Aluminizing method of GH4049 ball

A technology of aluminizing and spheres, which is applied in the field of GH4049 sphere aluminizing, can solve the problems that the hardness is difficult to meet the design requirements, increase the difficulty of heat treatment, and difficult to guarantee the hardness value, etc., achieve good production verification results, reduce the risk of hardness, and shorten production the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

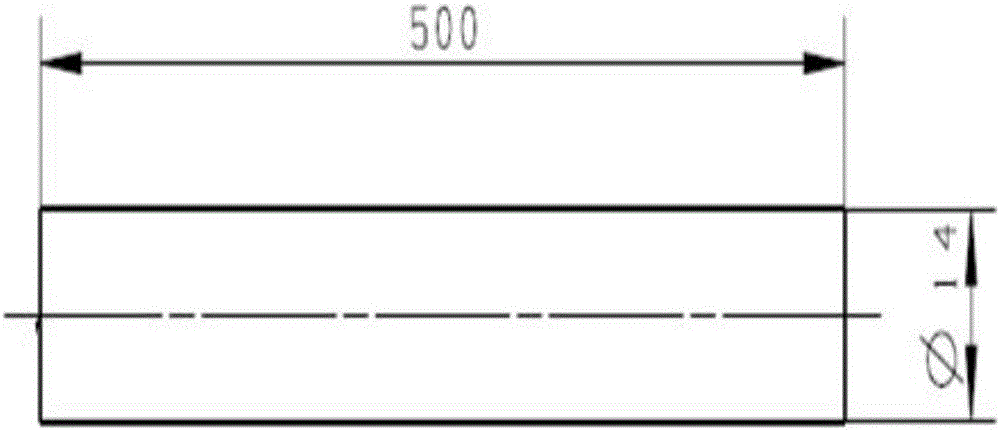

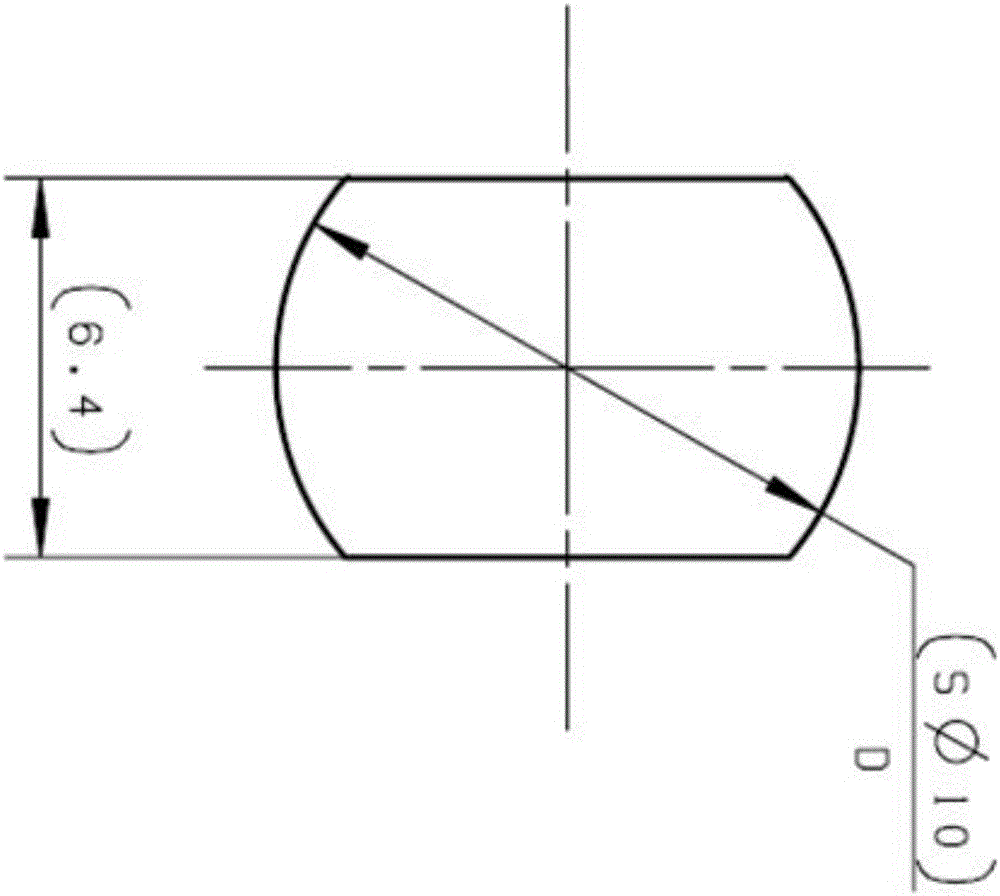

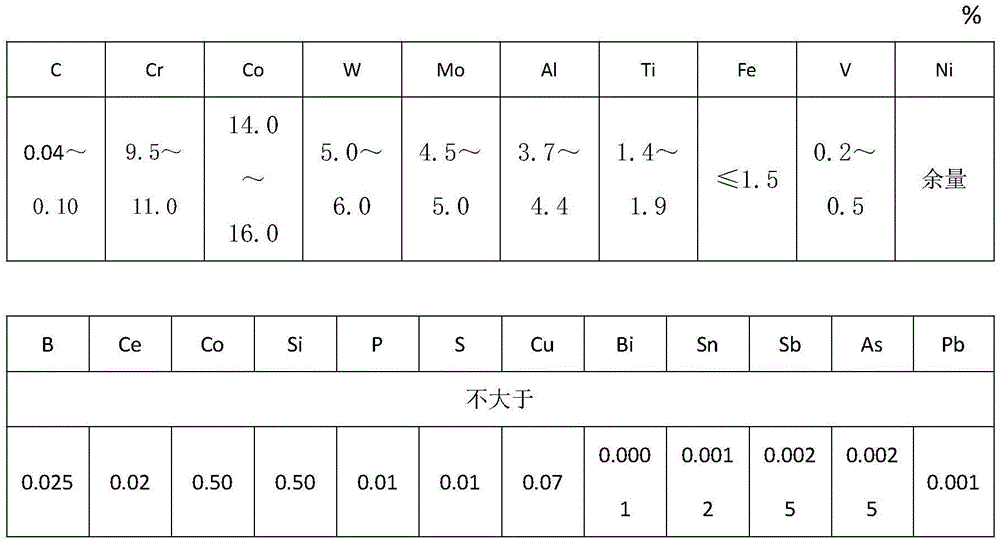

[0021] Such as figure 1 and 2 As shown, the traditional heat treatment scheme is to first figure 1 The rough blank shown (the cross-sectional diameter of the round bar blank is Ф14mm, the length is 500mm, the chemical composition of the blank is as follows image 3 Shown) for solid solution + aging treatment, to ensure the hardness HB285 ~ 352, after the parts are processed to figure 2 When the shape is shown (the diameter of the spherical surface D is Ф10mm, and the distance between a pair of parallel planes is 6.4mm), then aluminized. The disadvantage is that the hardness of the parts and the depth of the aluminized layer will be affected during the subsequent aluminizing, and the required hardness value and depth of the aluminized layer will not be reached.

[0022] The heat treatment method of the present invention has broken the train of thought of tradition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com