Bending axis for forming underwear back button

A technology for bending shafts and underwear, applied in the field of bending shafts for forming underwear back buckles, can solve the problems of troublesome head processing and grinding, difficult to ensure product qualification, high production costs, saving high-quality steel, reducing production and use costs, Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

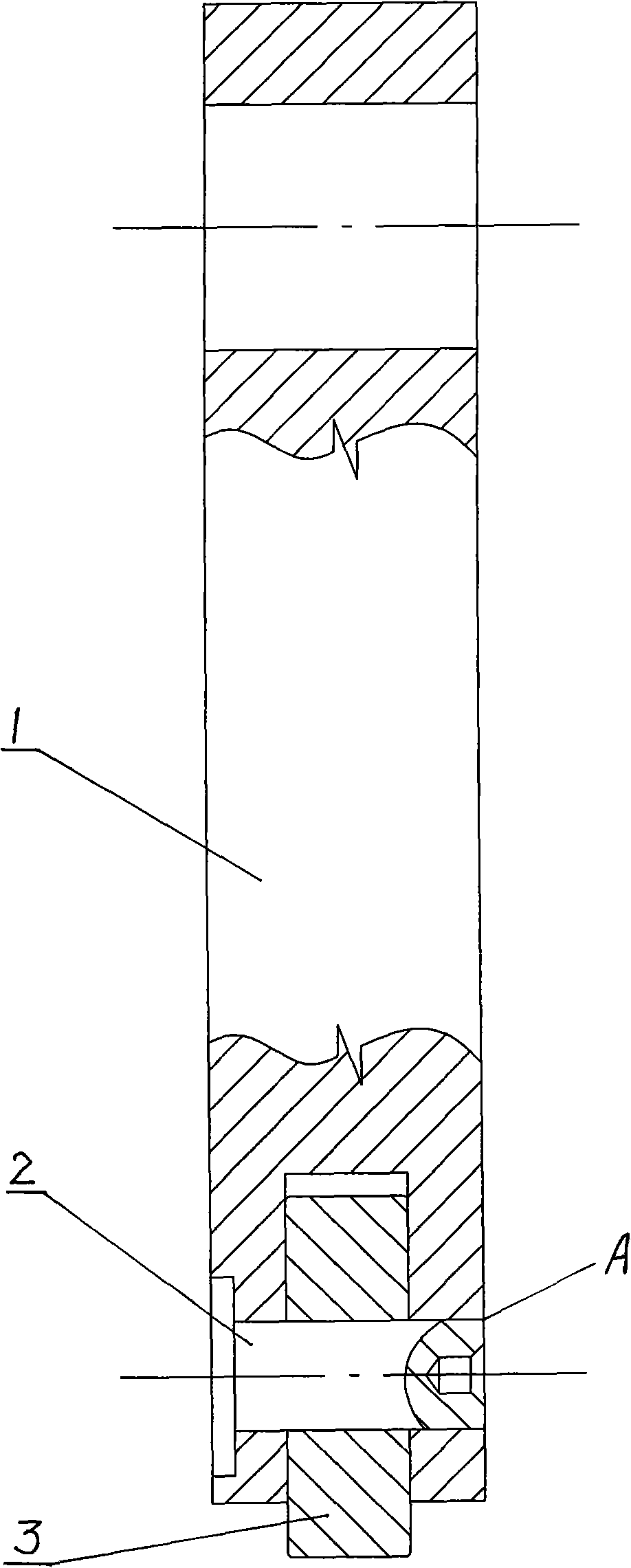

[0008] Referring to the accompanying drawings, a pressure roller 3 is arranged in the opening groove of the head of the bending shaft body 1. The pressure roller is disc-shaped and rotatably fits with the mandrel 2, and a part of the pressure roller is exposed outside the opening groove. The mandrel 2 is tightly matched with the bent shaft body, and is riveted at its tail end A. The pressure roller 3 is made of tungsten carbide material, and the bent shaft body 1 is made of high carbon steel material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com