Pervious concrete

A technology of permeable concrete and water reducing agent, which is applied in the field of building materials to achieve significant temperature peaks, small thermal expansion coefficients, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

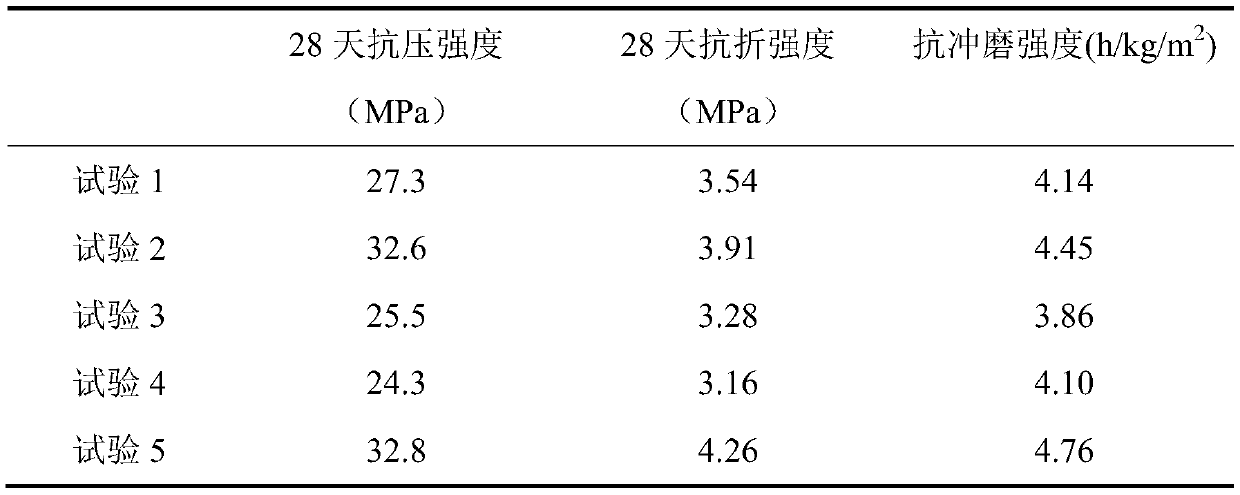

Examples

Embodiment 1

[0045] This embodiment provides a kind of permeable concrete. According to the mass parts, the permeable concrete is prepared from the following components: 1500kg of limestone aggregate, 240kg of cement, 32kg of silica fume, 32kg of silicon nitride, 16kg of fly ash, water reducing Agent 4.5kg and water 105kg.

Embodiment 2

[0047] This embodiment provides a kind of permeable concrete. According to the mass parts, the permeable concrete is prepared from the following components: 1542kg of granite aggregate, 257kg of cement, 37kg of silica fume, 37kg of silicon nitride, 37kg of fly ash, water reducing Agent 5.1kg and water 110kg.

Embodiment 3

[0049] This embodiment provides a kind of permeable concrete. According to the parts by mass, the permeable concrete is prepared from the following components: 1600kg of basalt aggregate, 273kg of cement, 42kg of silica fume, 42kg of silicon carbide, 63kg of fly ash, and water reducer 5.9kg and 114kg of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com