Segment deformation control and flood-proof device and operation method for tunnel opening construction

A deformation control and segment technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as deformation of tunnels with open construction segments, and achieve the effect of ensuring integrity and avoiding additional deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

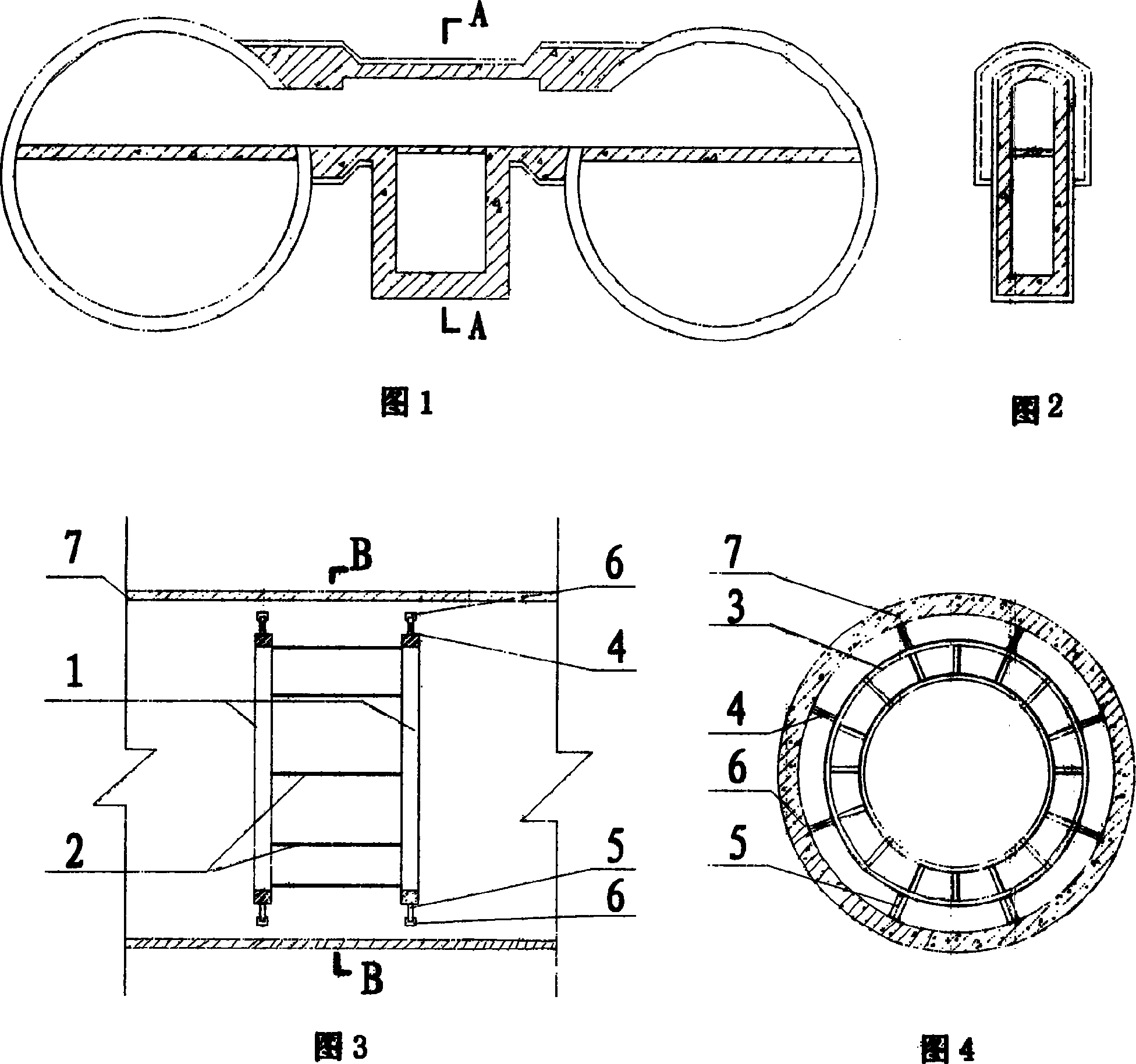

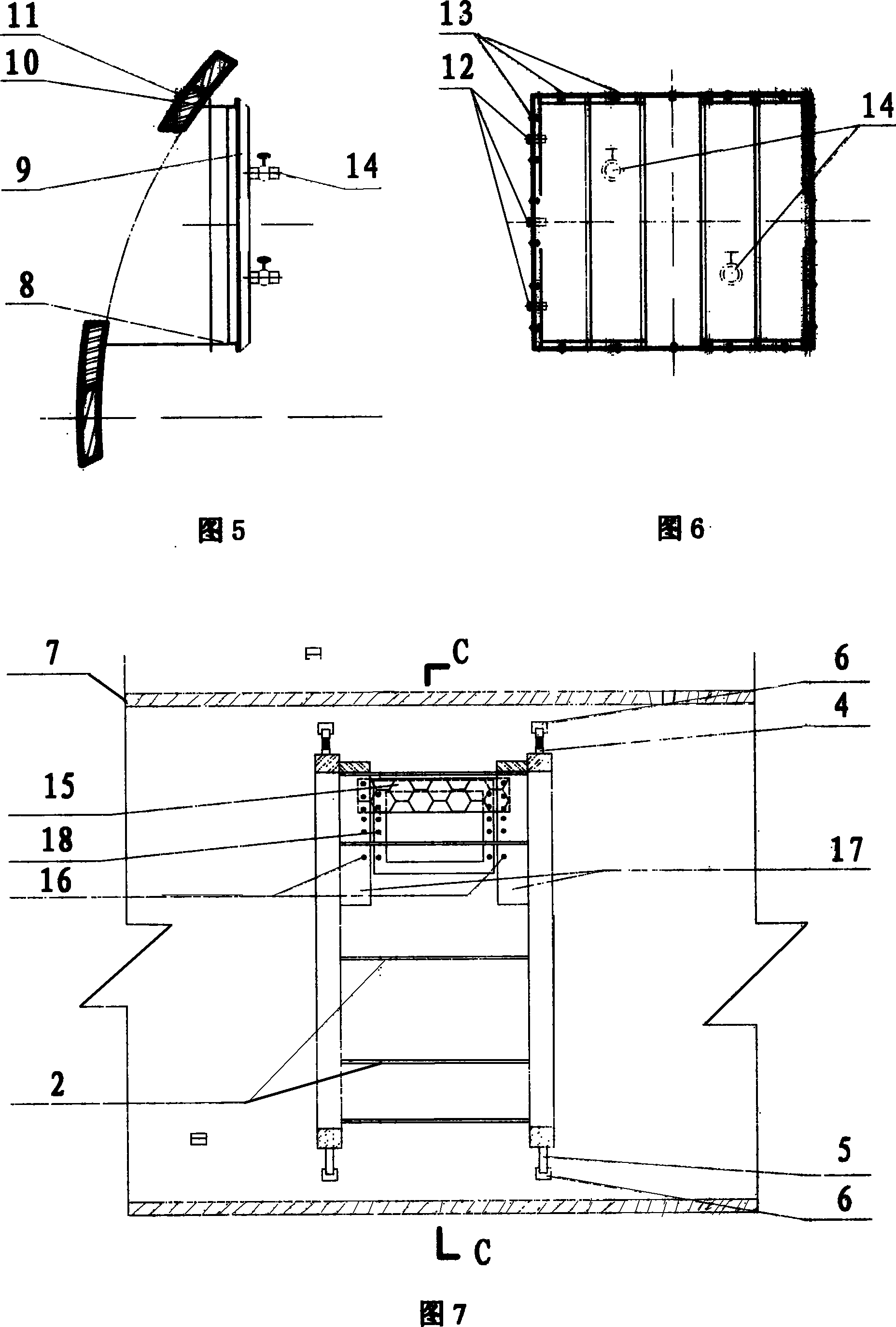

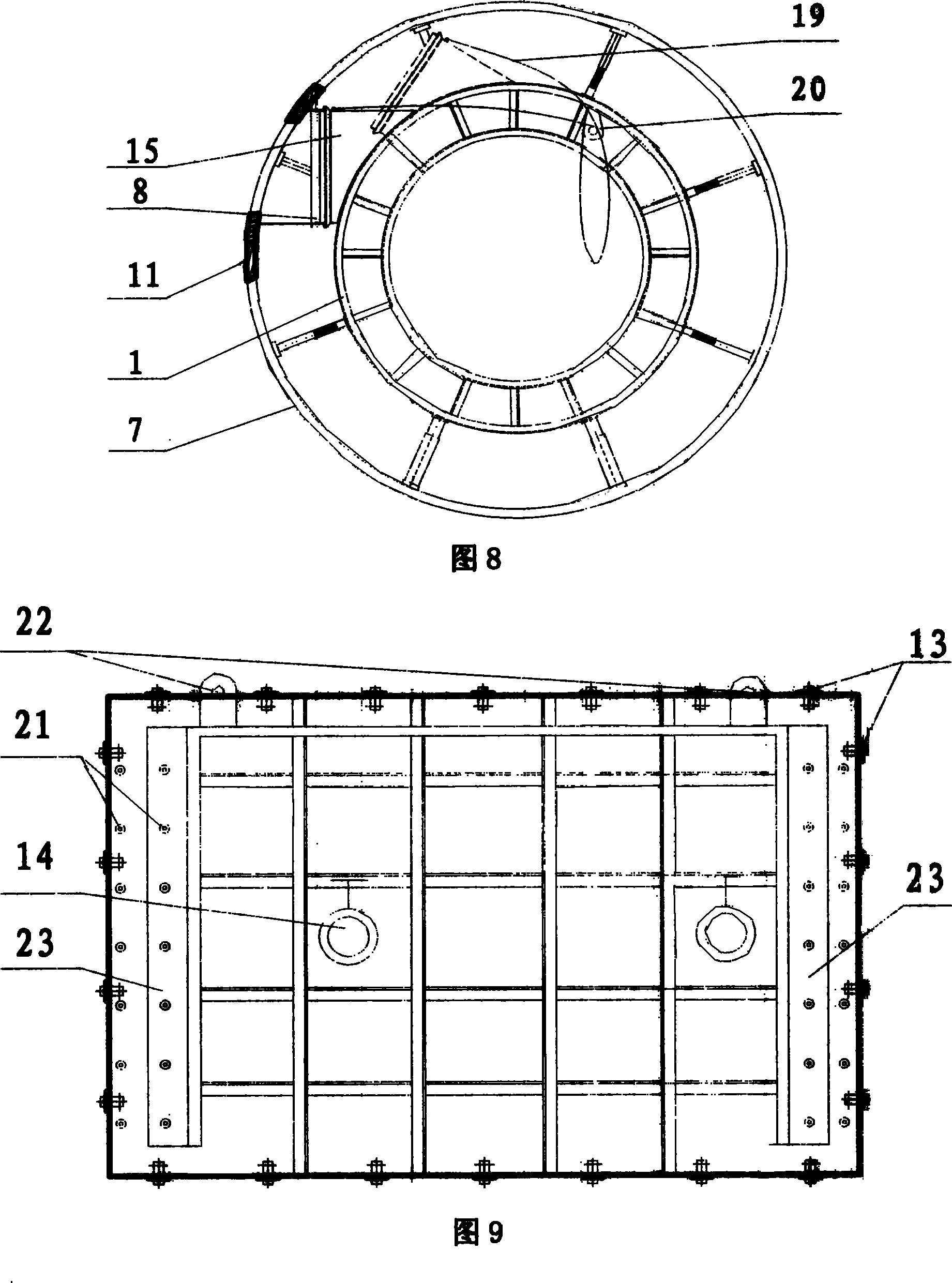

[0030] A new type of shield tunnel opening construction segment deformation control and anti-flooding device, including prestressed support, door frame 8, sliding cover plate 15, traction device 19, 20, closing of tunnel anti-flooding door, door frame 8 and its connection The stability of the steel pipe sheet 11 is realized by the prestressed support 1 of the pipe deformation control system.

[0031] The anti-flooding door is made up of door frame 8, sliding type cover plate 15. The door frame 8 is connected to the steel pipe sheet 11 at the opening by means of welding, rivets, etc., and each edge has a row of a certain number of connection holes for riveting and fixing with the sliding cover plate 15; the sliding cover plate 15 is curved on one side and flat on the other. Dustpan-shaped, upside down on the arc-shaped steel guide rails 17 of the left and right prestressed brackets 1, and can be controlled by traction devices 19, 20 to move up and down along the arc-shaped stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com