Hot-press-free antibacterial and anti-scraping optical explosion-proof film

An explosion-proof film and optical technology, applied in the direction of film/sheet adhesive, adhesive type, polyether adhesive, etc., can solve the problem of insufficient scratch resistance and wear resistance, no antibacterial performance, and low service life To achieve the effect of improving mechanical properties, shortening production and processing costs, and improving interface interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

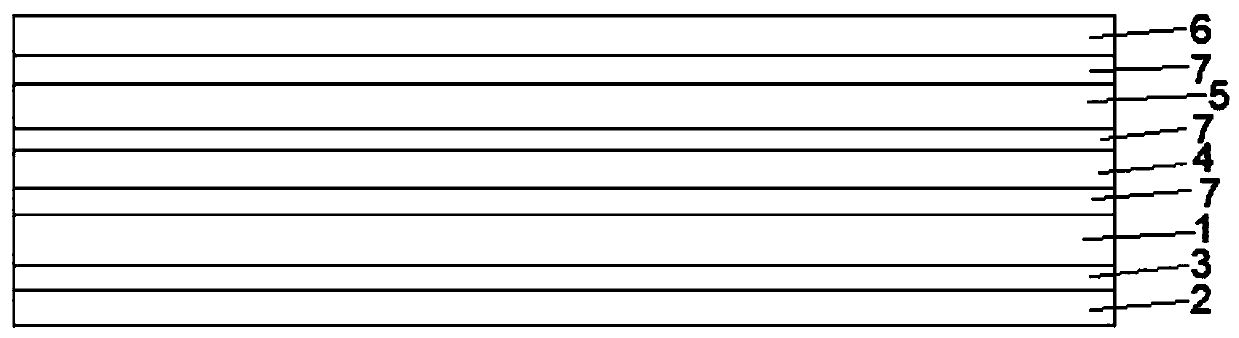

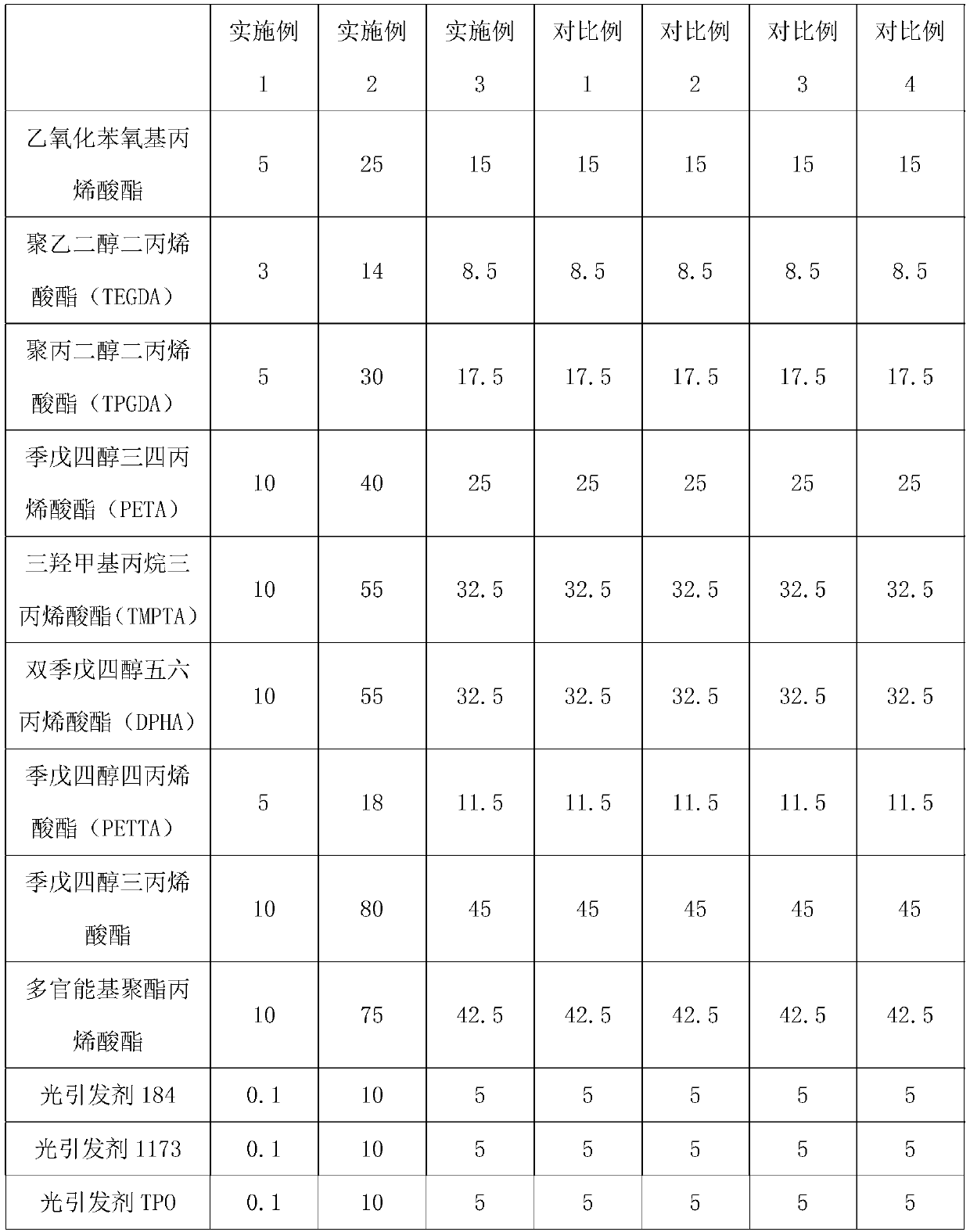

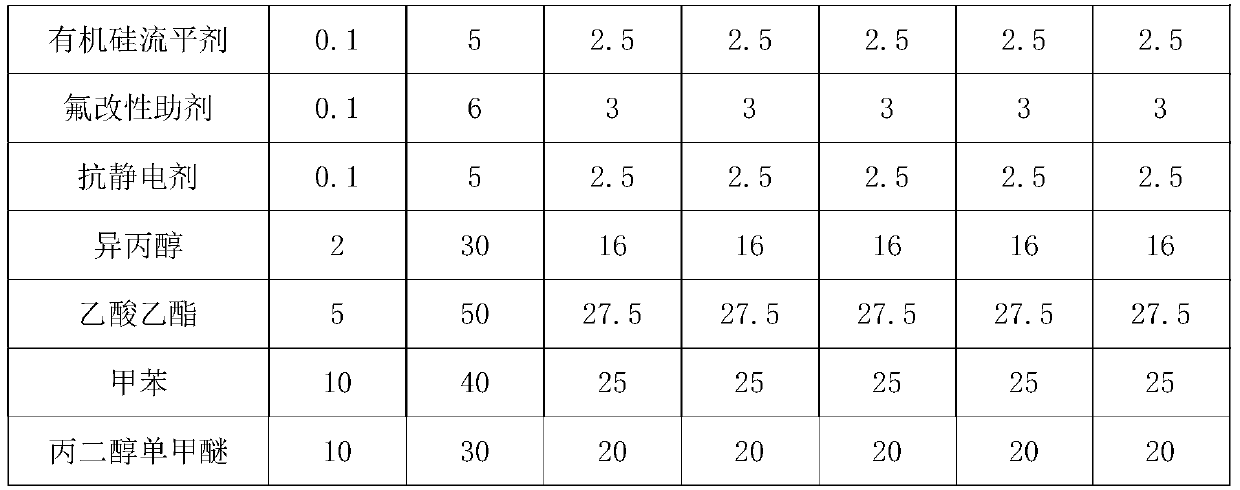

[0020] Such as figure 1 As shown, the present invention discloses a heat-free antibacterial anti-scratch optical explosion-proof film, which includes an optical-grade PET substrate 1 with a thickness of 60-150 μm, which is conducive to ensuring the hardness requirement, and the light transmittance is ≥ 90%. The surface of the PET substrate 1 is corona-treated, and the lower surface of the corona-treated PET substrate 1 is coated with a UV-curable adhesive layer 3, and the lower end of the UV-curable adhesive layer 3 on the lower surface of the PET substrate is compounded with a release film layer 2 , the upper surface of the PET substrate 1 is sequentially compounded with a TPU film layer 4, an explosion-proof structure layer 5 and an anti-bacterial, scratch-resistant and wear-resistant protective layer 6, and the TPU film layer 4, the explosion-proof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com