Anti-carbonation quenching distortion control method of large-size dual-herringbone gear

A control method, carburizing and quenching technology, applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve problems such as carburizing and quenching distortion of large-sized double herringbone gears, achieve improved contact fatigue strength and bending fatigue, and reduce manufacturing costs , the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

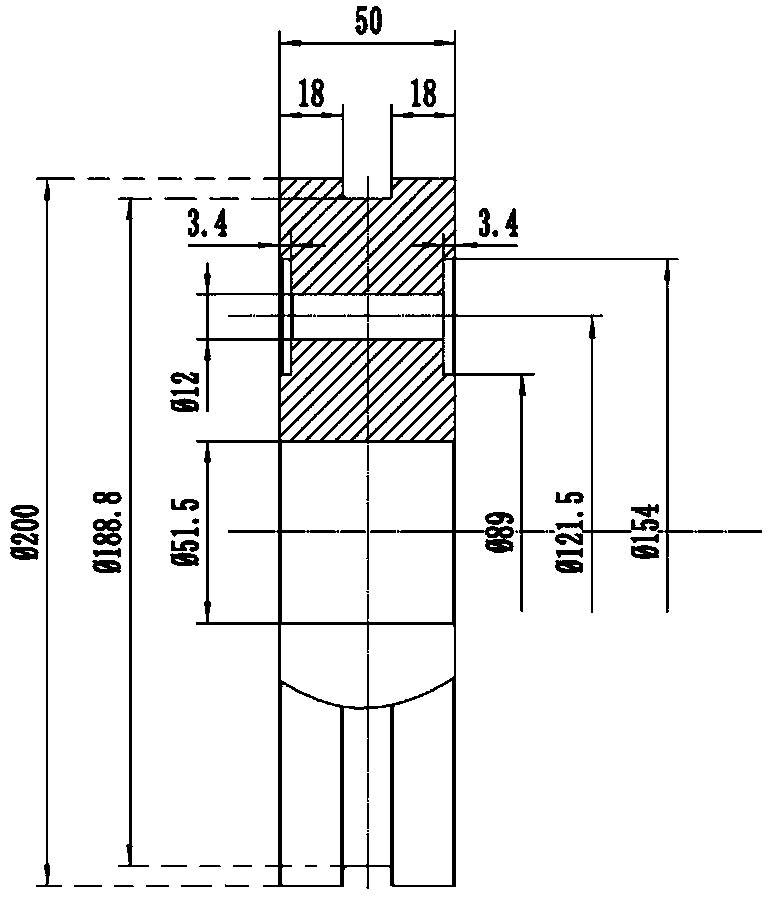

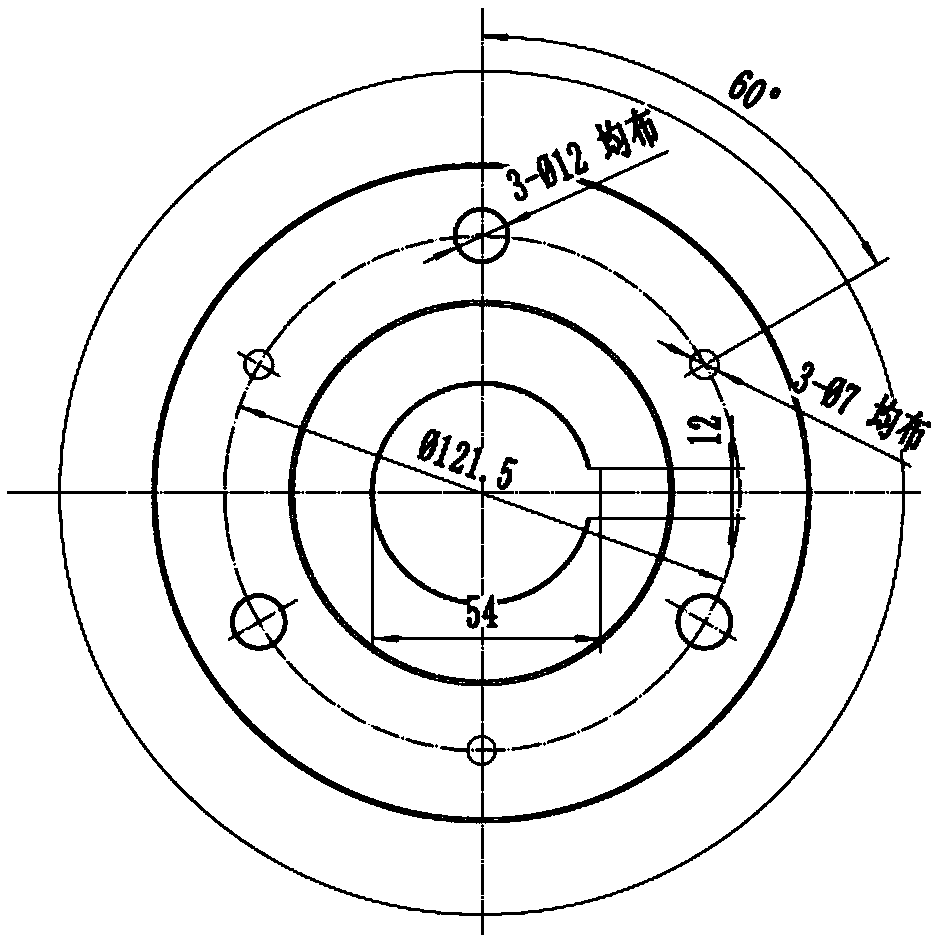

[0030] The simulated gear material is 12Cr2Ni4 (the chemical composition meets the GB / T3077-1999 standard), and the size of the simulated gear can be found in figure 1 and figure 2 , using it to test the method of anti-carburizing and quenching distortion control of double herringbone gears, including the following steps:

[0031] (1) Preliminary heat treatment: normalizing at 950°C, holding for 5 hours, air cooling; quenching at 860°C, holding for 5 hours, oil cooling, tempering at 650°C, holding for 7.5 hours, air cooling, and conducting metallographic structure inspection, the grain size controlled at level 6.

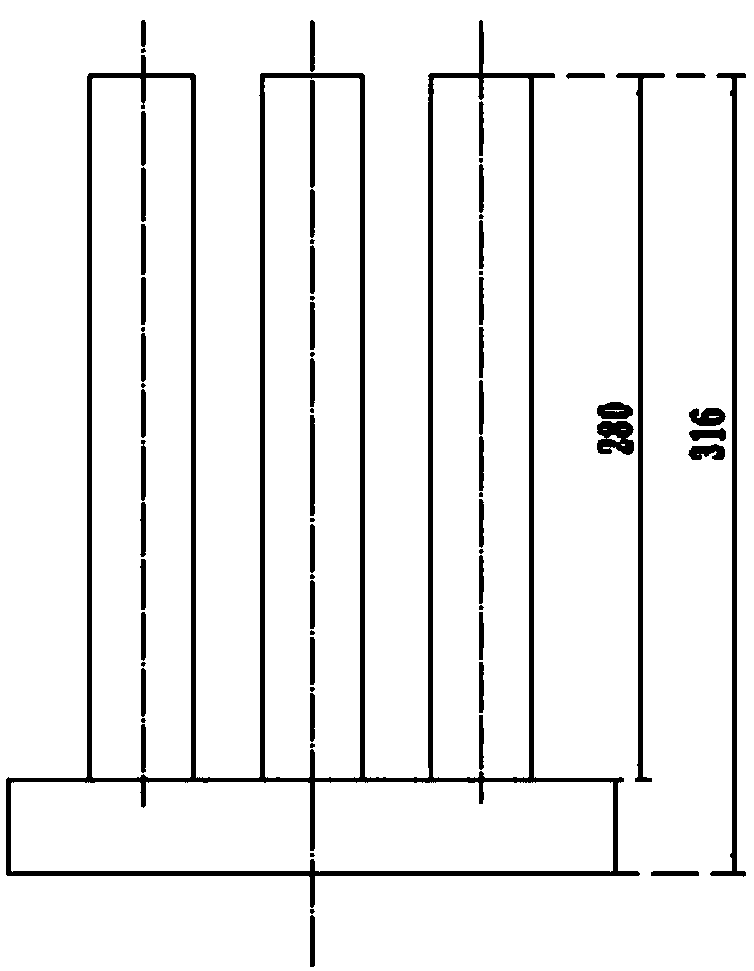

[0032] (2) Carburizing and quenching furnace: see image 3 and Figure 4, using three-point support tooling, the ratio of the upper surface area of the three-point support tooling to the upper surface area of the original support tooling is 0.2, so that the contact area between the three-point support tooling and the gear is less than 40% of the contact area...

Embodiment 2

[0043] The simulated gear material is 12Cr2Ni4 (the chemical composition meets the GB / T3077-1999 standard), and the size of the simulated gear can be found in figure 1 and figure 2 , using it to test the method of anti-carburizing and quenching distortion control of double herringbone gears, including the following steps:

[0044] (1) Preliminary heat treatment: normalizing at 950°C, holding for 5 hours, air cooling; quenching at 860°C, holding for 5 hours, oil cooling, tempering at 650°C, holding for 7.5 hours, air cooling, and conducting metallographic structure inspection, the grain size controlled at level 6.

[0045] (2) Carburizing and quenching furnace: see image 3 and Figure 4 , using three-point support tooling, the ratio of the upper surface area of the three-point support tooling to the upper surface area of the original support tooling is 0.35, so that the contact area between the three-point support tooling and the gear is less than 40% of the original t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com