Patents

Literature

34results about How to "Guaranteed hardness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot-press-free antibacterial and anti-scraping optical explosion-proof film

InactiveCN109096940AEnhanced interfacial interaction forceGood dispersionFilm/foil adhesivesPolyureas/polyurethane adhesivesOptical transparencyTransmittance

The invention relates to hot-press-free antibacterial and anti-scraping optical explosion-proof film. Konjac glucomannan nanocrystalline is added into a protection layer and modified through chitosan,the interfacial interaction force among molecules in a formula system is greatly increased, the dispersing performance and the compatibility among components are improved, and thus the mechanical performance of the structure of the protection layer is improved; by adding inorganic and organic compound synergistic antibacterial agents, the antibacterial effect of the protection layer is greatly improved, and cross propagation of bacteria after surface contact of the human body is avoided; the antibacterial and anti-scraping optical explosion-proof film is subjected to hot-press-free curing molding, and the processing procedure and the processing cost are reduced; TPU is good in processability and flexibility and resistant to shock, an optical-grade PET base material is good in optical transparency, the requirement of the explosion-proof film for the optical performance is met, and the light transmittance of the explosion-proof film is increased. The explosion-proof film has good lighttransmittance, static resistance, wear resistance, scraping resistance and bacterial resistance; through the arrangement of the explosion-proof structure layer, the safety and stability during use areguaranteed, and meanwhile the requirement for optical-grade appearance is met.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

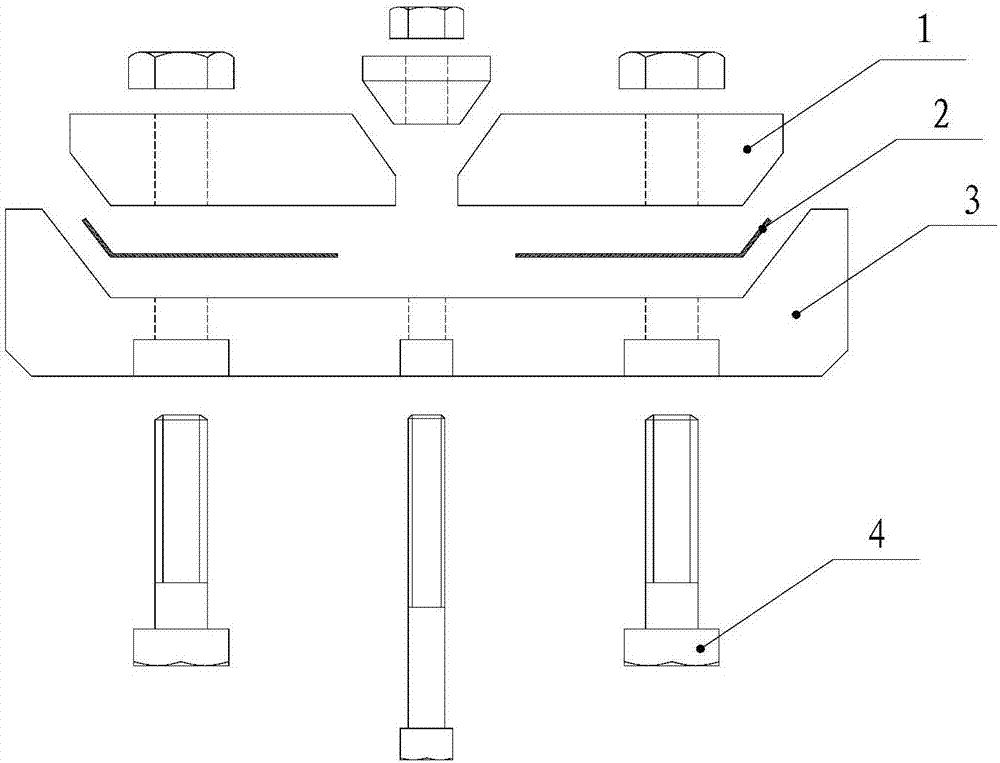

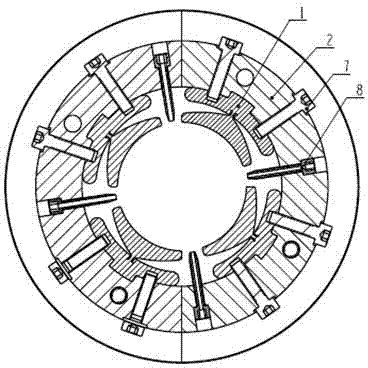

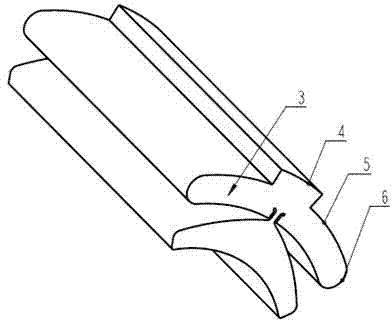

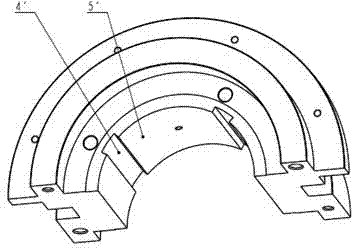

Heat treatment distortion control method for leaf spring parts

InactiveCN107058708AFit tightlyEven by forceFurnace typesHeat treatment process controlHardnessMaterials science

The invention discloses a heat treatment deformation control method for spring sheet parts, which belongs to the field of heat treatment deformation control. The method is as follows: ①Quenching the parts after cold forming; ②Put the spring piece into the shape-correcting fixture, fix it with appropriate pre-tightening bolts, and temper them together at the specified temperature; ③Tighten the bolts fully after half the tempering time, Put it into the furnace again and heat until the tempering process is over. The invention has the advantages that the method of fixture shape maintenance and heat correction can effectively correct the distortion and deformation of the spring sheet after quenching, ensure the corresponding structure and hardness requirements, and achieve the purpose of heat treatment shape control.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

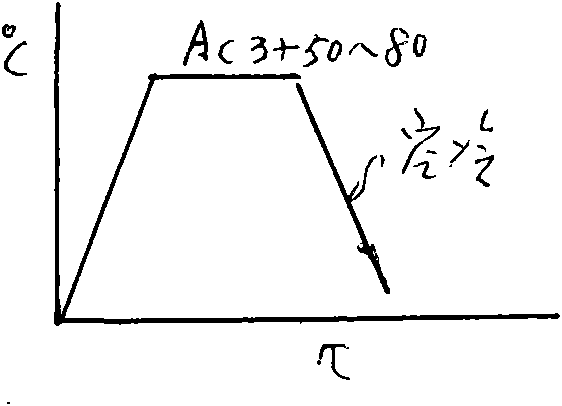

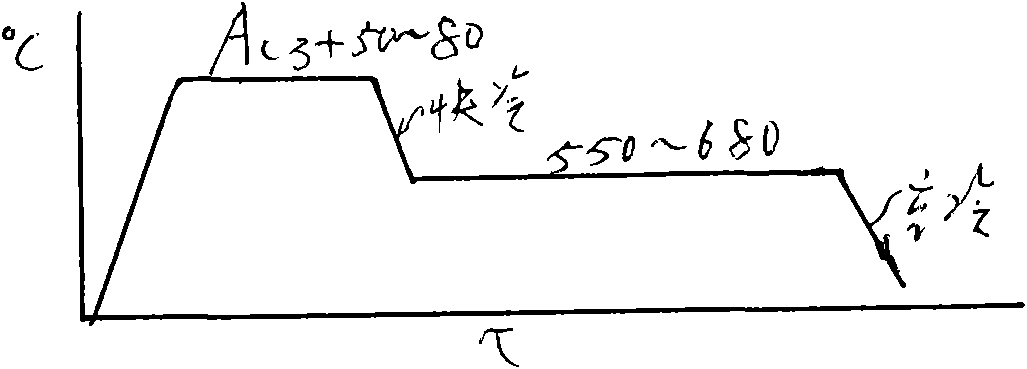

Gear blank isothermal annealing process and isothermal annealing production line

InactiveCN101886163AEnsure consistencyReduce heat lossFurnace typesIncreasing energy efficiencyProduction lineHardness

The invention relates to a heating treatment process for scale production of gear blanks and a corresponding heating treatment production line. The invention eliminates the integral recrystallization heating of the gear blanks, and gears can stably obtain a metallographic structure with excellent cutting performance and an expected hardness value no matter using a forging waste heat isothermal annealing process or an isothermal annealing process conducted after the blank is cooled of the invention.

Owner:天津市天瑞硬化工程有限公司

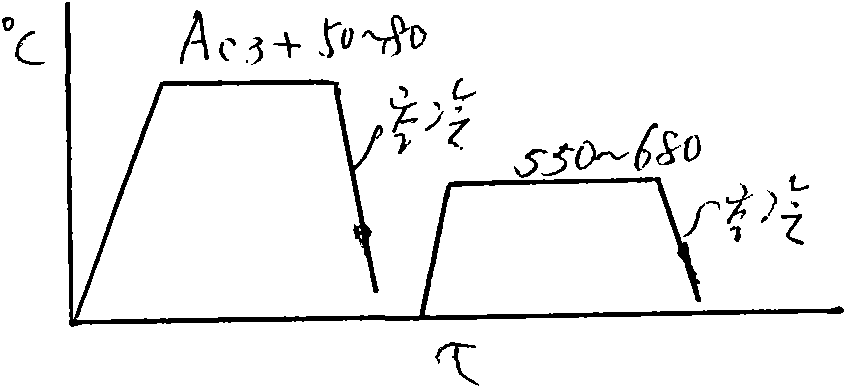

Cold roll bulk heat treatment process

InactiveCN108103302AImprove plasticityGood welding performanceFurnace typesIncreasing energy efficiencyCold treatmentMedium frequency

The invention discloses a cold roll bulk heat treatment process. A roll is subjected to normalizing, annealing, quenching and tempering, medium-frequency hardening and cold treatment, the hardness, toughness and impact resistance of a final structure meet the operation requirements, and the service life of the roll is greatly prolonged. A batch-type furnace and a well type electric furnace are used for heating, an overall rapid heating and hardening method is adopted, and the hardening quality of 60CrMnMo steel cold roll can still be ensured.

Owner:CHANGZHOU ECCO ROLLER

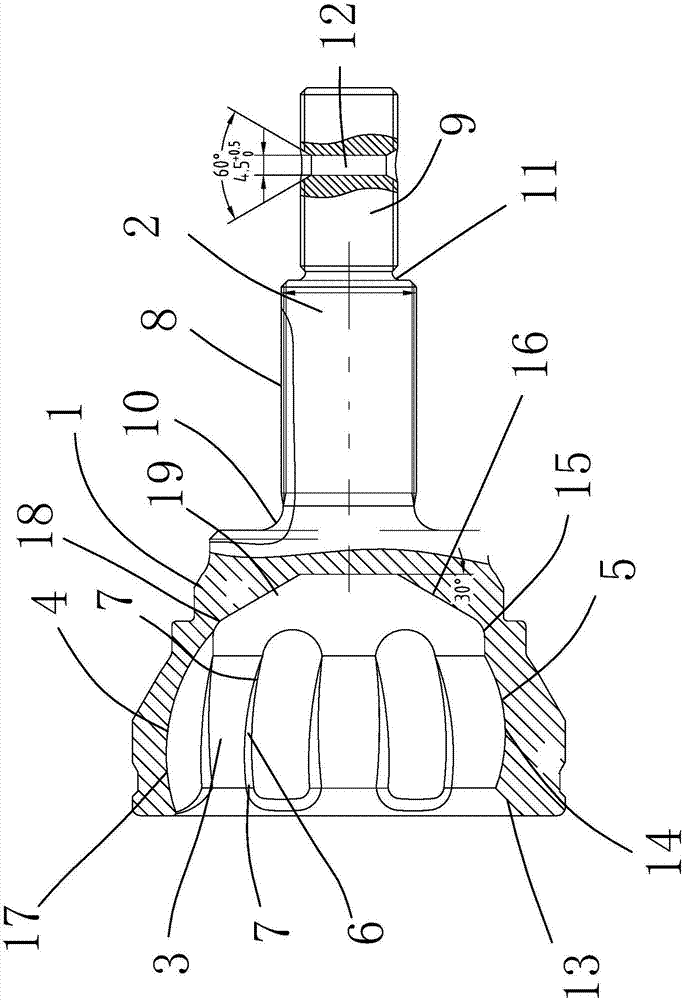

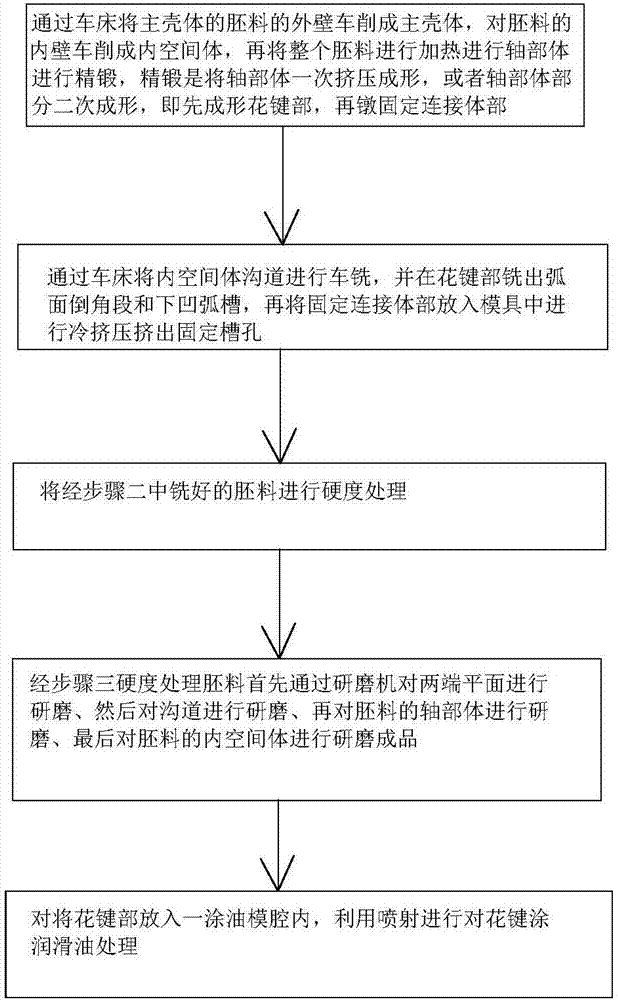

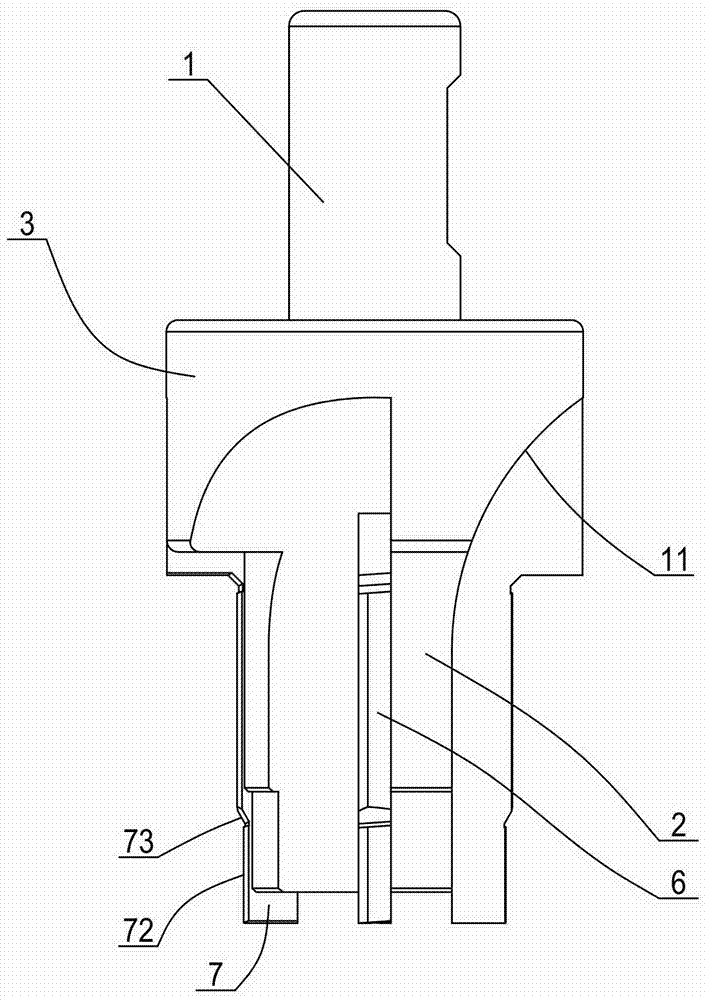

Driving shaft bell-shaped housing structure and process treatment method thereof

PendingCN107120357AImprove carrying capacityPrevent temper brittlenessYielding couplingFurnace typesStructural engineeringIndustrial engineering

The invention belongs to the technical field of automobile driving accessories, and provides a driving shaft bell-shaped housing structure and a process treatment method of the driving shaft bell-shaped housing structure. The driving shaft bell-shaped housing structure comprises a main housing and a shaft body; each channel chamfer angle is reduced from the left end to the right end; the shaft body comprises a spline part and a fixed connection body part; a cambered chamfer section is arranged between the left end of the spline part and the main housing; and a lower concave arc groove is formed between the right end of the spline part and the fixed connection body part. The process treatment method is characterized in that the inner wall of a blank is lathed into an inner space body, then the whole blank is heated and precision forging of the shaft body is carried out, precision forging means the shaft body is subjected to extrusion forming at one time or is partly subjected to secondary forming, that is the spline part is formed first, and the milled blank is subjected rigidity treatment and a spline is subjected to lubricating oil treatment. The driving shaft bell-shaped housing structure has the advantages that due to the channel chamfer angles, steel balls can be kept in the centers to the greatest extent when the steel balls rotate, the carrying capacity is improved, a situation that ballistic work is lowered due to temper brittleness is avoided, and the integral torque performance is high, thus the rigidity requirement is met.

Owner:NINGBO V SHINE AUTO PARTS

Rotating handle table tennis bat

InactiveCN106964124AConvenient handle angle needsImprove adaptabilityRacket sportsLower faceRacketball

The invention belongs to the technical field of sports equipment, and particularly relates to a rotating handle table tennis bat. An elongated slot is formed in the bottom end of a base plate. A connecting column is arranged inside the elongated slot. A connecting portion is arranged at the top end of a handle. A hinged hole is formed inside the connecting portion. The connecting column is located inside the hinged hole. The connecting portion is located inside the elongated slot. A first through groove is formed in one side of the elongated slot, a second through groove is formed in the other side of the elongated slot, one end of the connecting column is located inside the first through groove, the other end of the connecting column is located inside the second through groove, a first limiting plate is arranged at one end of the connecting column, a second limiting plate is arranged at the other end of the connecting column, the first limiting plate and the second limiting plate are located on the two sides of the base plate respectively, an upper sponge layer is arranged on the upper face of the base plate, an upper rubber layer is arranged on the upper face of the upper sponge layer, an upper antiskid layer is arranged on the upper surface of the upper rubber layer, a lower sponge layer is arranged on the lower face of the base plate, a lower rubber layer is arranged on the lower face of the lower sponge layer, and a lower antiskid layer is arranged on the lower bottom face of the lower rubber layer.

Owner:佶迩体育用品贸易(天津)有限责任公司

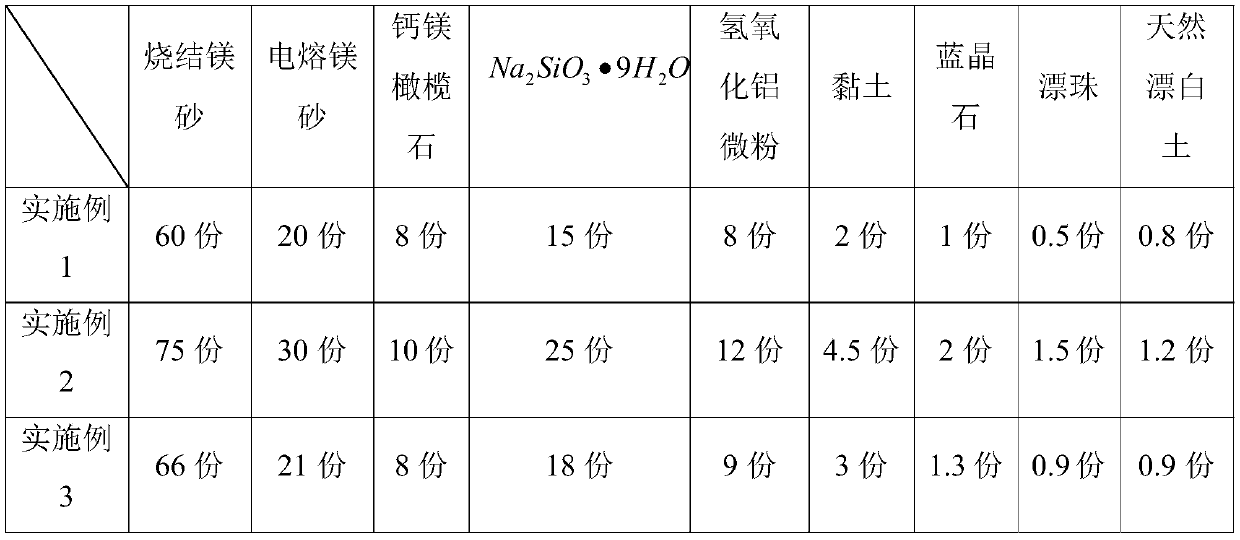

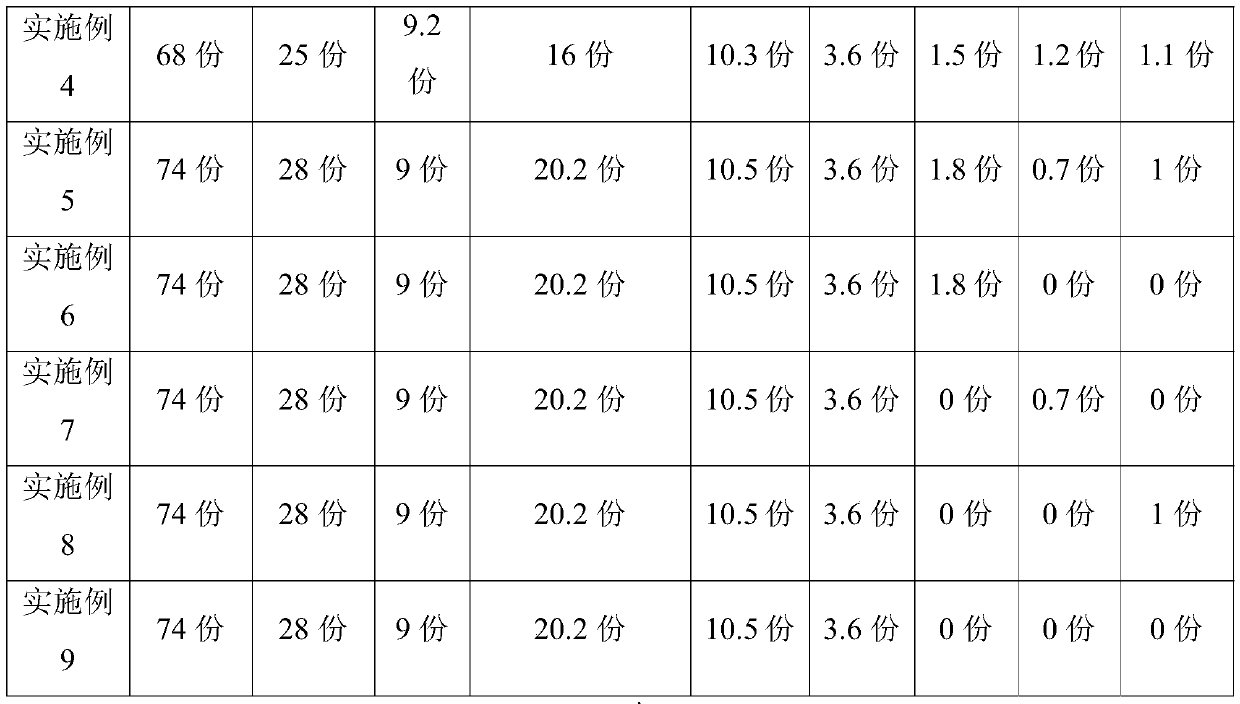

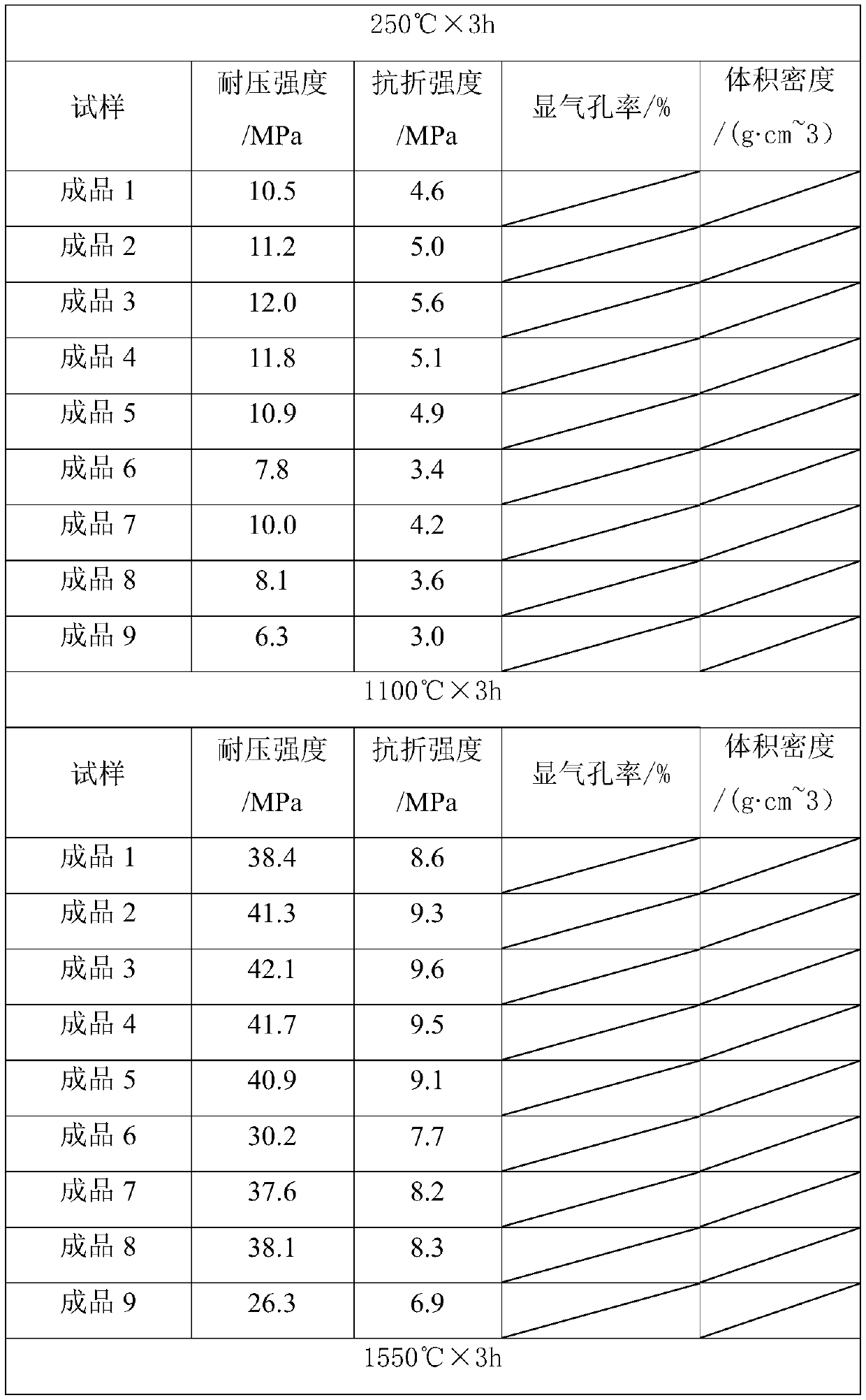

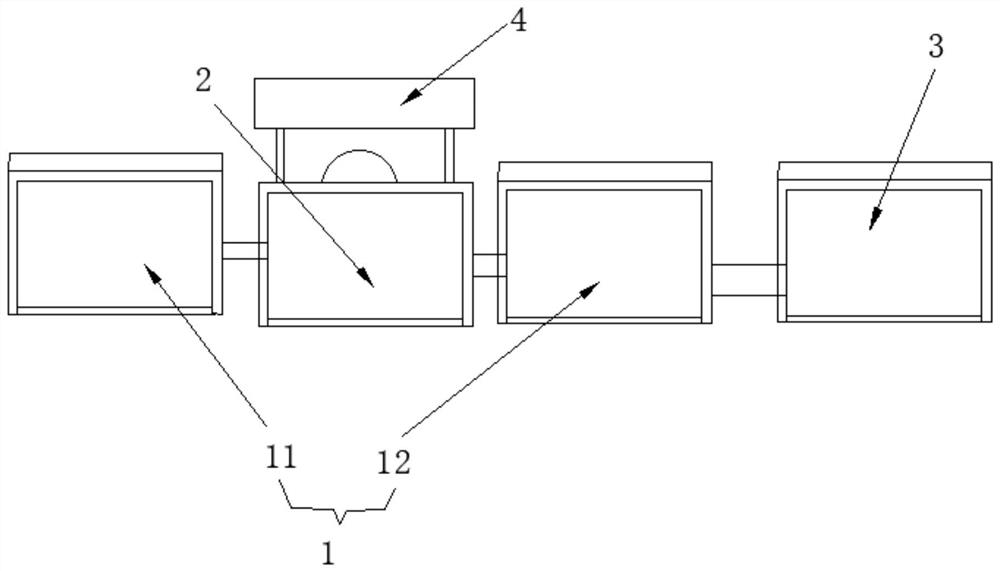

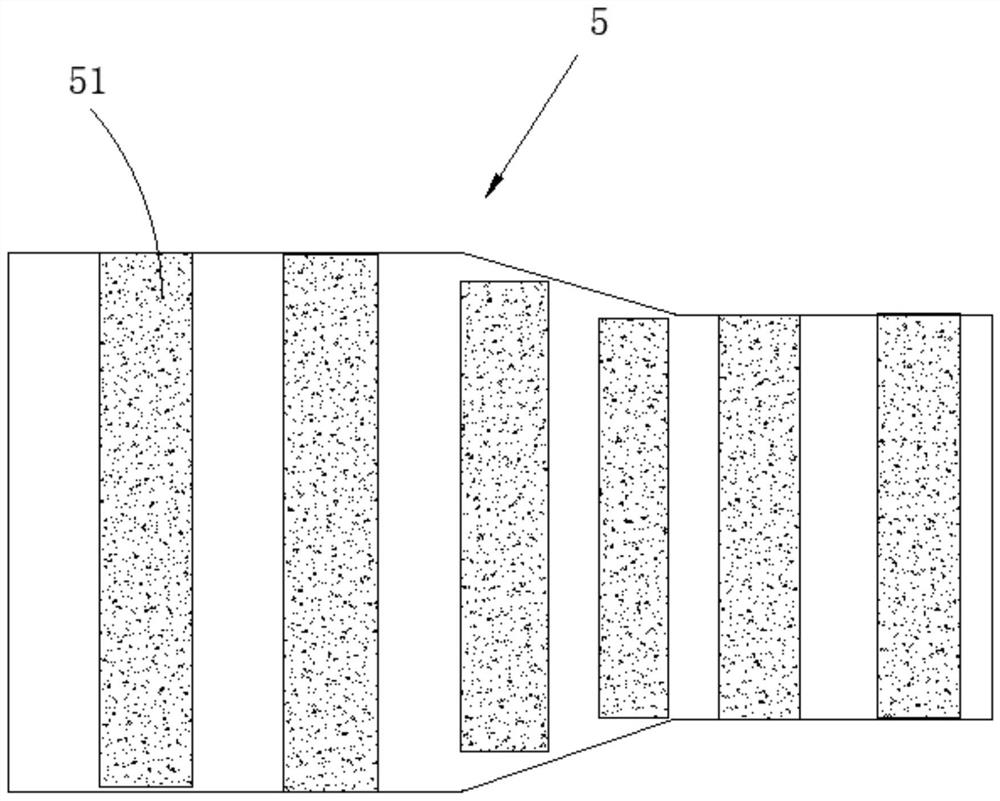

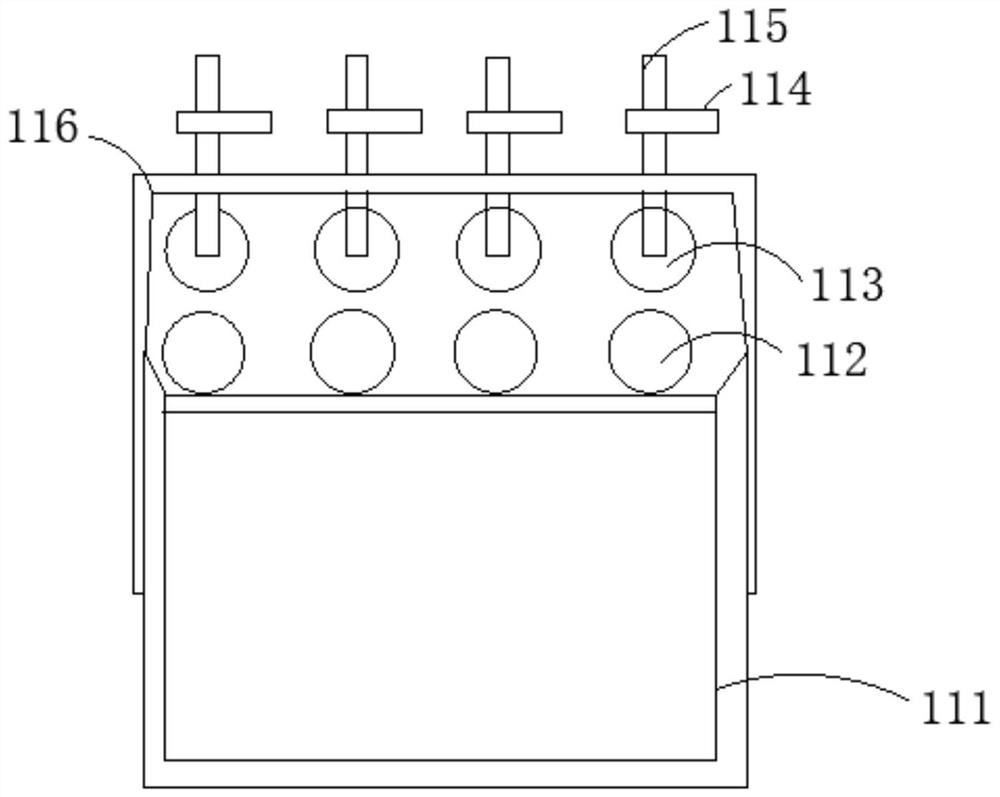

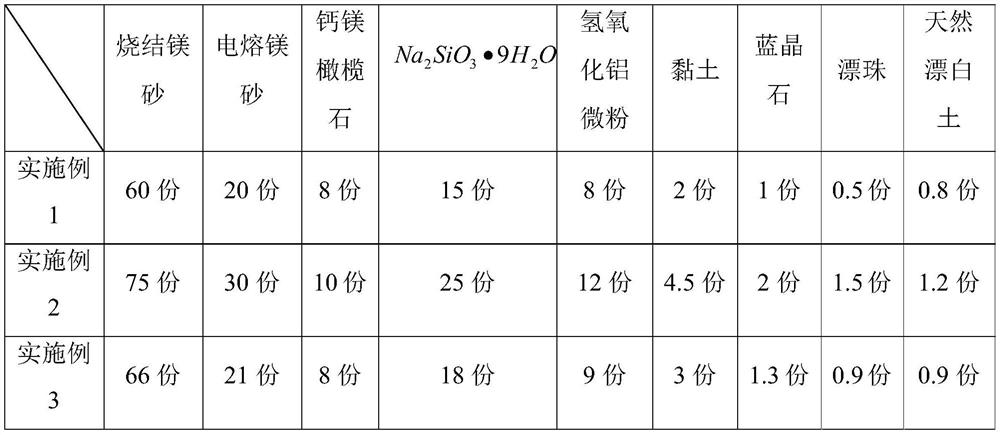

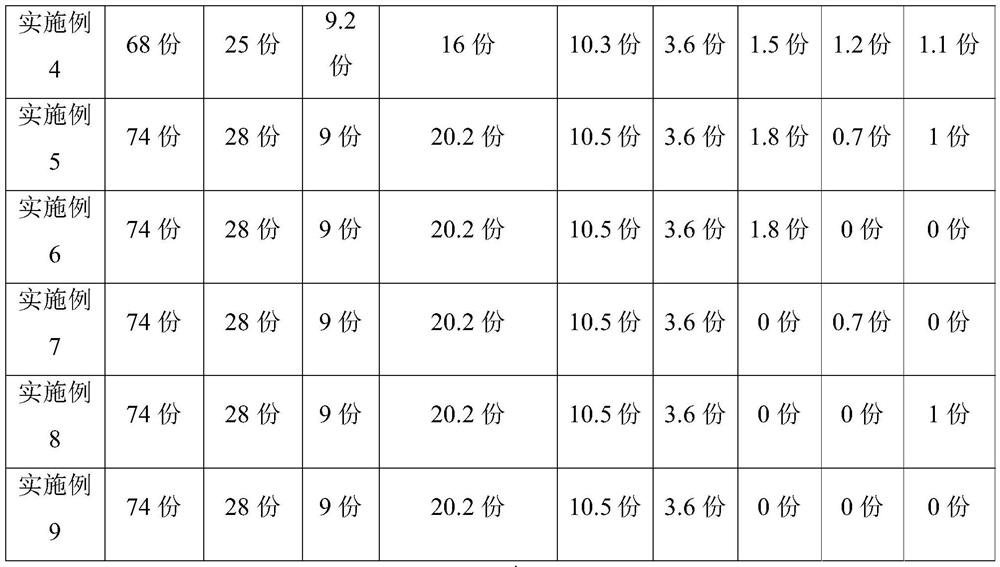

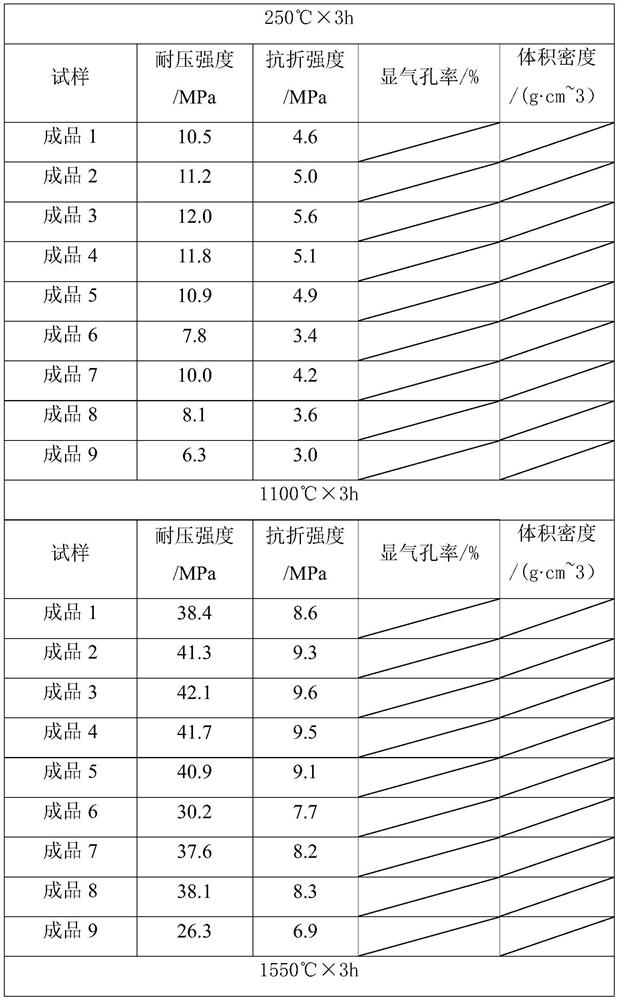

Environment-friendly magnesian dry material and preparation process thereof

An environment-friendly magnesian dry material comprises sintered magnesia, fused magnesia, calcium forsterite, a binding agent, aluminum hydroxide micro powder, a high-temperature sintering agent, anexpanding agent, floating beads and bentonite in a mass ratio of (60-75): (20-30): (8-10): (15-25): (8-12): (2-4.5): (1-2): (0.5-1.5): (0.8-1.2). According to the invention, the proportion of each component of the dry material is optimized; by adopting the environment-friendly binding agent, the problem that the binding agent is decomposed into toxic and harmful substances under a high-temperature condition can be effectively solved, the dry material is more energy-saving and environment-friendly, the hardness requirement of the dry material in the using process can be ensured on the premisethat the dry material has no pungent smell in the using process and is more beneficial to the production environment, and the scouring resistance of the dry material is ensured.

Owner:浙江欣辉耐火材料股份有限公司

Flexible cover plate and flexible display screen

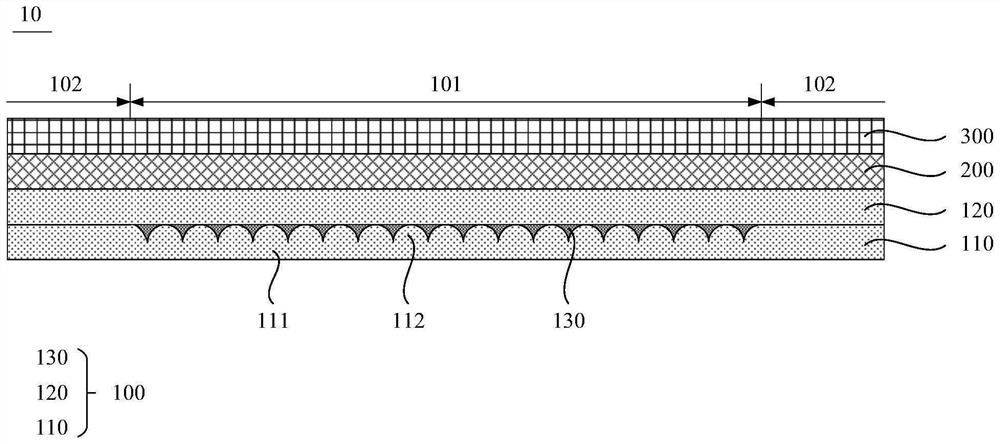

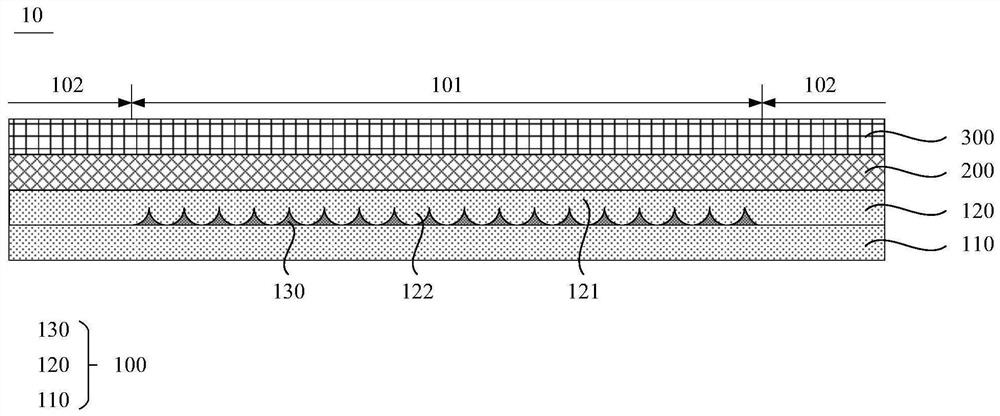

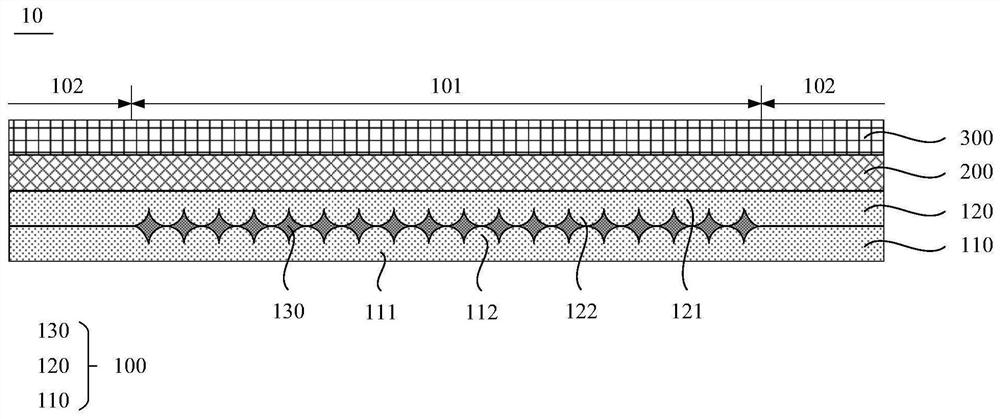

PendingCN111613140AHigh hardnessSolve the lack of hardnessIdentification meansOptical elementsEngineeringFlexible display

The invention provides a flexible cover plate and a flexible display screen, and the flexible cover plate comprises a composite layer which comprises first flexible glass, second flexible glass, and atransparent organic filling layer; a polymer material layer formed on the composite layer; and a hardened layer which is formed on the polymer material layer and is far away from one side of the composite layer; wherein in the bending area, the first flexible glass comprises a first base part and a plurality of first protrusions regularly arranged on the first base part, and the first protrusionsare arranged on the side close to the second flexible glass; the first flexible glass and the second flexible glass are oppositely arranged to form a gap, and the gap between the first flexible glassand the second flexible glass is filled with the transparent organic filling layer. The first flexible glass and the second flexible glass guarantee the hardness requirement of the flexible cover plate, meanwhile, in the bending area, the transparent organic filling layer improves the flexibility and bending resistance of the flexible cover plate, and the risk that the flexible cover plate cracksdue to stress concentration in the bending process of the flexible display screen is avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

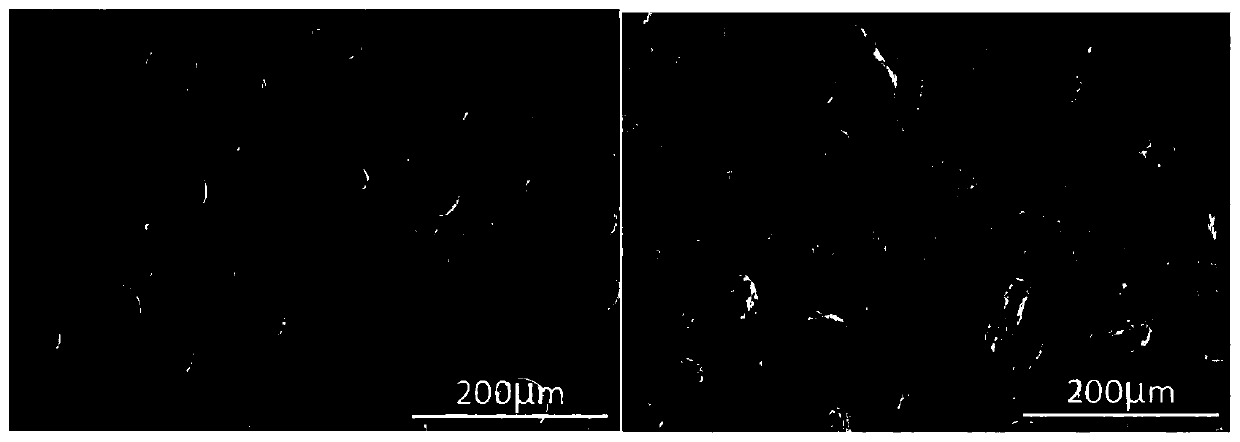

Steel for inner raceway of constant velocity universal joint and production method thereof

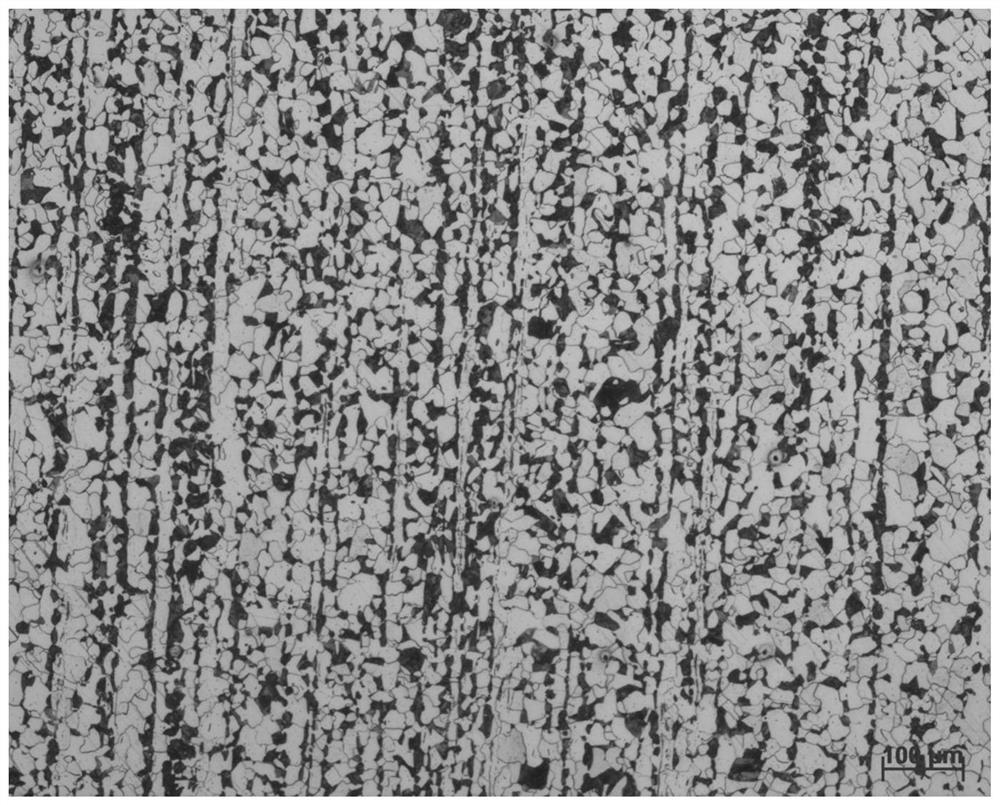

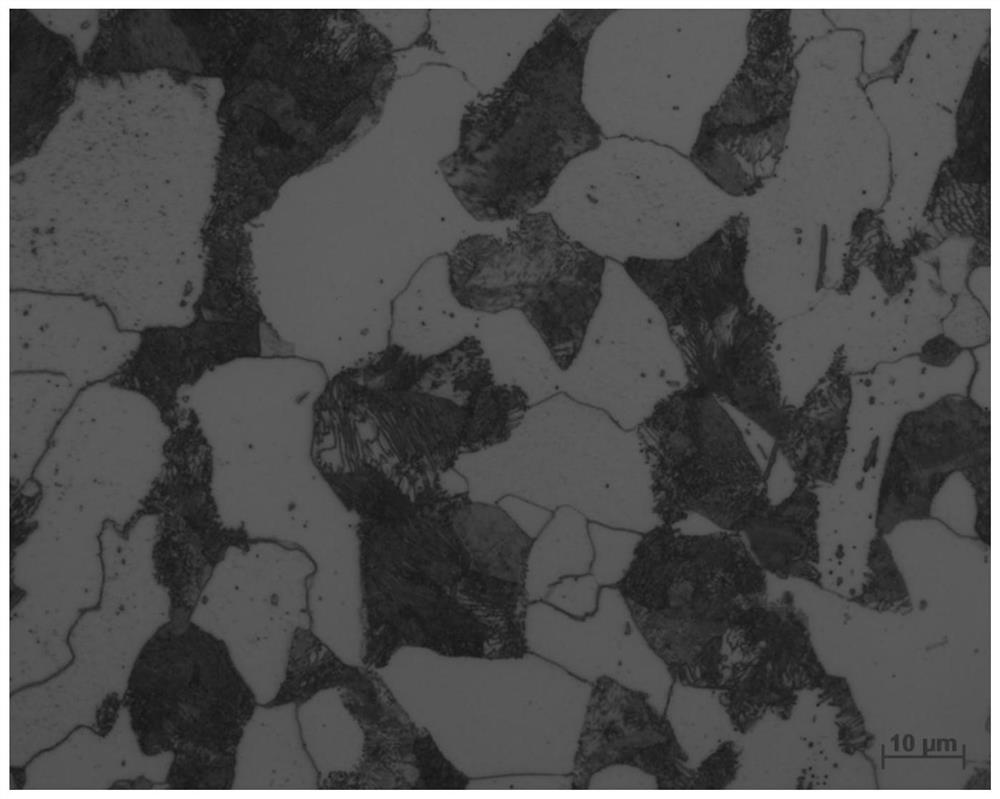

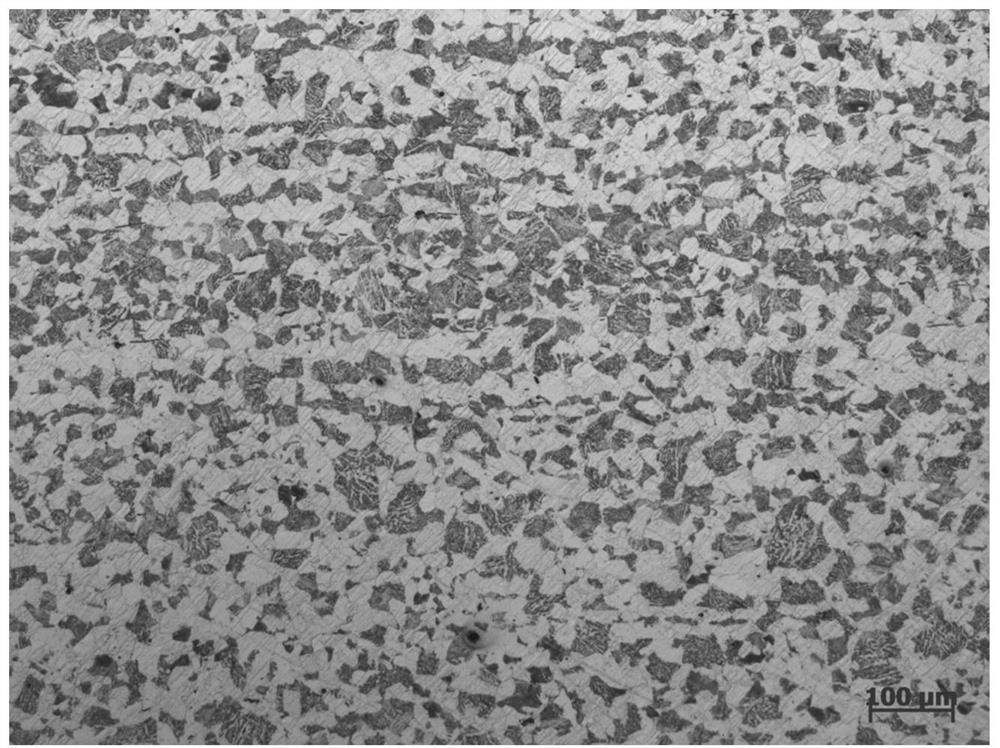

ActiveCN112981236AGuaranteed MicrostructureGuaranteed hardness requirementsFurnace typesHeat treatment furnacesAustenite grainUniversal joint

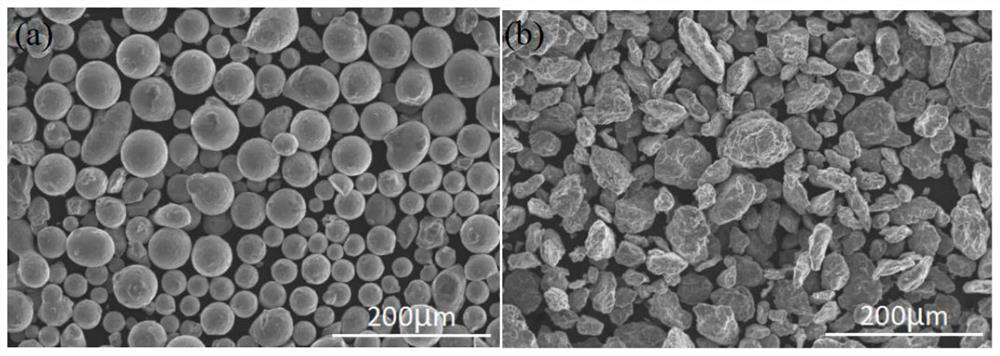

The invention discloses steel for an inner raceway of a constant velocity universal joint and a production method thereof. The steel comprises, by weight, 0.15-0.25% of C, 0.01-0.15% of Si, 0.25-0.75% of Mn, 0.80-1.30% of Cr, 0.001-0.003% of B, 0.010-0.040% of Ti, less than or equal to 0.015% of S, less than or equal to 0.025% of P, less than or equal to 0.25% of Ni, less than or equal to 0.20% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.05% of Al, less than or equal to 0.0010% of Ca, less than or equal to 0.0010% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb and the balance Fe and inevitable impurities. The production process comprises the steps of carrying out primary smelting, carrying out refining, carrying out vacuum degassing, carrying out continuous casting, carrying out continuous rolling, carrying out annealing and carrying out finishing. The hardness of the steel is less than or equal to 80HRB; the microscopic structure is ferrite and pearlite; the austenite grain size of the steel is greater than or equal to 6 grade; the banded structure of the steel is graded according to GB / T 13299 and does not exceed 2.0 grade. The hardenability of the tail end of the steel is evaluated according to a GB / T 225 method, and the hardenability of the J5 point is 36-44 HRC, and the hardenability of the J13 point is 24-32 HRC. The steel for the inner raceway of the constant velocity universal joint belongs to novel carburized steel for a universal joint inner raceway, and meets the hardenability, wear resistance and cold forging performance of the steel for the universal joint inner raceway.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

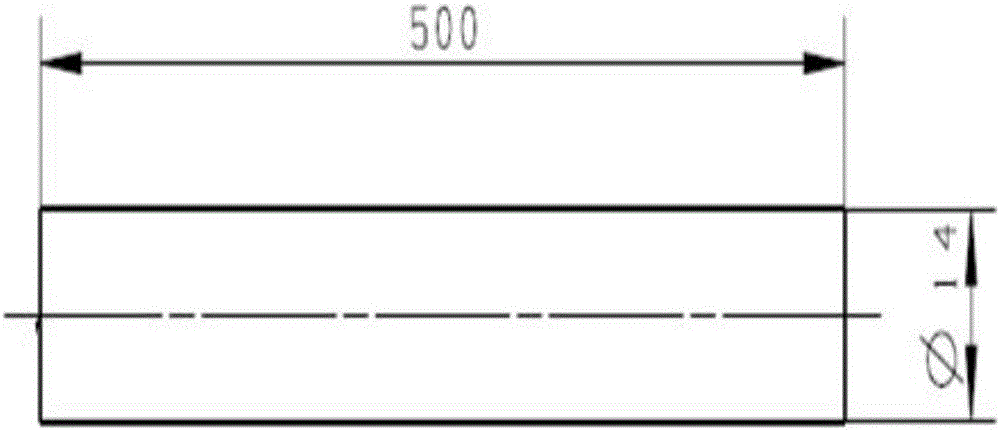

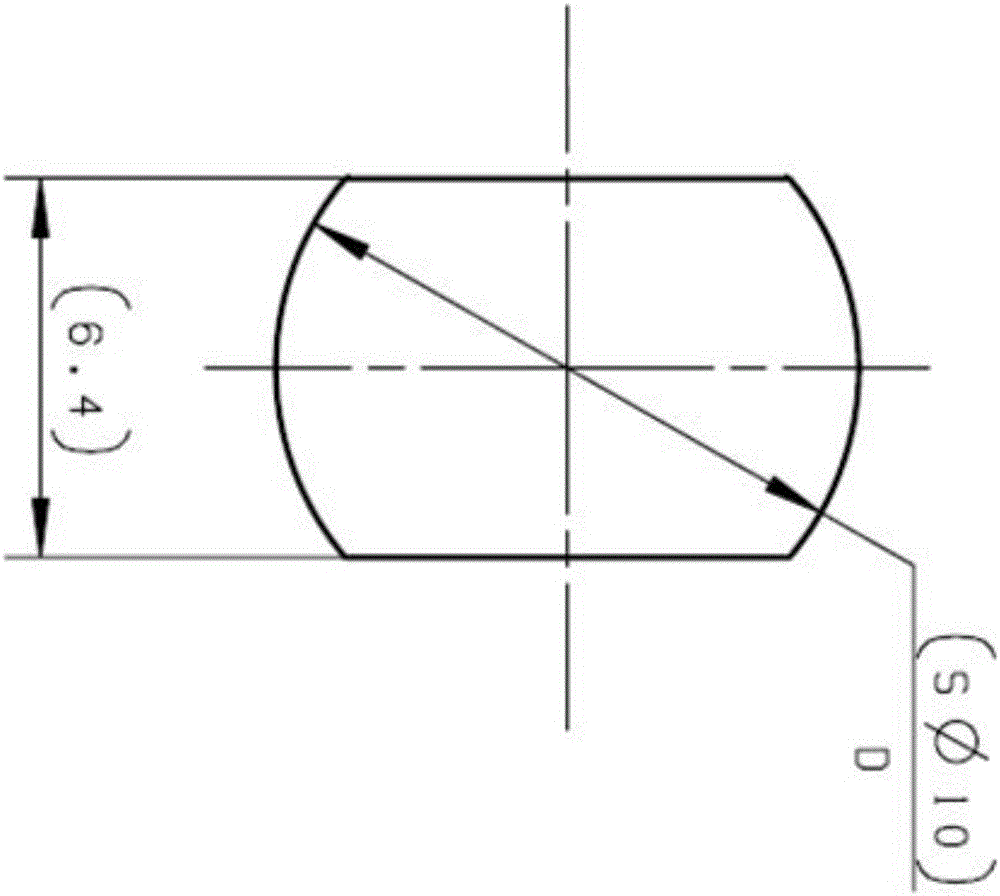

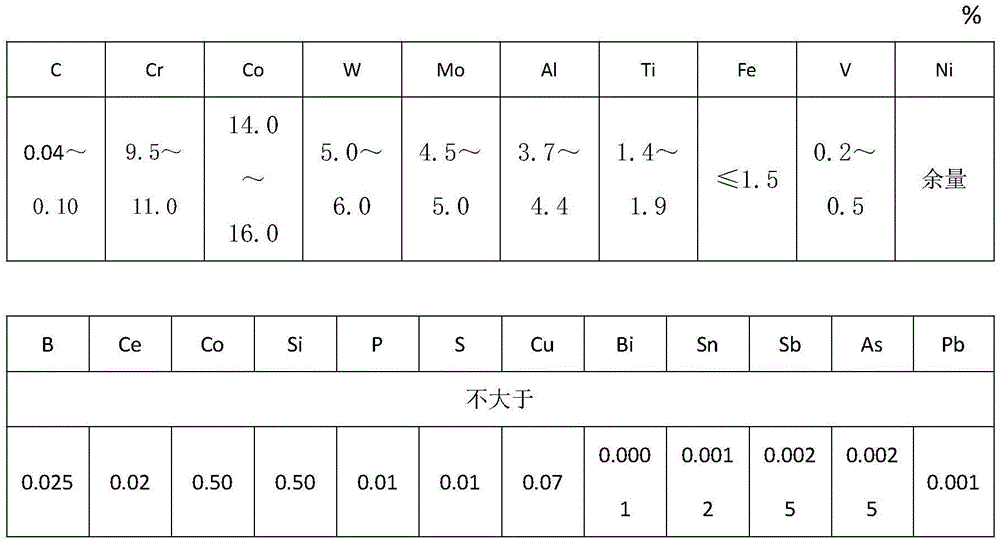

Aluminizing method of GH4049 ball

ActiveCN106756684AGuaranteed depthShorten heat treatment timeSolid state diffusion coatingWork in processHardness

The invention discloses an aluminizing method of a GH4049 ball. The aluminizing method comprises the steps of firstly, carrying out solid solution treatment on a GH4049 blank; then, processing the blank subjected to solid solution treatment into a semi-finished product with a spherical surface D; and finally, carrying out aging treatment on the entire semi-finished product while carrying out aluminizing on the spherical surface D of the semi-finished product at the aging temperature. According to the aluminizing method, the hardness is guaranteed to reach HB285 to HB352 while the depth of an aluminized layer is guaranteed to be 30 [mu]m to 50 [mu]m.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

A kind of hard anodic oxidation treatment method of cast aluminum alloy workpiece

ActiveCN103343374BImprove continuityHigh hardnessSurface reaction electrolytic coatingAnodizingDie casting

Owner:ZHEJIANG SUPOR CO LTD

Repair material for automobile dashboard foaming bodies

The invention relates to a repair material for automobile dashboard foaming bodies. The adopted technical scheme is as follows: the repair material is composed of a component A and a component B, wherein the component A is composed of the following ingredients in parts by weight: 100 parts of polyether polyols, 1.7-2 parts of crosslinking agent, 0.4-0.9 part of polyurethane amine catalyst, 0.3-0.4 part of silicone oil, and 2-2.5 parts of hole-opening agent; and the component B is isocyanate. A repair method is implemented through taking the repair material, mixing the component A and the component B in a weight ratio 10:1, fully stirring 10-15 seconds, feeding the mixed material into an injector through inhaling, injecting the mixed material into the defective positions of dashboard foaming bodies until the positions are filled with the mixed material, and curing the mixed material for 0.5-1 hour. According to the invention, defects of foaming bodies can be repaired without affecting the quality of products.

Owner:SHENYANG JINBEI YANFENG AUTOMOTIVE INTERIOR SYST CO LTD

Engine case machining process

The invention relates to an engine case machining process. The engine case machining process comprises the following steps: (1) raw material formation: a raw material is cleaned and dried, and is formed by plastic deformation; the formed material is rolled into a cylinder according to the size by a pipe rolling machine; and parts at other portions of an engine case are machined on a lathe; (2) welding: the cylinder is cleaned, dried and fixed; the welded surfaces of the cleaned cylinder with other parts of the case are polished and cleaned; and then seamless welding is performed after drying; (3) detection: the condition whether the case formed after welding has cracks and defects is detected; and the precision of the case and the condition that whether weld seams exist are checked; and (4) finish machining: the surface of the case is polished to remove an oxidation layer; then, primer and finishing coat are sprayed; and the lettering is performed. The machining process can guarantee the precision and the quality of the engine case, and improves the production efficiency.

Owner:SHAANXI HUATONG ELECTROMECHANICAL MFG CO LTD

Abrasion-resistant counter sinking cutter

InactiveCN102873379AEnsure straightnessEnsure heightTransportation and packagingTrepanning drillsEngineeringMechanical engineering

The invention discloses an abrasion-resistant counter sinking cutter, which comprises a cylindrical cutter handle and a cutter bar; a rectangular main blade fixing groove is formed in the middle of the lower end face of the cutter bar; a first L-shaped gap is formed on the lower end face of the cutter bar and positioned on each of two sides of the main blade fixing groove; a main blade is arranged in the main blade fixing groove; a main cutting edge gradually approaches to the axis of the cutter bar from the outer side of the main blade to the center of the main blade so as to form an inclined shape; a second L-shaped gap extending axially along the cutter bar and communicated with the main blade fixing groove is formed on each of two sides of the lower end face of the cutter bar and is close to the main cutting edge, so that a chip removal groove of the main cutting edge is formed; a secondary blade is arranged on a lateral surface of each first L-shaped gap; an end cutting edge is formed at the end of each secondary blade; a lateral cutting edge is formed on the outer lateral surface of each secondary blade; and the end cutting edges are 0.1 to 0.2 millimeter shorter than the main cutting edge in the axial direction. According to the cutter, the service lives of the cutting edges are long; the size precision of the cutter is high; the cutter bar has high strength; and the cutter is high in cutting efficiency and easy and convenient to manufacture, install and maintain.

Owner:MAIN PLAN NINGBO BATHROOM COLLECTIONS

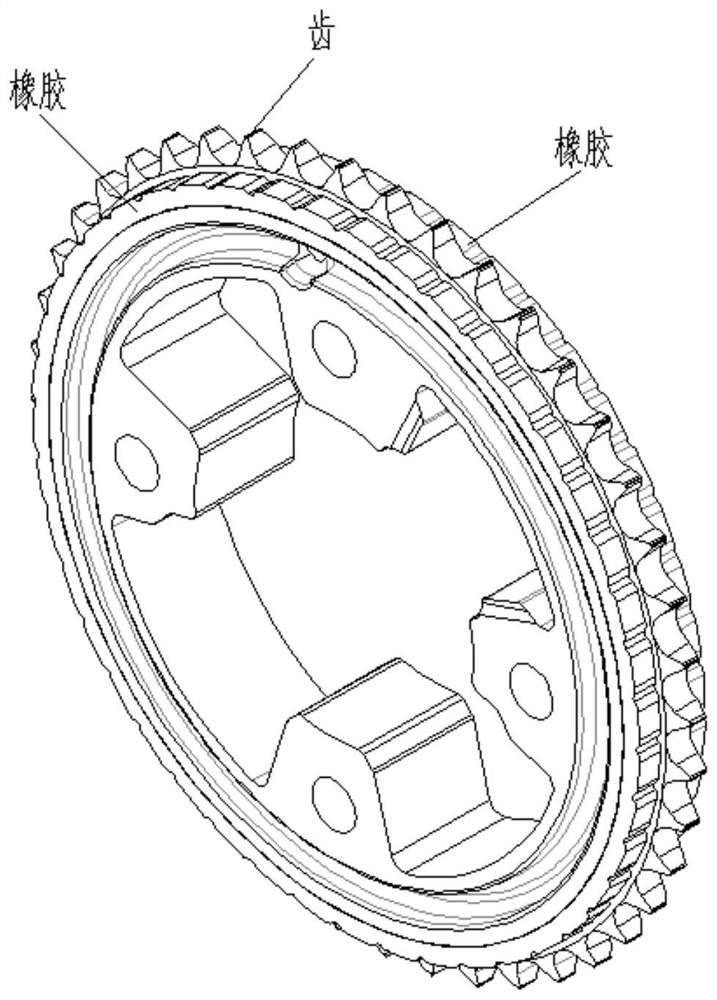

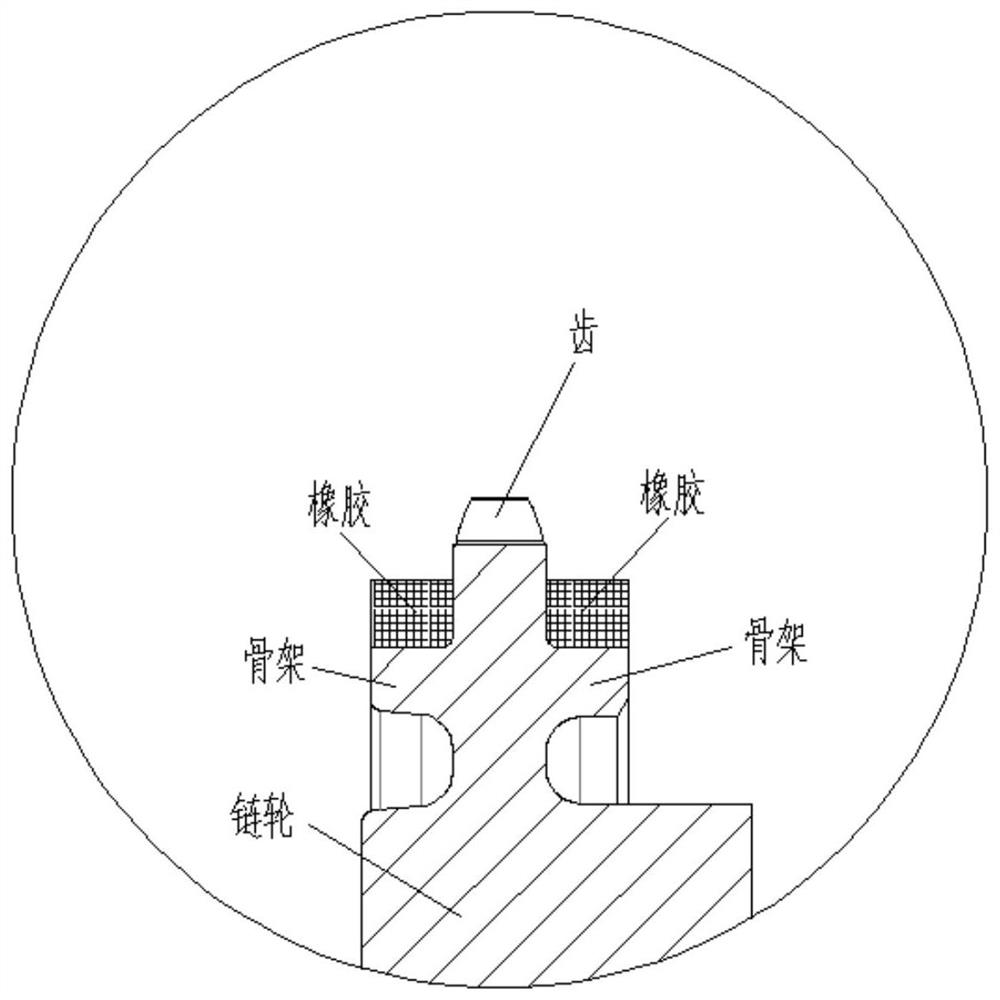

Preparation method of high-precision powder metallurgy rubber-coated gear

ActiveCN113579235AHigh precisionEnsure high precision requirementsIncreasing energy efficiencyGear wheelsVulcanizationCrazing

The invention discloses a preparation method of a high-precision powder metallurgy rubber-coated gear, and belongs to the technical field of powder metallurgy. The preparation method comprises the following steps in sequence: mixing, forming, sintering, oil immersion, shaping, steam treatment, heat treatment, sand blasting, adhesive coating, rubber coating and finish machining to obtain the high-precision powder metallurgy rubber-coated gear. The gear is subjected to steam treatment after the shaping step and before the induction quenching step, oil in the gear can be removed, a compact oxide layer is formed on the outer surface, the hole sealing effect is good, and the treatment cost is low; the tooth hardness requirement of the gear can be met through the induction quenching step; the magnetic powder inspection step can inspect gear tooth cracks; and after magnetic powder inspection is completed, the rubber-coated surface of the gear is subjected to sand blasting treatment, the rubber-coated surface with the surface roughness meeting the requirement is obtained, then the rubber-coated surface is coated with a layer of adhesive, phosphating treatment is not needed, and through rubber injection molding and vulcanization, the requirement for effective bonding of the rubber-coated gear product and rubber is met, and meanwhile the indexes of high precision and hardness of the gear are met.

Owner:扬州保来得科技实业有限公司

Forging process for preventing forging cracking of 11Cr17

The invention discloses a forging process capable of preventing forging cracking of 11Cr17. The forging process capable of preventing forging cracking of 11Cr17 can replace an existing forging process, the cracking probability of 11Cr17 tooth head forgings in the machining process is reduced, and the performance of the tooth head forgings is improved. The specific operation includes the following steps that firstly, raw materials are prepared, a lathe is used for conducting turning operation on an existing rod body raw material with the diameter being 30 mm, then a rod material with the diameter being 28.5 mm is obtained, after that, a sawing machine is used for conducting blanking operation on the rod material with the diameter being 28.5 mm, a section of rod body raw material with the length value being 40 mm is obtained, and finally surface treatment is conducted on the two ends of the rod body raw material. According to the forging process capable of preventing forging cracking of 11Cr17, turning pretreatment is conducted on the initial rod body raw material, cracks on the surface of the raw material are effectively removed, forging cracks caused by the cracks of the raw material are prevented in the later period. Rounding treatment is conducted on the two ends of the single rod body raw material obtained through blanking, so that the material flowability is improved, and the machining problems of overburning of sharp burrs, folding, inclusion and the like are prevented.

Owner:昆山众诚精密锻造有限公司

Bending axis for forming underwear back button

InactiveCN101323004AWon't hurtGuaranteed StrengthShaping toolsClothes buttonsEngineeringFriction force

The invention discloses a bending axis used for shaping an underclothes back buckle which relates to a shaping die for the underclothes back buckle of a woman. The bending axis consists of a bending axis body, a pressing wheel and a mandrel; the pressing wheel is in a disc shape and arranged in a notch of the head part of the bending axis body; part of the pressing wheel reveals outside the notch; besides, the pressing wheel and the mandrel fixed on the bending axis body form a rotatable fit. The pressing wheel and the bending axis body are component of different materials; the mandrel and the bending axis body are pivoted and pressed into a whole. The bending axis is used for shaping and processing the underclothes back buckle (hook shape piece, circle shape piece); has little friction when being bended; can not damage a workpiece membrane layer and improve the quantified rate of products; besides, the bending axis is easy to be manufactured and saves the steels with excellent quality; after the service life becomes due, the pressing wheel can be replaced, thus avoiding being integrally wasted and greatly reducing the manufacturing and using cost.

Owner:泰州菁茂科技有限公司

Annealing process for comb teeth of turbonator

Owner:HARBIN ELECTRIC MASCH CO LTD

Method of guaranteeing hardness of welded closed impeller after welding

The invention provides a method of guaranteeing hardness of welded closed impeller after welding. The method is characterized in that aluminium alloy closed impeller, after a conventional machining and welding, is taken out of a salt bath furnace, put into a boiling water of 100 DEG C for fried salt treatment within two minutes, with a time being controlled in 30-50 minutes, and then is subjected to an artificial aging for 10-12 hours under a temperature of 160-180 DEG C, so that the hardness HB of the aluminium alloy closed impeller after welding is more than or equal to 100.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

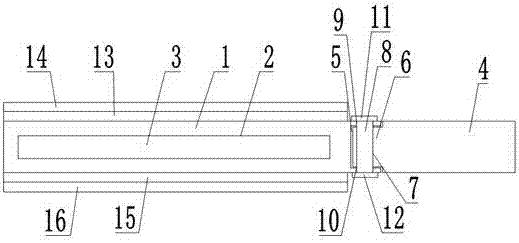

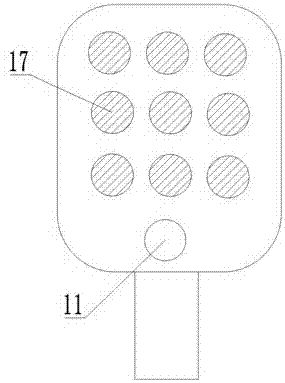

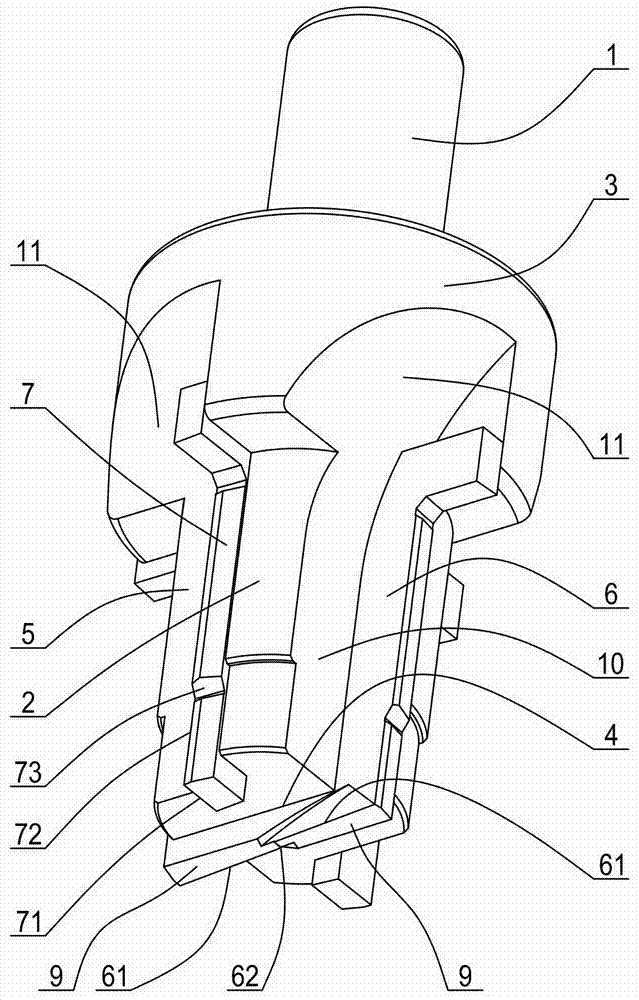

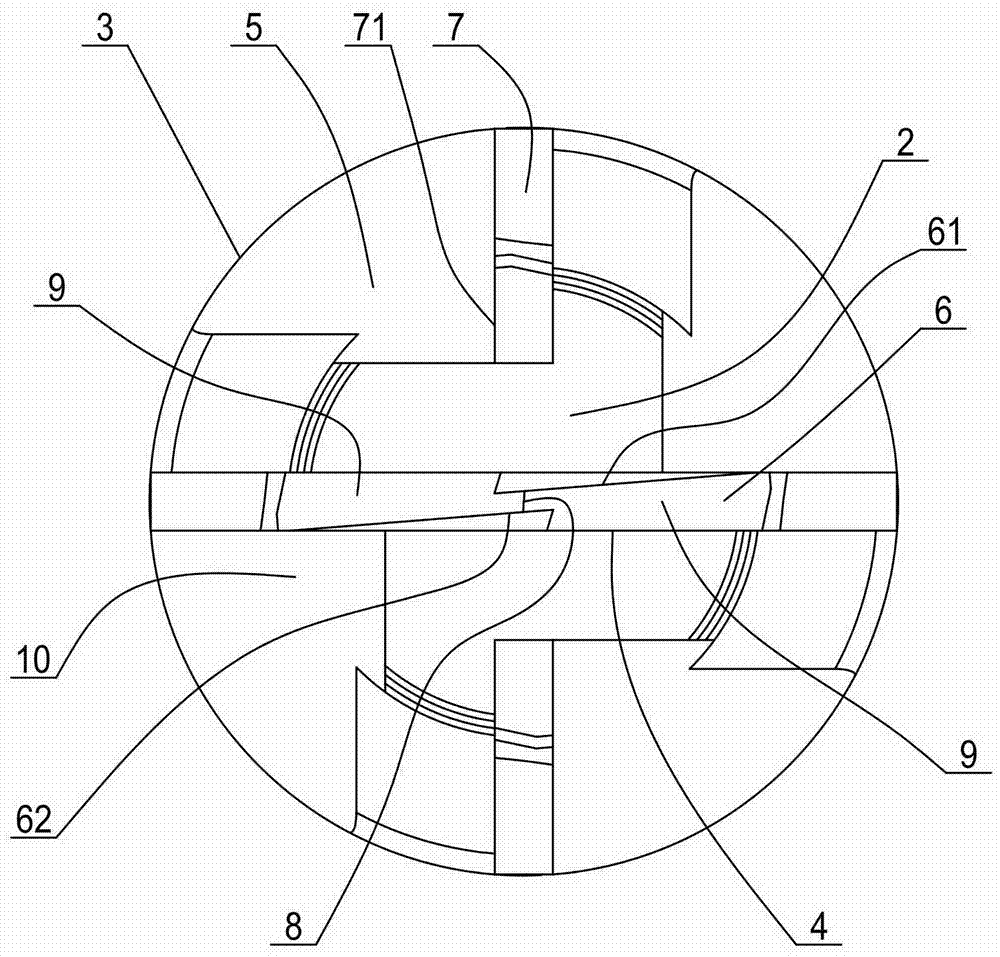

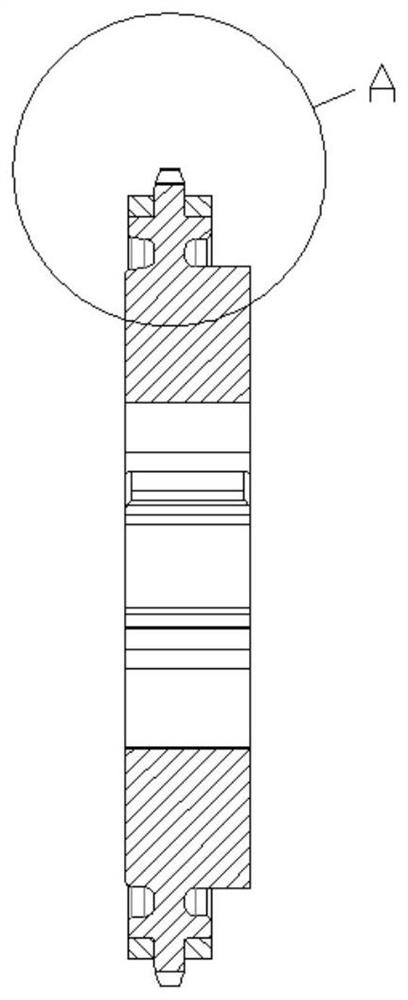

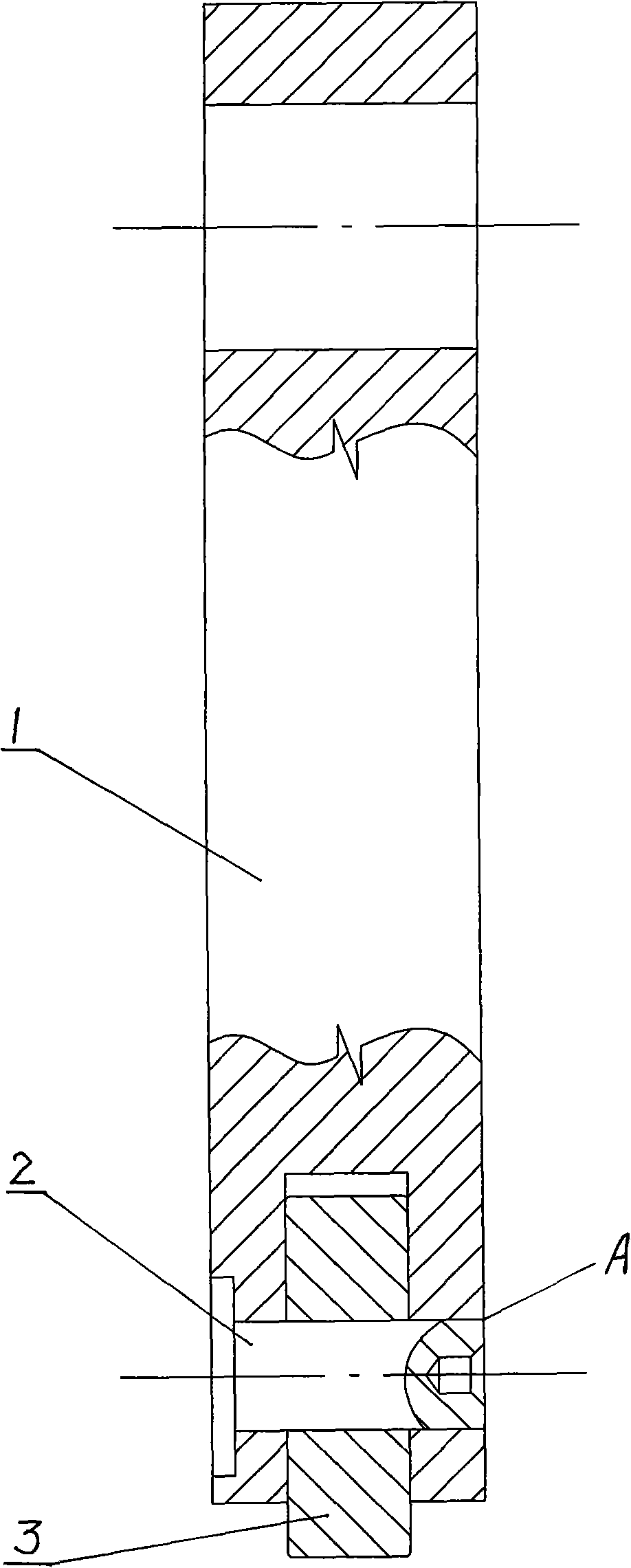

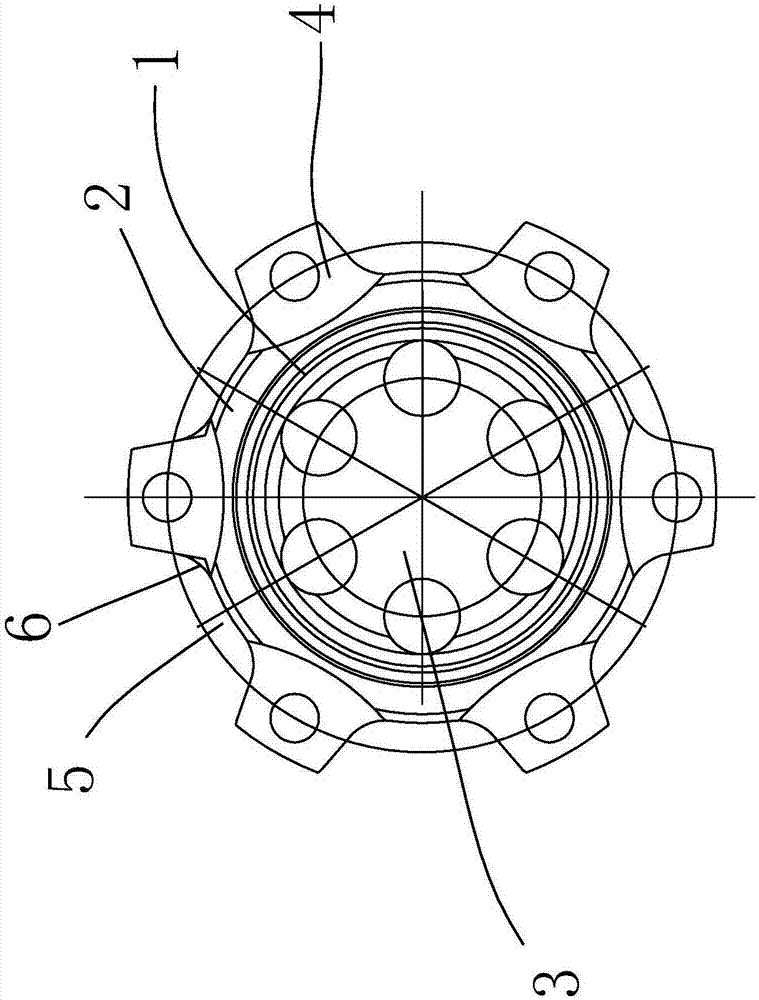

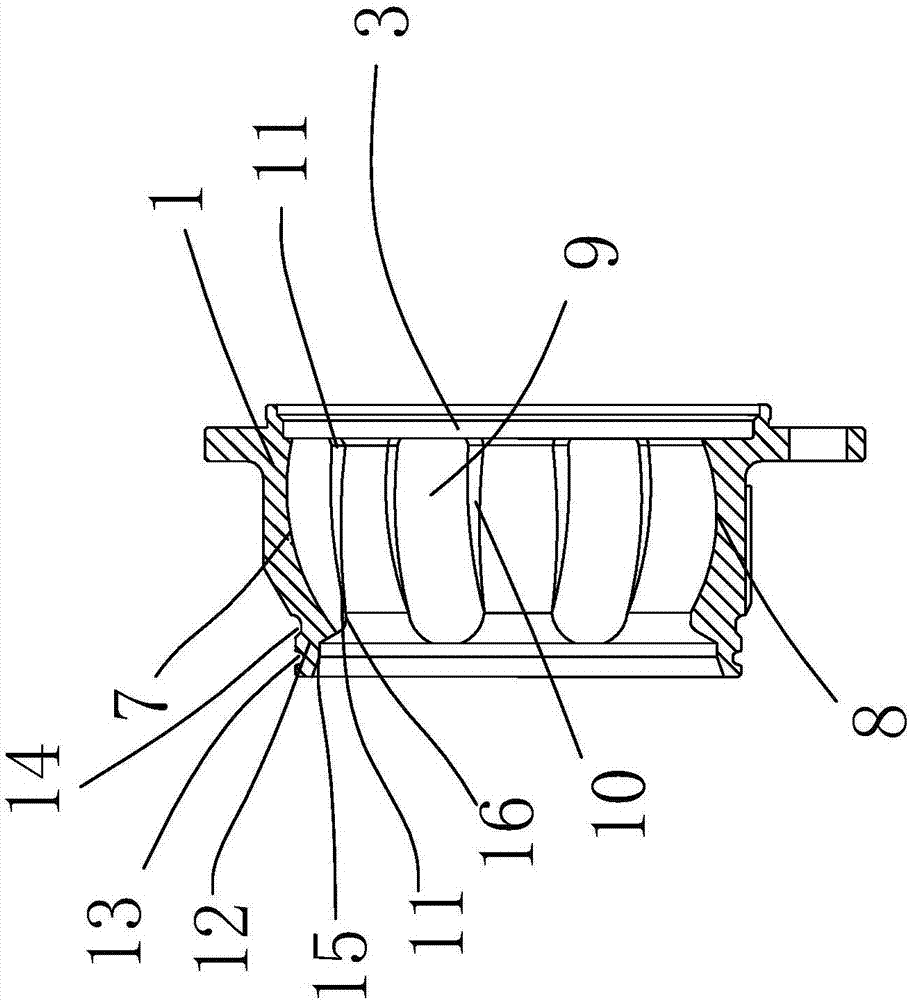

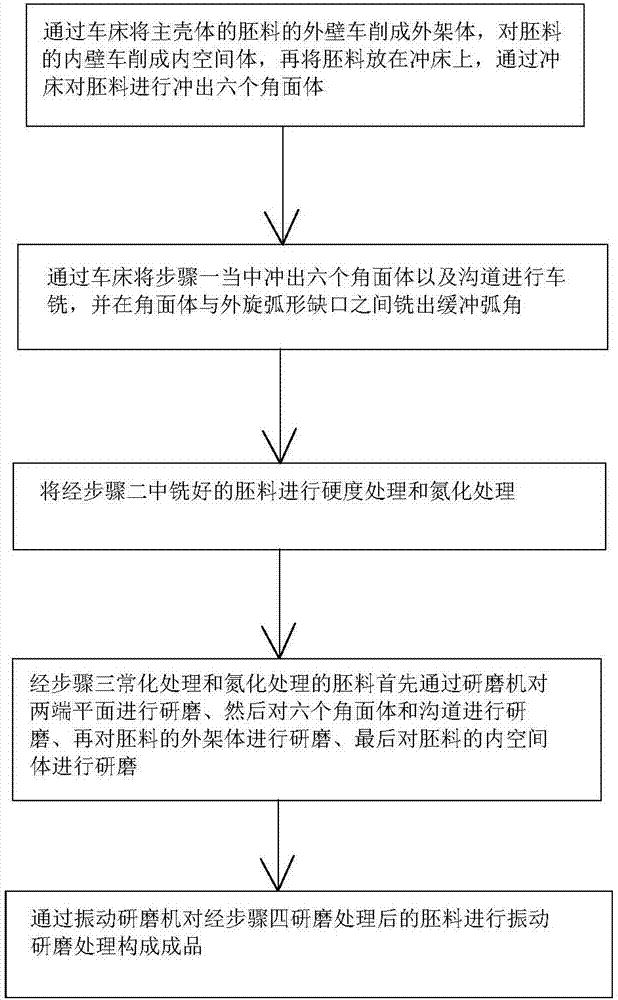

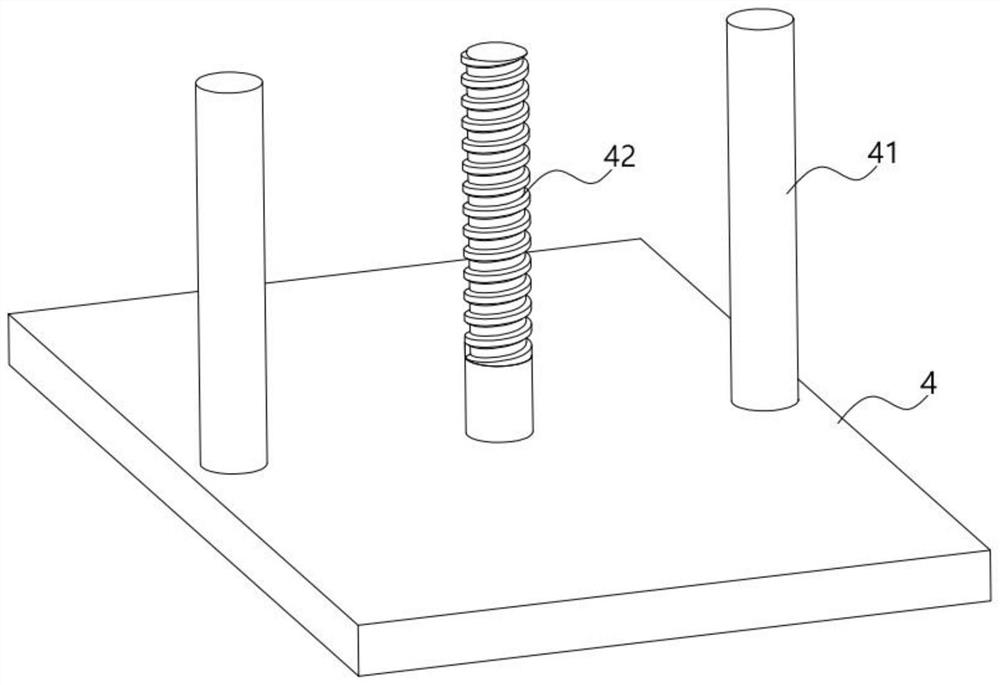

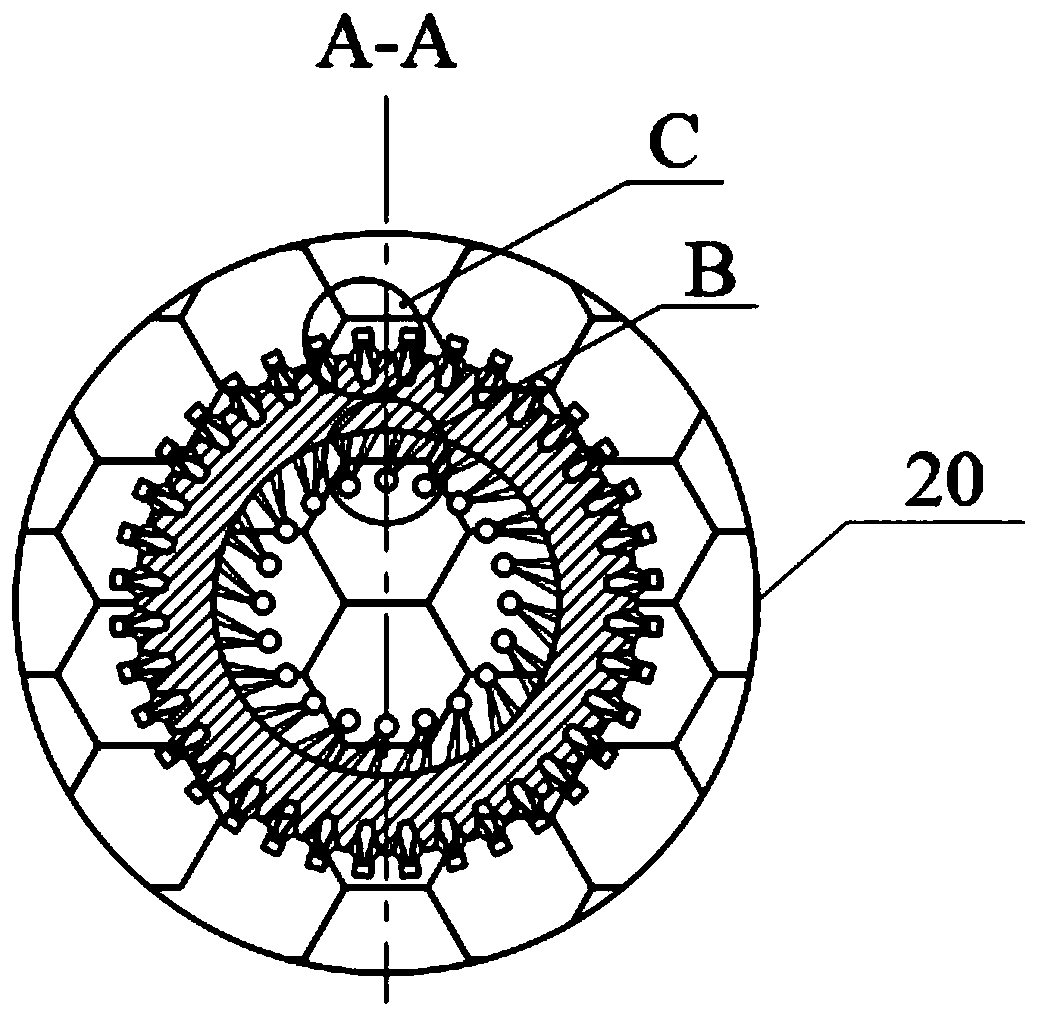

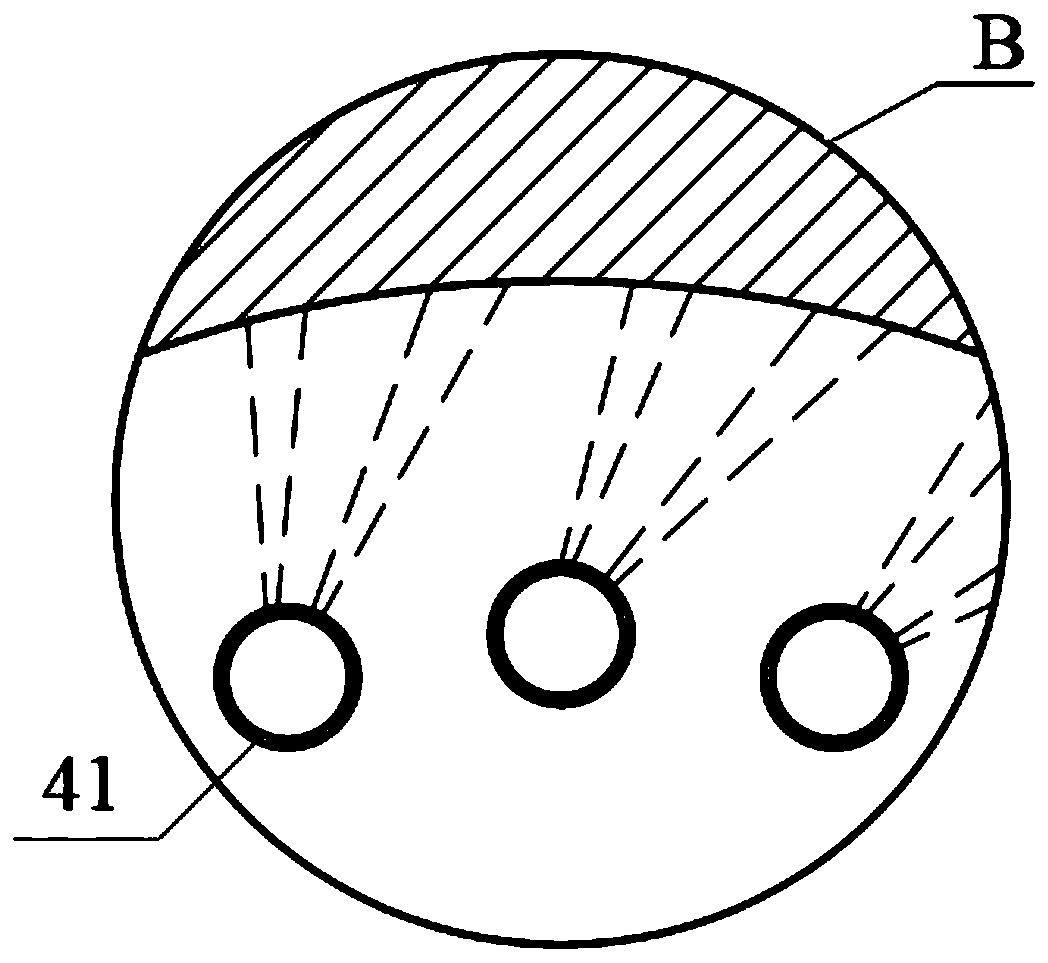

Spherical cage and spherical shell structure and technological processing method thereof

PendingCN107061529AImprove carrying capacityPrevent temper brittlenessClutchesYielding couplingEdge surfaceDuctility

The invention belongs to the technical field of automobile drive accessories, and provides a spherical cage and spherical shell structure and a technological processing method thereof. The spherical cage and spherical shell structure comprises a main shell. The main shell is divided into an outer frame body and an inner space body. A steel ball is arranged in the inner space body. Six edged surface bodies are arranged on the surface of the outer frame body along the circumferential face of the main shell. An outward-rotation arc-shaped notch is formed between every two adjacent edged surface bodies. The hardness of the outer frame body and the inner space body which are subjected to technological processing reaches the Rockwell hardness being 58-62. The outer wall of a blank of the main shell is subjected to turning through a lathe to form the outer frame body, the inner wall of the blank is subjected to turning to form the inner space body, then, the blank is put on a punching machine, punching is conducted on the blank through the punching machine to form the six edged surface bodies, and hardness treatment and nitrogen treatment are conducted on the milled blank. The spherical cage and spherical shell structure and the technological processing method have the beneficial effects that by means of the channel chamfering angle, it can be ensured that the steel ball is at the center position as much as possible when the steel ball rotates, the bearing capacity is improved, and the hardness is regulated to 20-26 HRC. Therefore, the ductility and hardness requirement of a whole spherical cage and spherical shell is ensured.

Owner:NINGBO V SHINE AUTO PARTS

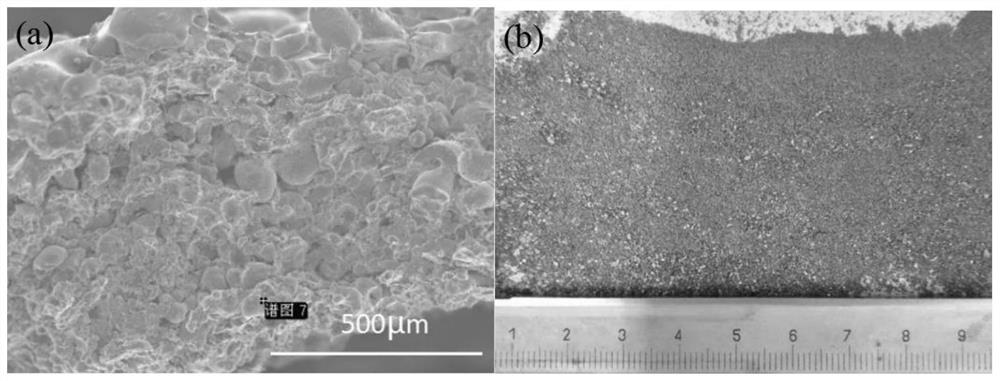

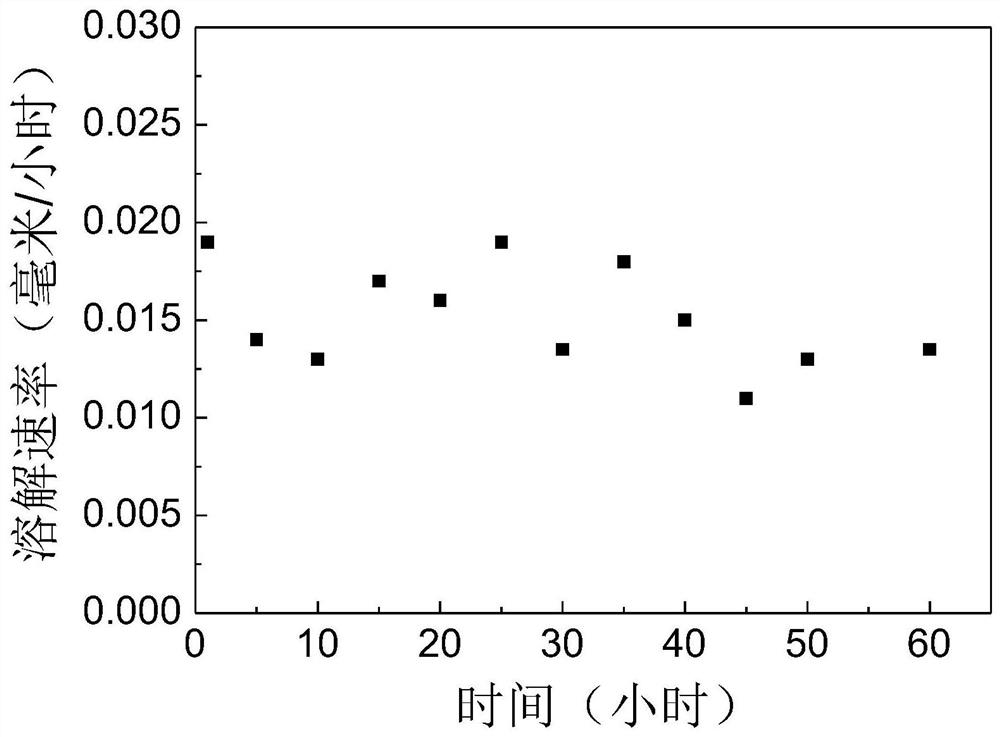

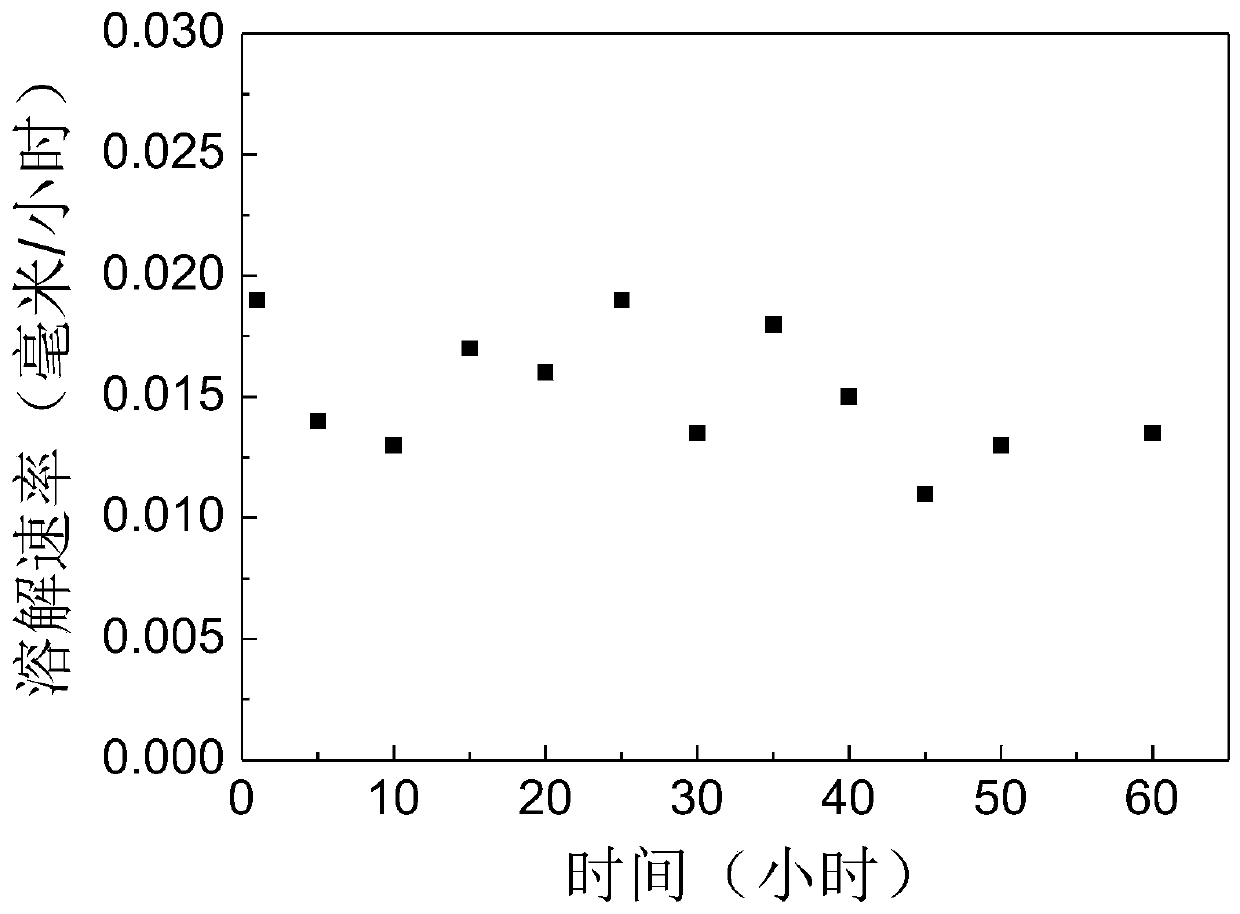

A kind of cemented carbide coating completely soluble in water medium and its preparation method and application

The invention discloses a cemented carbide coating completely soluble in water medium, a preparation method and application thereof. The cemented carbide coating is composed of soluble alloy powder and cemented carbide powder, with moderate dissolution speed and high hardness. It is prepared as follows: uniformly mix cemented carbide powder and soluble alloy powder, and then spray it on the workpiece by plasma spraying, flame spraying or supersonic spraying process to obtain a cemented carbide coating, which is well combined with the substrate. The cemented carbide coating can be applied to the protection of the surface of tools or parts used in the fracturing reconstruction of oil and gas fields. After the construction, the cemented carbide coating can be completely dissolved, eliminating the need for subsequent grinding and milling processes, which is beneficial to flowback and improves construction efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

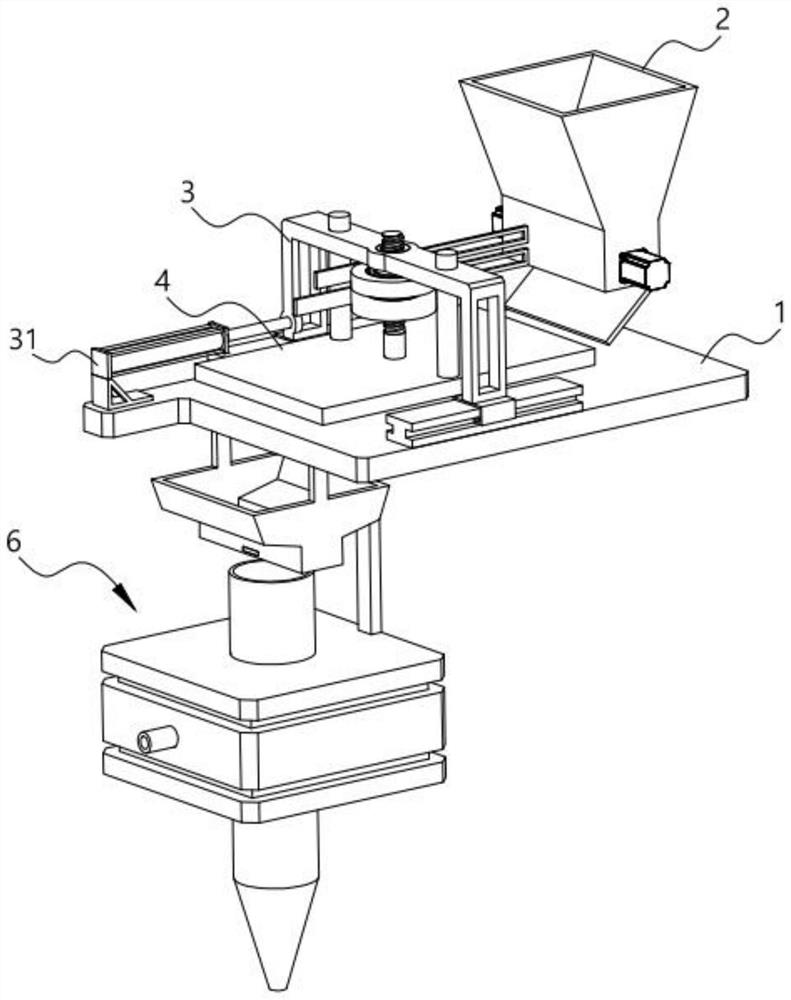

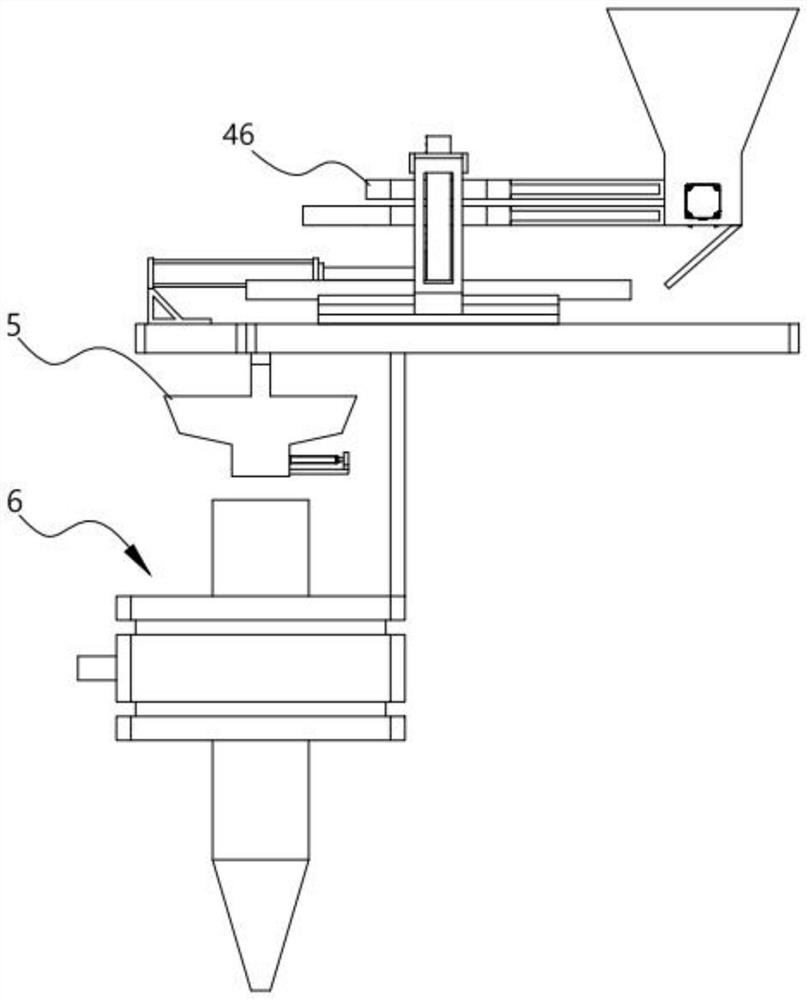

Grinding wheel sand blasting hardness machine

InactiveCN114689454AGuaranteed hardness requirementsInvestigating material hardnessSand blastingGrinding wheel

The invention provides a grinding wheel sand blasting hardness machine which comprises a lower extrusion plate, a hopper, a supporting frame, an upper extrusion plate, a weighing hopper and a sand blasting assembly, a quantitative discharging assembly is arranged at the bottom of the hopper and used for achieving quantitative discharging, the supporting frame is arranged on the lower extrusion plate through a linear guide pair, and the upper extrusion plate is movably installed on the supporting frame; wherein an extrusion gap is formed between the upper extrusion plate and the lower extrusion plate, a reciprocating driving assembly is arranged between the supporting frame and the upper extrusion plate and used for driving the upper extrusion plate to ascend and descend in a reciprocating mode, a feeding port of the weighing hopper is located below the end of the upper extrusion plate, and the sand blasting assembly is located at the bottom of a discharging port of the weighing hopper. Materials are extruded and conveyed through the upper extrusion plate and the lower extrusion plate, then hardened materials are thoroughly scattered, the upper extrusion plate reciprocates and translates along the lower extrusion plate in a reciprocating mode, the materials can be quantitatively conveyed on the premise that the materials are extruded, and the hardness requirement of sand blasting is met.

Owner:歌玛磨具南通有限公司

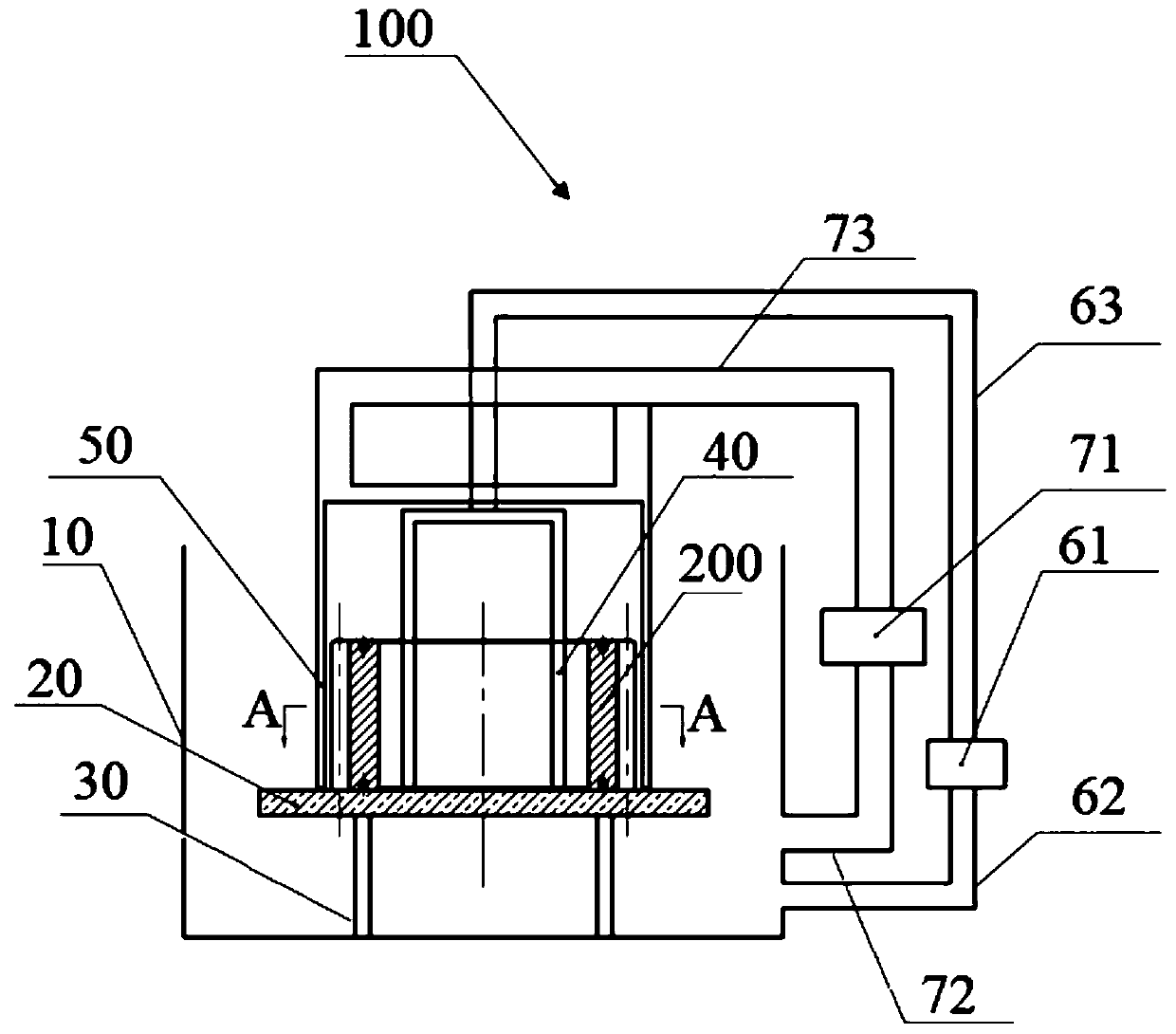

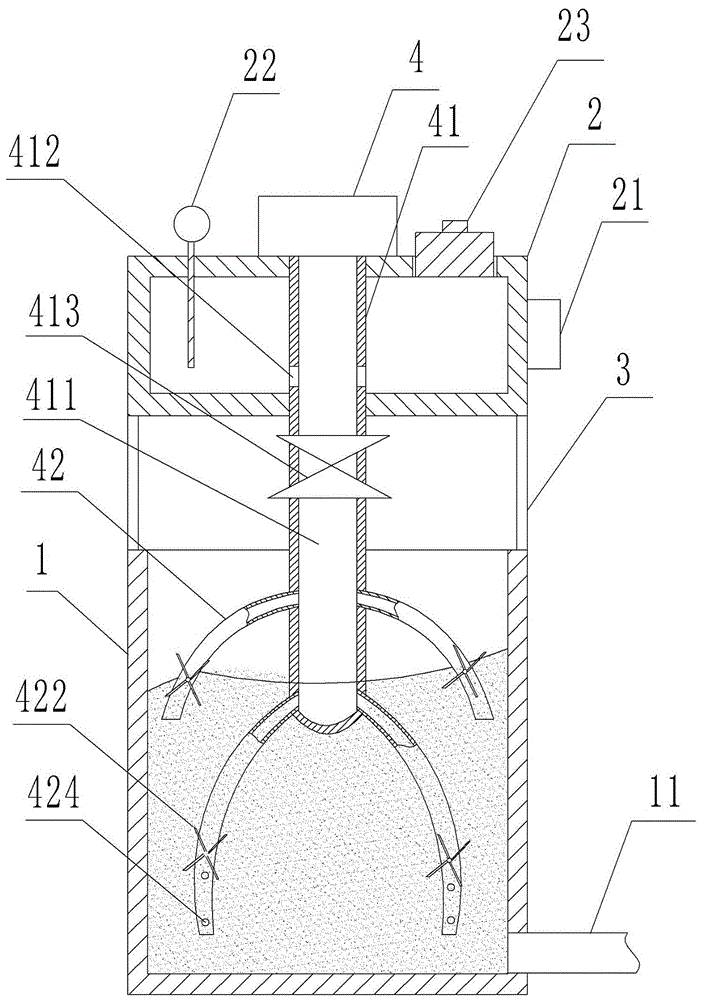

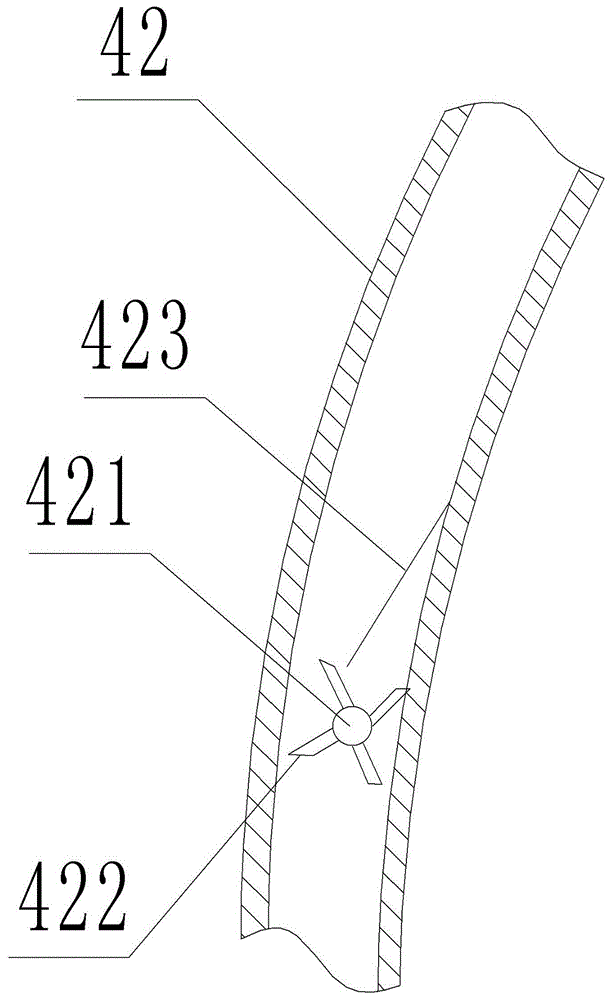

Buried liquid quenching and spraying device

PendingCN110157874AAdjust cooling speedImprove performanceFurnace typesHeat treatment furnacesEngineeringHardness

The invention discloses a buried liquid quenching and spraying device. The device comprises an outer groove for accommodating quenching mediums, a lifting platform for bearing parts, and a lifting device for driving the lifting platform to lift. The buried liquid quenching and spraying device suitable for parts with inner holes further comprises an inner spraying device for spraying the inner holes of the parts, an outer spraying device for spraying the outer side surfaces of the parts, a first circulating device for extracting the quenching mediums in the outer groove to spray by the inner spraying device, and a second circulating device for extracting the quenching mediums in the outer groove to spray by the outer spraying device. The buried liquid quenching and spraying device effectively guarantees the internal and external hardness of the parts, and controls the consistency of different batches of parts.

Owner:NANJING HIGH SPEED GEAR MFG

A processing technology of an engine casing

The invention relates to an engine case machining process. The engine case machining process comprises the following steps: (1) raw material formation: a raw material is cleaned and dried, and is formed by plastic deformation; the formed material is rolled into a cylinder according to the size by a pipe rolling machine; and parts at other portions of an engine case are machined on a lathe; (2) welding: the cylinder is cleaned, dried and fixed; the welded surfaces of the cleaned cylinder with other parts of the case are polished and cleaned; and then seamless welding is performed after drying; (3) detection: the condition whether the case formed after welding has cracks and defects is detected; and the precision of the case and the condition that whether weld seams exist are checked; and (4) finish machining: the surface of the case is polished to remove an oxidation layer; then, primer and finishing coat are sprayed; and the lettering is performed. The machining process can guarantee the precision and the quality of the engine case, and improves the production efficiency.

Owner:SHAANXI HUATONG ELECTROMECHANICAL MFG CO LTD

Independent oil supply sliding bearing with changeable pads and compressor equipped with bearing

The invention discloses an independent oil supply sliding bearing with changeable pads. The independent oil supply sliding bearing comprises a bearing body and the pads which are concentric, wherein the bearing body comprises an inner contact surface provided with a plurality of grooves, each pad comprises an outer arc-shaped plate, each outer arc-shaped plate comprises an outer contact surface which is in seamless contact with the inner contact surface, a boss which is in interference fit with the groove is arranged on each outer contact surface, an inner arc-shaped plate is fixedly connected at the midline on the inner side of each outer arc-shaped plate, and the pads are symmetrical by taking the central axis of the bosses as the symmetrical axle; the number of the grooves corresponds to that of the pads; and a plurality of oil inlet rods are distributed on the bearing body and penetrate through the bearing body. According to the independent oil supply sliding bearing disclosed by the invention, only the pads which are simple in structure and low in cost need to be replaced; furthermore, the processing precision is reduced, and the using requirements can be met by only ensuring the processing precision and the hardness requirements on the contact surface between each pad and the bearing; and the oil inlet rods are simple in structure and convenient to mount, and a gap between each oil guide rod and a shaft can be adjustable.

Owner:SANY ENVIRONMENTAL PROTECTION TECH CO LTD

Hard alloy coating layer capable of being totally dissolved in water medium and preparation method and application thereof

The invention discloses a hard alloy coating layer capable of being totally dissolved in a water medium and a preparation method and application thereof. The hard alloy coating layer consists of dissoluble alloy powder and hard alloy powder; the dissolving speed is proper; and the hardness is high. The preparation method comprises the following steps: the hard alloy powder and the dissoluble alloypowder are uniformly mixed for spraying to workpieces through a plasma spraying, flame spraying or supersonic spraying process to obtain the hard alloy coating layer; and the combination with basal bodies is excellent. The hard alloy coating layer can be applied to the surface protection of tools or parts used in the oil and gas field fracturing modification construction, can be totally dissolvedafter construction to save subsequent grinding and milling procedures, facilitates flowback, and improves the construction efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Repair material for automobile dashboard foaming bodies

The invention relates to a repair material for automobile dashboard foaming bodies. The adopted technical scheme is as follows: the repair material is composed of a component A and a component B, wherein the component A is composed of the following ingredients in parts by weight: 100 parts of polyether polyols, 1.7-2 parts of crosslinking agent, 0.4-0.9 part of polyurethane amine catalyst, 0.3-0.4 part of silicone oil, and 2-2.5 parts of hole-opening agent; and the component B is isocyanate. A repair method is implemented through taking the repair material, mixing the component A and the component B in a weight ratio 10:1, fully stirring 10-15 seconds, feeding the mixed material into an injector through inhaling, injecting the mixed material into the defective positions of dashboard foaming bodies until the positions are filled with the mixed material, and curing the mixed material for 0.5-1 hour. According to the invention, defects of foaming bodies can be repaired without affecting the quality of products.

Owner:SHENYANG JINBEI YANFENG AUTOMOTIVE INTERIOR SYST CO LTD

Chafing dish bottom material and making method thereof

The invention relates to a chafing dish bottom material and a making method thereof. The chafing dish bottom material comprises the following raw materials of beef tallow for the chafing dish bottom material, a thick broad-bean sauce, old ginger, garlic, Ciba hot peppers, a soybean sauce similar with fermented soya beans, red peppercorns, edible oil, yellow wine, spice, pepper fruits, edible salt, white sugar, monosodium glutamate, I+G, chafing dish mate, ethyl maltol, chive oil, oil for a spiced chicken with a chili sauce, and flavored protein cream. The making method comprises the following steps of I, putting the beef tallow for the chafing dish bottom material in a bottom material pot, and performing melting to obtain a mixture I; II, putting the Ciba hot peppers to the mixture I in the step 1 to obtain a mixture II; III, adding the thick broad-bean sauce, the old ginger, the garlic, the soybean sauce similar with fermented soya beans and the yellow wine to the mixture II in the step II to obtain a mixture III; IV, adding the edible salt and the white sugar to the mixture III in step III to obtain a mixture IV; step V, adding the red peppercorns to the mixture IV in step IV to obtain a mixture V; step VI, heating the edible oil, and sprinkling the heated oil to the mixture V in step V, and turning off the fire to obtain a mixture VI; step VII, adding the chafing dish mate to the mixture VI in step VI; VIII, adding the ethyl maltol to the mixture VII in step VII to obtain a mixture VIII; step IX, adding the chive oil, the oil for a spiced chicken with a chili sauce and the flavored protein cream to the mixture VIII in step VIII to obtain a mixture IX; and step X; adding the monosodium glutamate and the I+G to the mixture IX in step IX. The scheme not only can guarantee the color of the chafing dish bottom material, but also can guarantee the hardness of the chafing dish bottom material.

Owner:重庆市长寿区可又可食品有限公司

Efficient edge banding machine for PVC foam board

PendingCN113001629AEasy to cutPrevent jumpingEdge grinding machinesMetal working apparatusStructural engineeringEdge banding

The invention provides an efficient edge banding machine for a PVC foam board. The efficient edge banding machine comprises a conveying mechanism, a pressing mechanism and an edge banding saw mechanism; the conveying mechanism comprises a feeding assembly and a discharging assembly; the edge banding saw mechanism is arranged between the feeding assembly and the discharging assembly and comprises an edge banding saw support and a saw blade assembly arranged on the edge banding saw support, the saw blade assembly comprises a high-steel saw blade, and the inclination of the high-steel saw blade is 30 degrees; the edge banding saw mechanism further comprises a control module used for controlling the rotating speed of the high-steel saw blade; the pressing mechanism comprises a pressing assembly and a positioning module and is used for positioning and pressing the board. The edge banding efficiency is improved, the technical problem of low edge banding efficiency of the board is solved, use of edge banding strips is reduced, and the cost is saved.

Owner:POTENTECH GUANGDONG

Environment-friendly magnesium dry material and its preparation process

The present invention adopts the following environment-friendly magnesium dry material, including a mass ratio of 60-75:20-30:8-10:15-25:8-12:2-4.5:1-2:0.5-1.5 : 0.8~1.2 sintered magnesia, fused magnesia, calcium magnesium olivine, binder, aluminum hydroxide powder, high temperature sintering agent, expansion agent, floating beads, bentonite. The invention optimizes the distribution ratio of each component of the dry material, adopts an environmentally friendly binder, can effectively solve the problem that the binder decomposes into toxic and harmful substances under high temperature conditions, is more energy-saving and environmentally friendly, and makes the dry material useless during use. The pungent taste is more conducive to the production environment, and it can also ensure the hardness requirements of the dry material during use and ensure its erosion resistance.

Owner:浙江欣辉耐火材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com