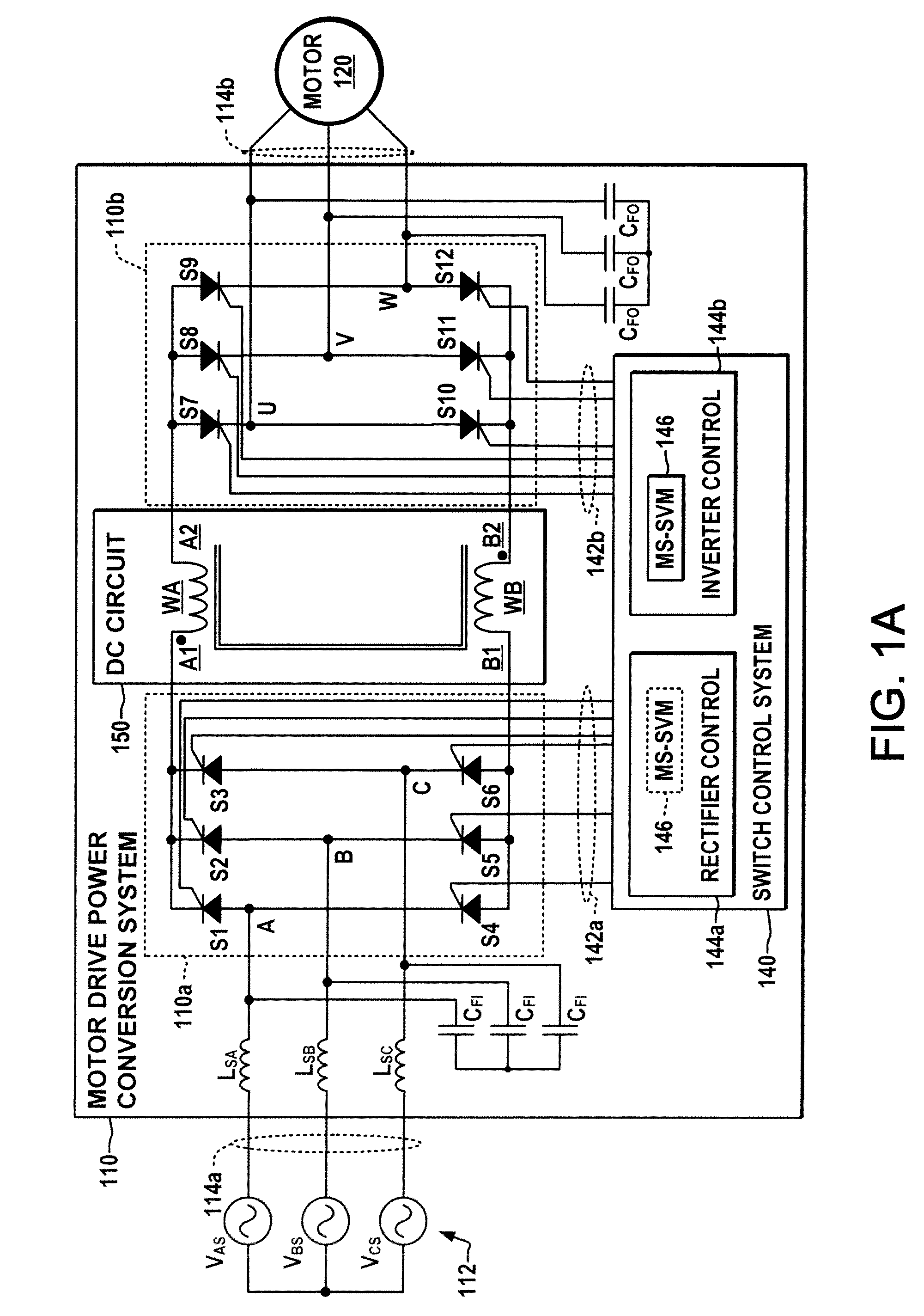

Power conversion systems and methods for controlling harmonic distortion

ActiveUS20100165674A1Superior low order harmonic distortion controlEasy to switchSingle-phase induction motor startersMotor/generator/converter stoppersControl powerReference vector

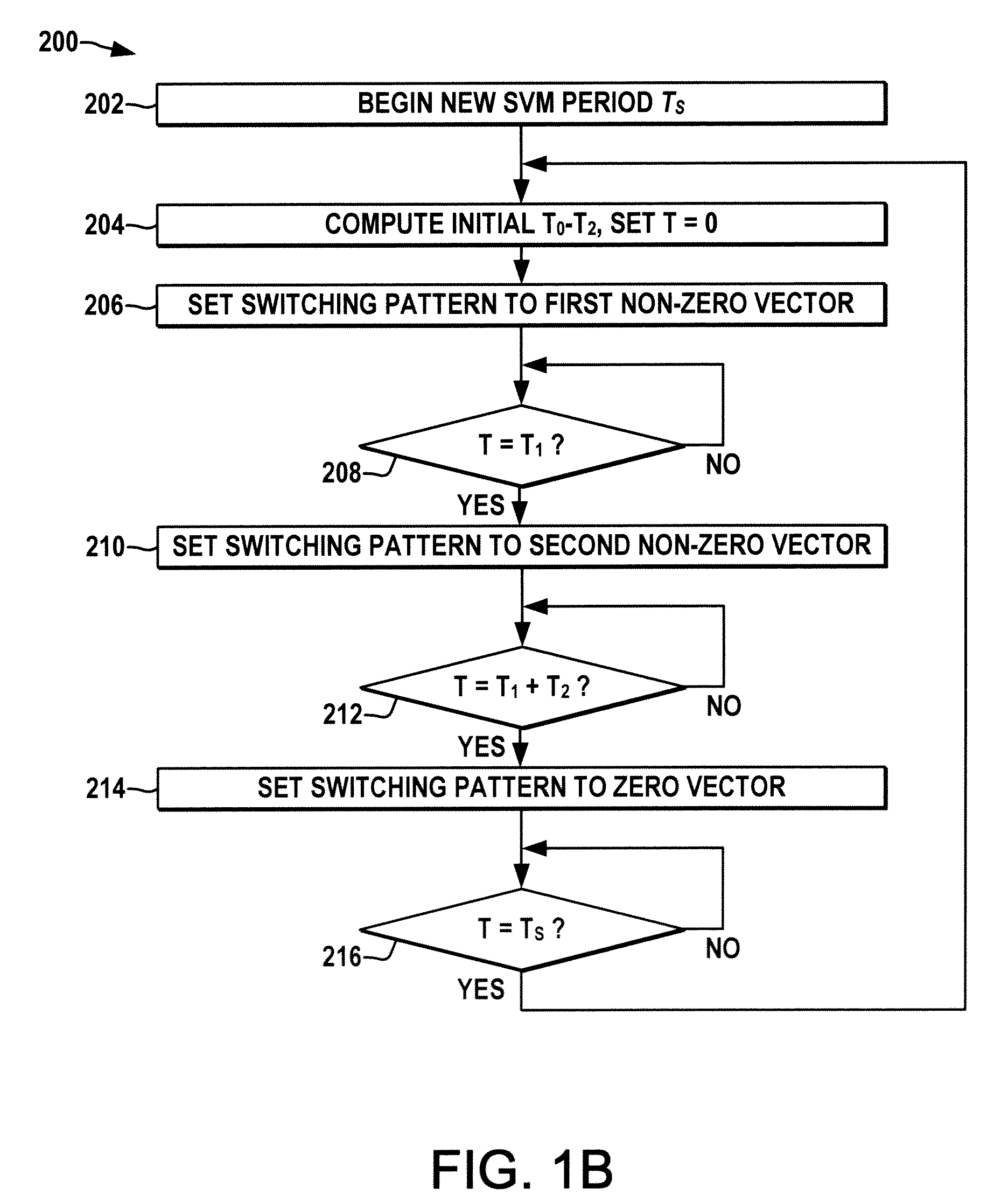

Control systems, methods and power conversion systems are presented for controlling harmonic distortion, in which multi-sampling space vector modulation (SVM) is employed for controlling power converter switching devices, with a reference vector being sampled two or more times during each SVM period to update the SVM dwell times more than once during each SVM cycle.

Owner:ROCKWELL AUTOMATION TECH

Power conversion systems and methods for controlling harmonic distortion

ActiveUS8044631B2Single-phase induction motor startersMotor/generator/converter stoppersReference vectorControl power

Control systems, methods and power conversion systems are presented for controlling harmonic distortion, in which multi-sampling space vector modulation (SVM) is employed for controlling power converter switching devices, with a reference vector being sampled two or more times during each SVM period to update the SVM dwell times more than once during each SVM cycle.

Owner:ROCKWELL AUTOMATION TECH

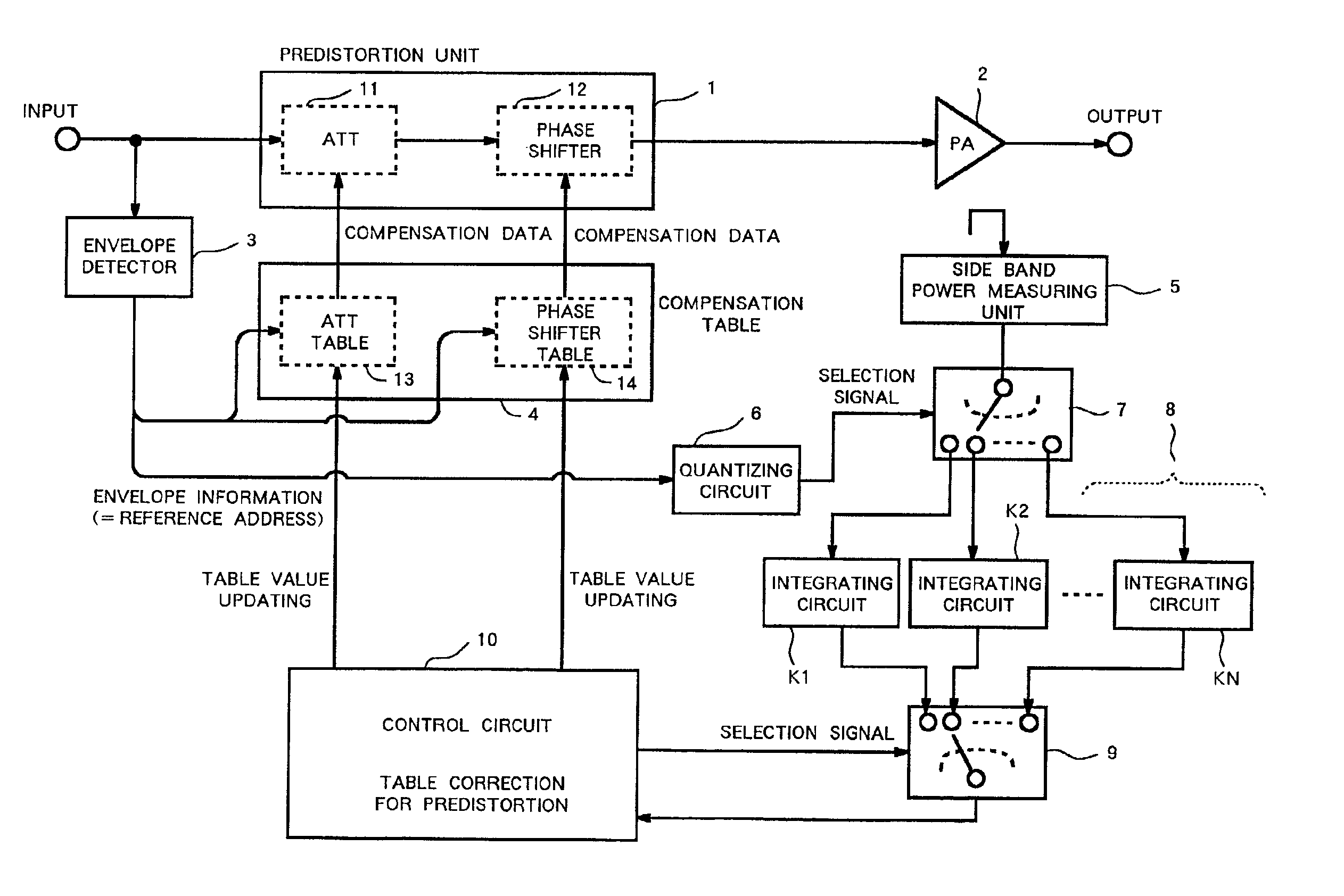

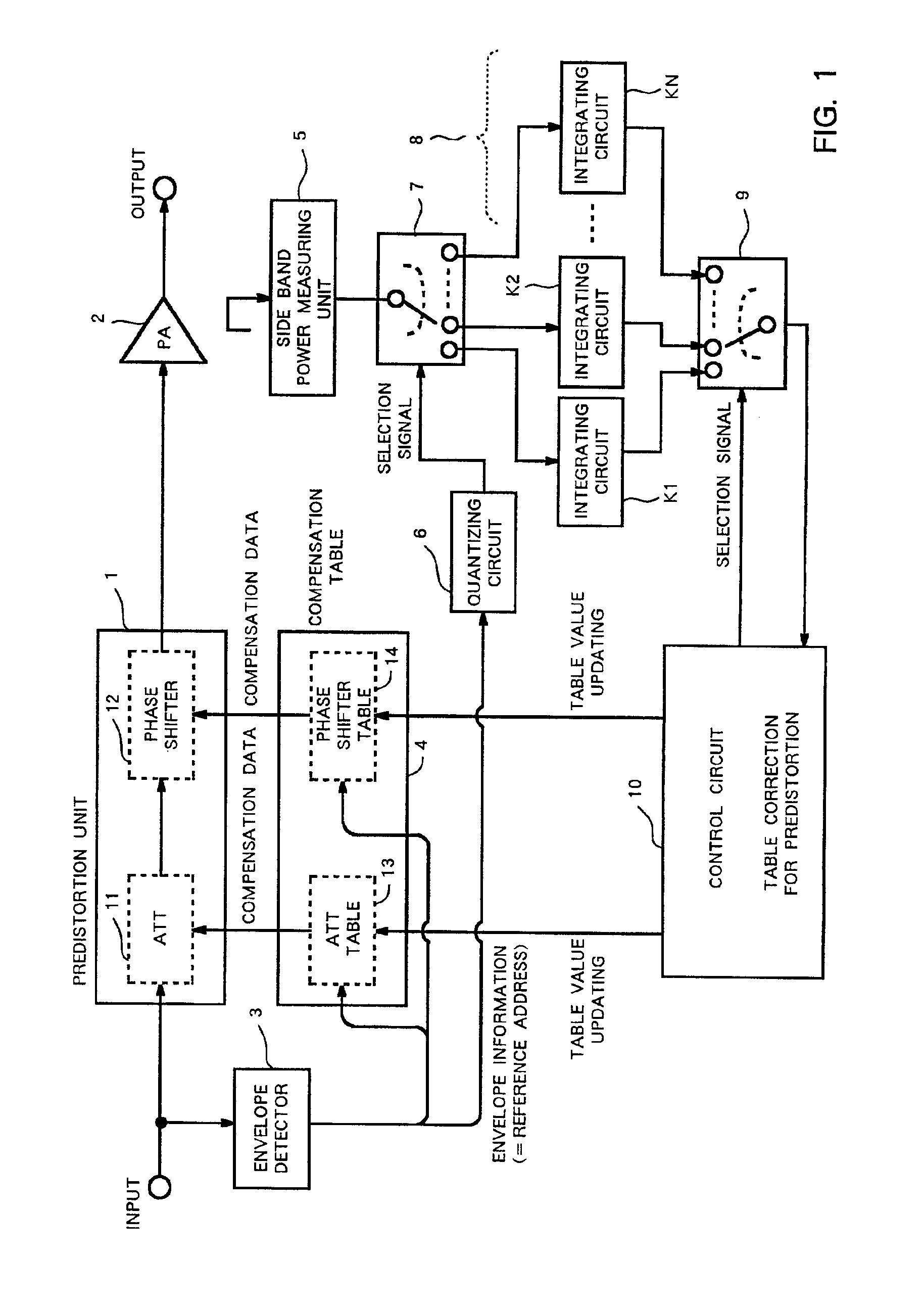

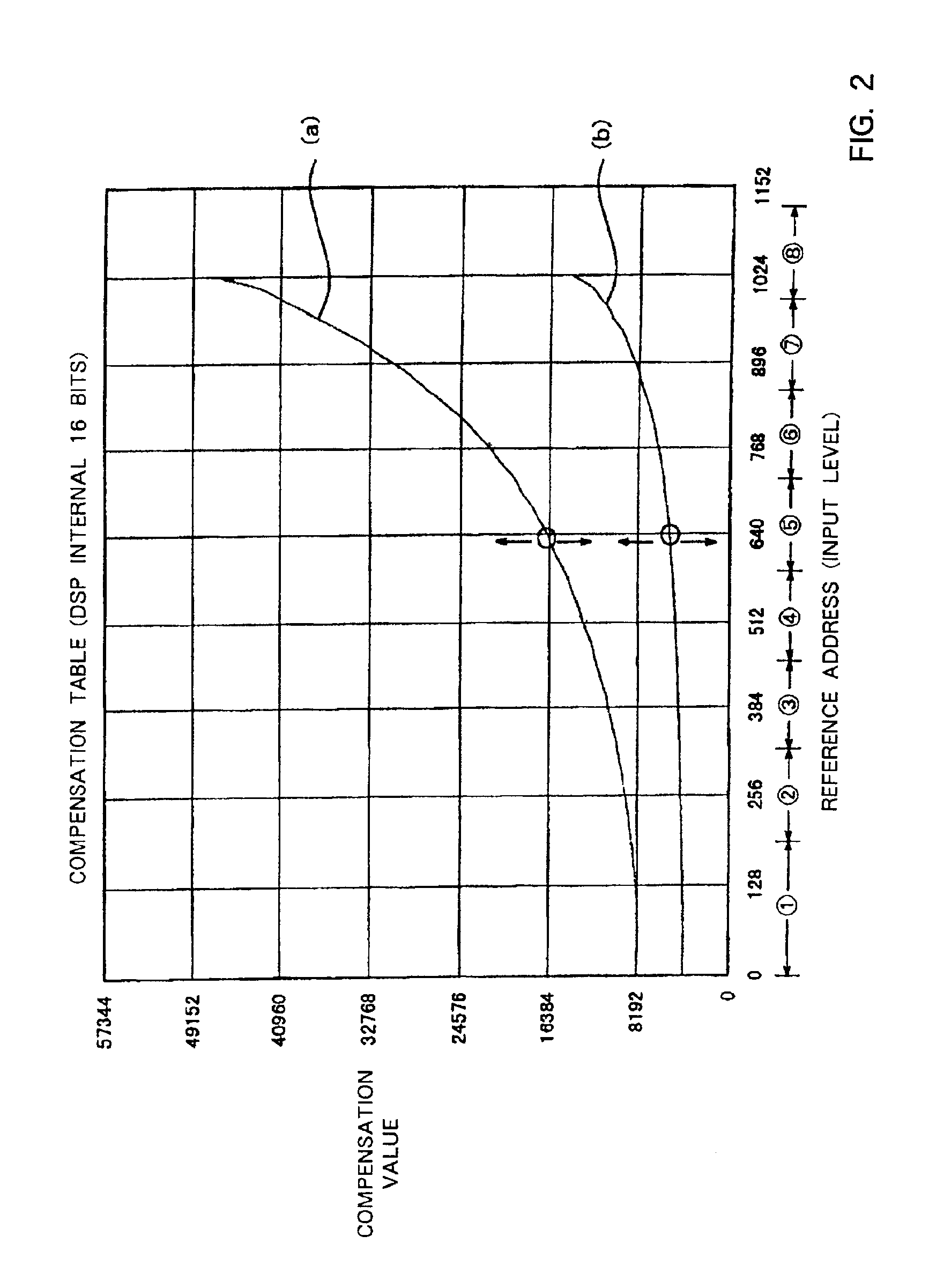

Predistortion type distortion compensation apparatus

To update the control value to a value of higher precision in a predistortion type distortion compensation apparatus for compensating the distortion occurring in an amplifier for amplifying an input signal by the control using a control value corresponding to the level of the input signal.Distortion generating means (1) generates distortion in an input signal, input signal level detecting means (3) detects the level of the input signal, distortion control means (4) controls the distortion generated by the distortion generating means 1 by using a control value corresponding to the level of the detected input signal, distortion component level detecting means (7) detects the level of distortion component contained in the amplified signal issued from the amplifier (2), integrating means K1 to KN integrate the level of the distortion component detected at every level of the detected input signal, and control value updating means (10) updates the control value corresponding to the level so that the integration result at every level of the input signal may be small.

Owner:KOKUSA ELECTRIC CO LTD

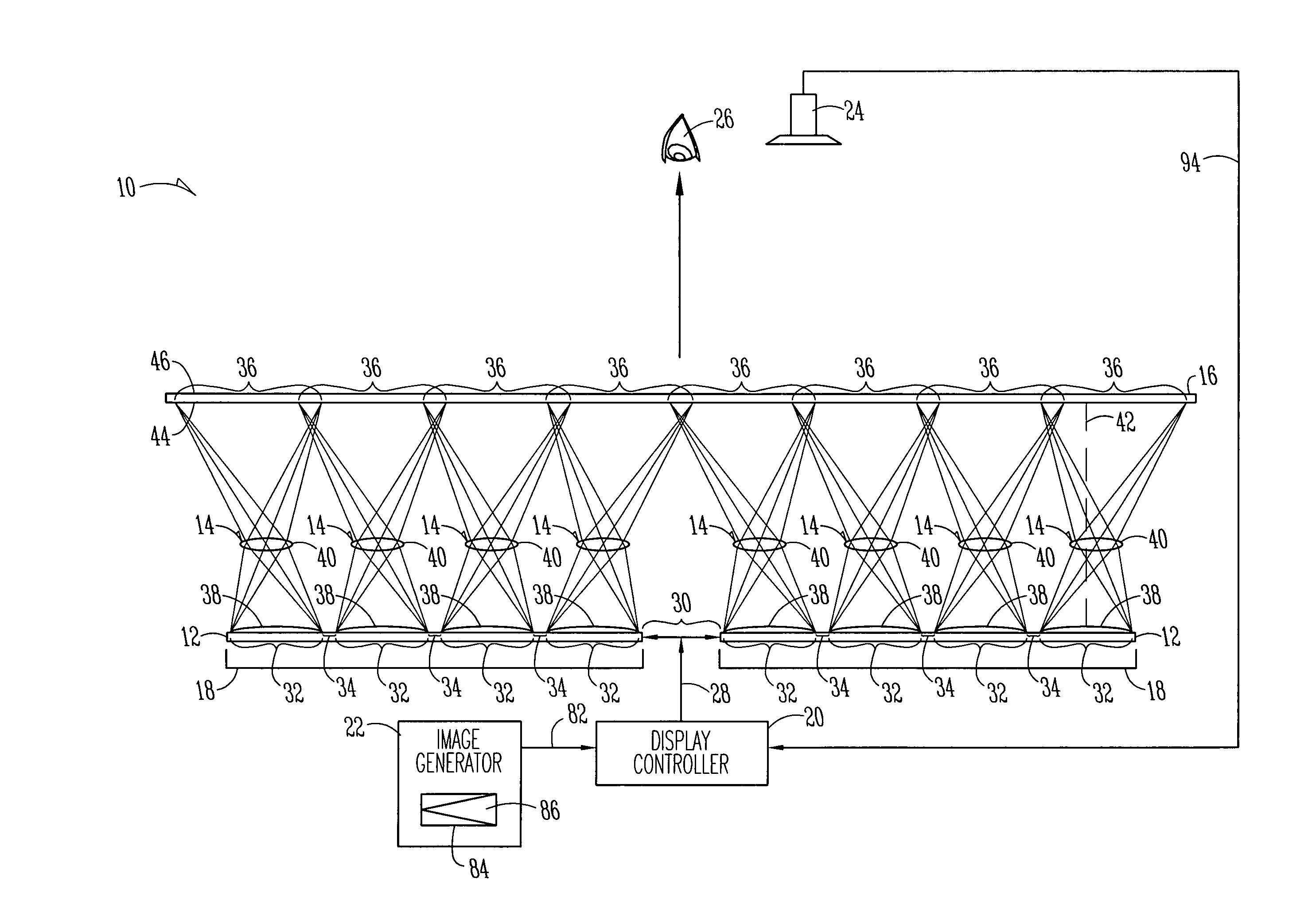

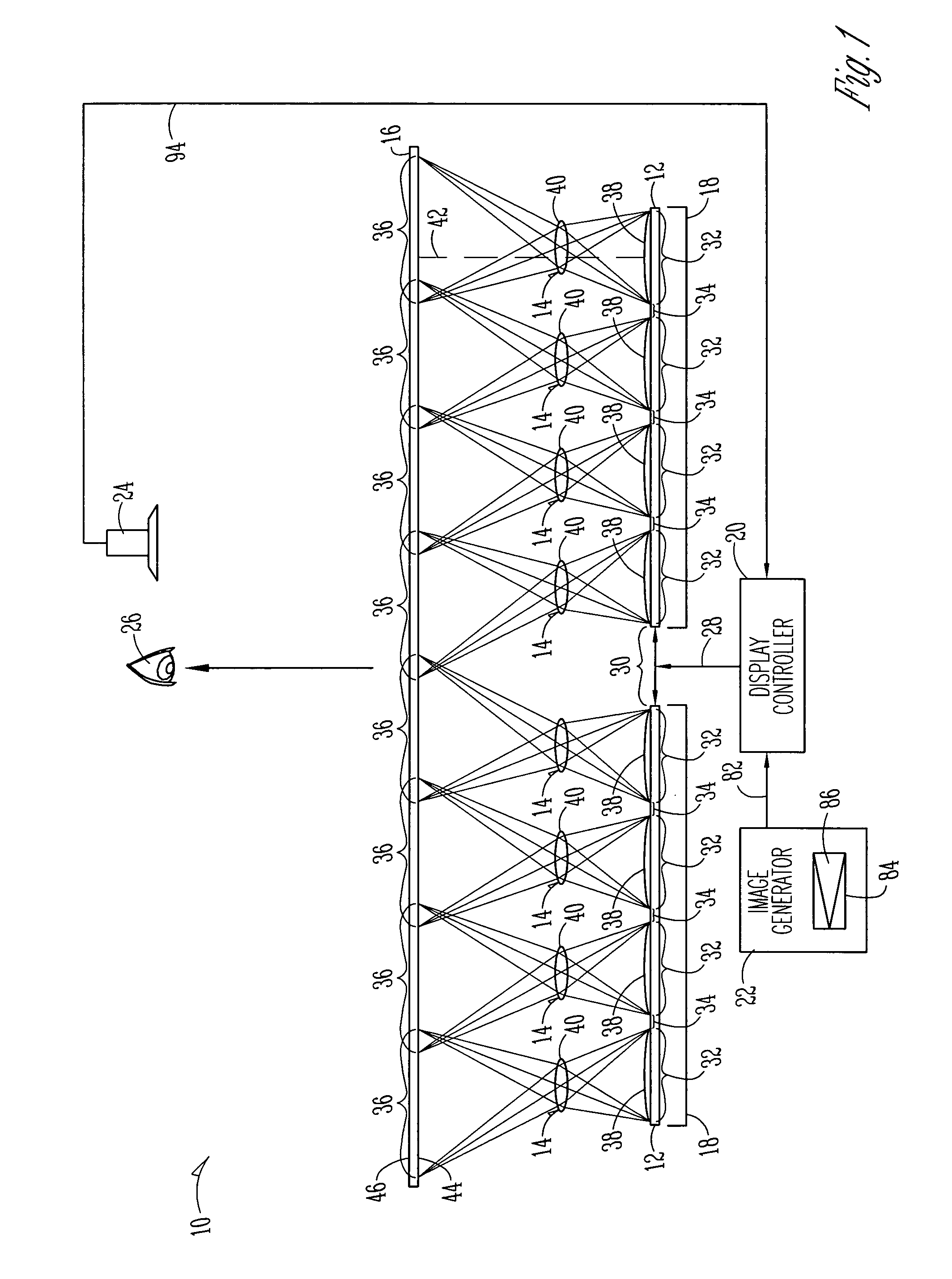

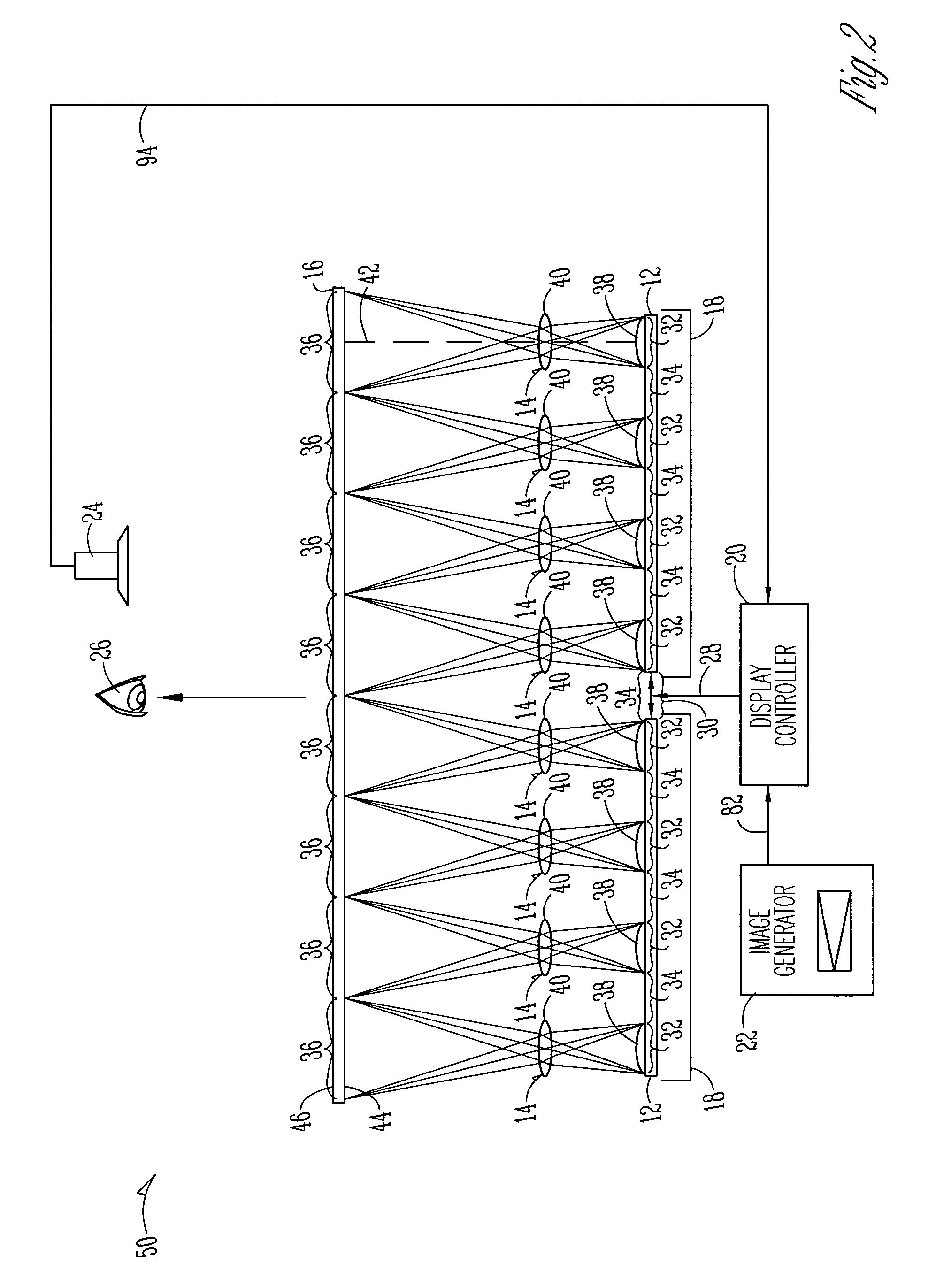

Distortion control for a seamless tile display system

InactiveUS7029124B2Television system scanning detailsProjectorsCamera lensComputer graphics (images)

A modular and scalable seamless tiled display apparatus includes multiple display devices, a screen, and multiple lens assemblies. Each display device is subdivided into multiple sections, and each section is configured to display a sectional image. One of the lens assemblies is optically coupled to each of the sections of each of the display devices to project the sectional image displayed on that section onto the screen. The multiple lens assemblies are configured to merge the projected sectional images to form a single tiled image. The projected sectional images may be merged on the screen by magnifying and shifting the images in an appropriate manner. The magnification and shifting of these images eliminates any visual effect on the tiled display that may result from dead-band regions defined between each pair of adjacent sections on each display device, and due to gaps between multiple display devices.

Owner:HONEYWELL INT INC

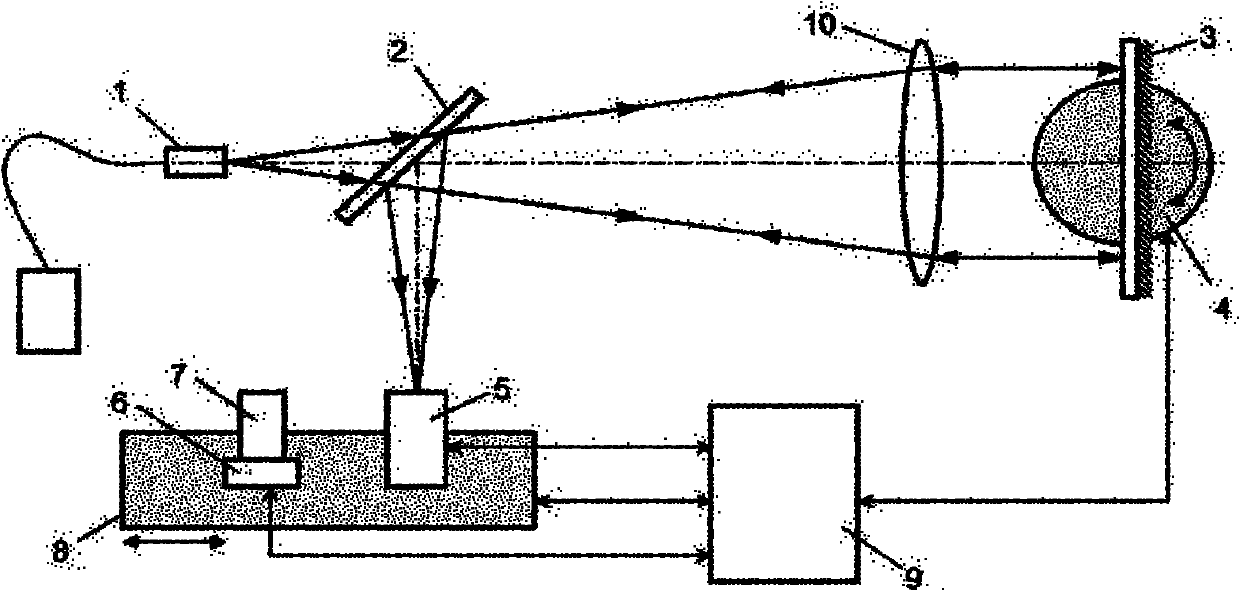

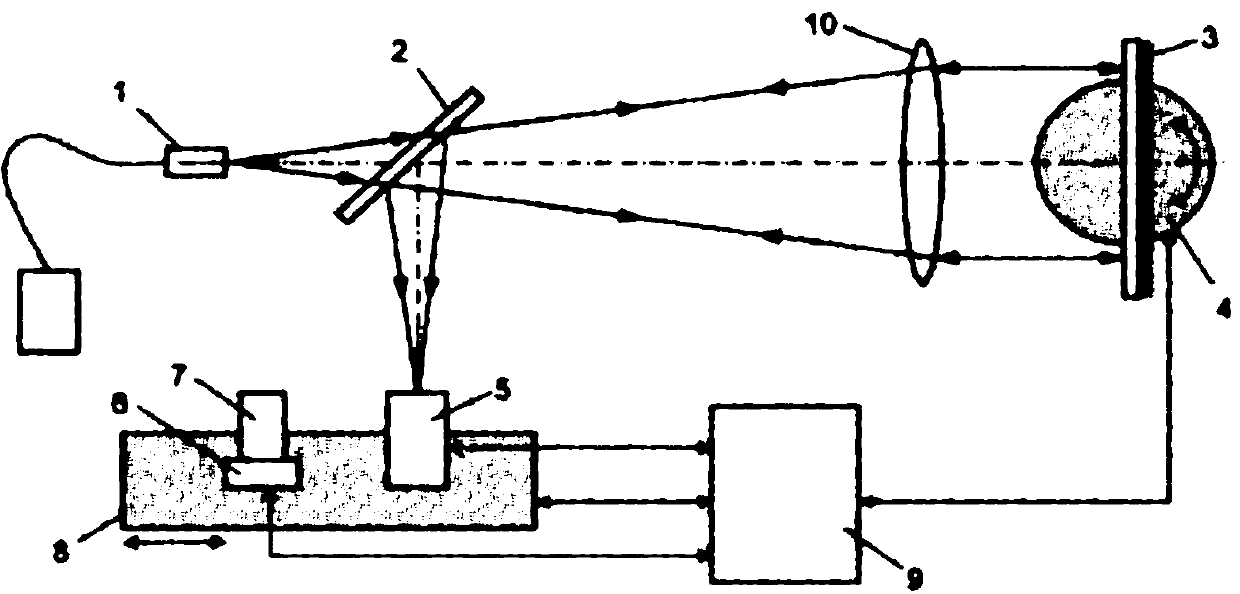

Device for measuring focal length and wavefront distortion of lens

InactiveCN102564731AConfidenceHigh degree of automationOptical measurementsTesting optical propertiesWavefrontPlane mirror

The invention relates to a device for measuring the focal length and wavefront distortion of a lens. The device for measuring the focal length and wavefront distortion of the lens comprises a laser, a semi-permeable semi-reflection flat mirror, a plane mirror and a focal length and wavefront distortion control unit. The semi-permeable semi-reflection flat mirror and the plane mirror are sequentially arranged on an emergence optical path of a laser; and the focal length and wavefront distortion control unit is arranged on a reflection optical path which is reflected onto the semi-permeable semi-reflection flat mirror by the plane mirror and then is reflected along the semi-permeable semi-reflection flat mirror. The invention provides the device for measuring the focal length and wavefront distortion of the lens, which has large measurement range, high stability, good repeatability and high confidence degree of a measurement result.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

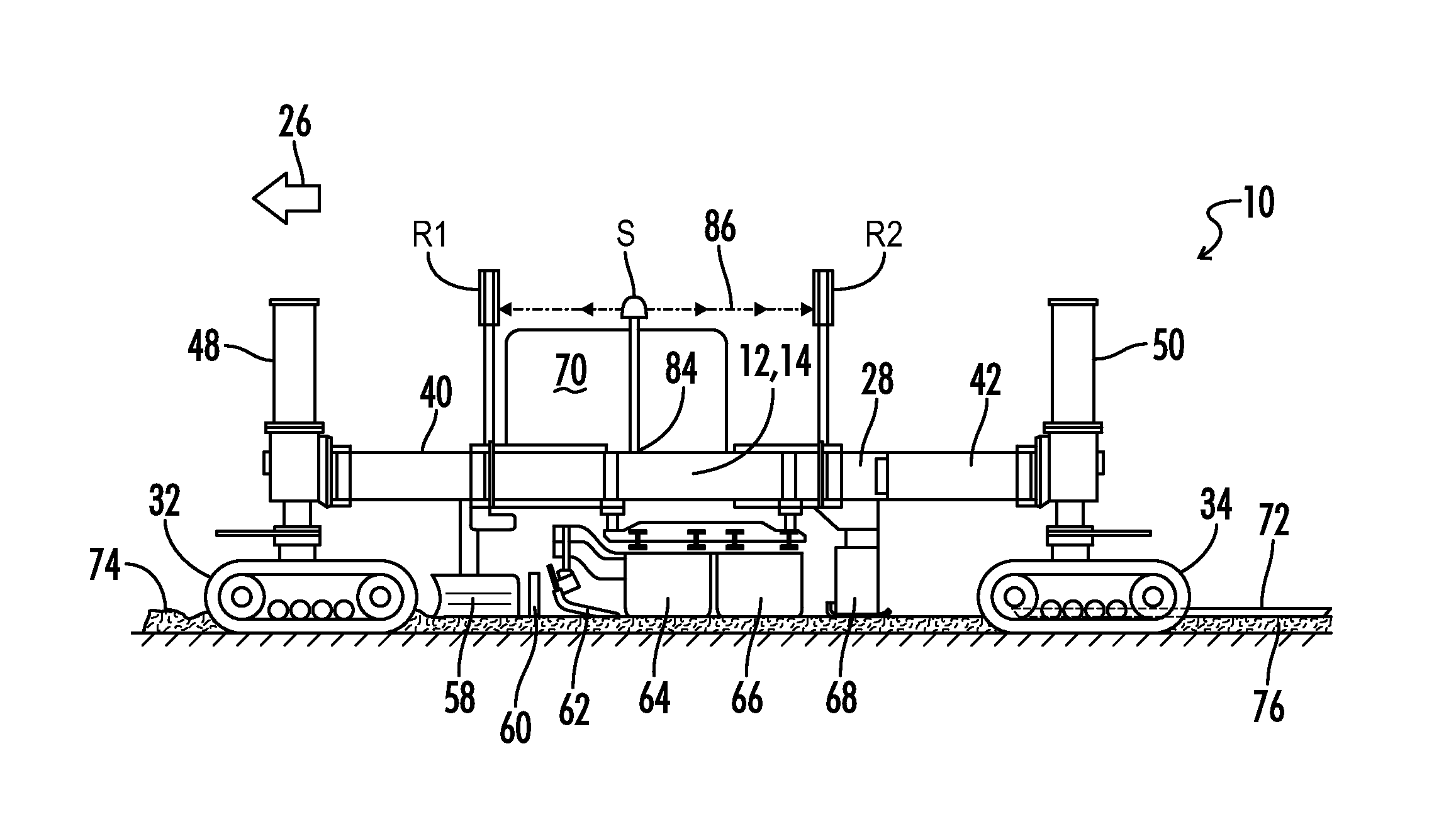

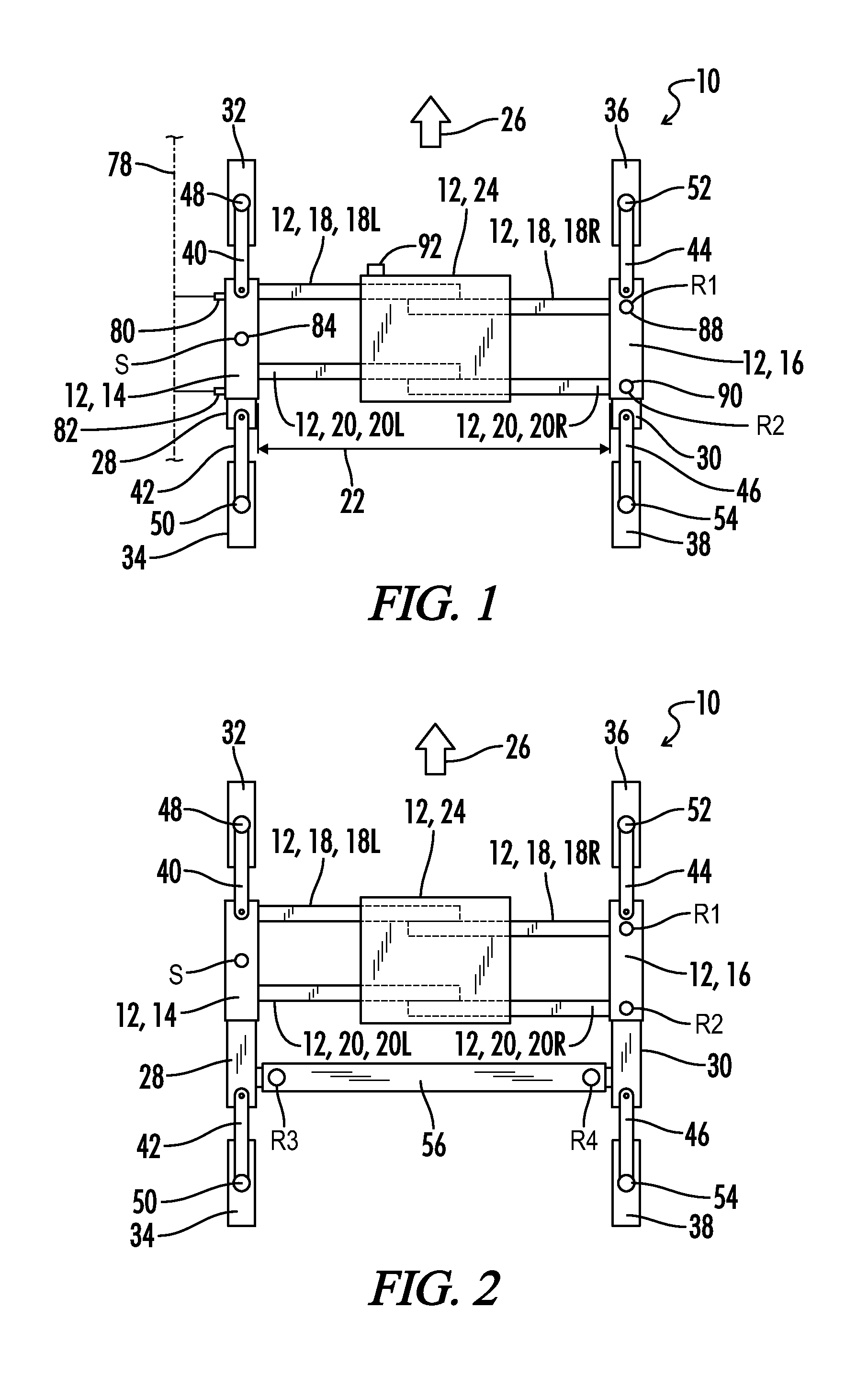

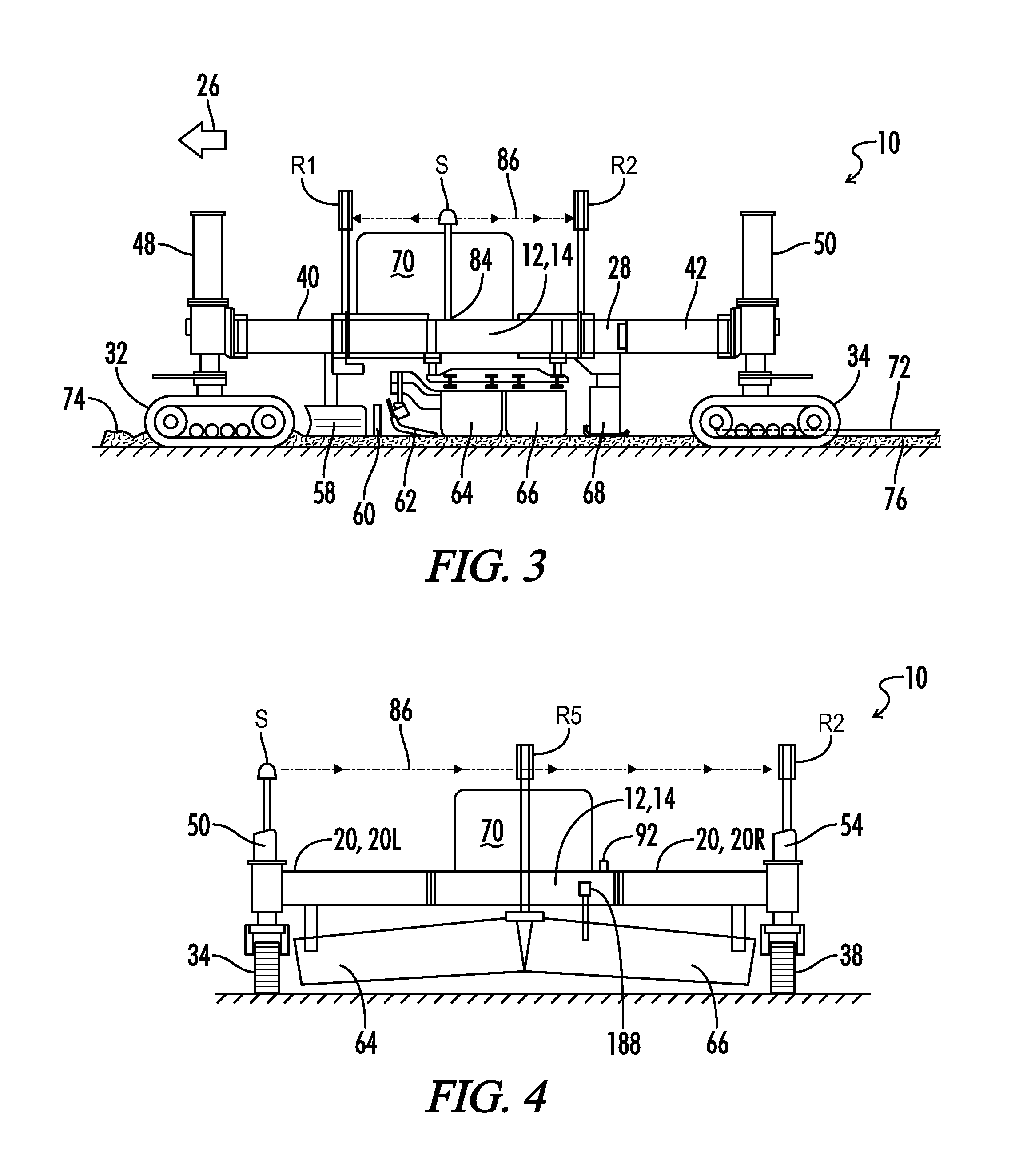

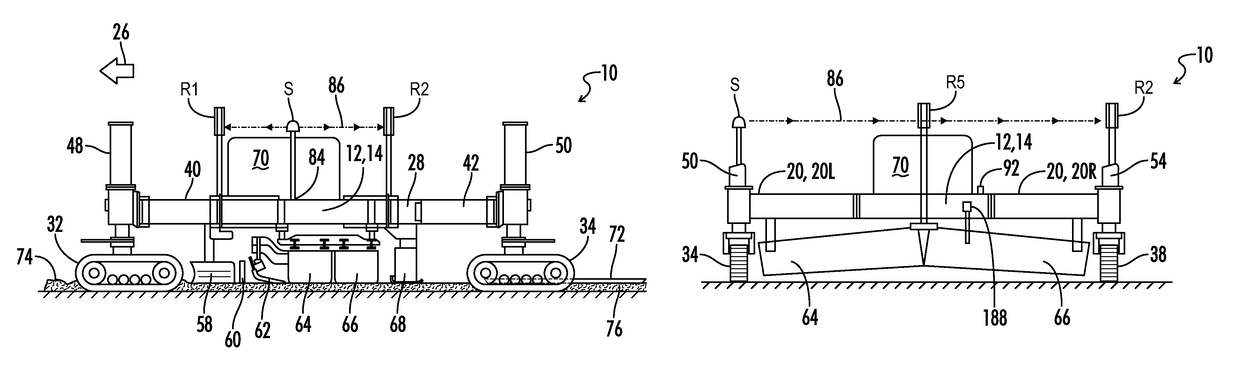

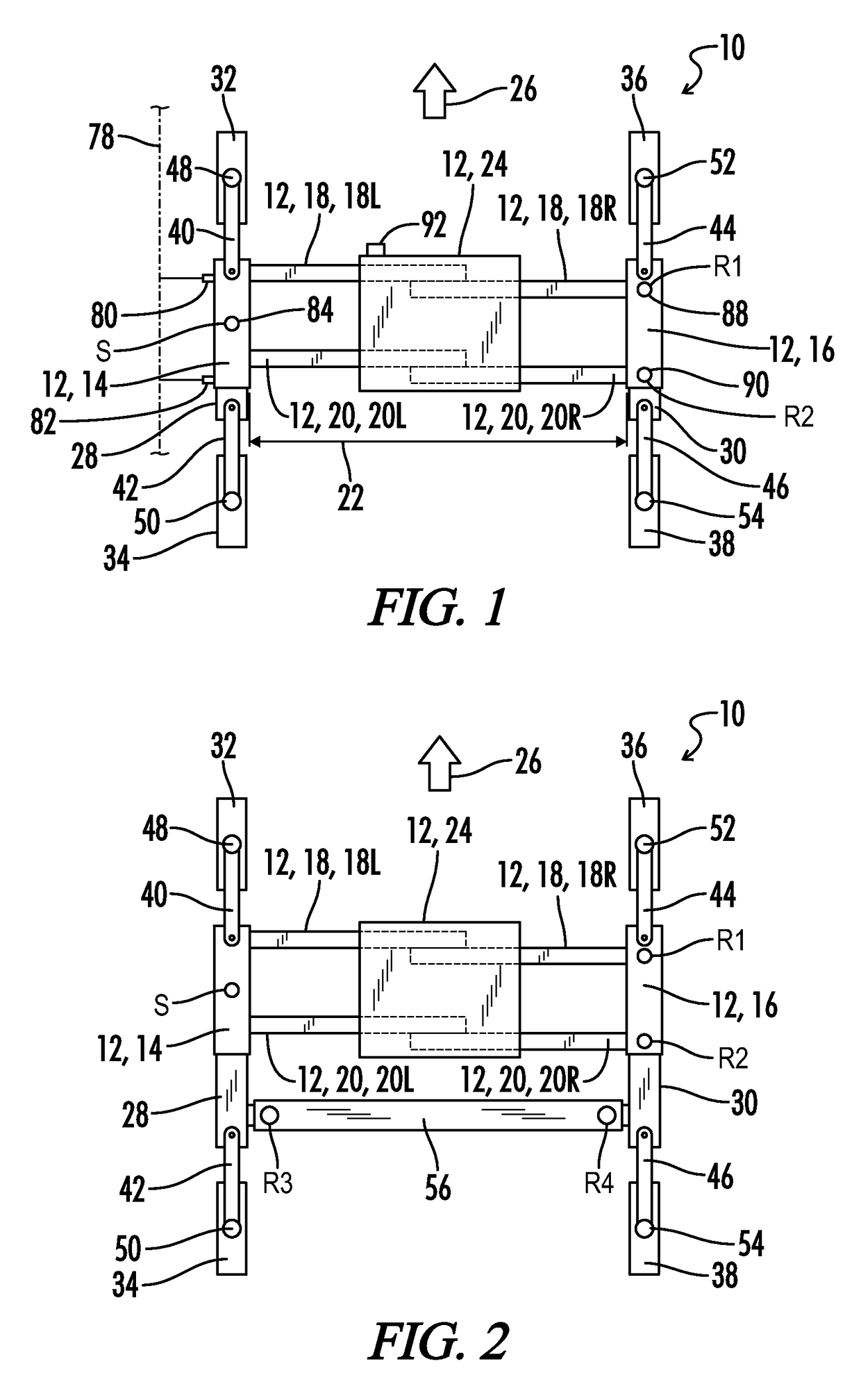

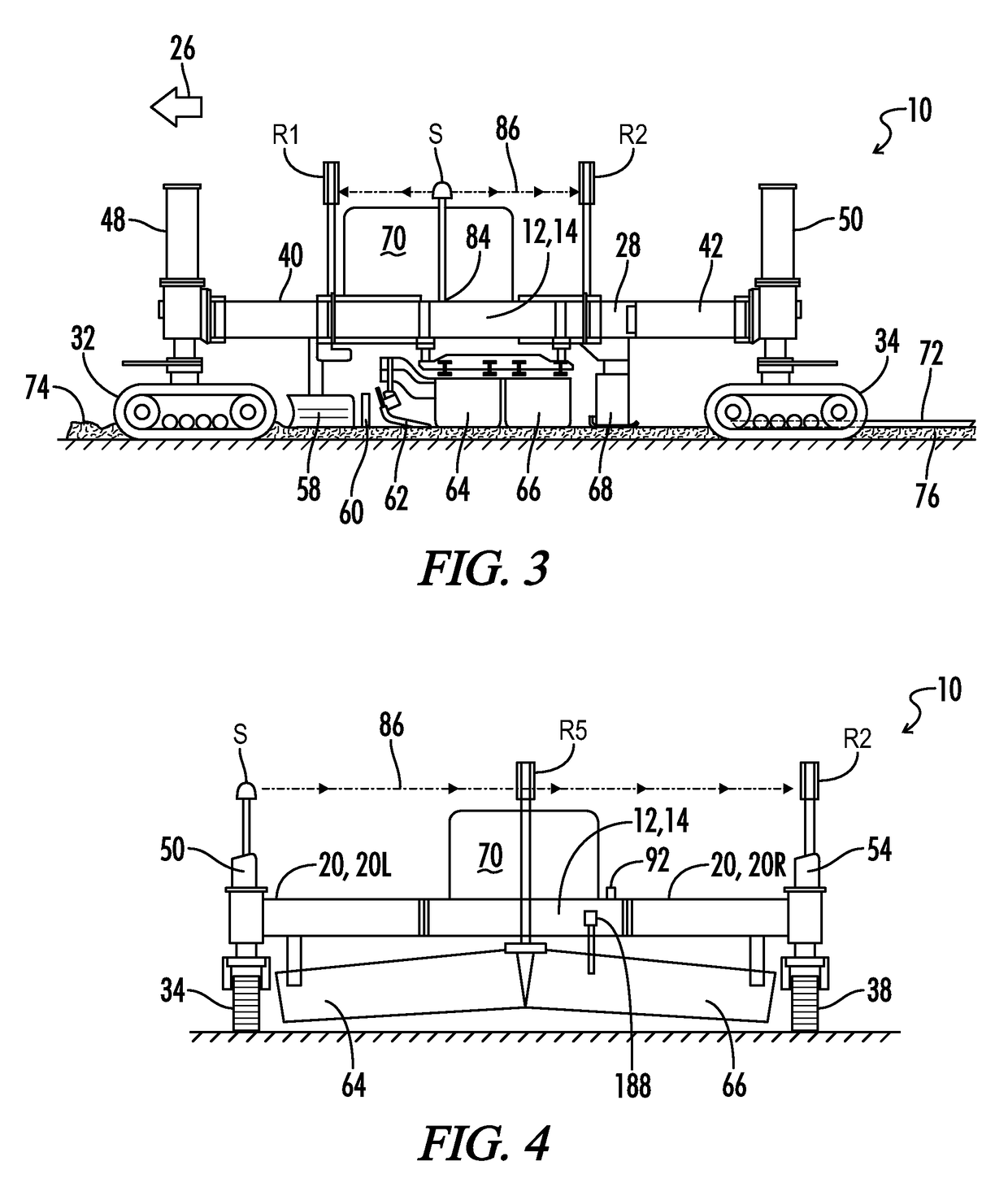

Frame Distortion Control

A slipform paving machine includes a laser source for generating a laser reference plane. At least two laser receivers are mounted on the machine and intersect the laser reference plane. Inputs from the laser receivers are utilized to control distortion of the frame of the slipform paver machine.

Owner:WIRTGEN GMBH

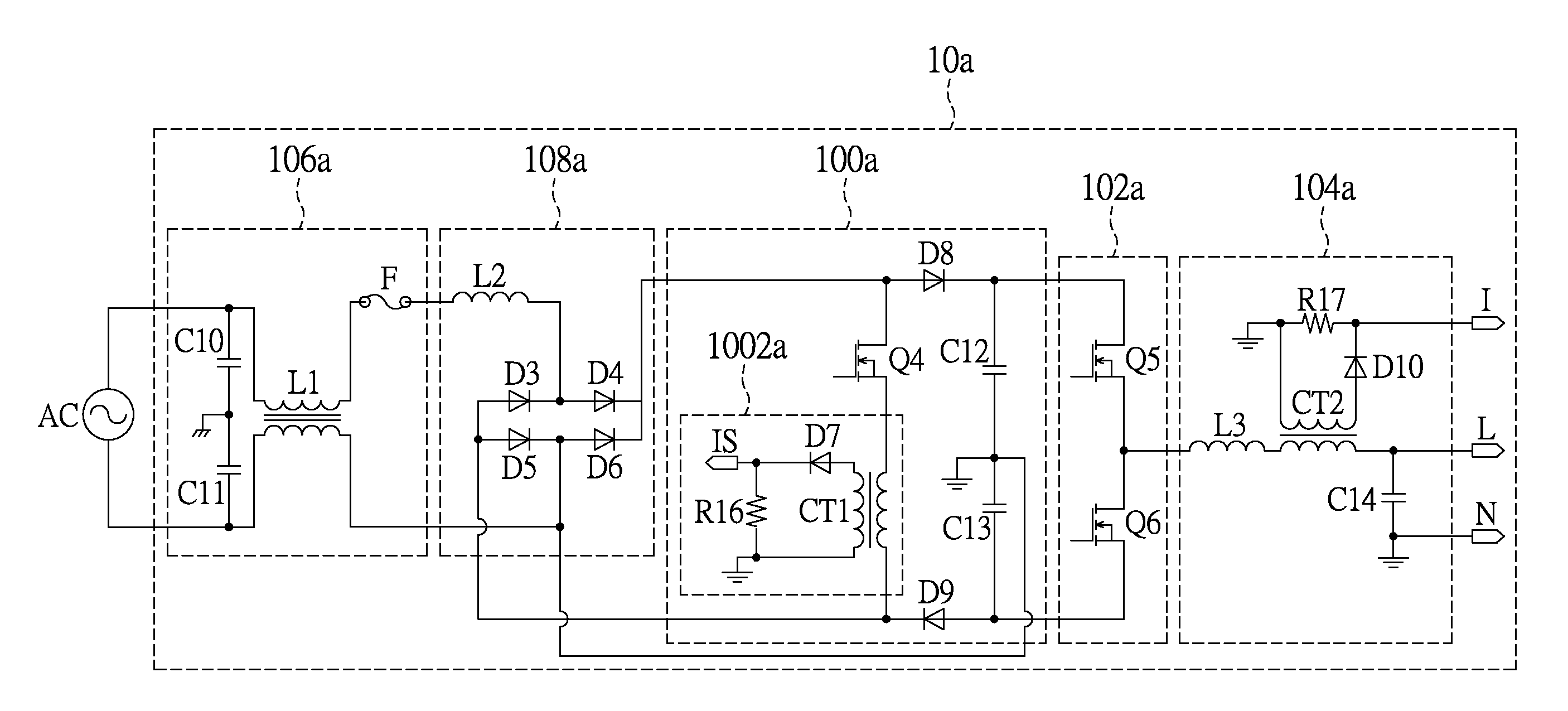

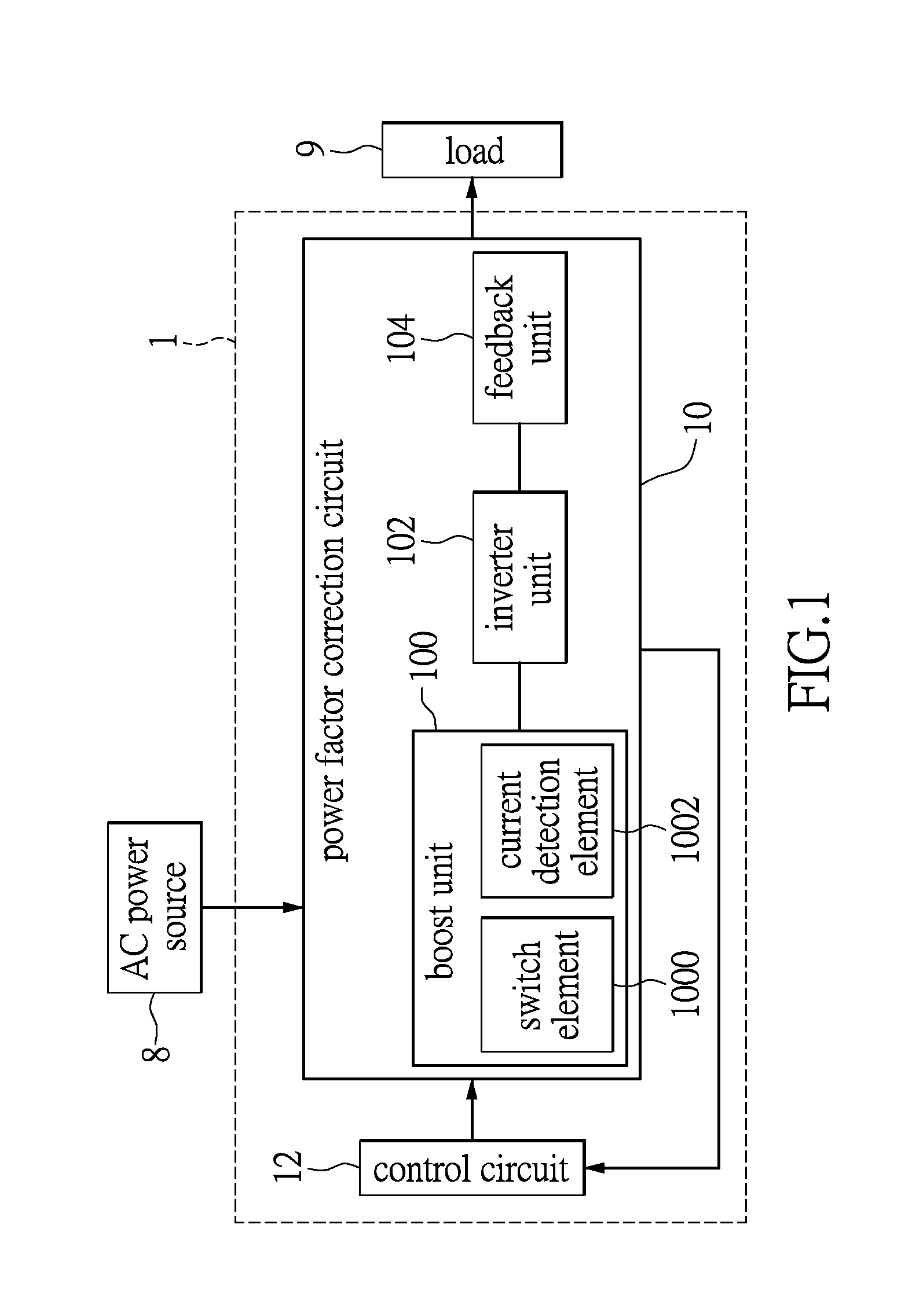

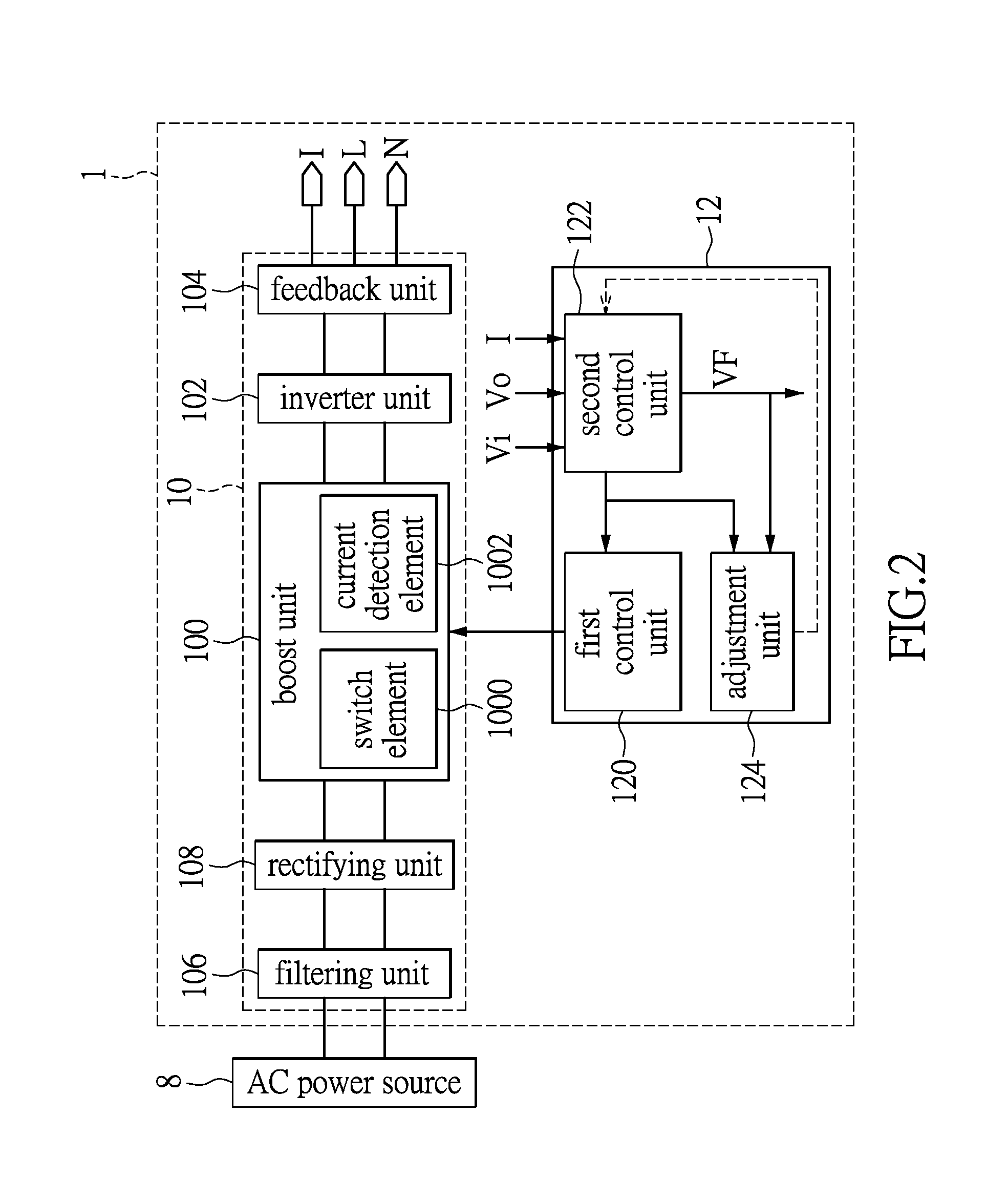

Total harmonic current distortion control circuit and method thereof

ActiveUS20150236581A1Wide rangeImprove comprehensive applicabilityEfficient power electronics conversionAc-dc conversionTotal harmonic distortionEngineering

A total harmonic current distortion (THDi) control circuit includes a power factor correction circuit and a control circuit. The power factor correction circuit includes a boost unit, an inverter unit, and a feedback unit. The boost unit includes a switch element and a current detection element series-coupled to the switch element. The feedback unit operatively detects an output voltage and an output current of the power factor correction circuit. The control circuit calculates an output power according to the output voltage and the output current, and calculates an input voltage and an input current according to the output power. The control circuit outputs a pulse width modulation signal and controls a conduction current generated by the switch element according to the input current. The control circuit adjusts the duty cycle of the pulse width modulation signal according to the conduction current detected by the current detection element.

Owner:VOLTRONIC POWER TECH CORP

Apparatus for providing an upmix signal representation on the basis of a downmix signal representation, apparatus for providing a bitstream representing a multichannel audio signal, methods, computer program and bitstream using a distortion control signaling

An apparatus for providing an upmix signal representation on the basis of a downmix signal representation and an object-related parametric information, which are included in a bitstream representation of an audio content, and in dependence on a rendering information, comprises a distortion limiter configured to adjust upmix parameters using a distortion control scheme to avoid or limit audible distortions which are caused by an inappropriate choice of rendering parameters. The distortion limiter is configured to obtain a distortion limitation control parameter, which is included in the bitstream representation of the audio content, and to adjust a distortion control scheme in dependence on the distortion limitation control parameter.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

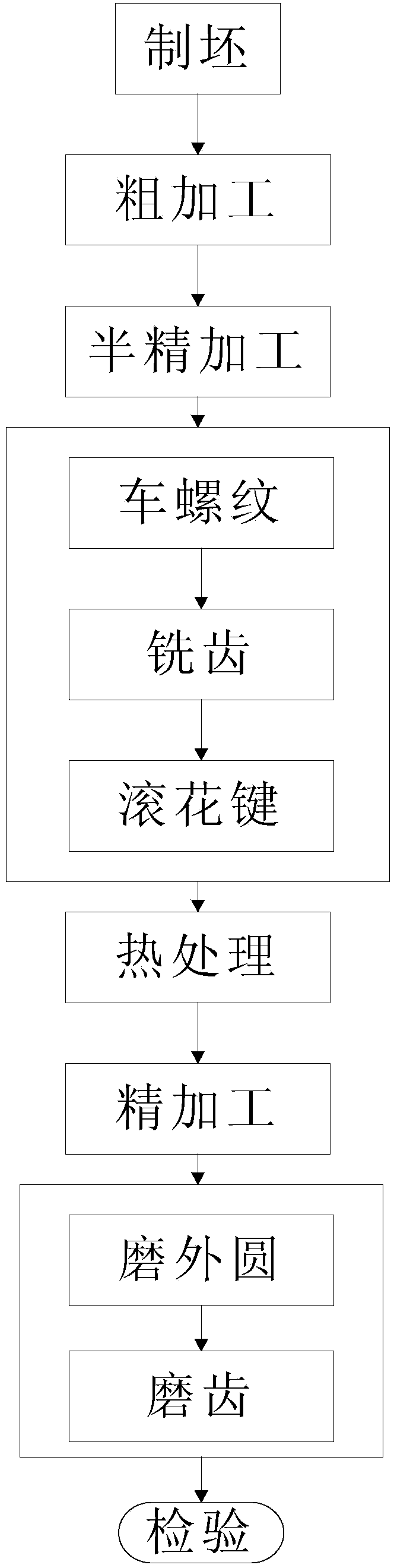

Process for machining gear main shaft of high-power wind turbine generator set

The invention provides a process for machining a gear main shaft of a high-power wind turbine generator set and relates to the adjustment of the sequence of heat treating and machining in the technological process. The specific process includes the steps of carrying out rough machining and semi-finishing machining on a blank, machining a gear and gear teeth, machining a spline, coating anti-seepage agents, carrying out heat treatment, and finally carrying out external grinding and tooth grinding. Accordingly, a part is machined. Meanwhile, in the machining process, imported high-end devices and tools are used in critical procedures and are cooperated with a heat treatment micro-distortion control technology so that specialized complete process machining from the blank to the finished product can be achieved. Through the process for machining the gear main shaft of the high-power wind turbine generator set, a fine metallographic structure and an even carburized layer can be obtained through the heat treatment. Consequently, the strength and accuracy of the spline are improved, the weight of the gear main shaft is reduced, and the service life of the gear main shaft is prolonged.

Owner:DALIAN CLEAN ENERGY HEAVY IND

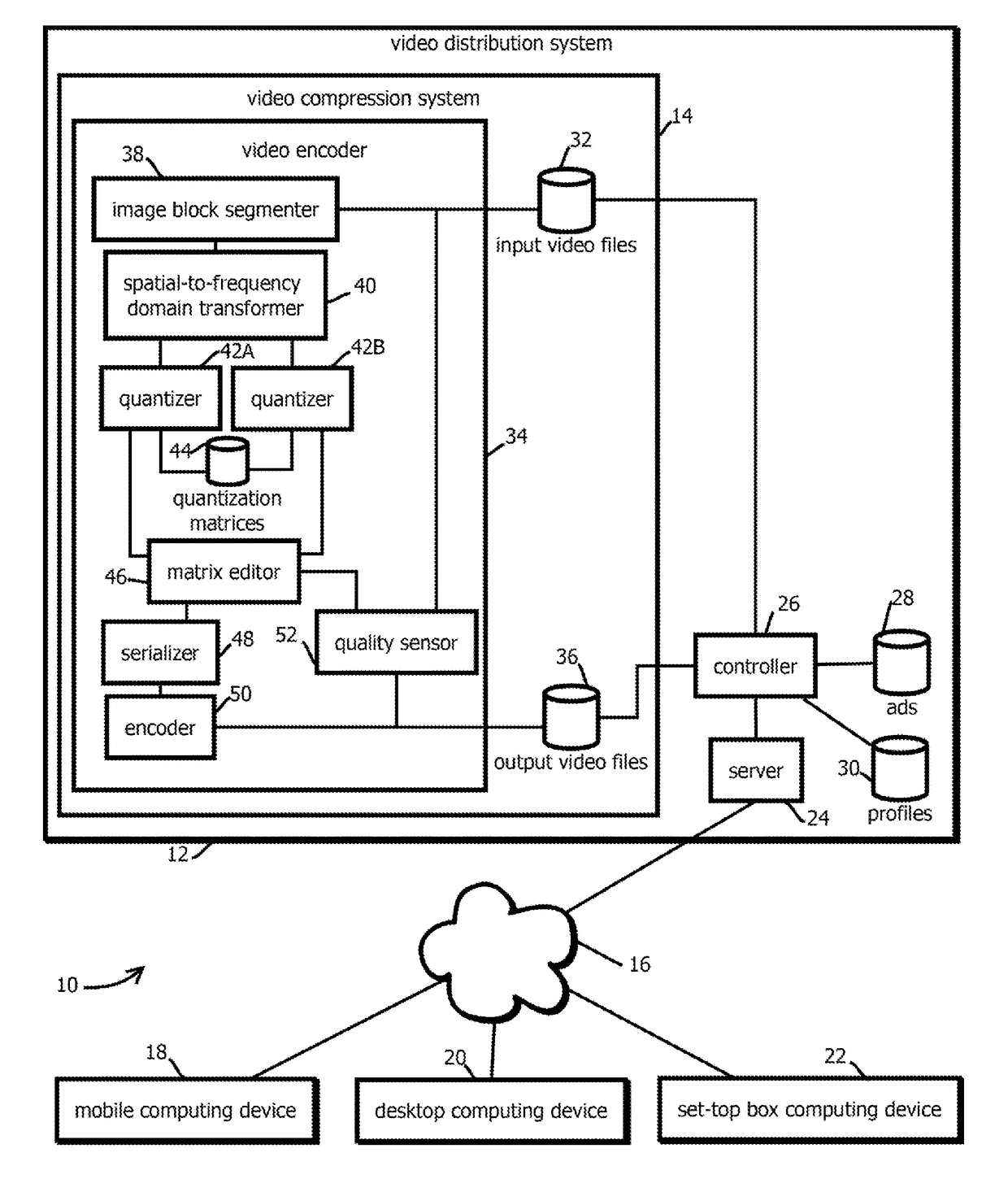

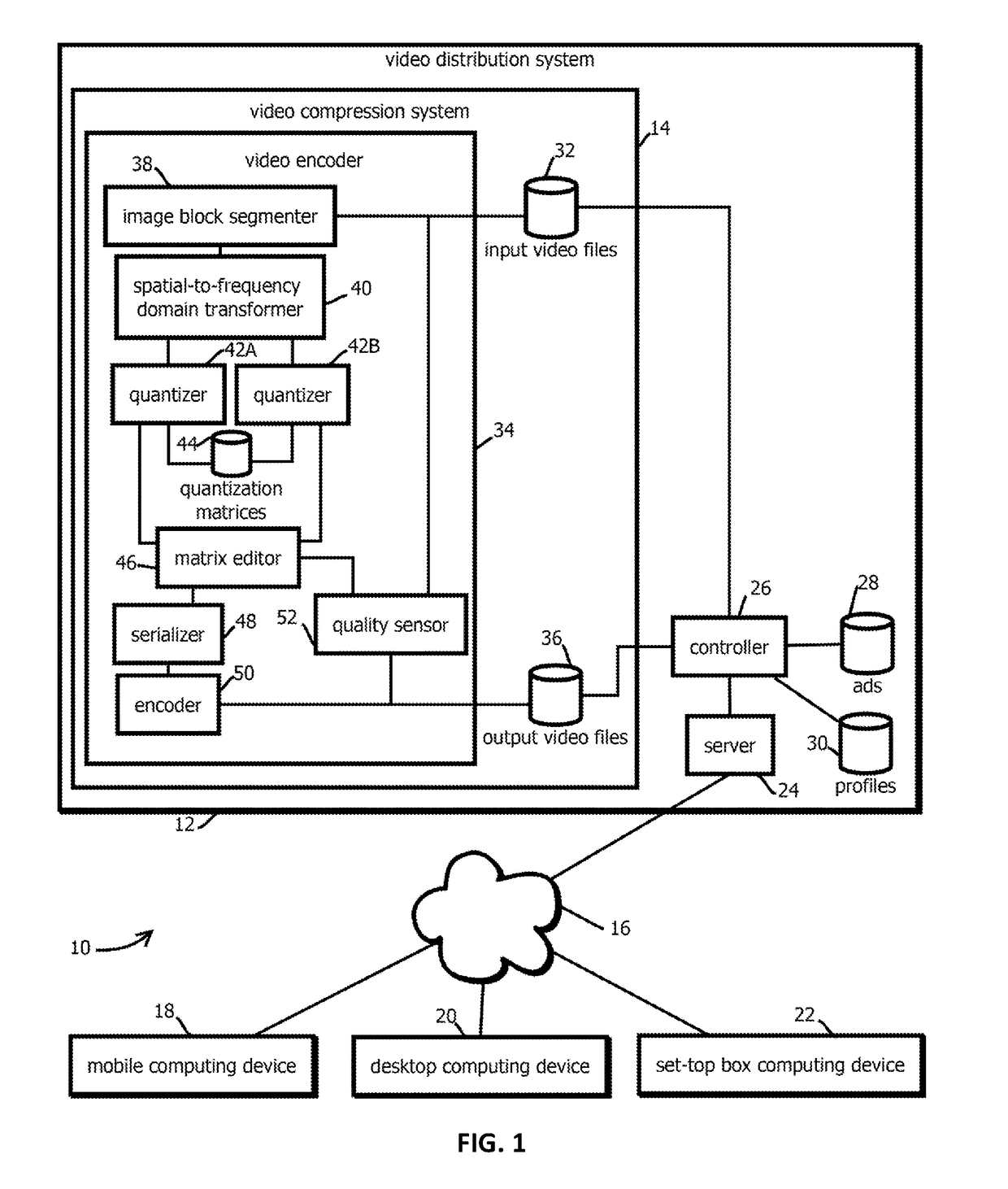

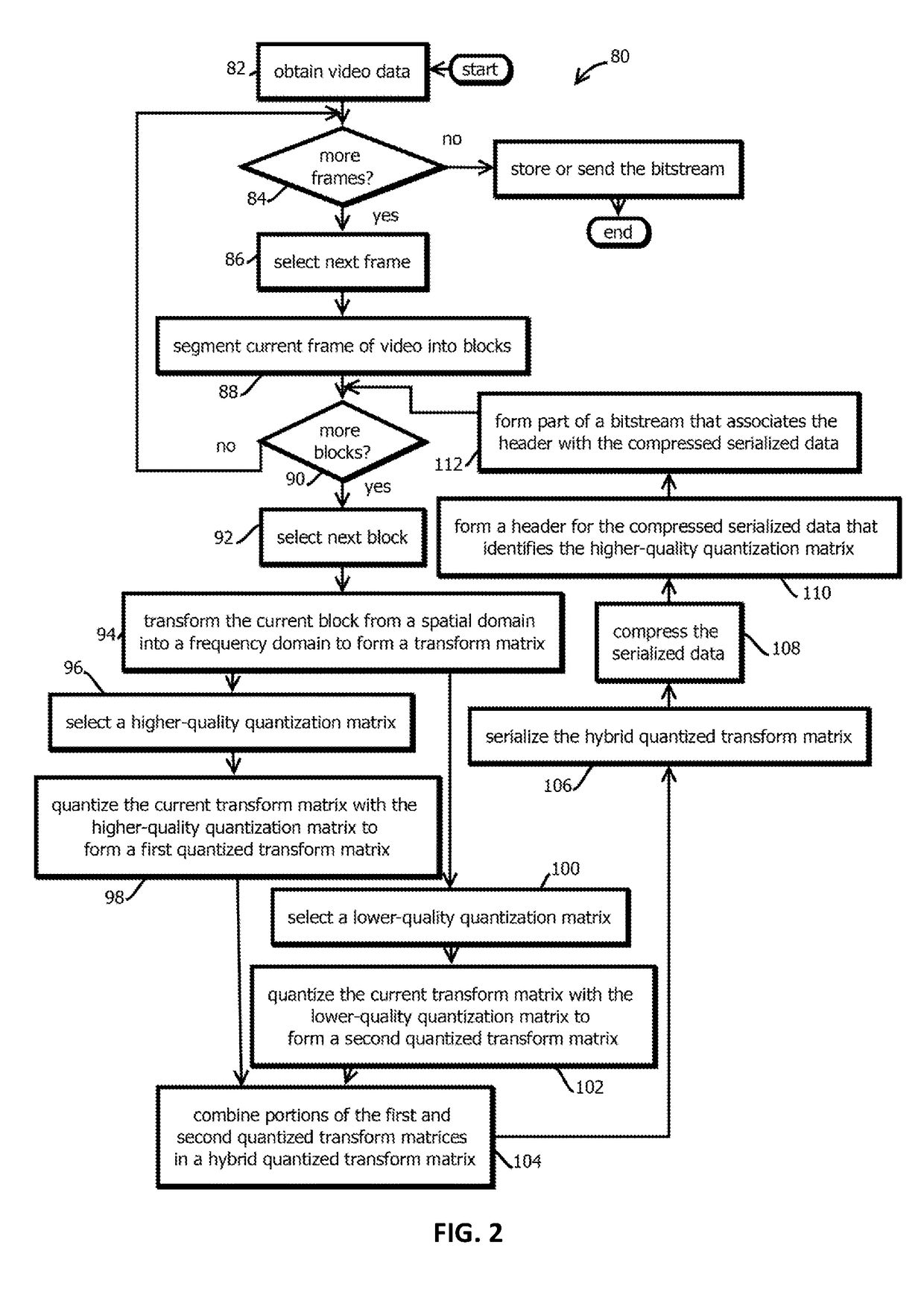

Video encoding with adaptive rate distortion control by skipping blocks of a lower quality video into a higher quality video

InactiveUS20180309991A1Speech analysisDigital video signal modificationVideo encodingRate distortion

Provided is a process including: segmenting a frame of video into a plurality of blocks; transforming each of the blocks to form respective transform matrices; for a given transform matrix, quantizing the given transform matrix with a first quantization matrix to form a first quantized transform matrix; quantizing the given transform matrix a second time with a second quantization matrix to form a second quantized transform matrix; and forming a sequence of hybrid quantized transform matrix values from part of the first quantized transform matrix and part of the second quantized transform matrix.

Owner:MATRIXVIEW

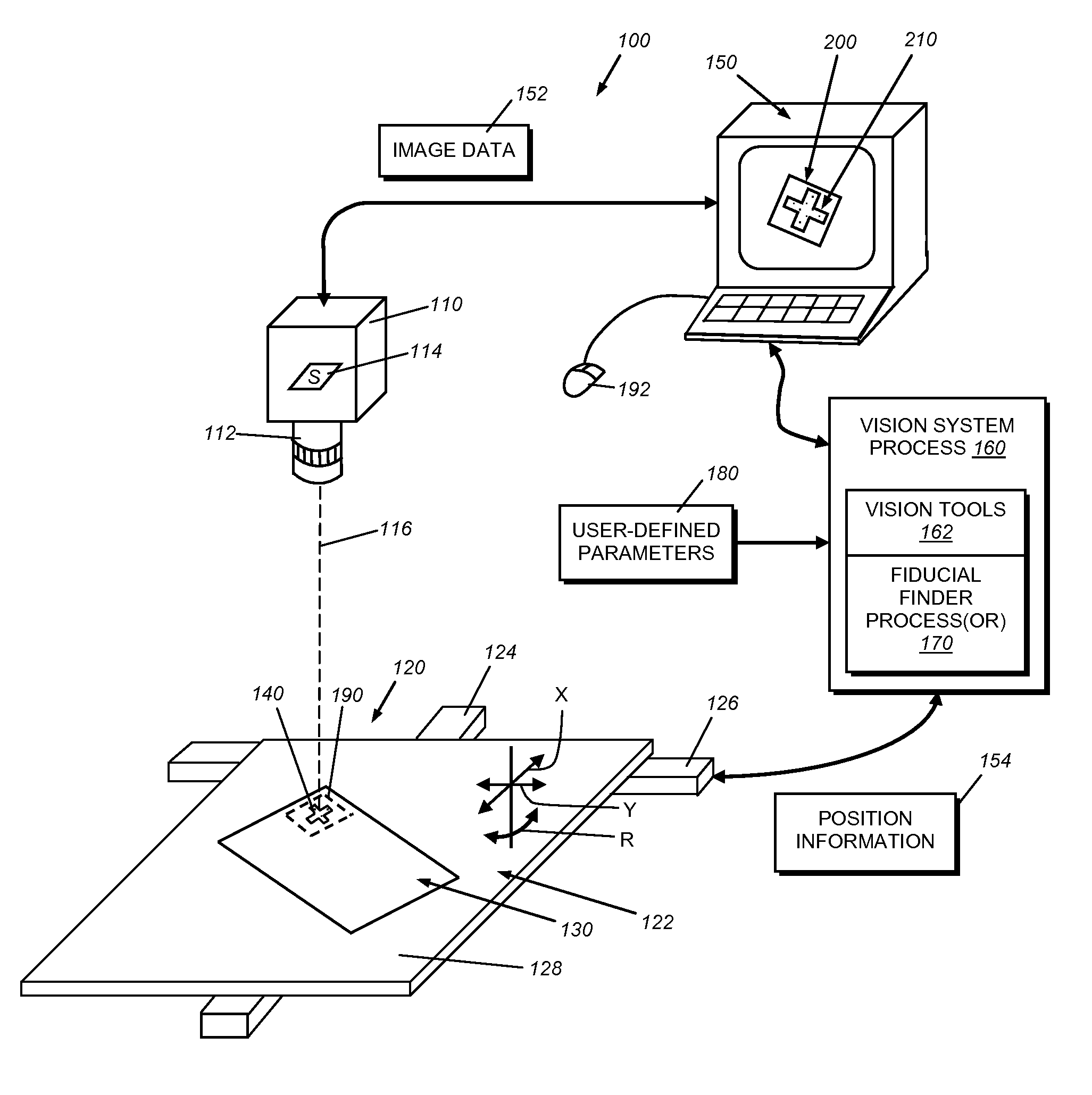

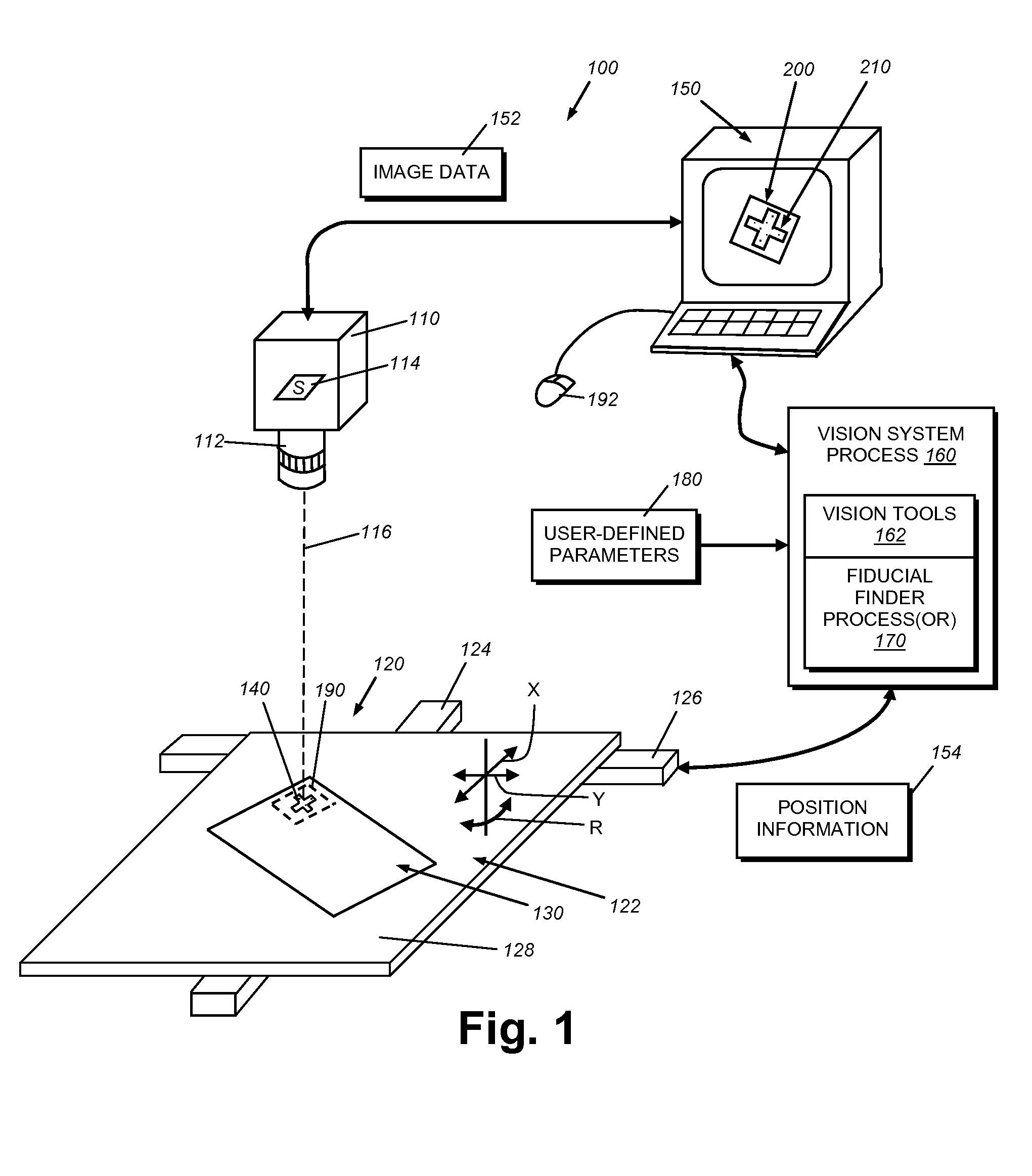

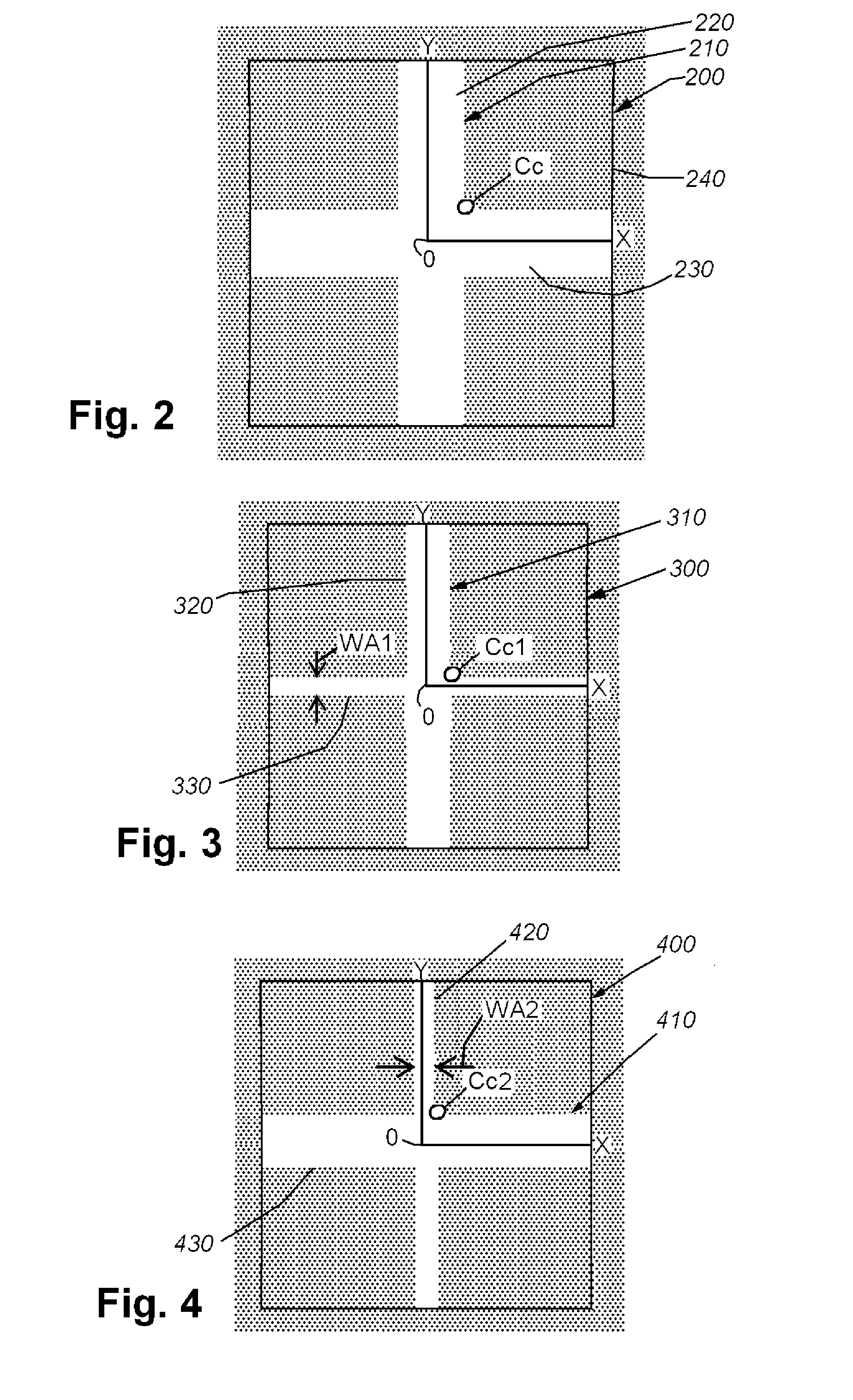

System and method for locating fiducials with known shape

ActiveUS20150104068A1Improve efficiencyImprove reliabilityImage enhancementImage analysisPeak valueDegrees of freedom

This invention provides a system and method for determining the pose of shapes that are known to a vision system that undergo both affine transformation and deformation. The object image with fiducial is acquired. The fiducial has affine parameters, including degrees of freedom (DOFs), search ranges and search step sizes, and control points with associated DOFs and step sizes. Each 2D affine parameter's search range and the distortion control points' DOFs are sampled and all combinations are obtained. The coarsely specified fiducial is transformed for each combination and a match metric is computed for the transformed fiducial, generating a score surface. Peaks are computed on this surface, as potential candidates, which are refined until a match metric is maximized. The refined representation exceeding a predetermined score is returned as potential shapes in the scene. Alternately the candidate with the best score can be used as a training fiducial.

Owner:COGNEX CORP

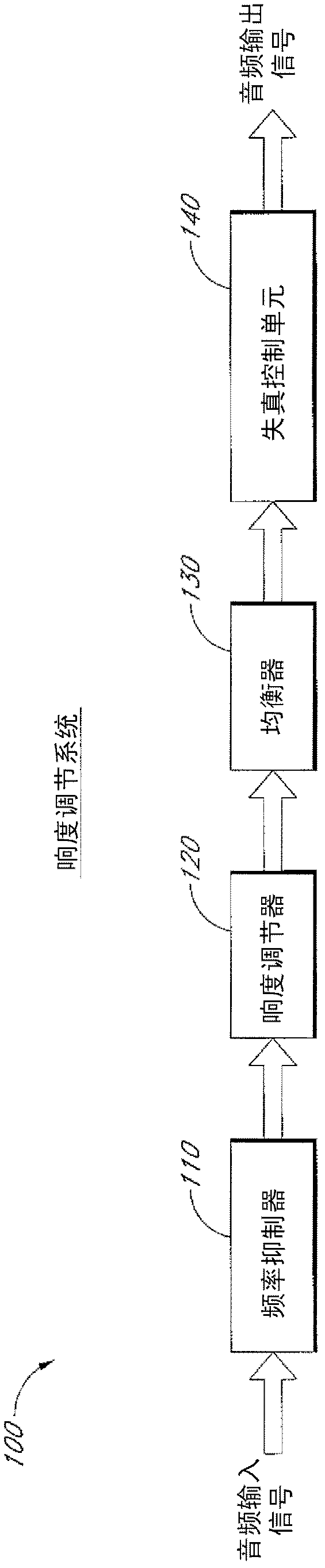

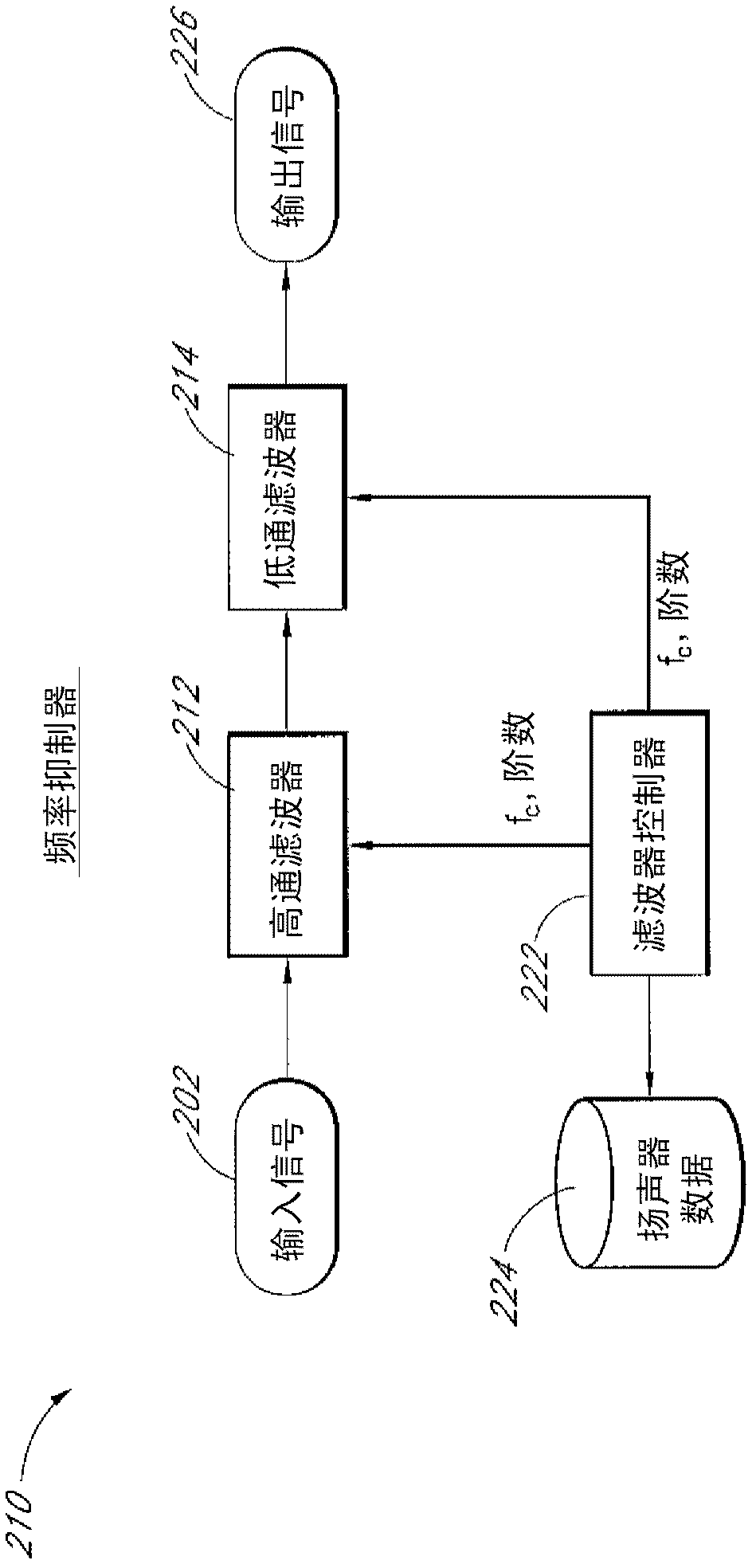

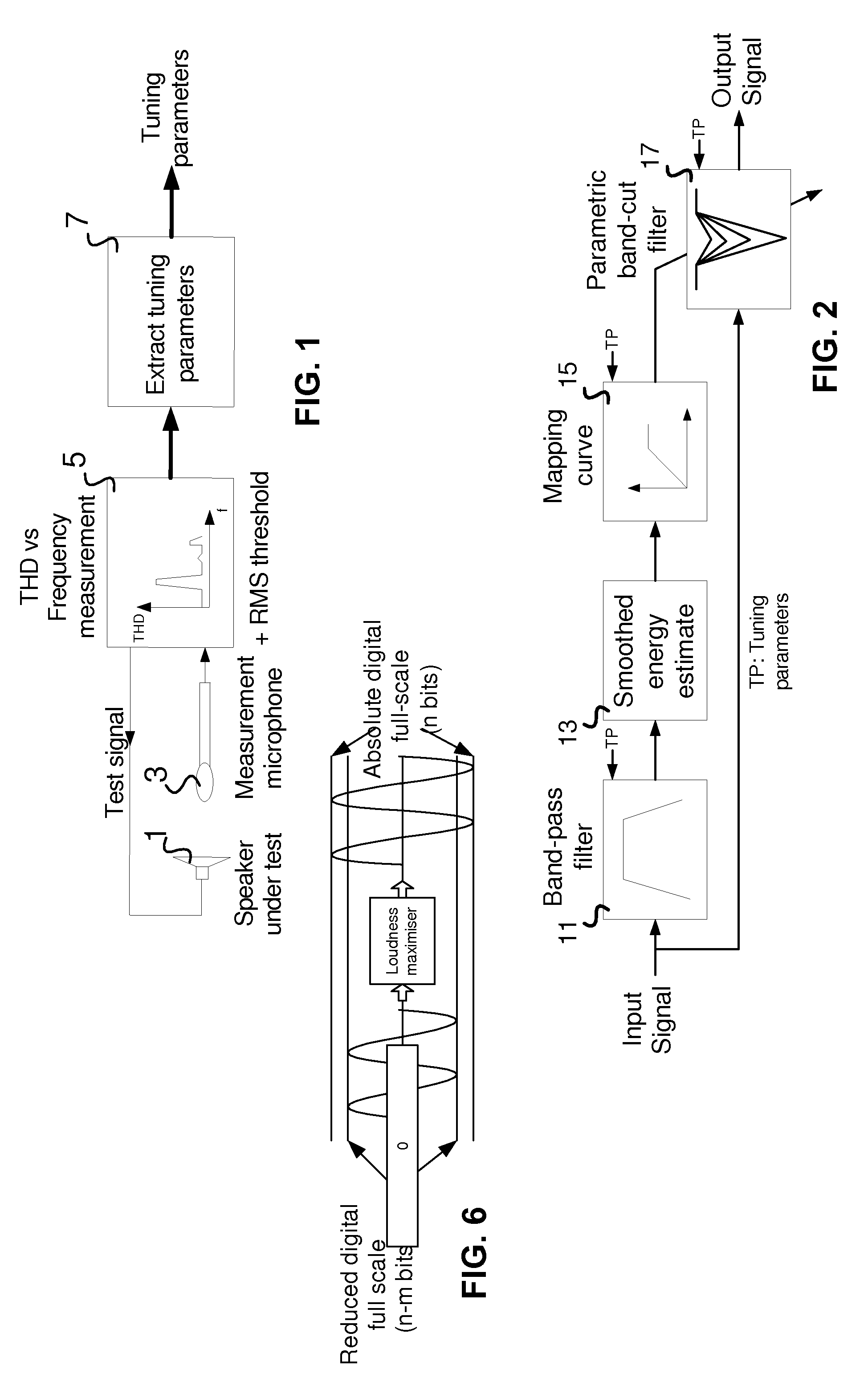

System for increasing perceived loudness of speakers

A system can be provided for increasing loudness of an audio signal to present a perceived loudness to a listener that is greater than a loudness provided natively by a loudspeaker. The system can include one or more of the following: a frequency suppressor, a loudness adjuster, an equalizer, and a distortion control module. The frequency suppressor can increase headroom in the audio signal by filtering out low and / or high frequencies. The loudness adjuster can calculate a loudness of the audio signal and apply a gain to the audio signal to increase the loudness. The equalizer can further increase headroom by attenuating portions of a passband of the loudspeaker's frequency response. The distortion control module can induce partial harmonic distortion in the audio signal to further increase loudness.

Owner:DTS

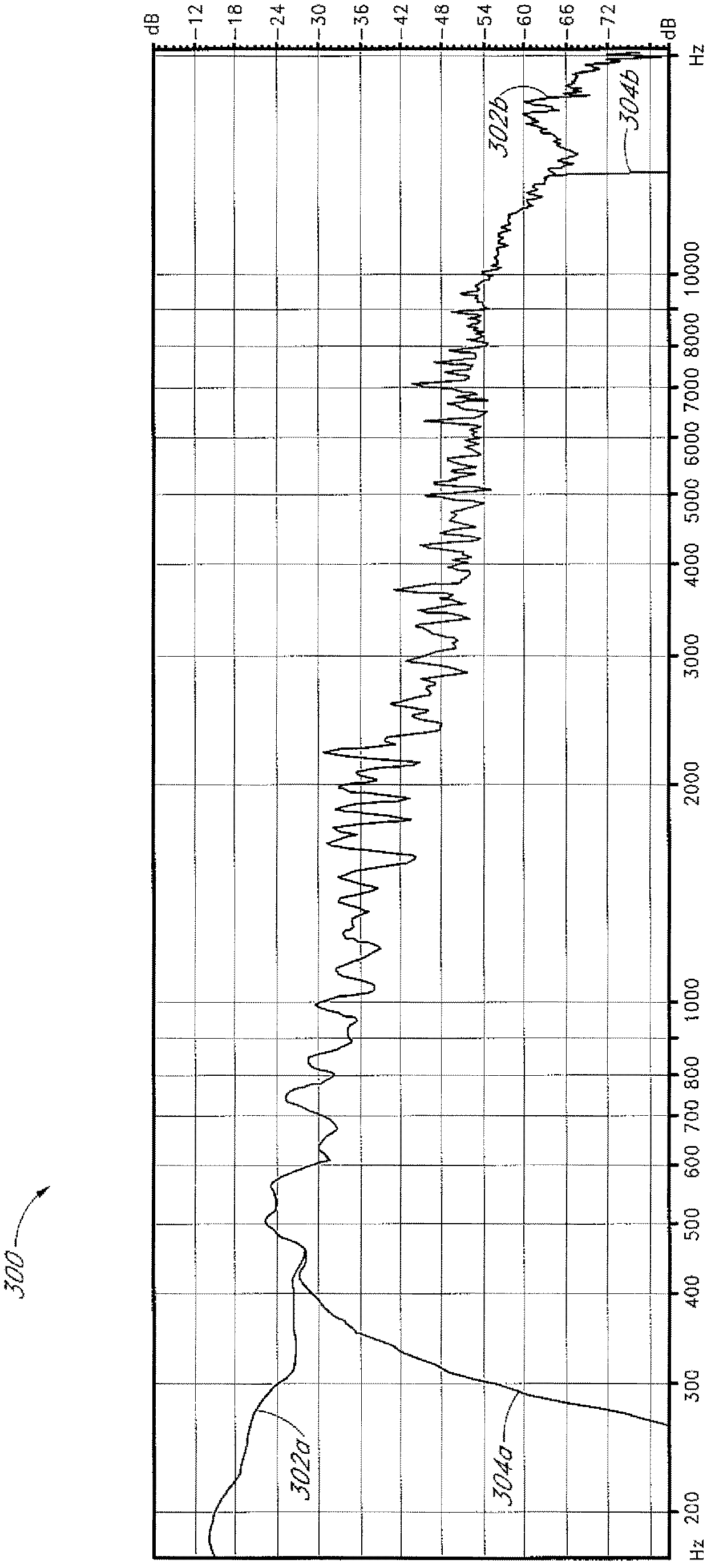

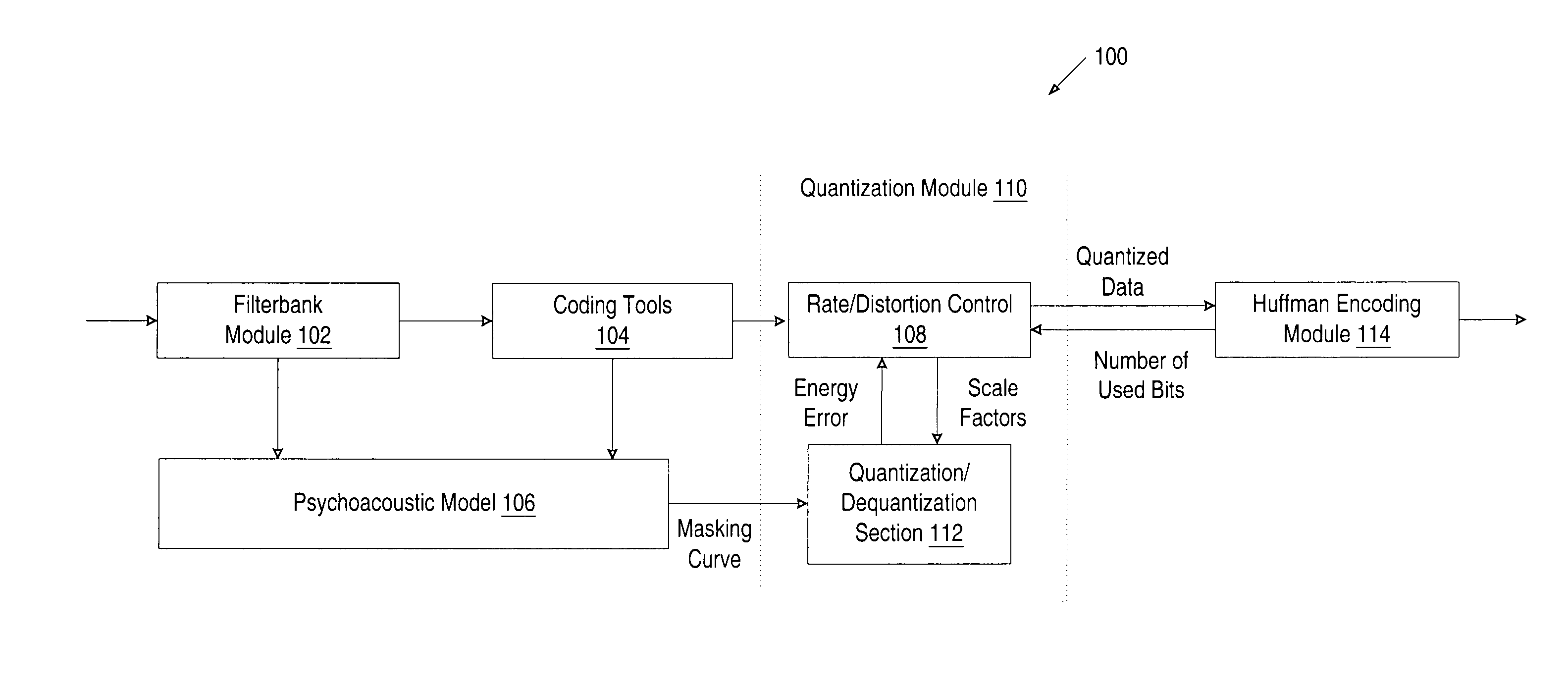

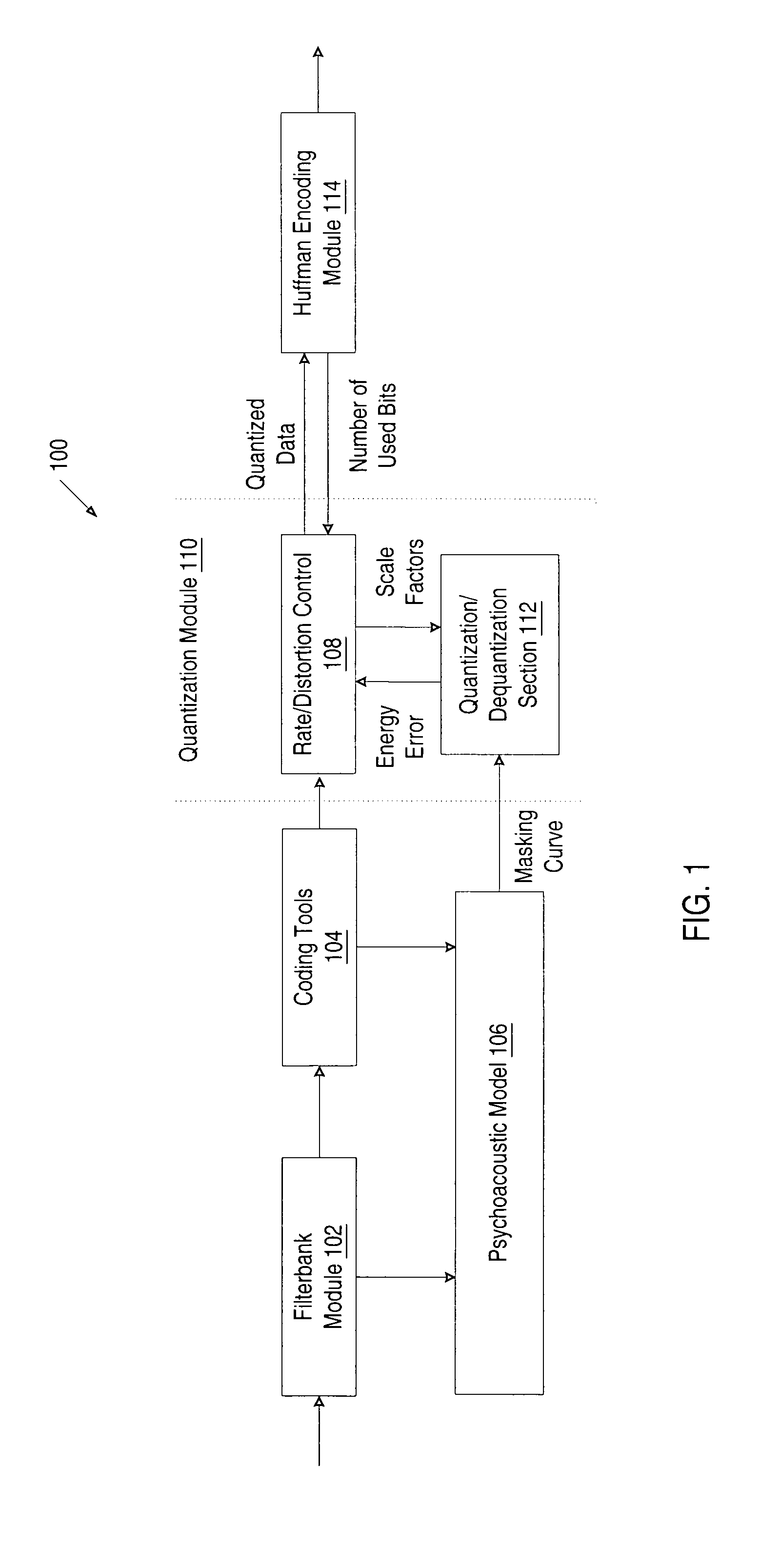

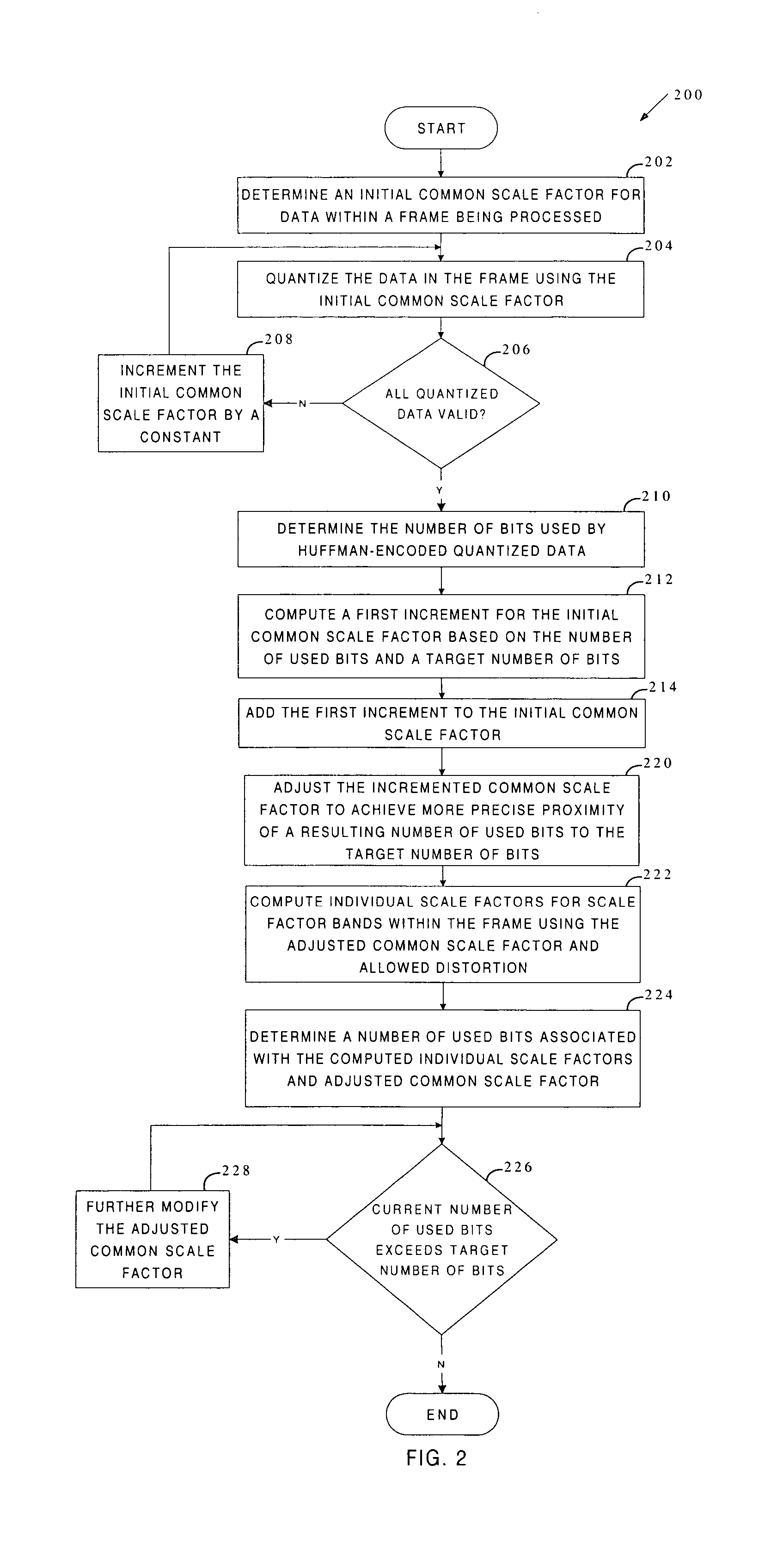

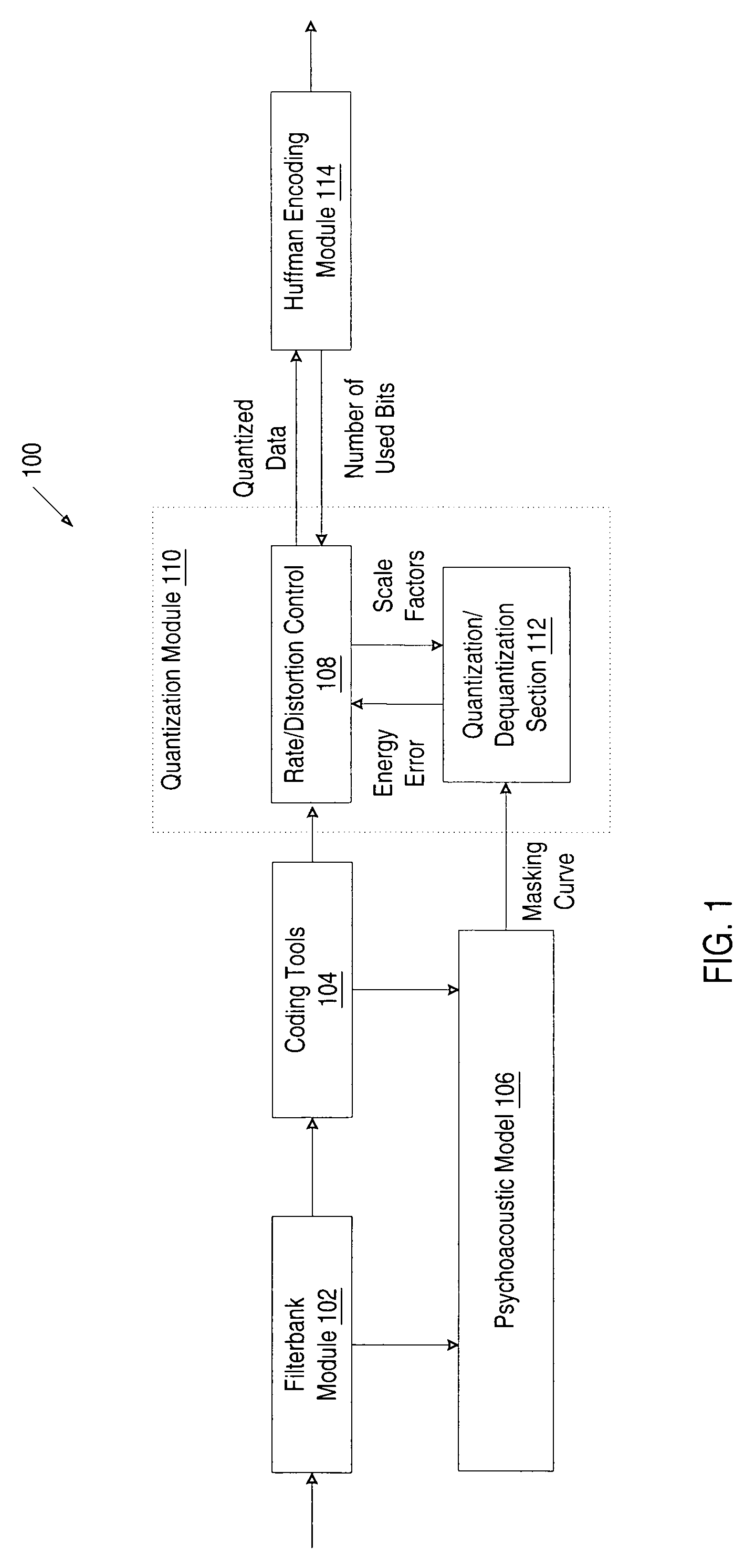

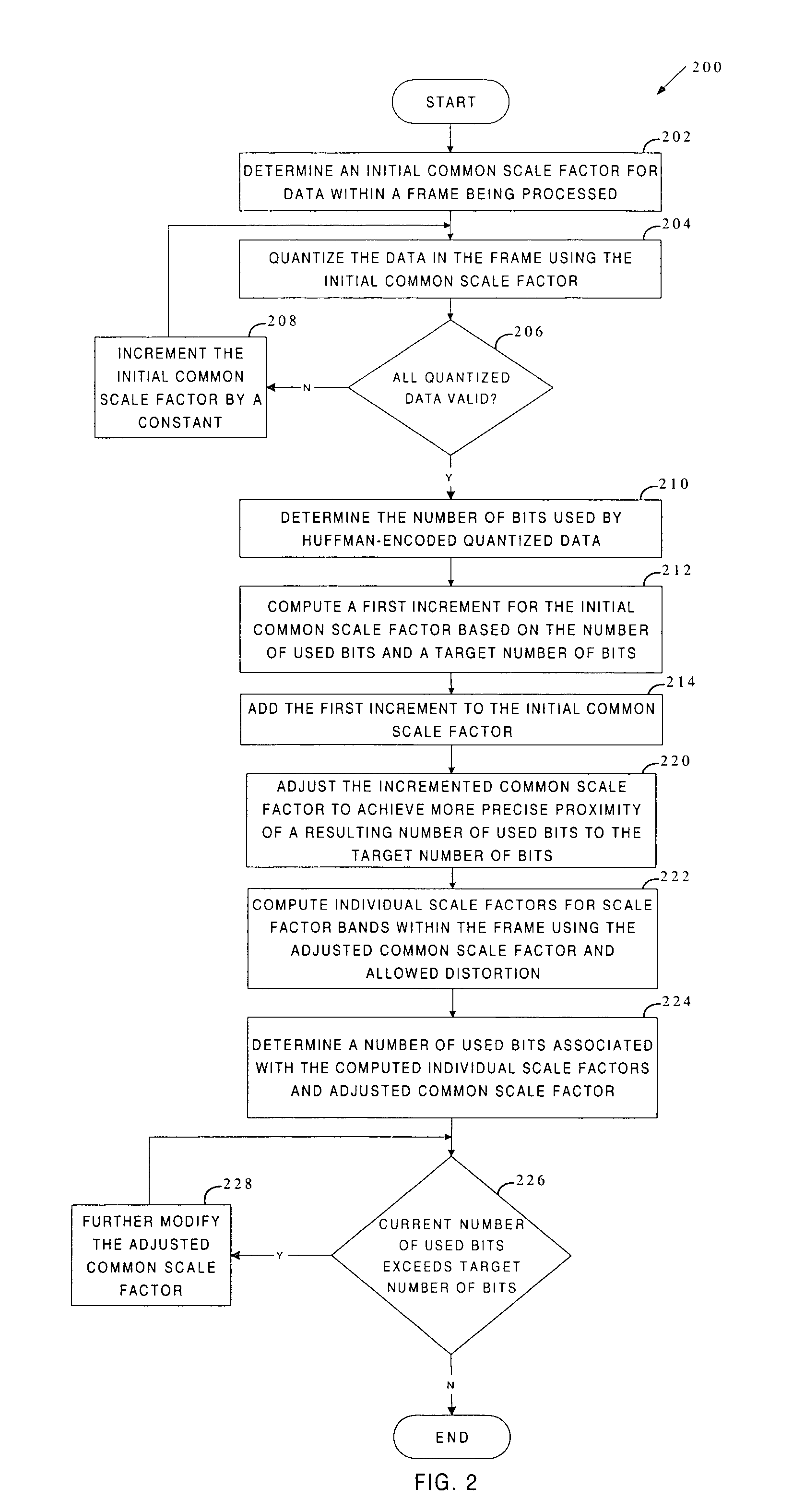

Rate-distortion control scheme in audio encoding

An initial number of bits associated with an initial common scale factor is determined, an initial increment is computed using the initial number of bits and a target number of bits, and the initial scale factor is incremented by the initial increment. Further, the incremented common scale factor is adjusted based on the target number of bits, and individual scale factors are computed based on the adjusted common scale factor and allowed distortion. If a current number of bits associated with the computed individual scale factors exceeds the target number of bits, the adjusted common scale factor is modified until a resulting number of bits no longer exceeds the target number of bits.

Owner:SONY CORP +1

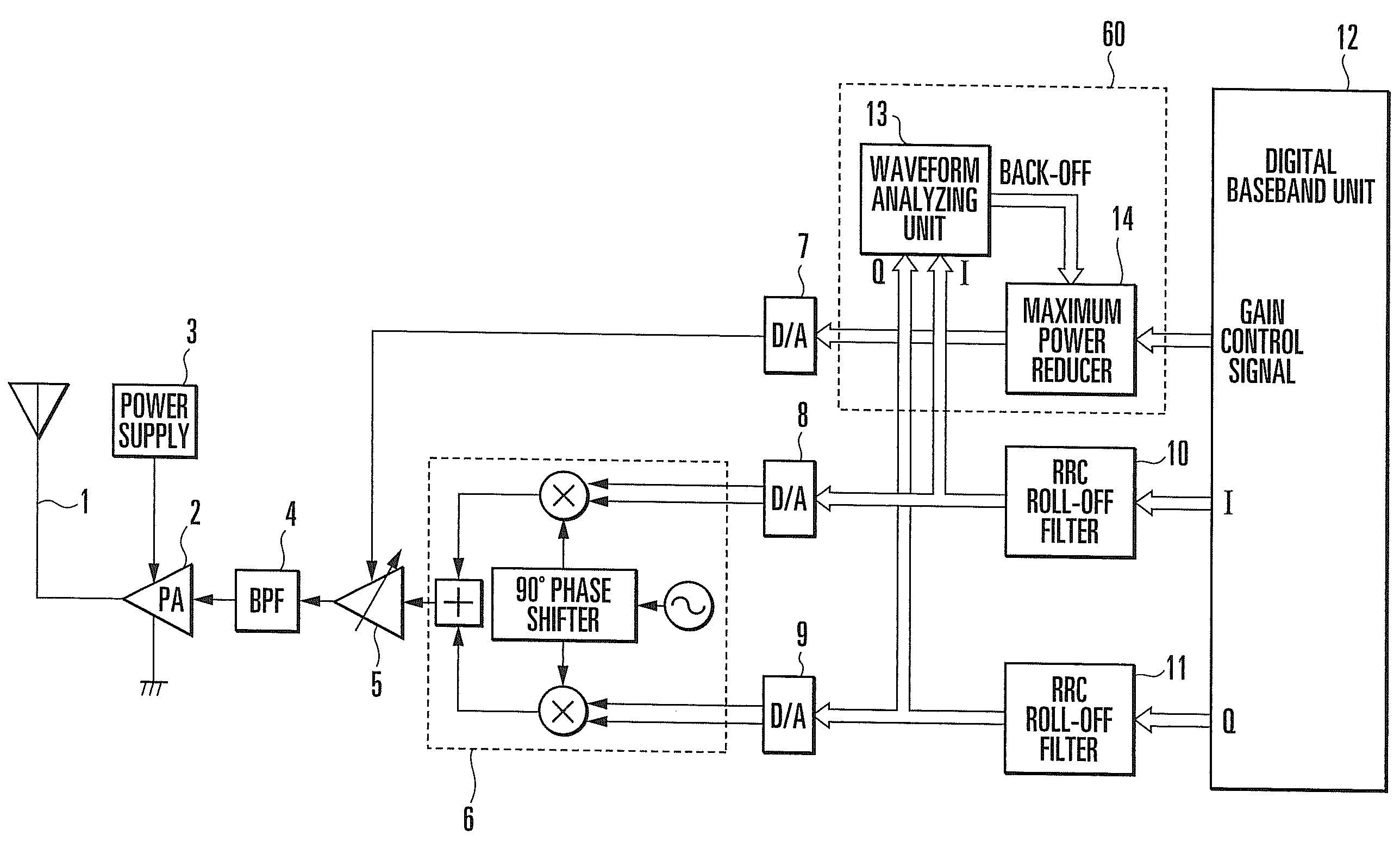

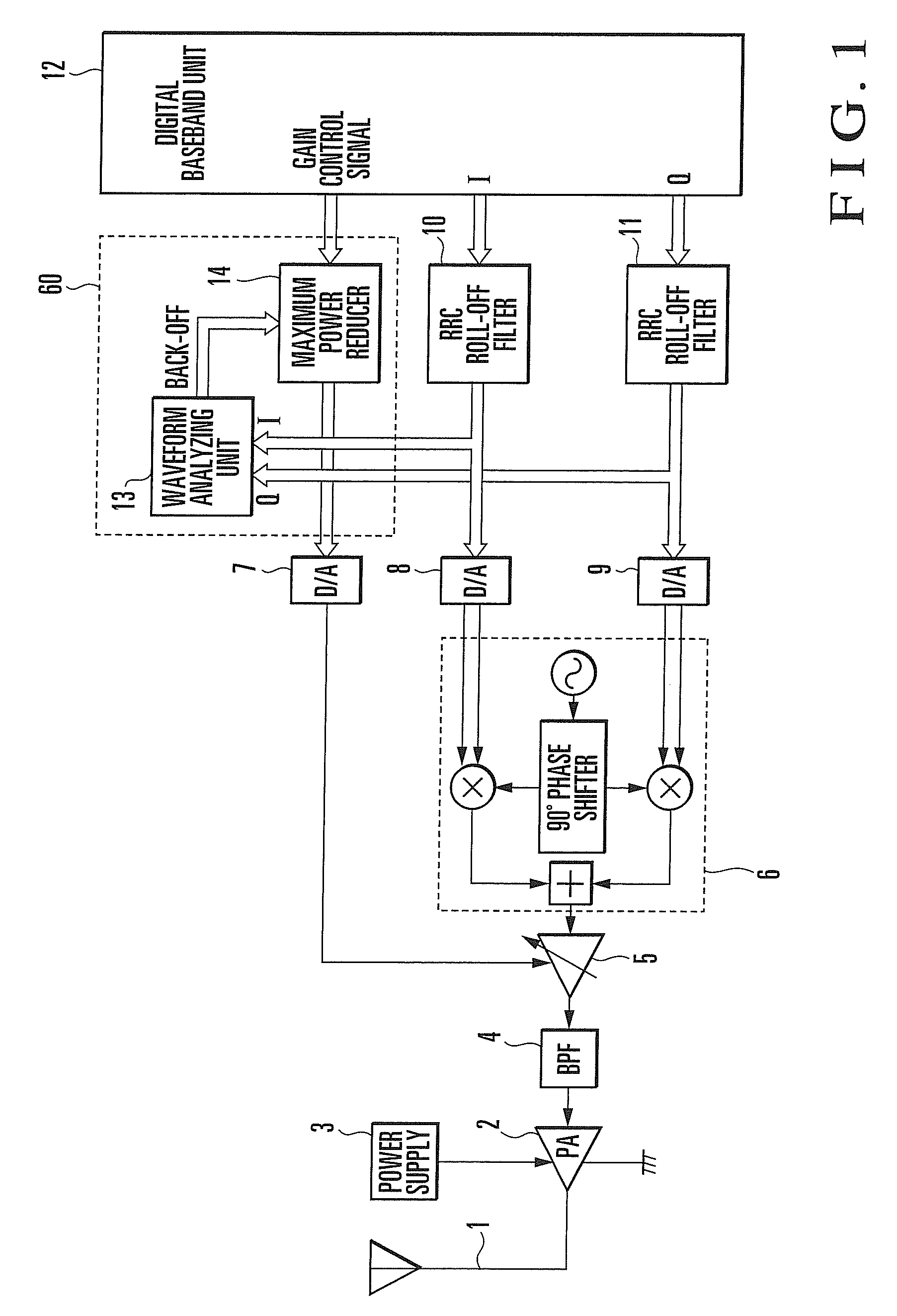

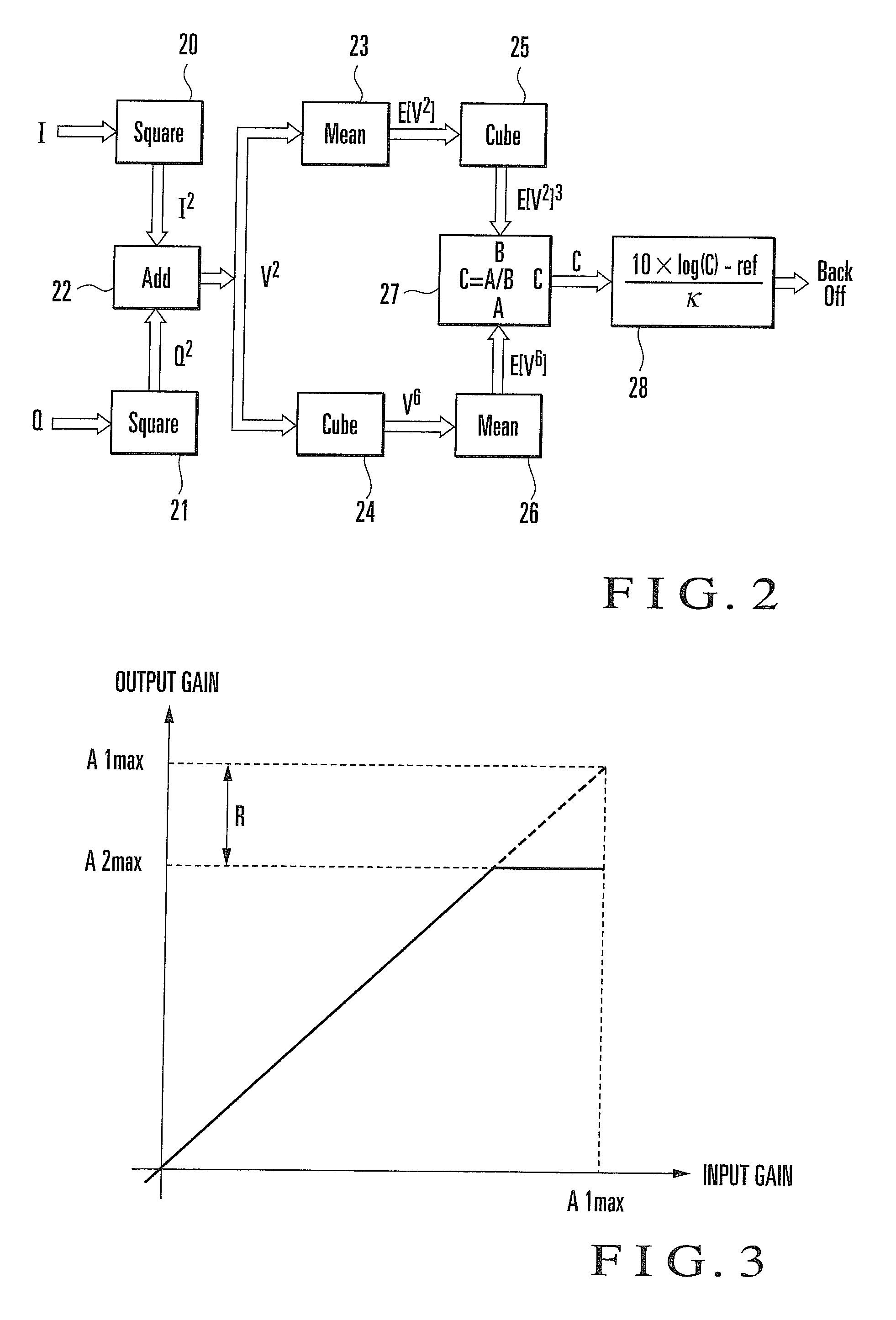

Distortion Control Device and Method

InactiveUS20090202017A1Improve leakageSupply voltage varying controlSecret communicationMultiplexingAudio power amplifier

This invention includes a waveform analyzing means (13) for calculating an estimated value of a back-off value required by a power amplifier (2), which amplifies a high-frequency signal generated from a baseband signal (I, Q) to a predetermined transmission power, by analyzing the waveform of the baseband signal (I, Q), and a control means (14) for controlling at least one of the amplitude of high-frequency power input to the power amplifier (2) and the supply power of the power amplifier (2) on the basis of the estimated value. The invention calculates the estimated value of a back-off value by analyzing the waveform of a baseband in this manner, and hence need not generate a table in advance by calculating a back-off value for each combination of code channels. The invention can therefore be applied to even a case in which the number of code channels greatly increases, and can effectively prevent an increase in adjacent channel leakage power due to a signal obtained by multiplexing these code channels.

Owner:LENOVO INNOVATIONS LTD HONG KONG

Rate-distortion control scheme in audio encoding

Owner:SONY CORP +1

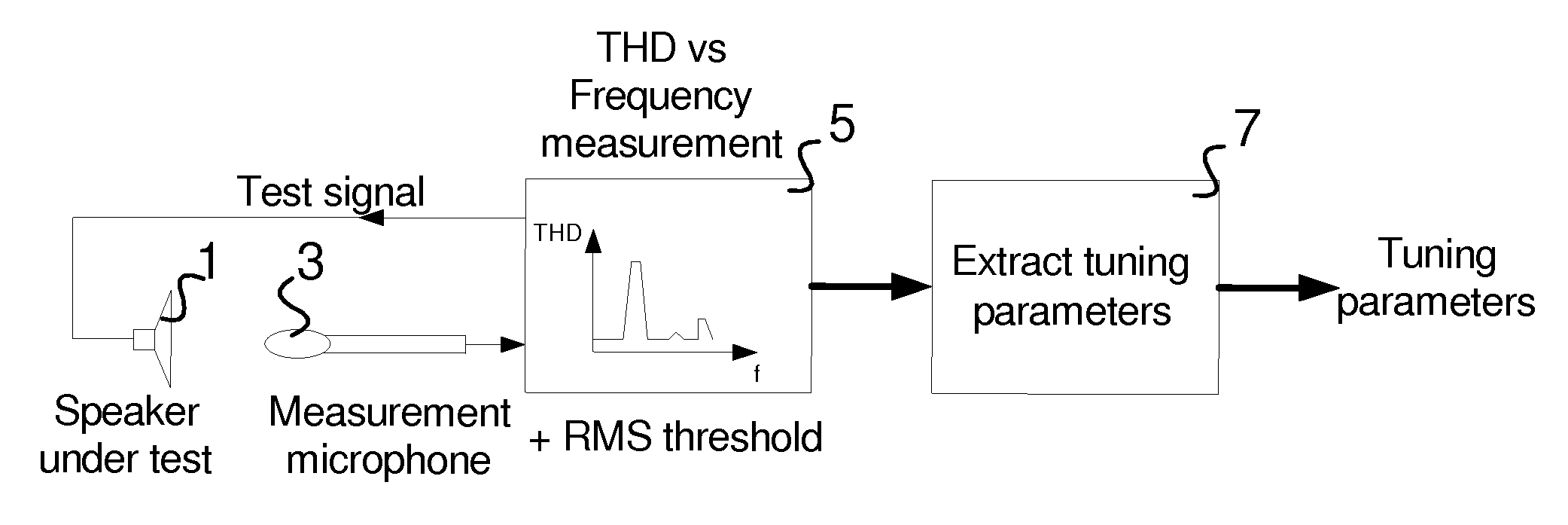

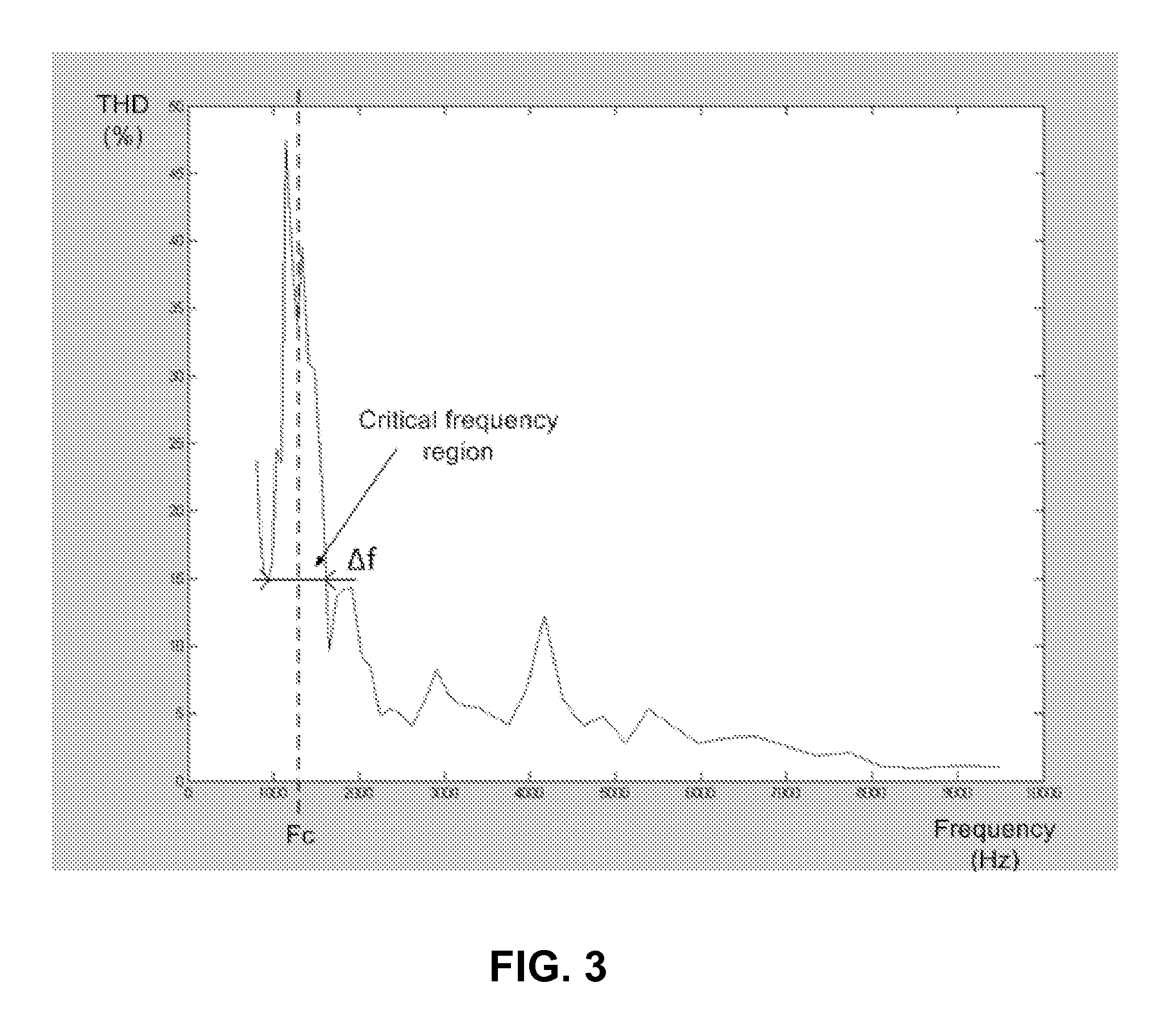

Method and system for controlling distortion in a critical frequency band of an audio signal

InactiveUS9130527B2Control distortionIncrease the loudnessGain controlTransducer protection circuitsTotal harmonic distortionLoudspeaker

In some embodiments, a method and system for controlling distortion of the output of a miniature speaker by attenuating critical frequency band of the input signal to be reproduced, using tuning parameters that have been predetermined where the critical frequency band is a frequency range of the speaker's frequency response in which Total Harmonic Distortion (THD) peaks. The distortion control is performed in a manner which allows an increase in the average loudness of the speaker's output without significantly increasing distortion. The tuning parameters include a center frequency and a bandwidth of the critical frequency band, and a power threshold value. In some embodiments, the system is a loudness maximizer configured to limit distortion of a speaker's output by limiting distortion in a critical frequency band using predetermined control parameters, and limit the dynamic range of the output signal and increase its perceived overall average loudness level.

Owner:DOLBY LAB LICENSING CORP

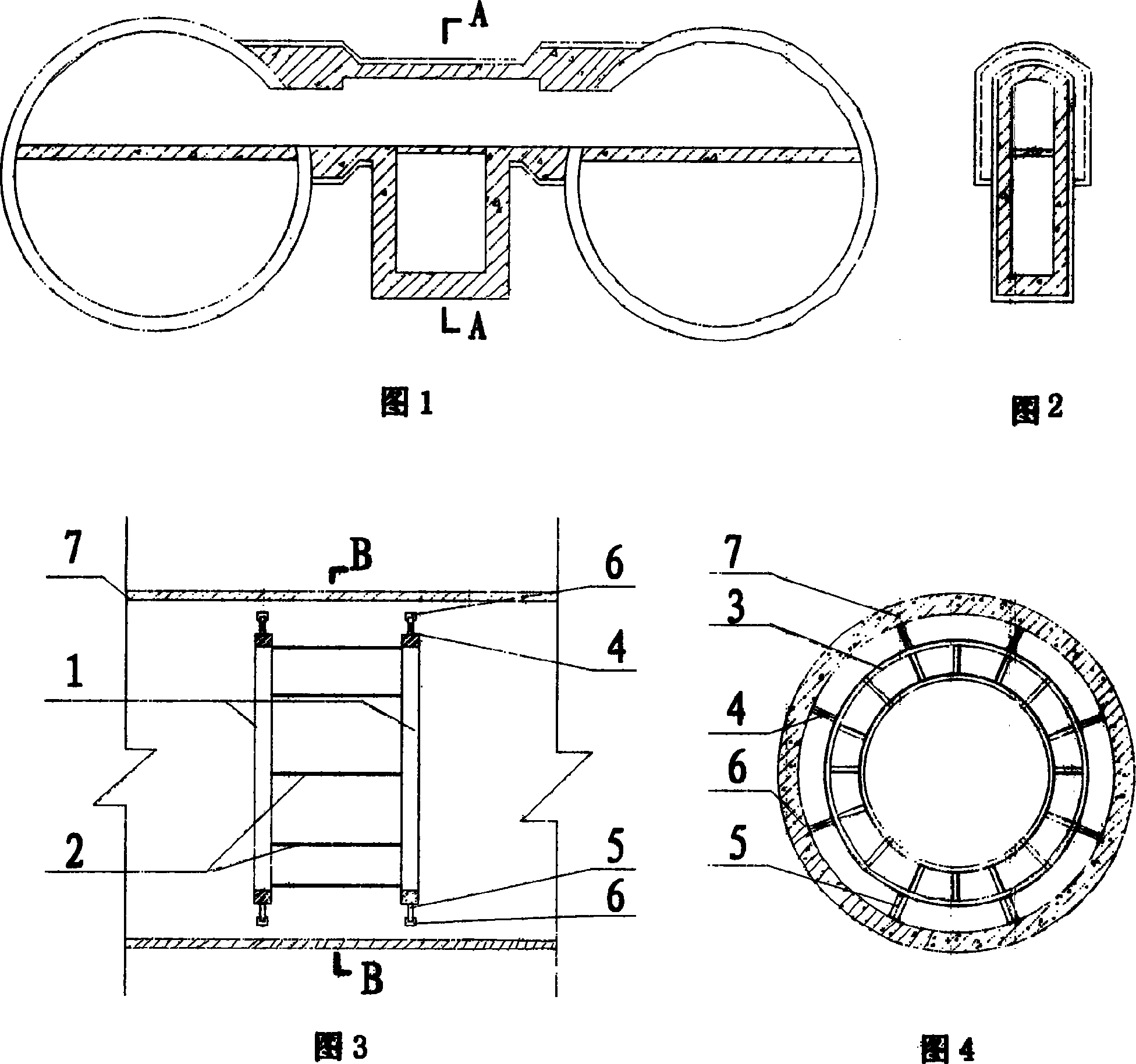

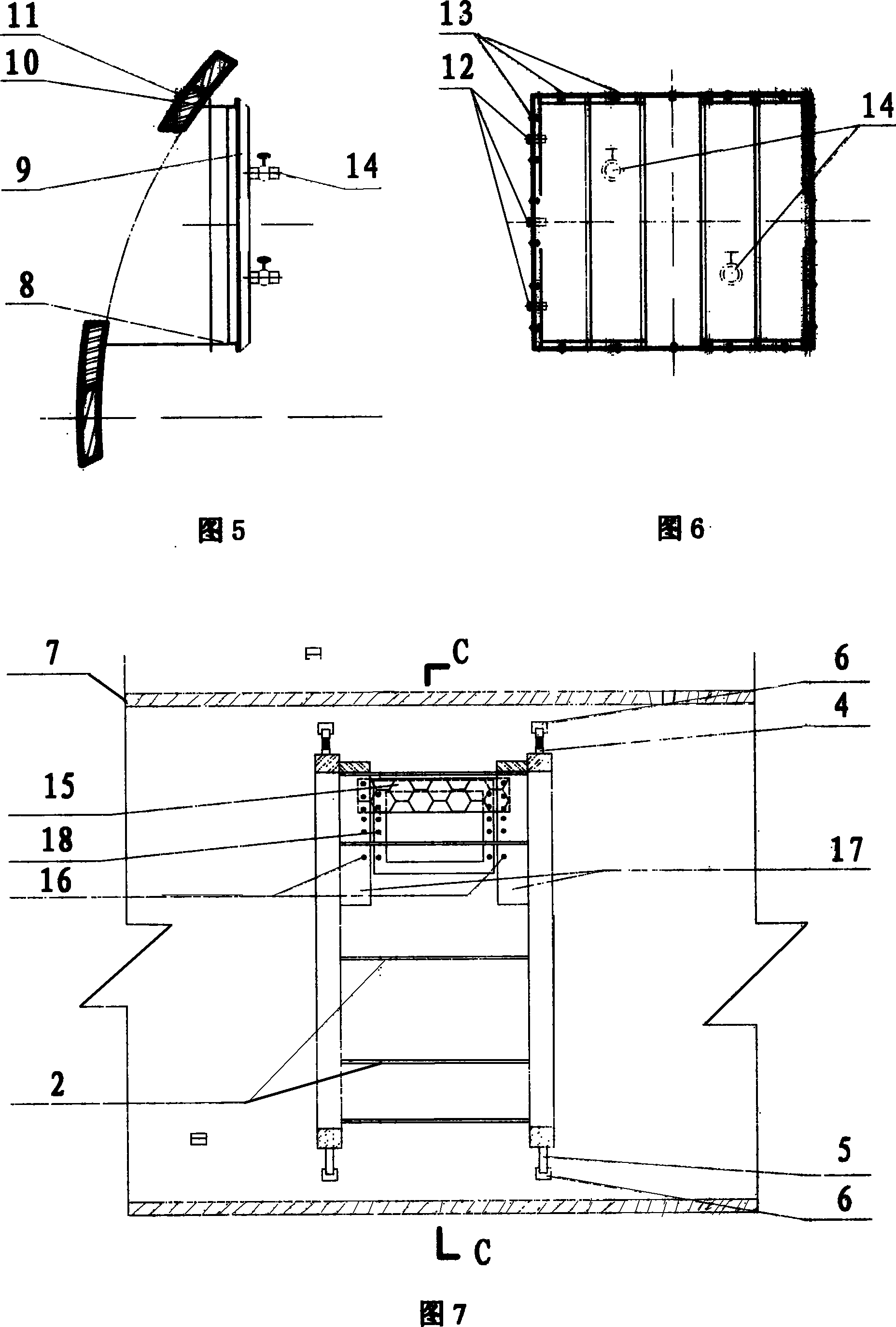

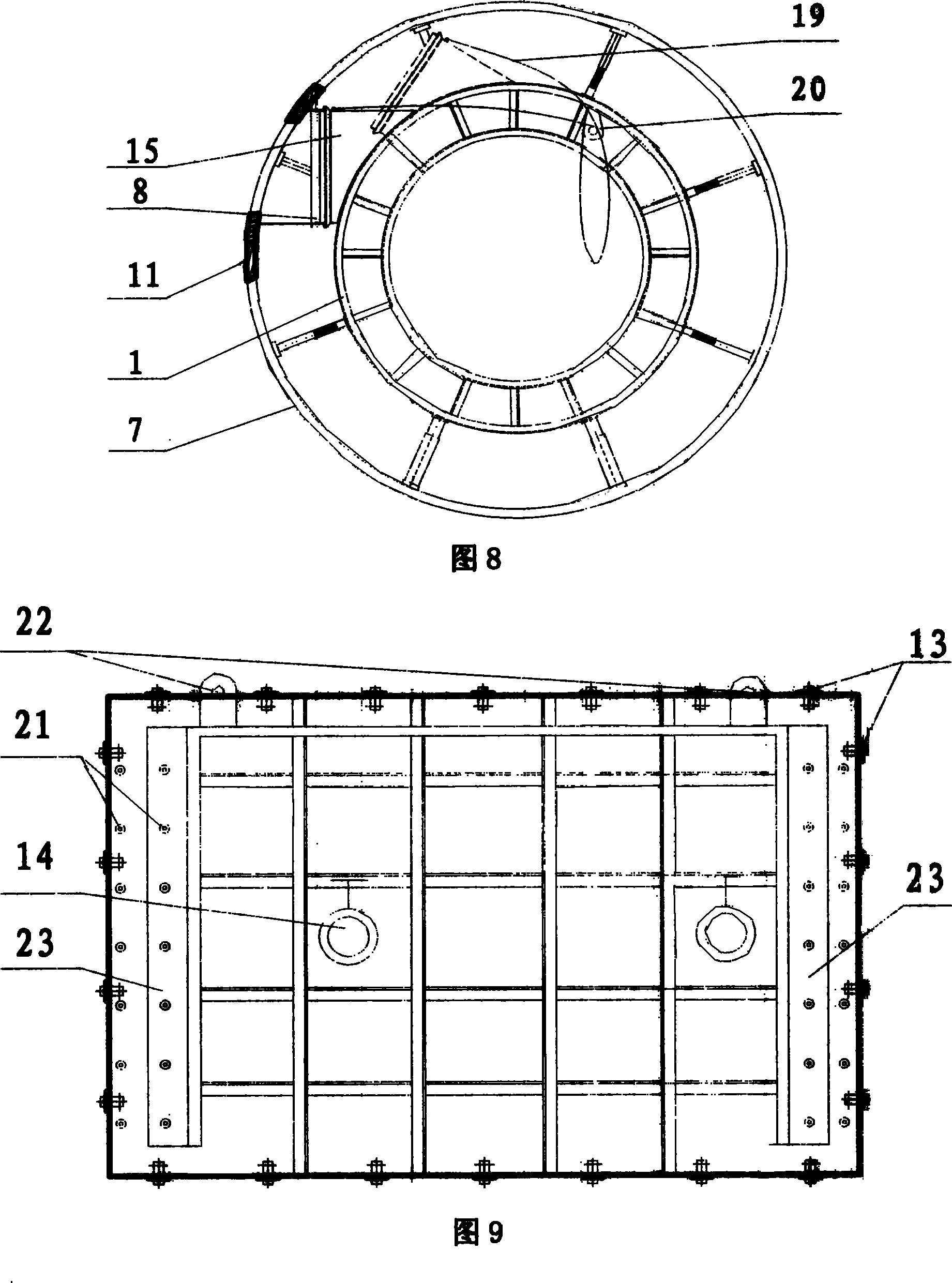

Segment deformation control and flood-proof device and operation method for tunnel opening construction

InactiveCN101100944ARealize submersion protection functionGuaranteed integrityUnderground chambersTunnel liningMain channelEngineering

This is a duck piece distortion control and anti-submerge device to prevent duck piece distortion during construction and collapse upon water / dust burst and submerge of main channel. The structure includes prestress bracket system, door frame, sliding cover and guiding device. The door frame is welded to the steel duck piece at hatch. The sliding cover is fastened on a curve steel rail of a circle bracket to the two sides of the hatch. The guiding device is composed by calbe and –·‘¨‰½. The sliding cover is capable of sliding along the rail to close the door by human control the cable. Loading on the slide cover is supported by the prestress bracket to avoid distortion to the duck piece and collapse.

Owner:TONGJI UNIV

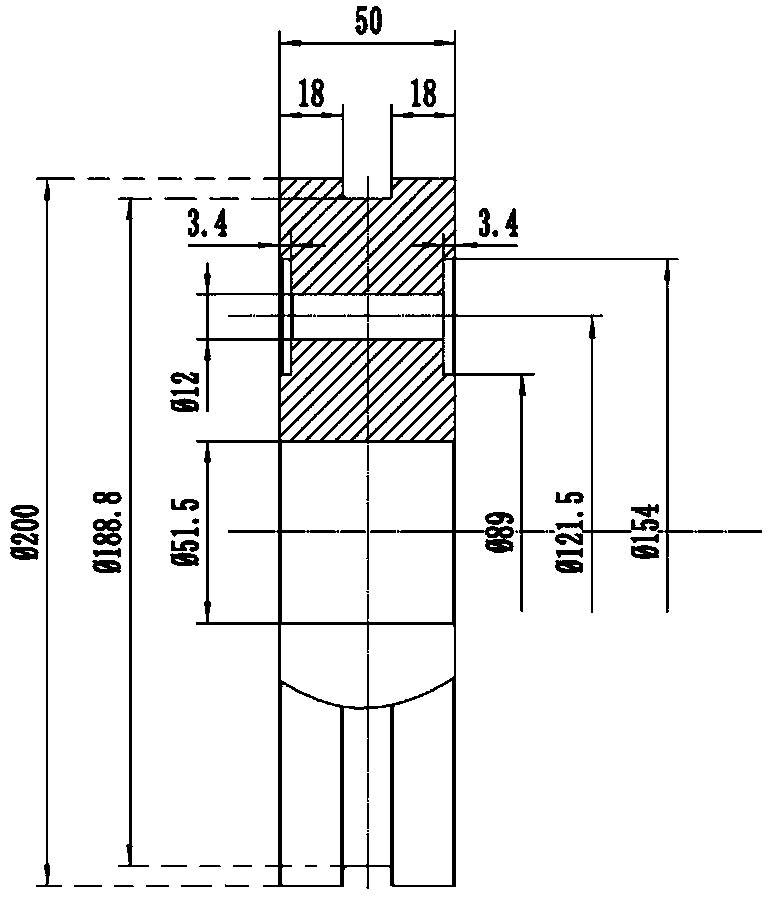

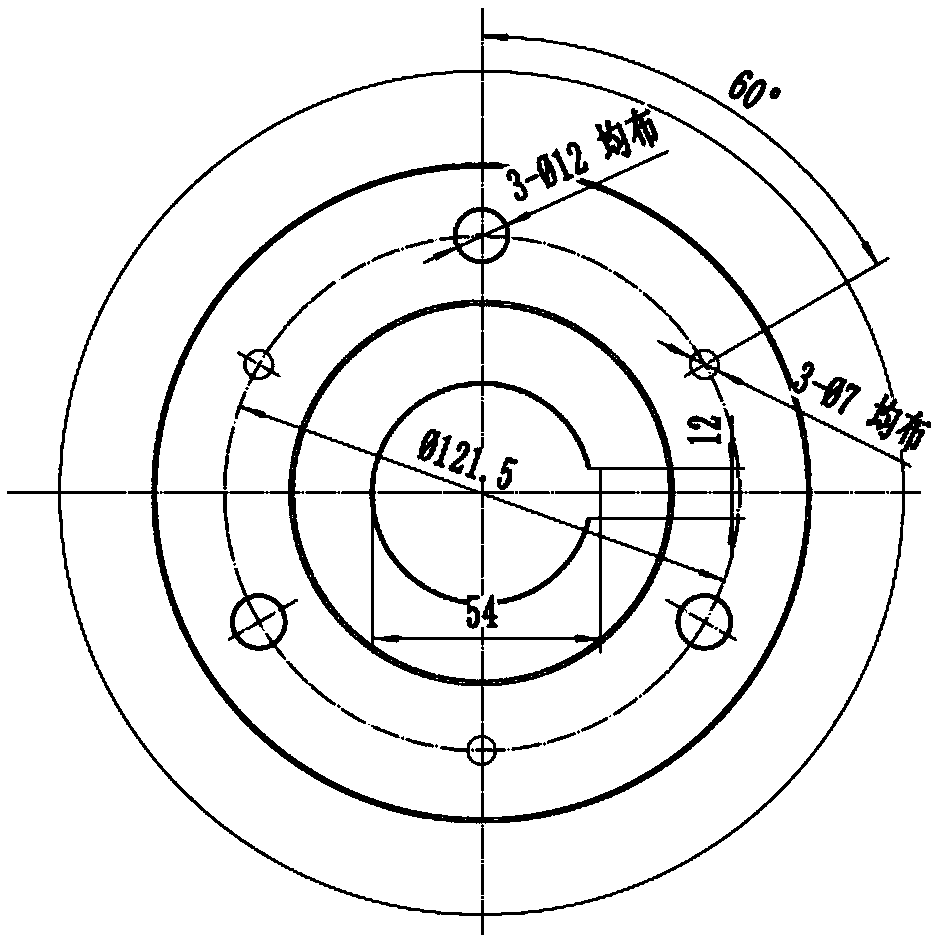

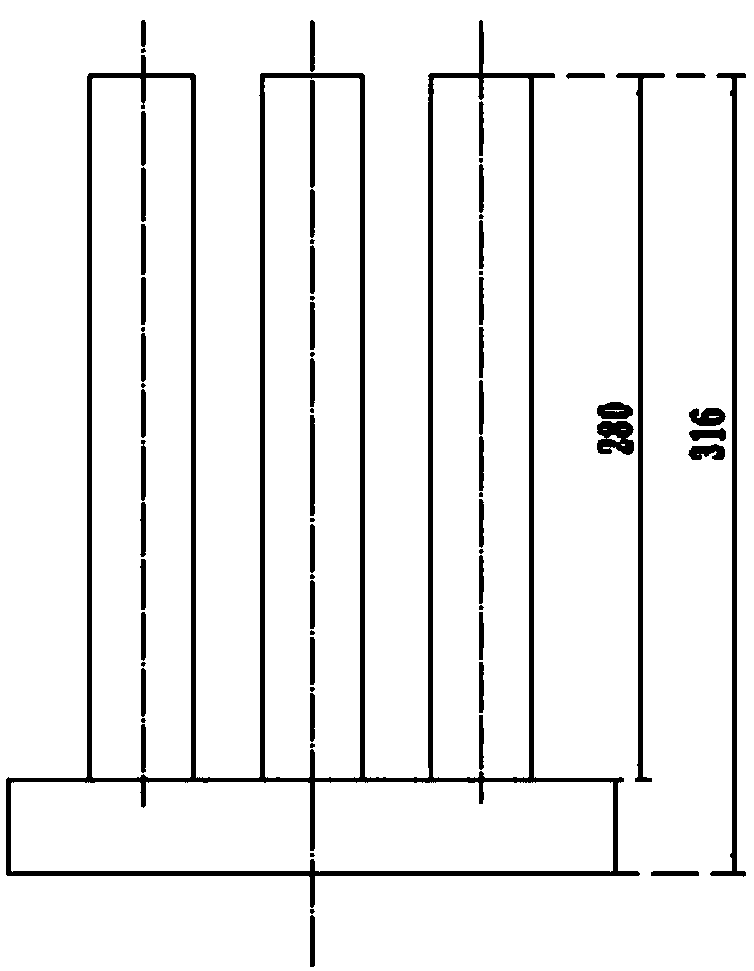

Anti-carbonation quenching distortion control method of large-size dual-herringbone gear

InactiveCN107937922AQuality improvementHigh strengthSolid state diffusion coatingFurnace typesHerringbone gearUltimate tensile strength

The invention provides an anti-carbonation quenching distortion control method of a large-size dual-herringbone gear. The anti-carbonation quenching distortion control method comprises the steps thatan existing carburizing and quenching tool is changed into a three-point supporting tool, before quenching charging after carburization, the upper face and the lower face of the gear are exchanged, and metallographic structure examination and the carburizing and quenching process parameter improvement after heat treatment are prepared. The anti-carbonation quenching distortion control method is used for the large-size dual-herringbone carburizing and quenching gear of a turbocompressor. According to the carburizing and quenching gear controlled through the anti-carbonation quenching distortioncontrol method, the deformation amount of the whole carburizing and quenching process is reduced by above 50%, the gear deformation amount is greatly reduced, the gear quality is greatly improved, the contact fatigue strength and bending fatigue are greatly improved, the grinding amount is reduced, and the cost is greatly reduced.

Owner:SHENYANG TURBO MASCH CORP

Frame distortion control

A slipform paving machine includes a laser source for generating a laser reference plane. At least two laser receivers are mounted on the machine and intersect the laser reference plane. Inputs from the laser receivers are utilized to control distortion of the frame of the slipform paver machine.

Owner:WIRTGEN GMBH

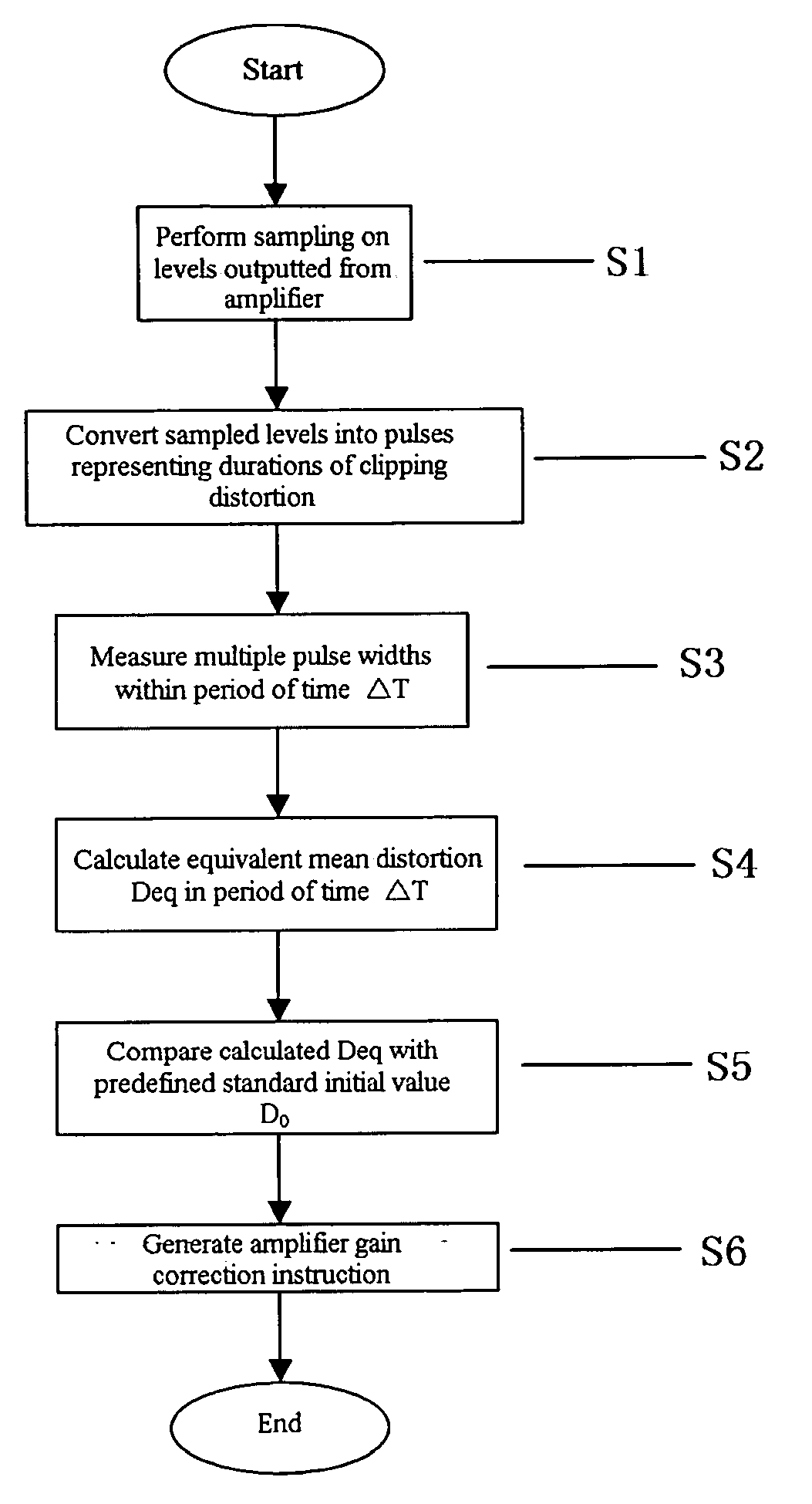

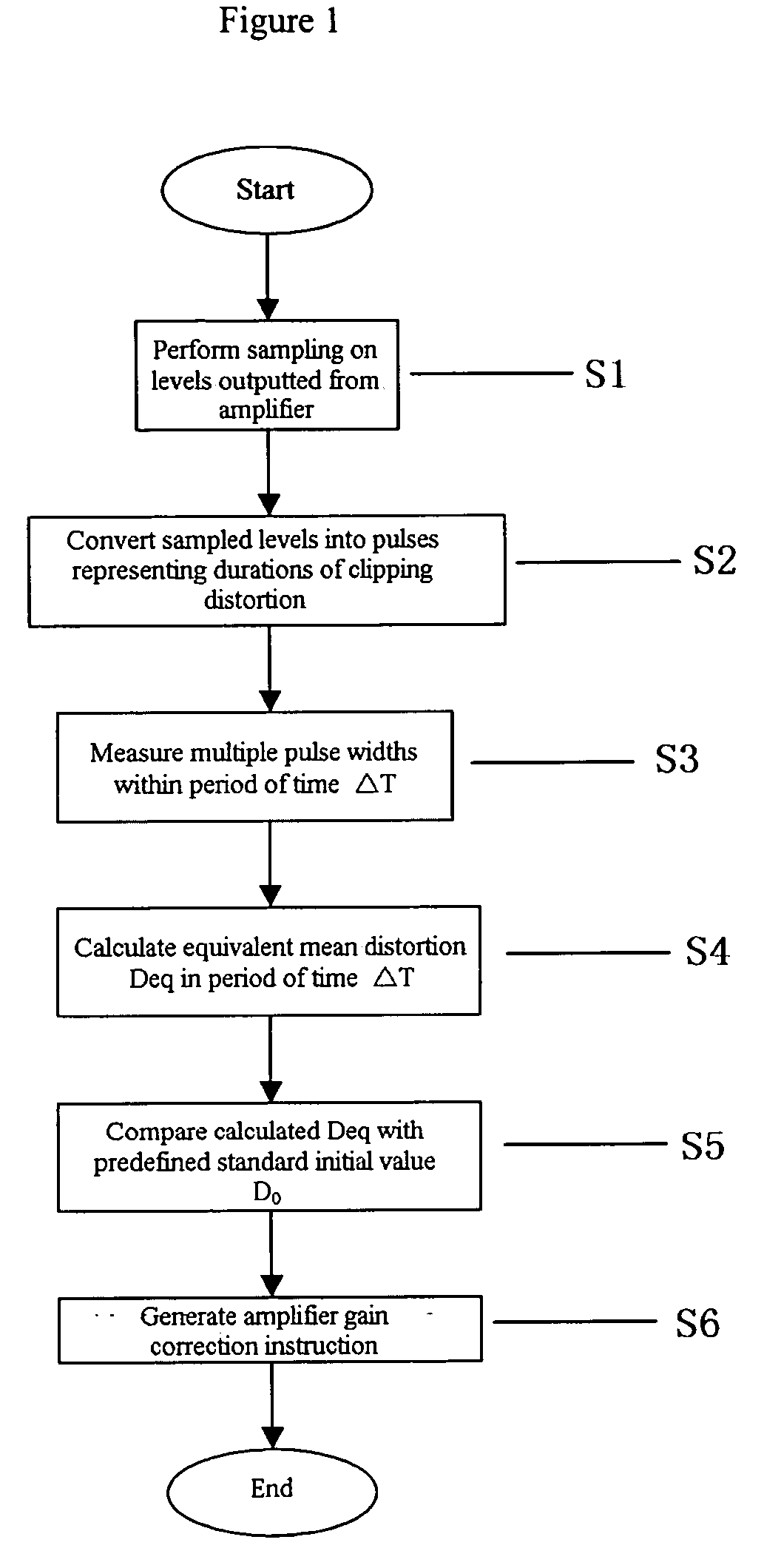

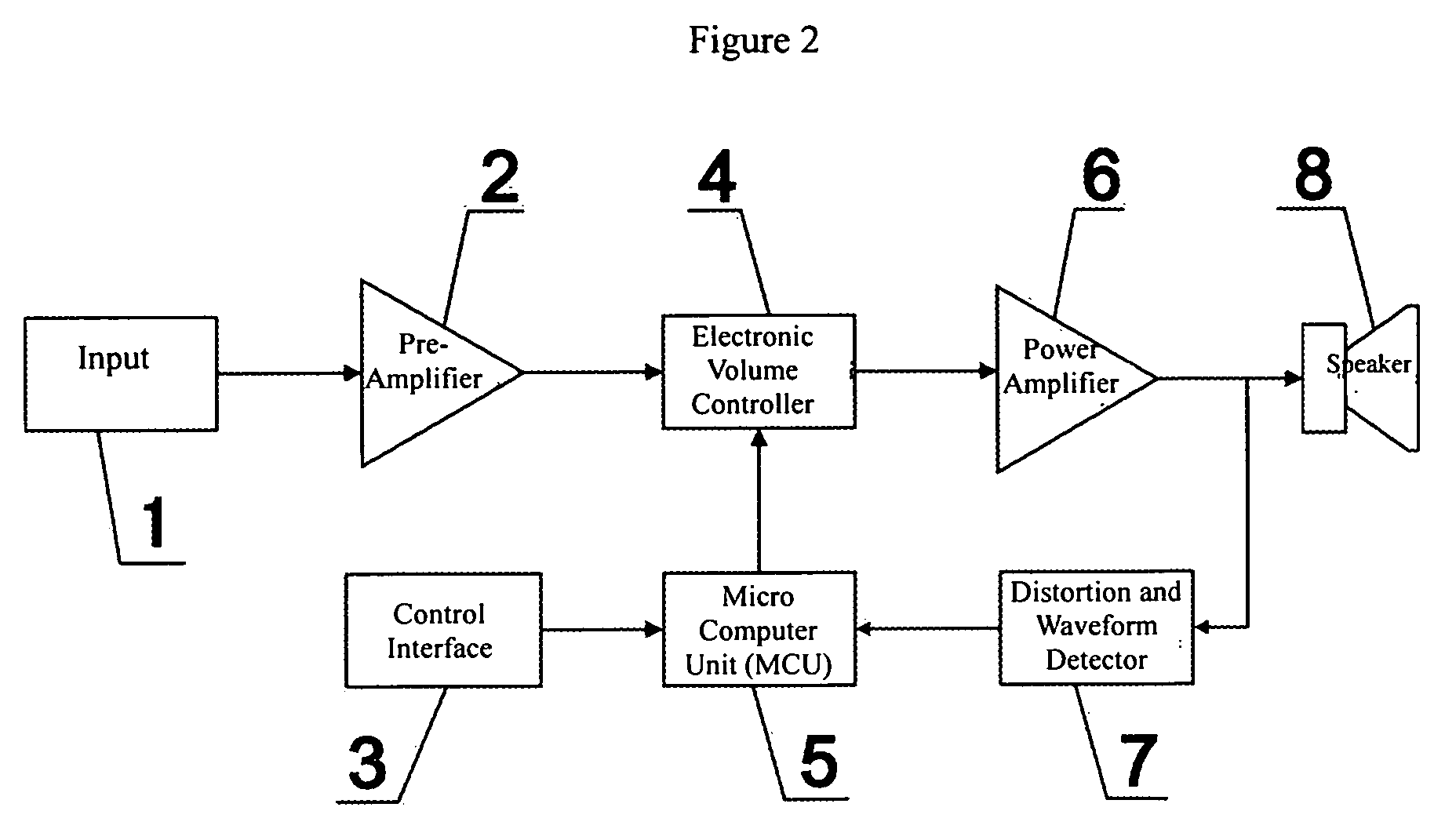

Automatic audio distortion control method and apparatus

ActiveUS20060256977A1Avoid damageAvoid problemsElectric devicesCurrent/voltage measurementAutomatic controlAudio power amplifier

Disclosed is an automatic audio distortion control method and apparatus, wherein the automatic audio distortion control apparatus comprises an amplifier (6) and a feedback loop which has its both ends coupled to an input and an output of the amplifier (6), wherein said feedback loop has clipping distortion of signals outputted from the amplifier (6) as a control parameter for automatic control on the distortion of the amplifier (6). Once the outputted level gets close to a limit-value of speakers, the method and the apparatus will regulate power amplifier gain automatically, in order to control distortion, prevent damage to the speakers, and provide compatibility with high or low levels inputted from various audio sources.

Owner:BEJING EDIFIER TECH CO LTD

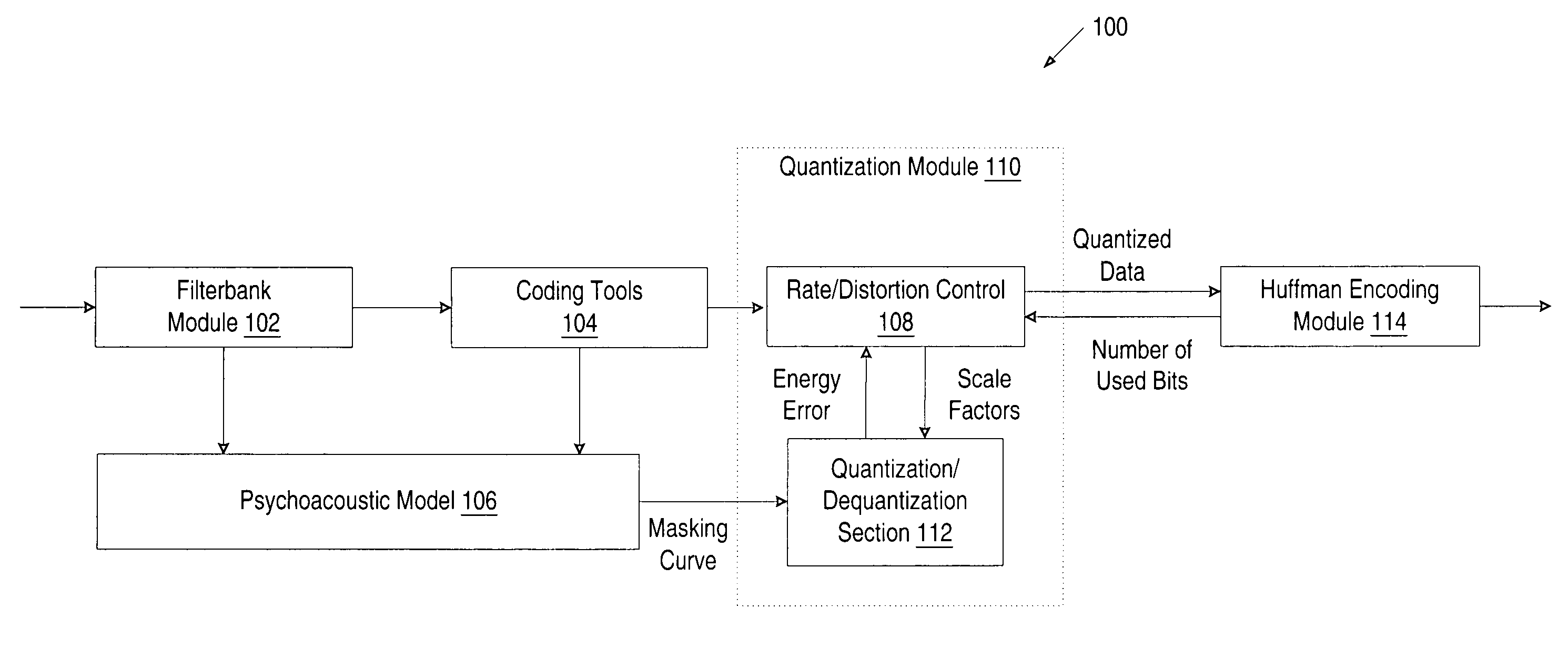

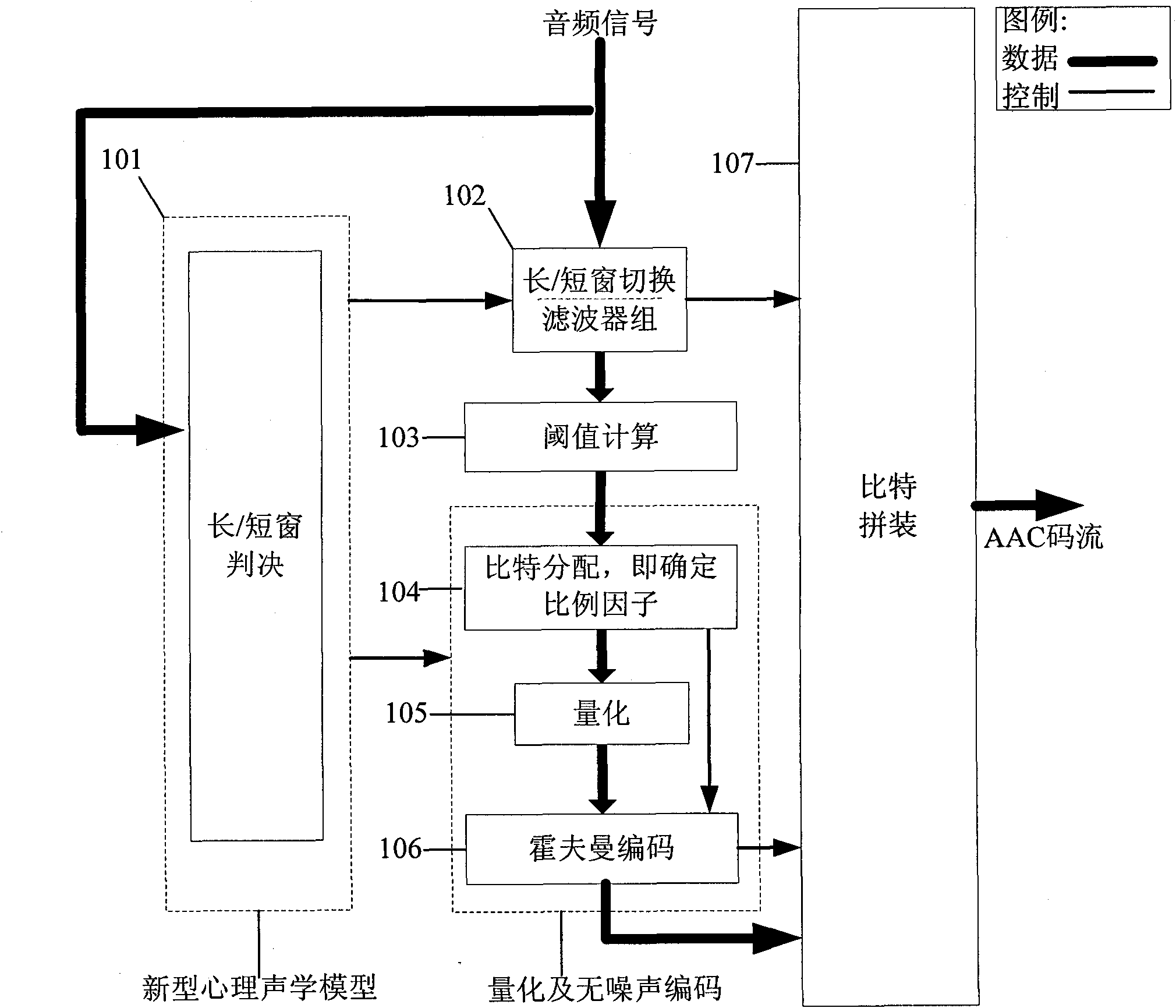

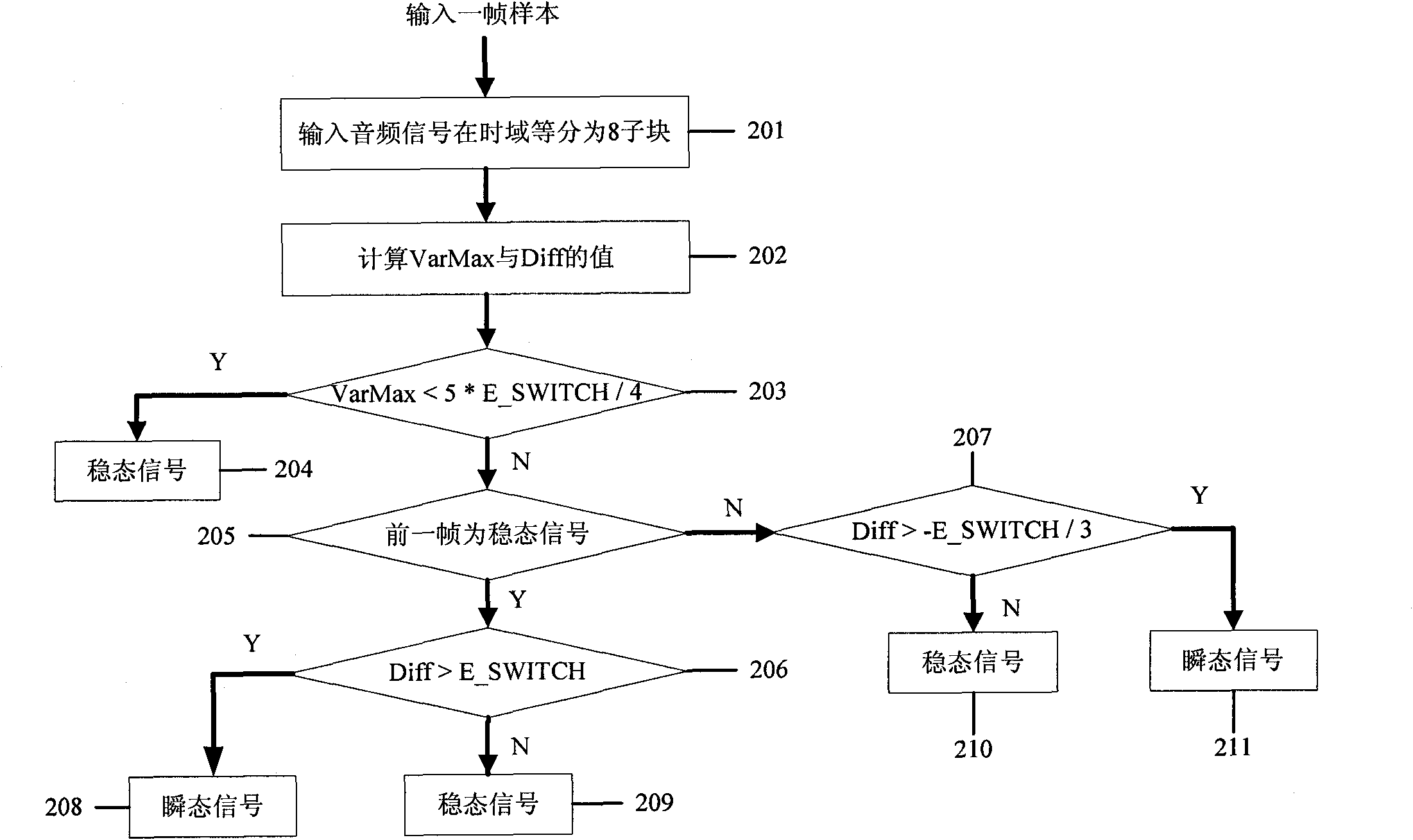

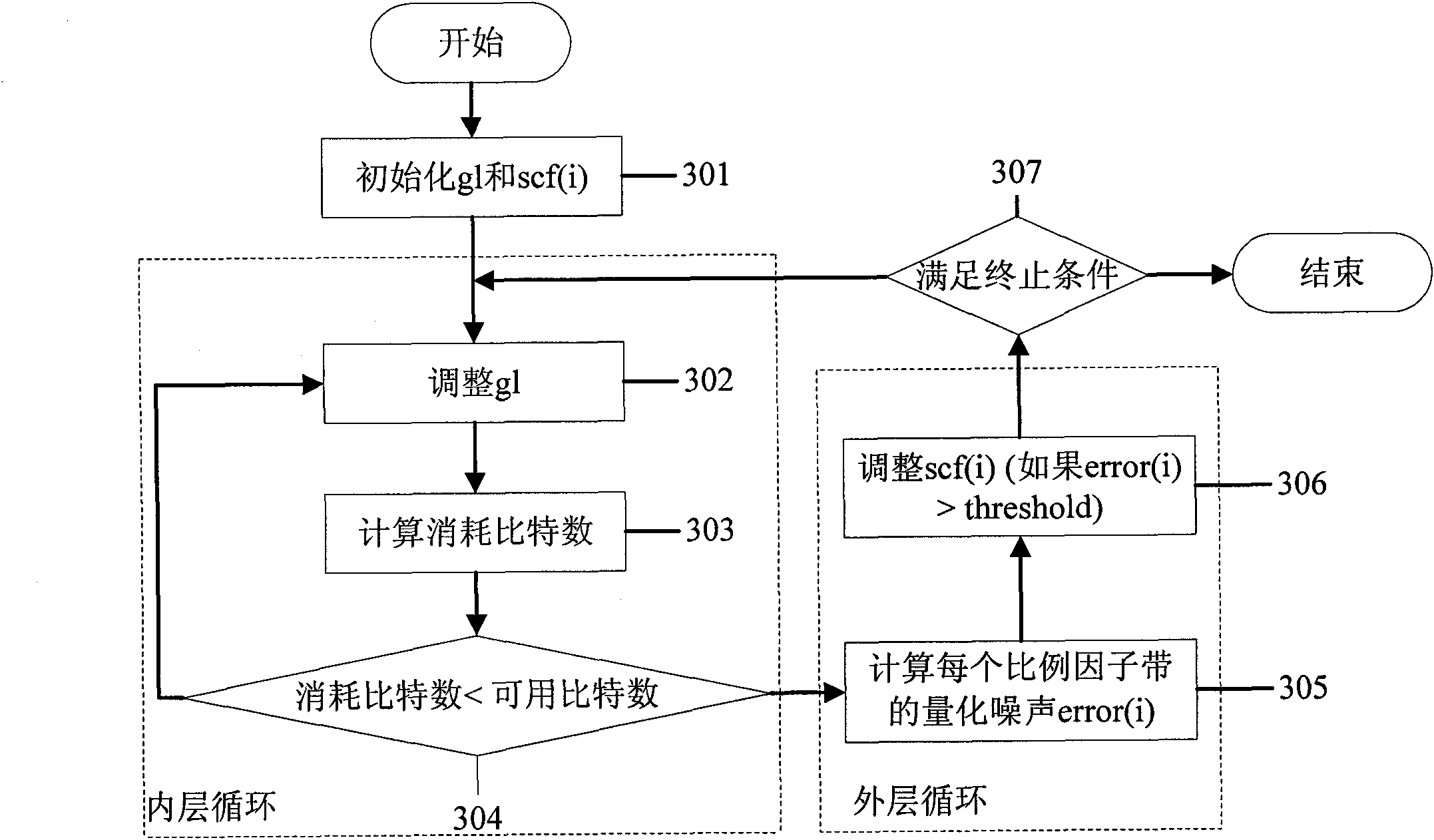

Method for realizing digital audio encoding by using new psychoacoustic model and quick bit allocation

InactiveCN101847413AOvercome the disadvantage of large amount of calculationAvoid sound qualitySpeech analysisRate distortionBit allocation

The invention provides a method for realizing digital audio encoding by using a new psychoacoustic model and quick bit allocation. The audio encoding method comprises the following steps of: by using a new psychoacoustic model, determining window types according to the variance of input audio signals; allocating quantized noise according to the determined window types and the energy of the input audio signals, namely calculating threshold values; performing quick bit allocation, giving up the conventional method of performing rate-distortion control by two layers of nested loops, taking a value of a global scale factor of the last frame as an initial value for global scale factors according to the short-time stable properties of the audio signals, and acquiring accurate an initial valve for each section of scale factor through model deduction; and finally acquiring values of a final global scale factor and each section of scale factor through fine adjustment. The method has the characteristics of low computational complexity and unconspicuous reduction of perceived tone quality.

Owner:BEIHANG UNIV

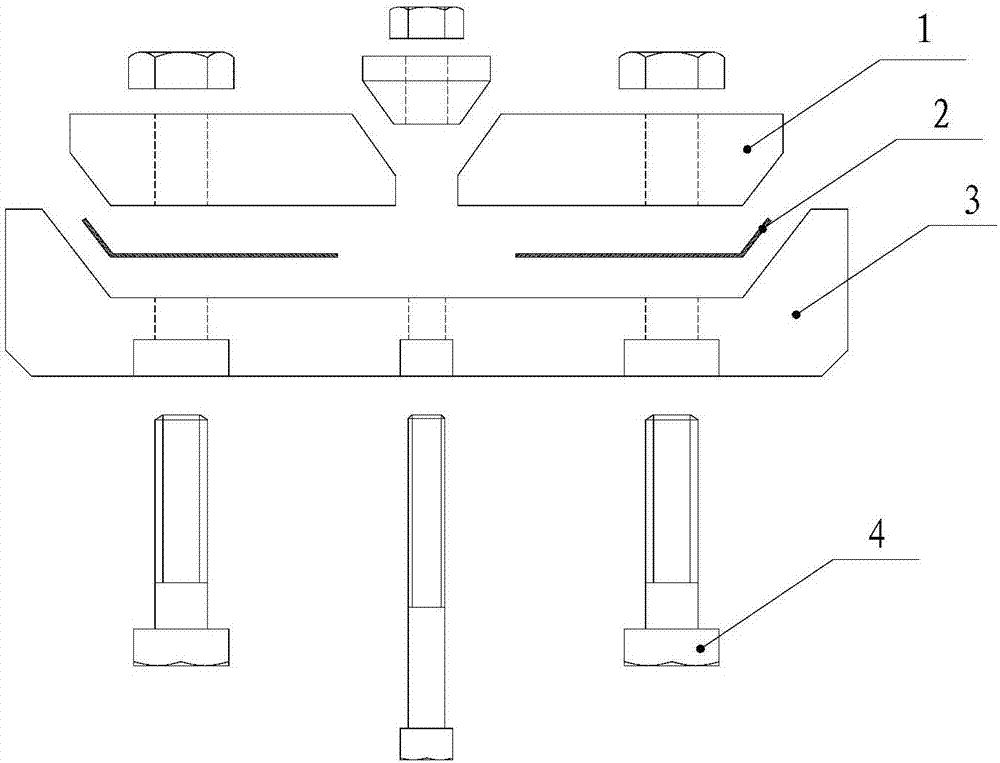

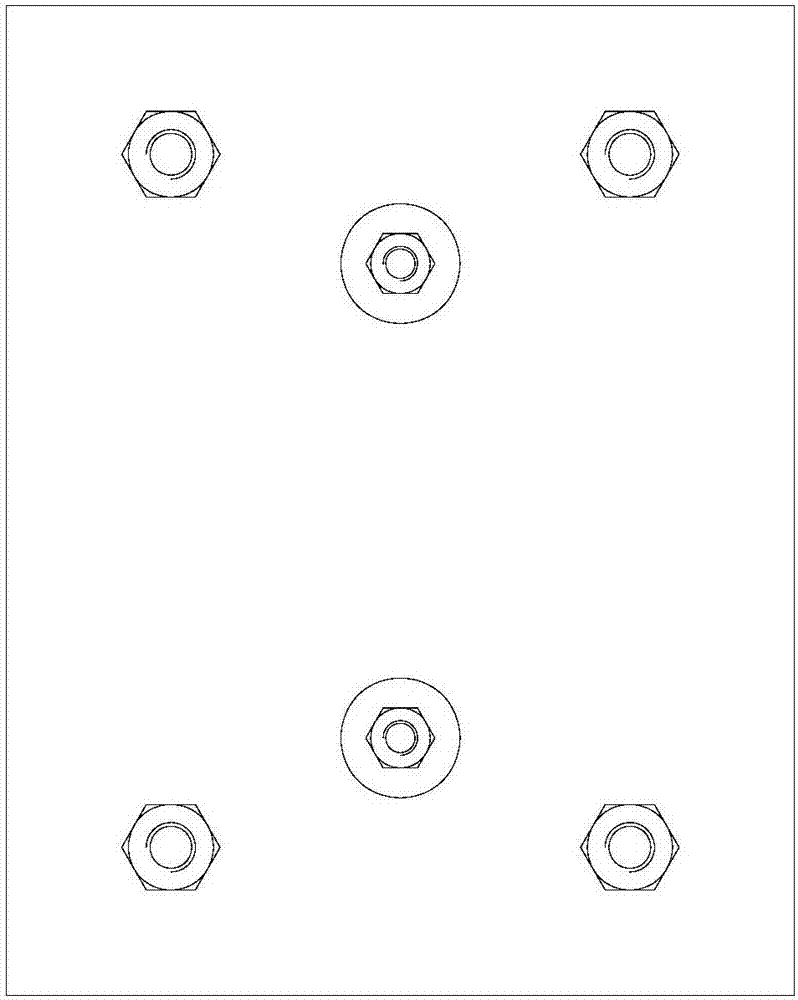

Heat treatment distortion control method for leaf spring parts

InactiveCN107058708AFit tightlyEven by forceFurnace typesHeat treatment process controlHardnessMaterials science

The invention discloses a heat treatment deformation control method for spring sheet parts, which belongs to the field of heat treatment deformation control. The method is as follows: ①Quenching the parts after cold forming; ②Put the spring piece into the shape-correcting fixture, fix it with appropriate pre-tightening bolts, and temper them together at the specified temperature; ③Tighten the bolts fully after half the tempering time, Put it into the furnace again and heat until the tempering process is over. The invention has the advantages that the method of fixture shape maintenance and heat correction can effectively correct the distortion and deformation of the spring sheet after quenching, ensure the corresponding structure and hardness requirements, and achieve the purpose of heat treatment shape control.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

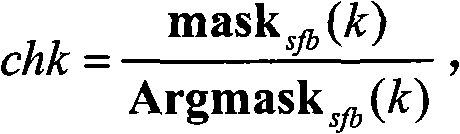

Psychoacoustics model processing method based on advanced audio decoder

ActiveCN101308659AImprove coding efficiencyImprove encoding qualitySpeech analysisRate distortionDiffusion matrix

The invention discloses a psychoacoustic model processing method based on an advanced audio encoder. The psychoacoustic model processing method includes the following steps: A, the perceptual entropy threshold value and the masking limen of a coding sub-band are obtained by the spectrum energy of the psychoacoustic of the sub-band of the bit stream to be encoded through masked diffusion matrix algorithm; B, anticipated bit consumption of the sub-band is calculated by employing time-frequency correction and anticipated echo correction through the perceptual entropy threshold value and the masking limen of the coding sub-band; C, the psychoacoustic model outputs the anticipated bit consumption of the sub-band, which then serves as a parameter for code rate distortion so as to carry out the encoding process. The psychoacoustic model processing method can obtain the bit consumption of the sub-band through the perceptual entropy more accurately and the anticipated value is taken by the encoder as the parameter for code rate distortion control, thus greatly improving quantizing encoding efficiency and quality of the encoder.

Owner:ZTE CORP

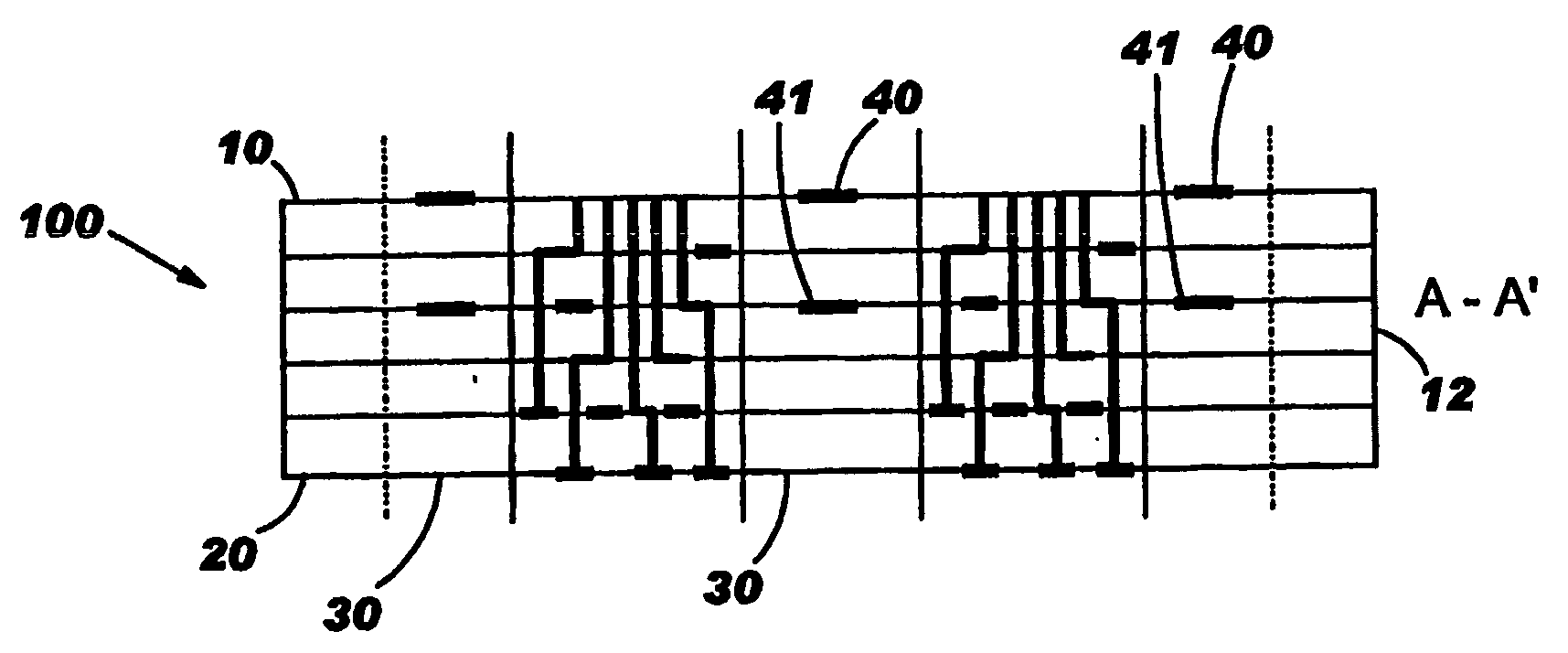

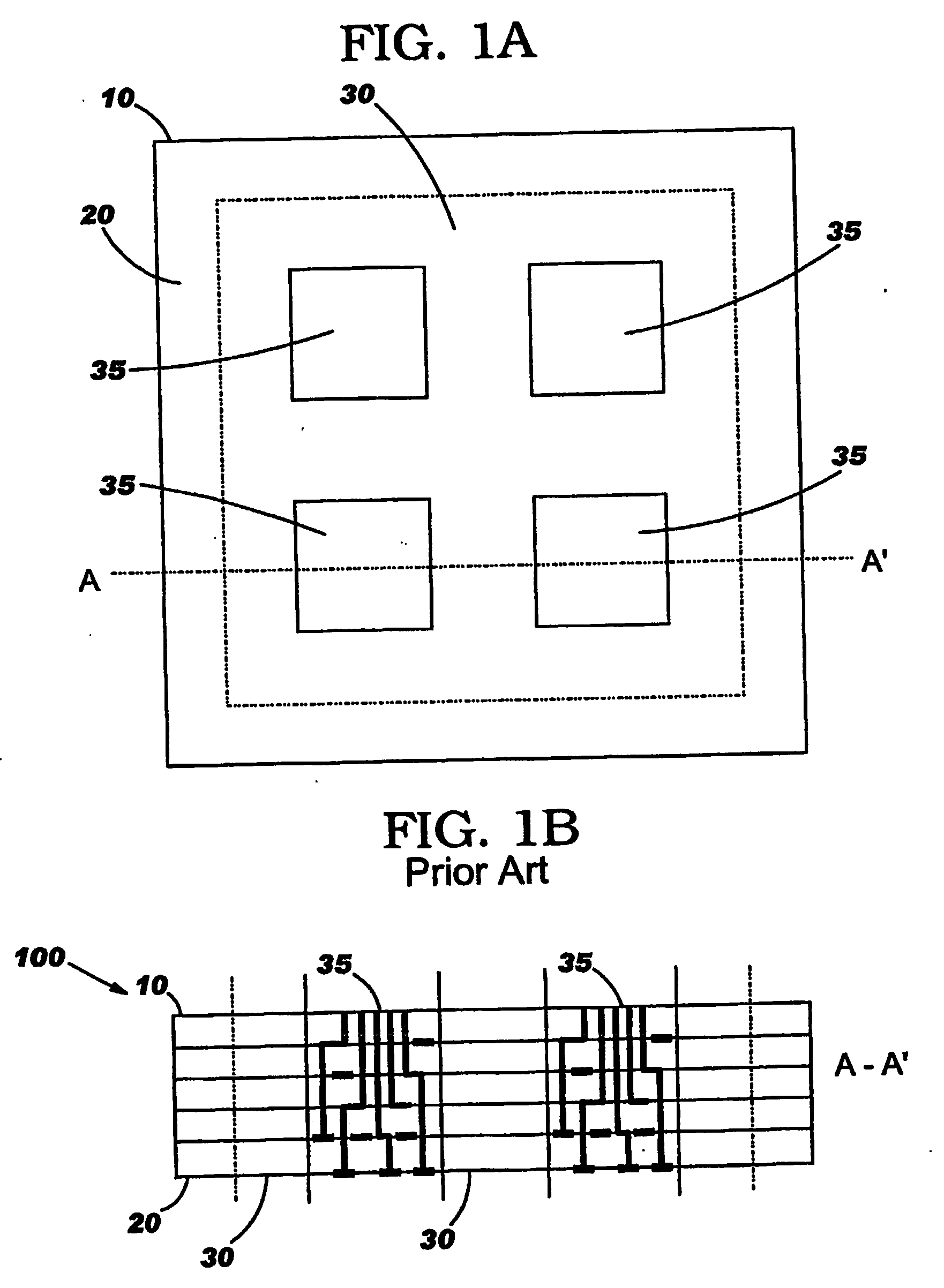

Hot pressing ceramic distortion control

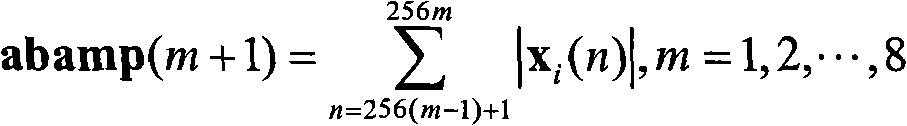

InactiveUS20070065647A1Control DimensionsLamination ancillary operationsPrinted circuit aspectsCeramic substrateMonolayer

A method to control the post sinter distortion of hot pressing sintered multilayer ceramic laminate by placing a non-densifying structure in the green ceramic laminate prior to sintering. One or more non-densifying structures are placed on one or more ceramic greensheets which are then stacked and laminated to form a green ceramic laminate. The laminate is then sintered and the non-densifying structure will control the dimensions of the hot pressed multilayer ceramic substrate. The method can be used to control post sinter dimensions in MLC substrates manufactured as either single or multi-up substrates by placing the non-densifying structure in the kerf area between the individual product ups prior to sintering.

Owner:GLOBALFOUNDRIES INC

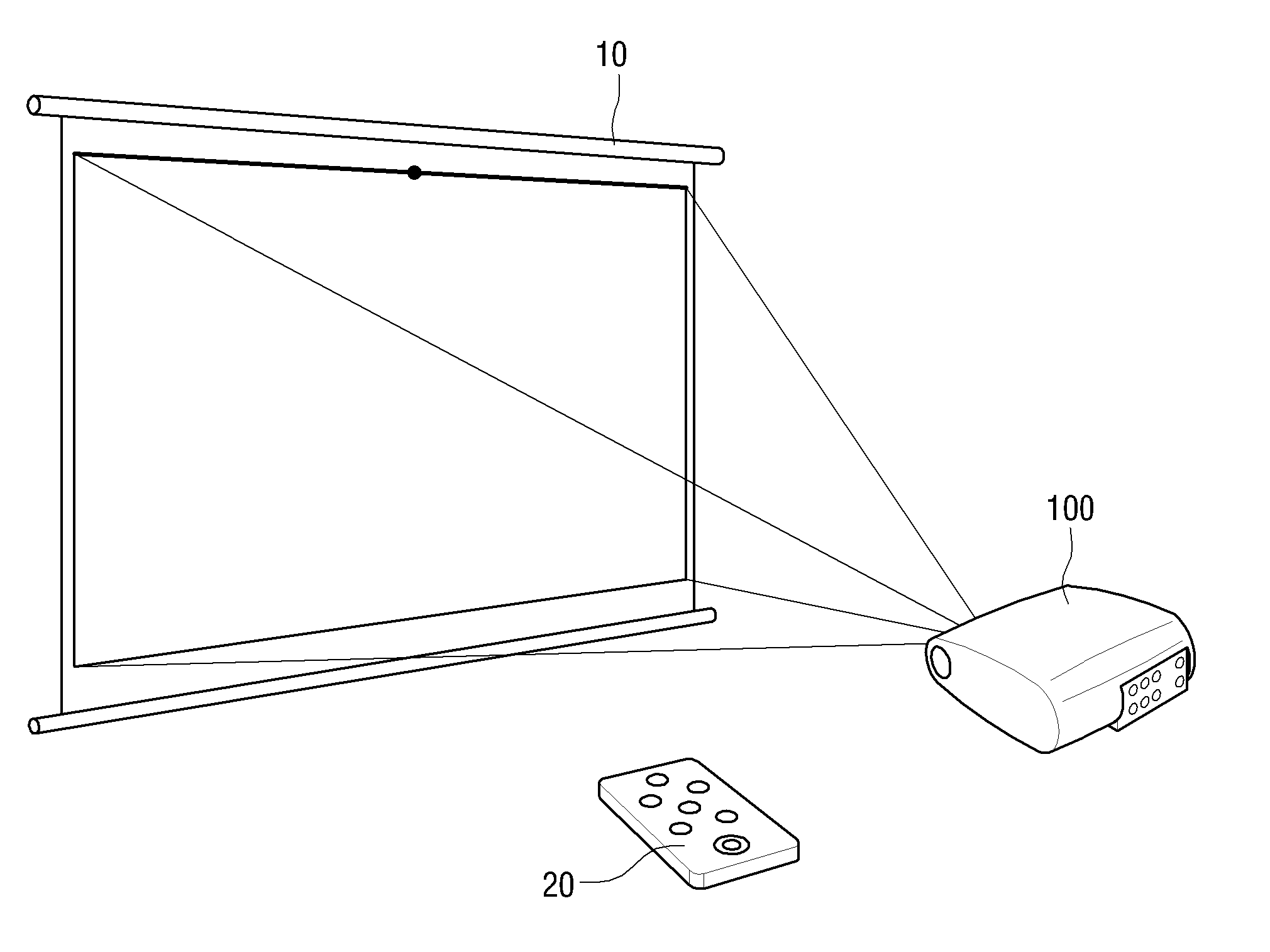

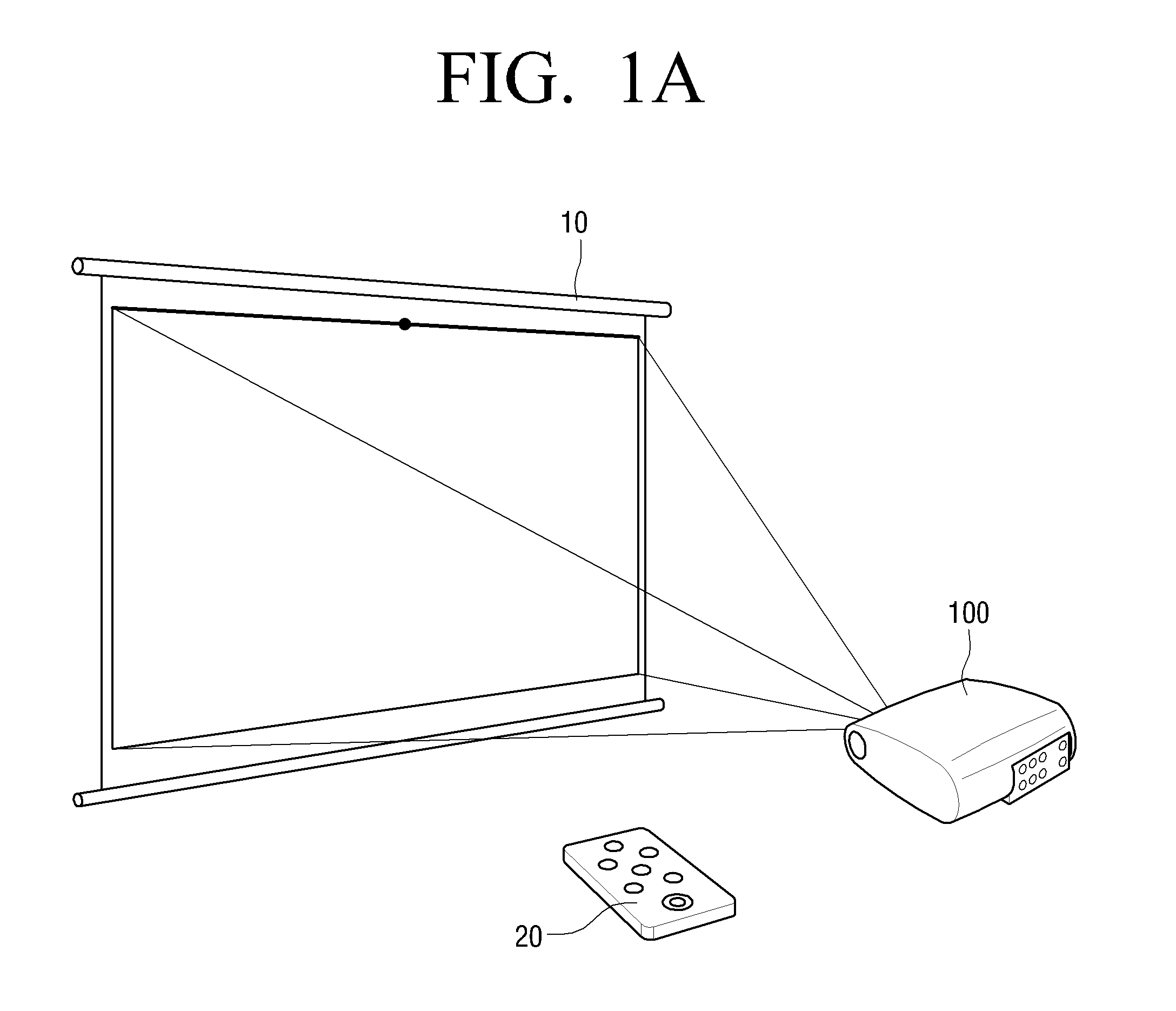

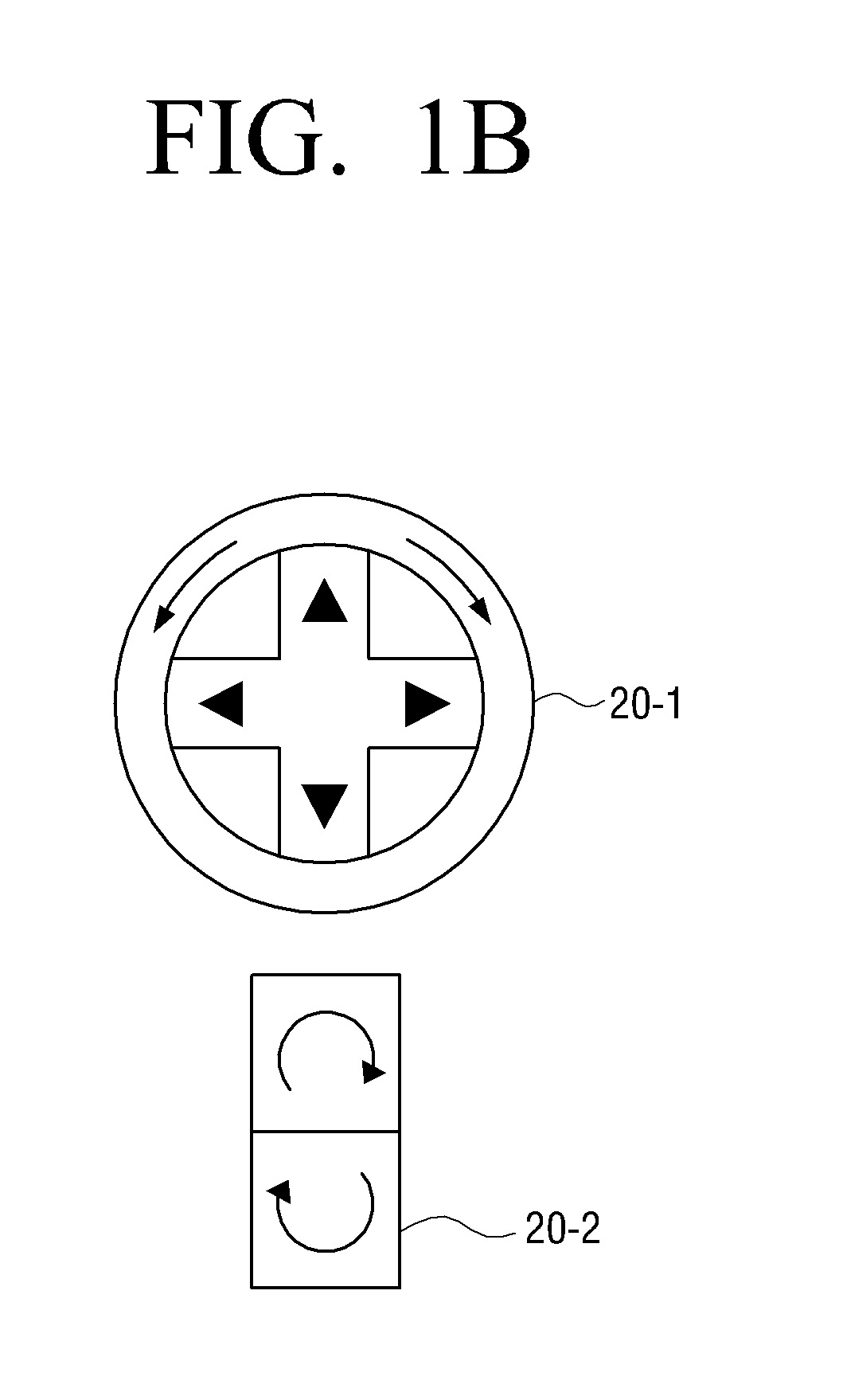

Image distortion correction apparatus and method

An image distortion correction apparatus and method are provided. The image distortion apparatus includes an image projector which projects an image on a projection screen; a user interface which receives an adjustment signal allowing a keystone correction on the projected image; a keystone correction unit which corrects a keystone distortion of the projected image by moving each side of the projected image according to the adjustment signal; and a controller which controls the image projector and the keystone correction unit to correct the image.

Owner:SAMSUNG ELECTRONICS CO LTD

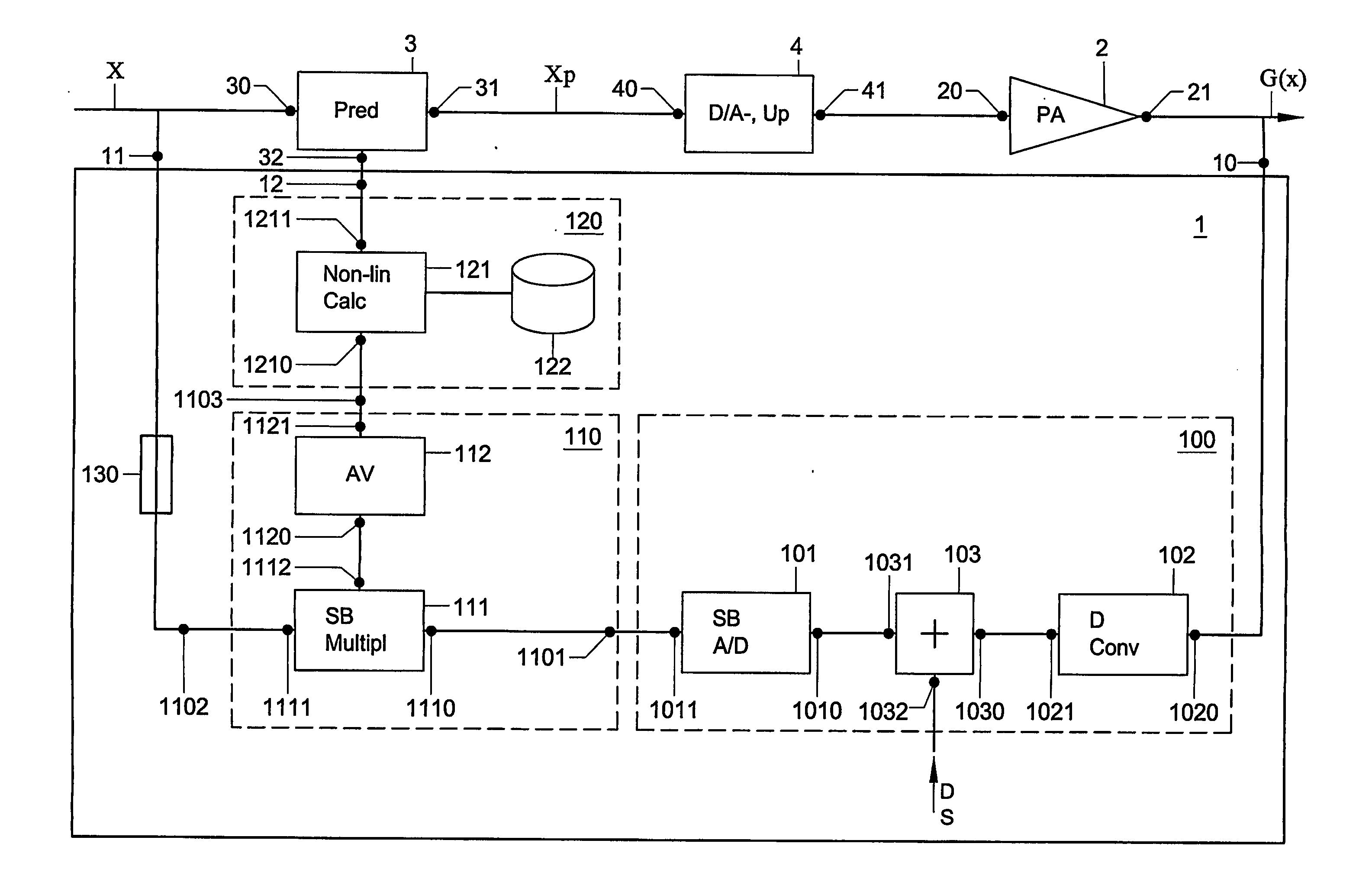

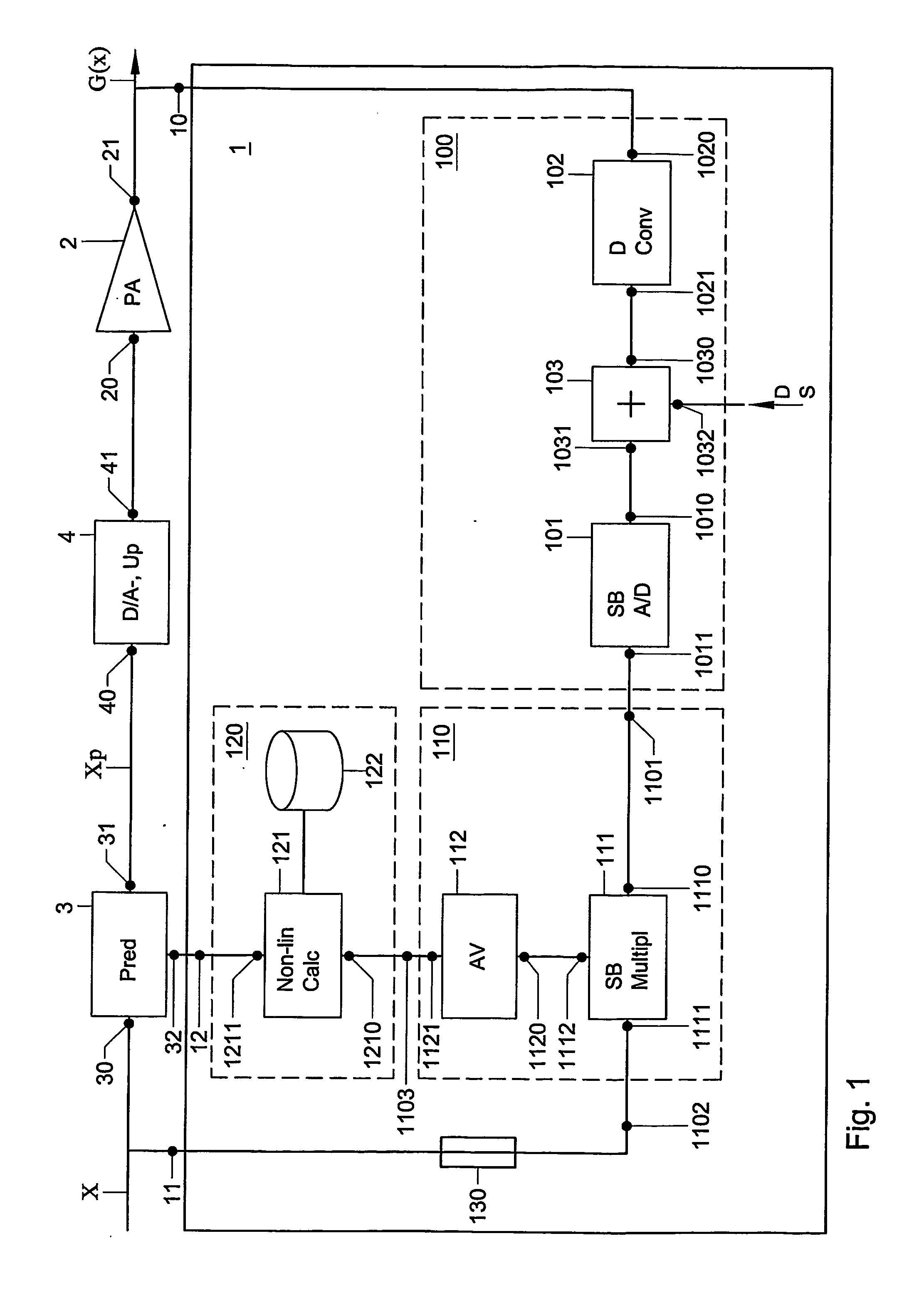

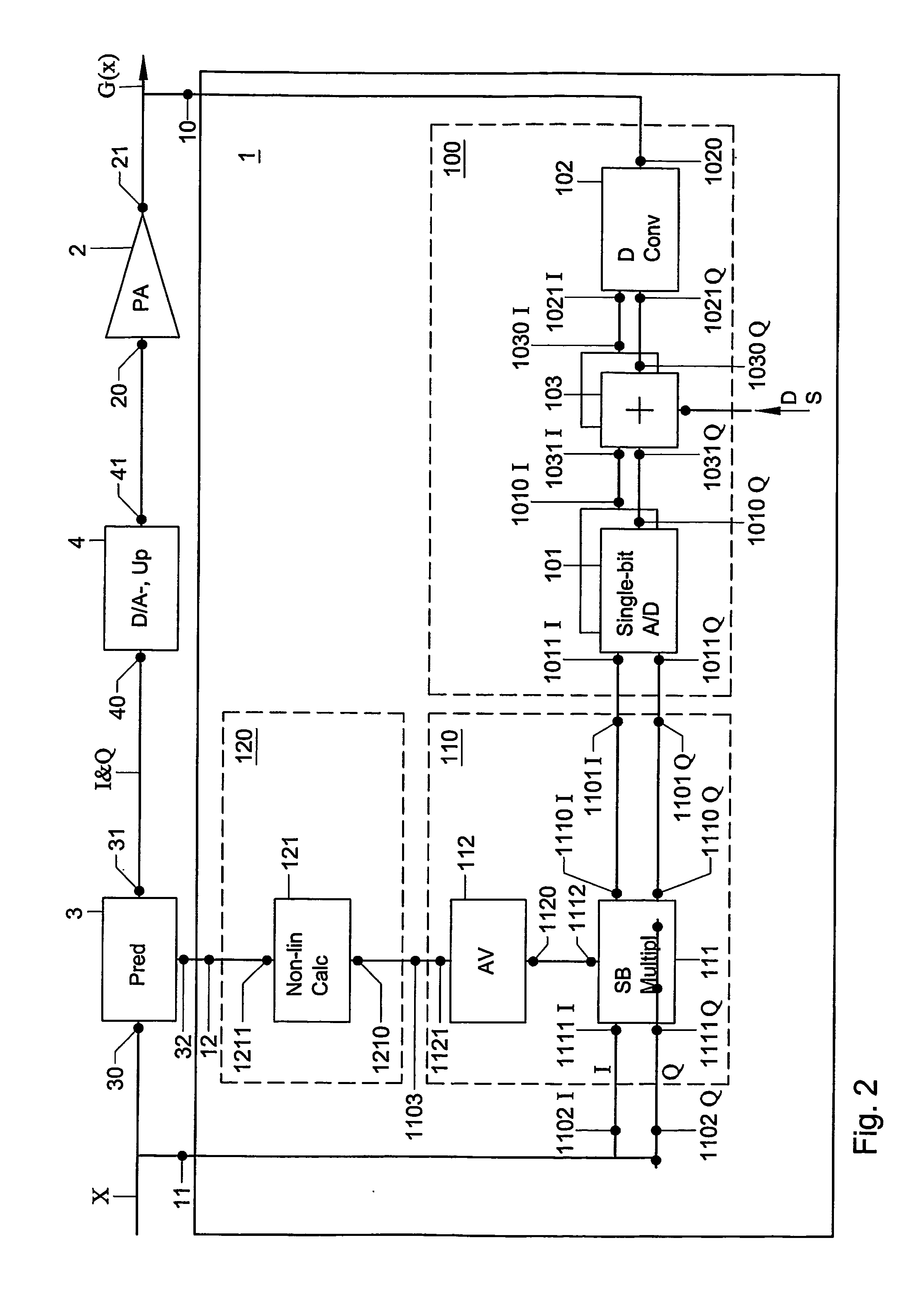

Predistortion control device and method, assembly including a predistortion control device

InactiveUS20070096811A1Less effectReduce the impact of noiseAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceAudio power amplifierControl signal

A predistortion control device (1). The device has a first predistortion control input connectable to a power amplifier output (21); a second predistortion control input (11) connectable to a signal contact of a predistortion device; and a predistortion control output (12) connectable to a control contact of the predistortion device. The predistortion control device (1) further includes a cross-correlator device (110). The cross-correlator device (110) is connected with a first cross-correlator input (1101, 1101I, 1101Q) to the first predistortion control input and a second cross-correlator input (1102, 1102I, 1102Q) to the second predistortion control input (11). The cross-correlator device (110) is further has a cross-correlator output (1112) at which a cross-correlation signal can be presented, the cross-correlation signal representing a measured cross-correlation of signals presented at the first cross-correlator input (1101, 1101I, 1101Q) and the second cross-correlator input (1102, 1102I, 1102Q). The predistortion control device (1) further has a predistortion function selector device (120) (120), connected with a selector input to the cross-correlator output (1112), and with a selector output to the predistortion control output (12), at which selector output a predistortion control signal can be presented. The predistortion control signal representing a predistortion function determined on the basis of said cross-correlator signal.

Owner:UNWIRED PLANET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com