A kind of preparation method of polylactic acid modified material

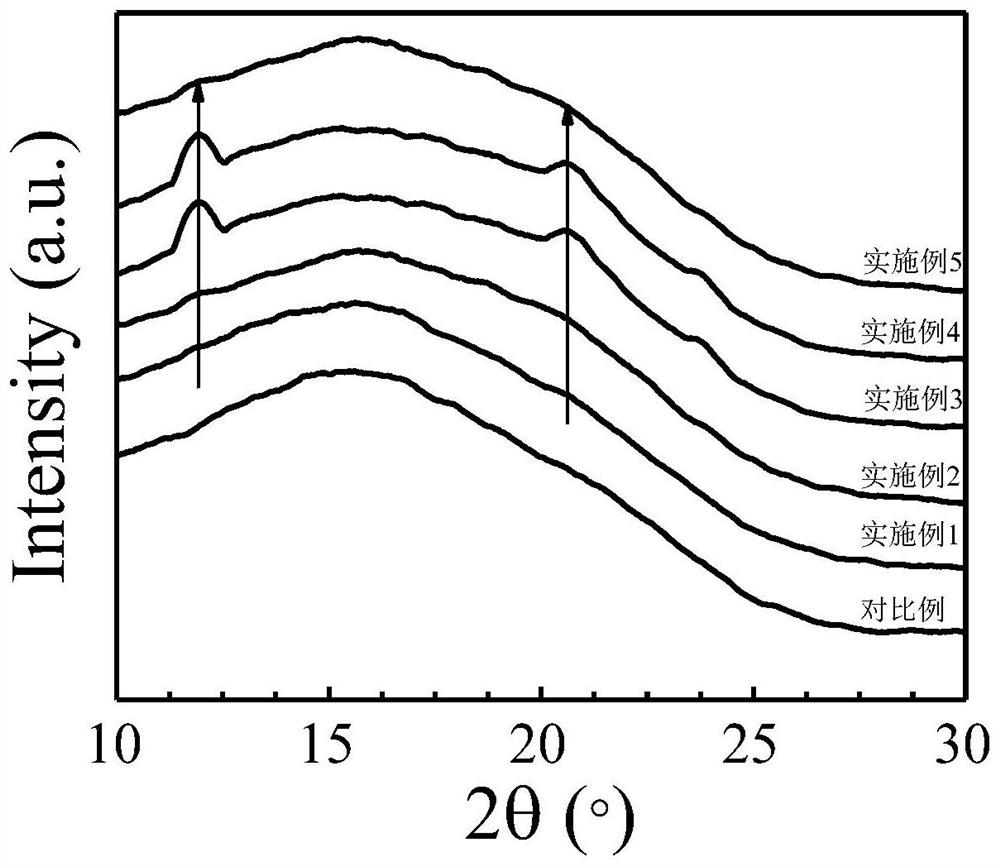

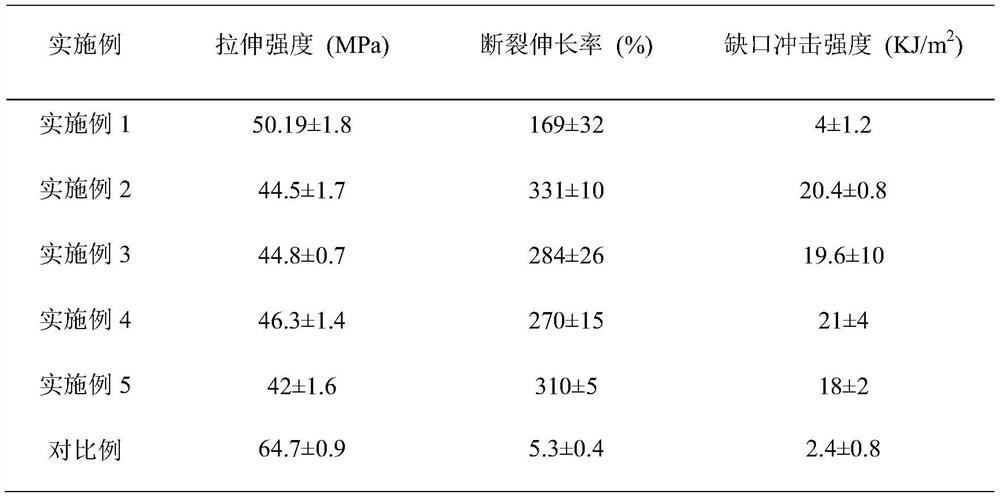

A modified material and polylactic acid technology, applied in the field of preparation of polylactic acid modified materials, can solve the problems of low grafting efficiency, cumbersome preparation process, etc., and achieve the effects of strong controllability, simple and easy method, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

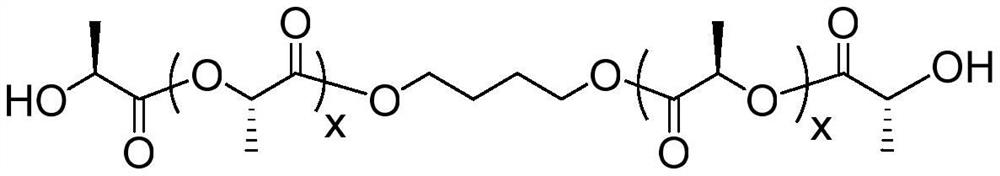

[0027] 1. In the glove box, add dry D-lactide, 1,4-butanediol and stannous octoate into the reactor, and react at 120°C for 12 hours under the protection of nitrogen atmosphere; Dissolved, then added to 10 times the mass of chloroform in cold methanol at 10°C, filtered after precipitation, and vacuum-dried at 60°C for 24 hours to obtain D-polylactic acid diol with a molecular weight of 2000g / mol, D-lactide and 1 , The mass ratio of 4-butanediol is 20:1, and the molar weight of stannous octoate is 0.1% of the molar weight of D-lactide.

[0028] 2. Dissolve the dry polycaprolactone diol and the D-polylactic acid diol prepared in step 1 in a molar ratio of 3:1 in toluene, then add hexamethylene diisocyanate and dilauric acid Dibutyltin acid, heated to 80°C for 6 hours to obtain isocyanate group-terminated polyurethane prepolymer; then add 1,4-butanediol to the reaction solution, and react at 80°C for 10 hours to obtain D-polylactic acid-containing polyurethane elastomer;

[002...

Embodiment 2

[0032] 1. In the glove box, add dry D-lactide, 1,4-butanediol and stannous octoate into the reactor, and react at 120°C for 12 hours under the protection of nitrogen atmosphere; Dissolved, then added to 10 times the mass of chloroform in cold methanol at 10°C, filtered after precipitation, and vacuum-dried at 60°C for 24 hours to obtain D-polylactic acid diol with a molecular weight of 2000g / mol, D-lactide and 1 , The mass ratio of 4-butanediol is 20:1, and the molar weight of stannous octoate is 0.1% of the molar weight of D-lactide.

[0033] 2. Dissolve the dry polycaprolactone diol and the D-polylactic acid diol prepared in step 1 in a molar ratio of 3:1 in toluene, then add hexamethylene diisocyanate and dilauric acid Dibutyltin acid, heated to 80°C for 6 hours to obtain isocyanate group-terminated polyurethane prepolymer; then add 1,4-butanediol to the reaction solution, and react at 80°C for 10 hours to obtain D-polylactic acid-containing polyurethane elastomer;

[003...

Embodiment 3

[0037] 1. In the glove box, add dry D-lactide, 1,4-butanediol and stannous octoate into the reactor, and react at 120°C for 12 hours under the protection of nitrogen atmosphere; Dissolved, then added to 10 times the mass of chloroform in cold methanol at 10°C, filtered after precipitation, and vacuum-dried at 60°C for 24 hours to obtain D-polylactic acid diol with a molecular weight of 2000g / mol, D-lactide and 1 , The mass ratio of 4-butanediol is 20:1, and the molar weight of stannous octoate is 0.1% of the molar weight of D-lactide.

[0038] 2. Dissolve the dry polycaprolactone diol and the D-polylactic acid diol prepared in step 1 in a molar ratio of 3:1 in toluene, then add hexamethylene diisocyanate and dilauric acid Dibutyltin acid, heated to 80°C for 6 hours to obtain isocyanate group-terminated polyurethane prepolymer; then add 1,4-butanediol to the reaction solution, and react at 80°C for 10 hours to obtain D-polylactic acid-containing polyurethane elastomer;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com