Preparation method of high-precision powder metallurgy rubber-coated gear

A powder metallurgy, high-precision technology, applied in the field of powder metallurgy, can solve the problems of poor sealing effect or oil removal effect, high processing cost, porous holes, etc., and achieve the effect of good sealing effect and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

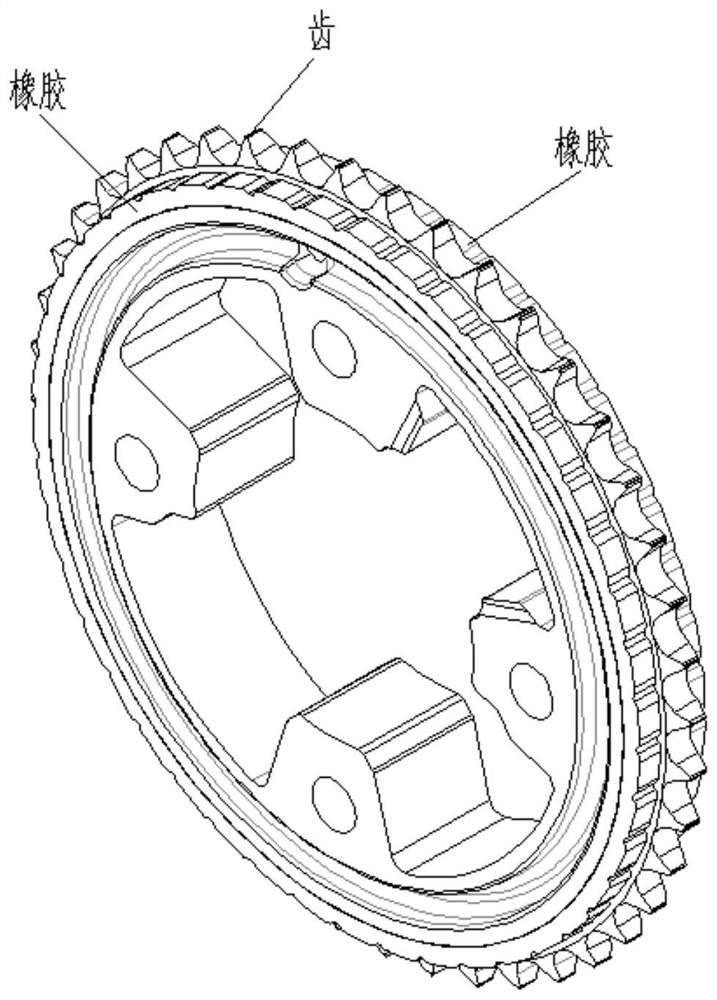

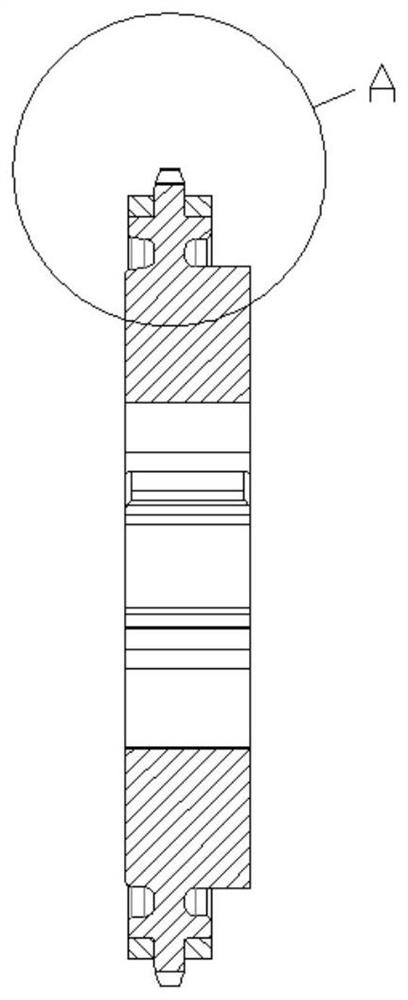

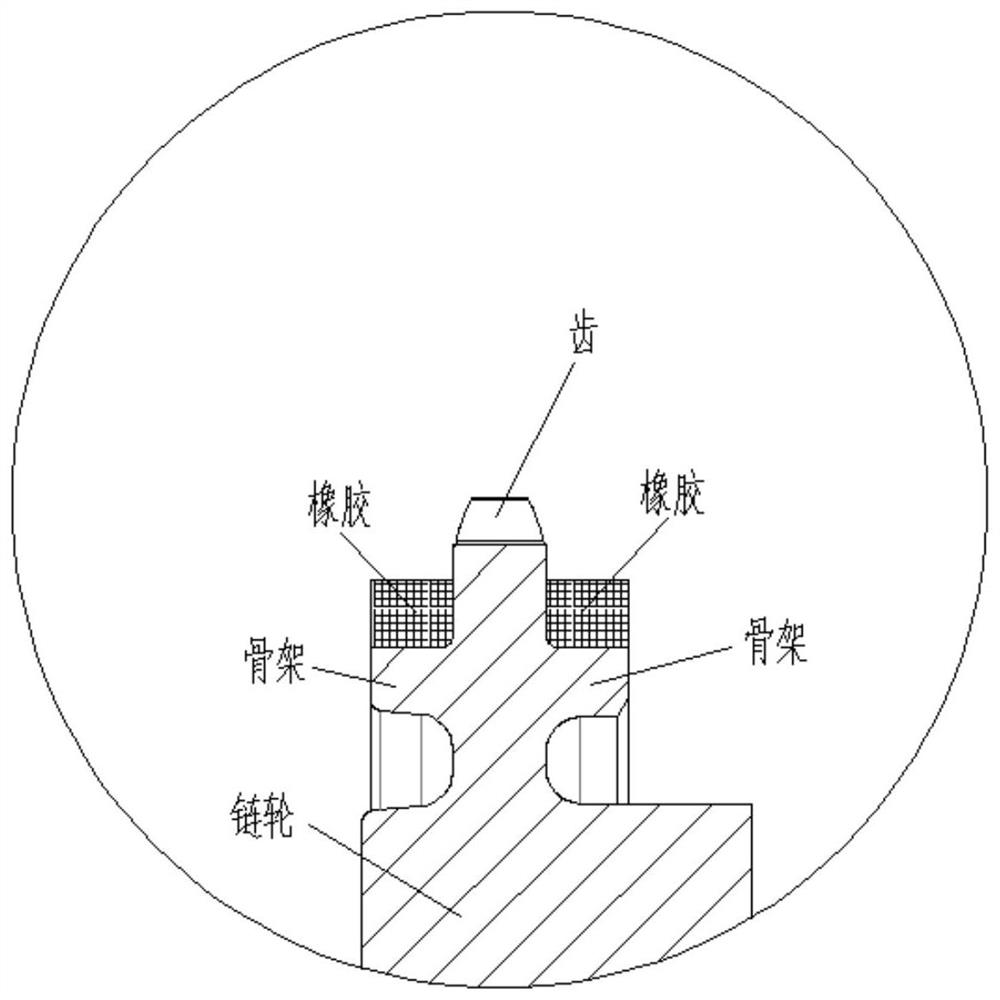

[0040] like figure 1 As shown, the rubber-coated stator sprocket with variable valve timing of the engine, the preparation method for making this high-precision rubber-coated stator sprocket includes the following steps in sequence:

[0041] 1. Mixing: Mix the following raw materials evenly according to the mass percentage: C: 0.75%, Cu: 1.8%, powder lubricant: 0.6%, Fe: the balance, and use a powder mixer to fully stir the mixture. Under this condition, the powder is evenly mixed and bonded together, and it is not easy to segregate.

[0042] 2. Forming: The mixed powder raw material is molded in a mold to obtain the stator sprocket green body, the pressing pressure is 680MPa, and the forming density is 7.0g / cm3.

[0043] 3. Sintering: Place the above-mentioned stator sprocket green body in a sintering furnace for sintering, the sintering temperature is 1120°C, and keep warm in a protective atmosphere, the protective atmosphere is N2 and H2, and the holding time is 30 minutes...

Embodiment 2

[0065] A rubber-covered crankshaft sprocket is manufactured, and the preparation method of the rubber-coated crankshaft sprocket comprises the following steps in sequence:

[0066] 1. Mixing: mix the following raw materials evenly according to the mass percentage: C: 0.75%, Cu: 1.8%, powder lubricant: 0.6%, Fe: the balance, the mixing method is to use the existing mixer to ensure uniformity .

[0067] 2. Forming: Mold the mixed powder raw materials in the mold to obtain the crankshaft sprocket green body. The pressing pressure is above 600MPa to ensure that the forming density is greater than 6.9g / cm 3 .

[0068] 3. Sintering: Put the crankshaft sprocket green body above into a sintering furnace for sintering, the sintering temperature is 1120°C±20°C, and keep warm in a protective atmosphere, the protective atmosphere is CO and H 2 , the holding time is 30 minutes, so that sintered necks are formed between the crankshaft sprocket green particles.

[0069] 4. Brushing edge: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com