Modified fly ash for plastic filling and reinforcement and preparation method thereof

A technology of filling reinforcement and fly ash, which is applied in the field of modified fly ash and its preparation, can solve the problems of insignificant metal oxide treatment effect, insignificant improvement of material physical properties, uneven modification of fly ash, etc. , to achieve the effects of reducing stress concentration and defects, improving mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

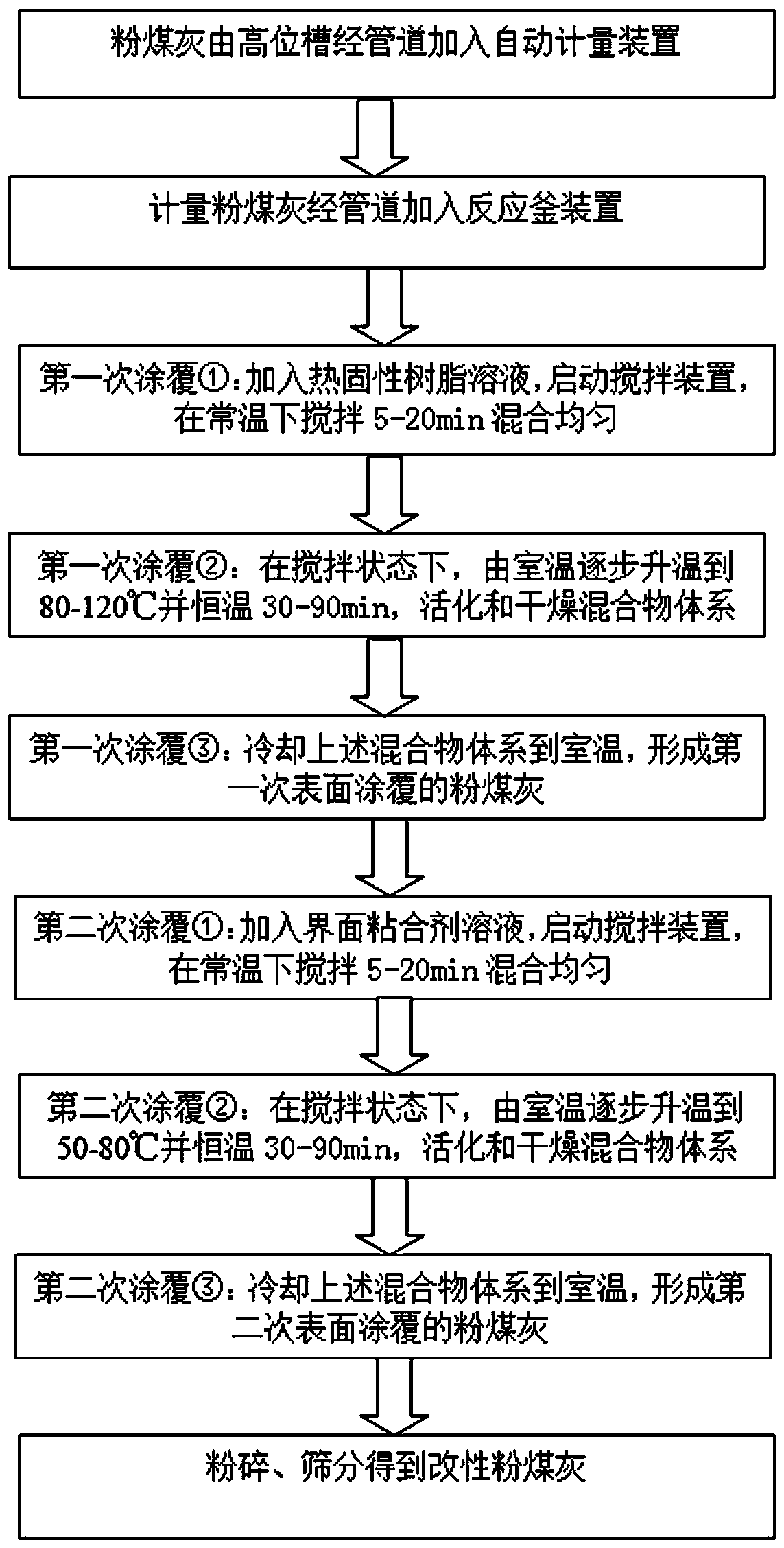

[0032] Such as figure 1 The flow chart of a modified fly ash used for plastic filling and reinforcement is shown. First, the fly ash, thermosetting resin solution and interface enhancer emulsion are respectively reinforced by the fly ash head tank, thermosetting resin solution head tank and interface reinforcement. The high level tank of the agent emulsion is added to the respective automatic metering device through the pipeline for metering; firstly, 100 parts by weight of fly ash after metering is added into the reactor device through the pipeline; Resin solution, wherein the raw materials and weight ratio of the thermosetting resin solution are: thermosetting resin: solvent = 100: 150; stir and mix the fly ash and the thermosetting resin solution in the reactor for 5 minutes, then heat up to 80°C, react and dry After 90 minutes, cool to room temperature to obtain the first coating of fly ash; then add 5 parts by weight of the measured interface enhancer emulsion to the mixt...

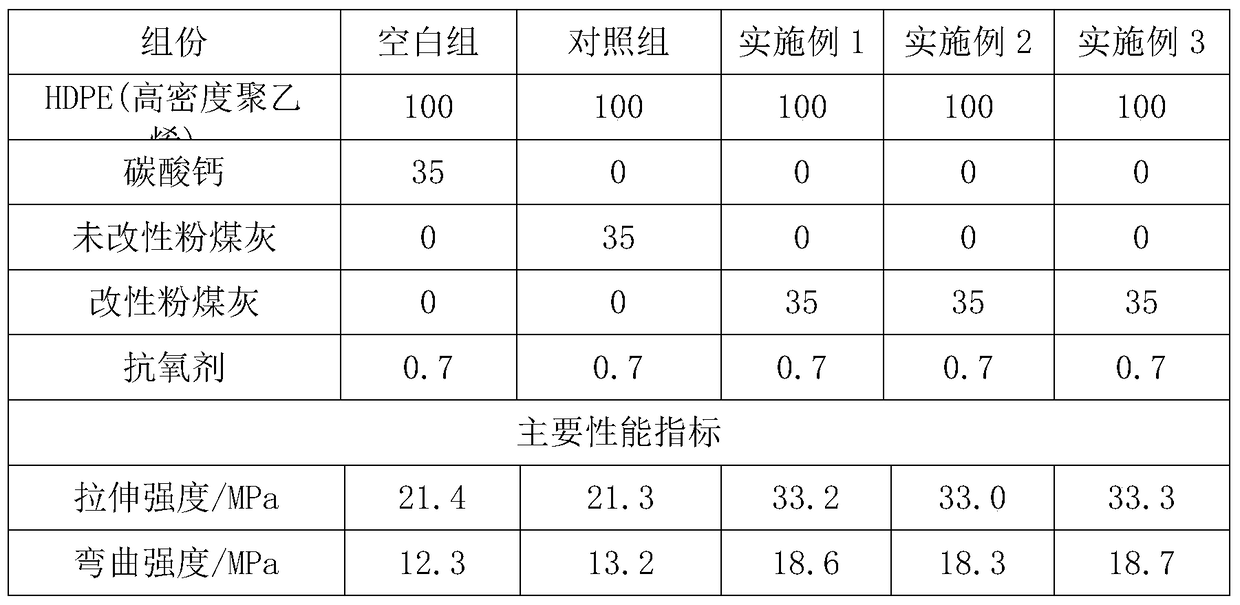

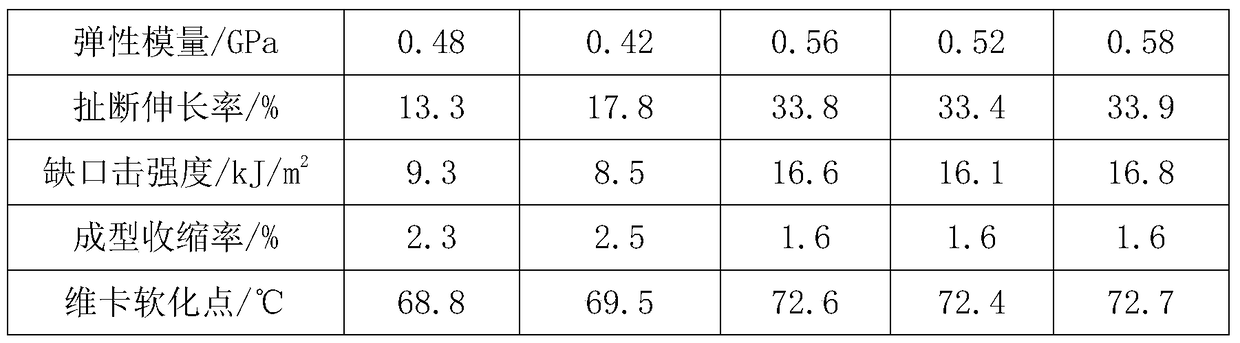

example 1

[0033] The application method of modified fly ash in plastic composites in example 1, by weight, add 35 parts of modified fly ash of the present embodiment, 100 parts of HDPE (high density polyethylene) in high-speed mixer , and 0.7 parts of antioxidant, mixed at room temperature for 15 minutes to obtain the initial mixture, and then the initial mixture was sucked into the high-level storage tank, and then added to the twin-screw extruder, and conveyed, compressed, melted and extruded into strips, after cooling Granulating to obtain the modified fly ash HDPE plastic composite material.

Embodiment 2

[0035] Such as figure 1 The flow chart of a modified fly ash used for plastic filling and reinforcement is shown. First, the fly ash, thermosetting resin solution and interface enhancer emulsion are respectively reinforced by the fly ash head tank, thermosetting resin solution head tank and interface reinforcement. The high-level tank of the agent emulsion is added to the respective automatic metering device through the pipeline for metering; firstly, 100 parts by weight of the measured fly ash is added to the reactor device through the pipeline; then 30 parts by weight of the measured thermosetting Resin solution, wherein the raw materials and weight ratio of the thermosetting resin solution are: thermosetting resin:solvent=100:400; stir and mix the fly ash and the thermosetting resin solution in the reactor for 20min, then heat up to 120°C, react and dry After 30 minutes, cool to room temperature to obtain the first coating of fly ash; then add 20 parts by weight of the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com