Semi-finished pre-grinding vertical-milling and ball-milling combined grinding device

A combined grinding and pre-grinding technology, applied in the field of cement grinding, can solve the problems of main fan wear, difficult maintenance, large power consumption, etc., and achieve reasonable cement particle gradation, good grinding particle shape, and maintenance handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

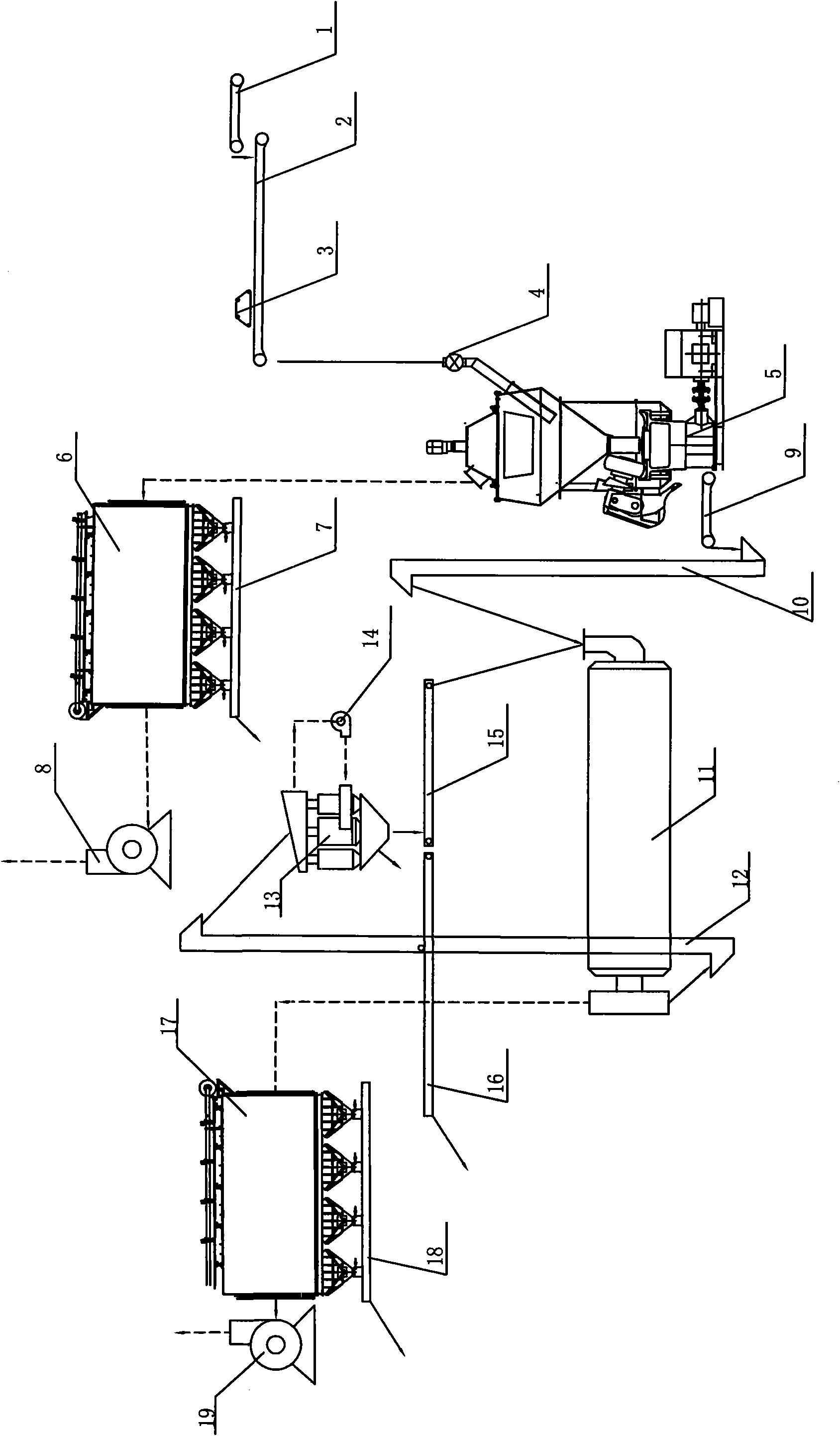

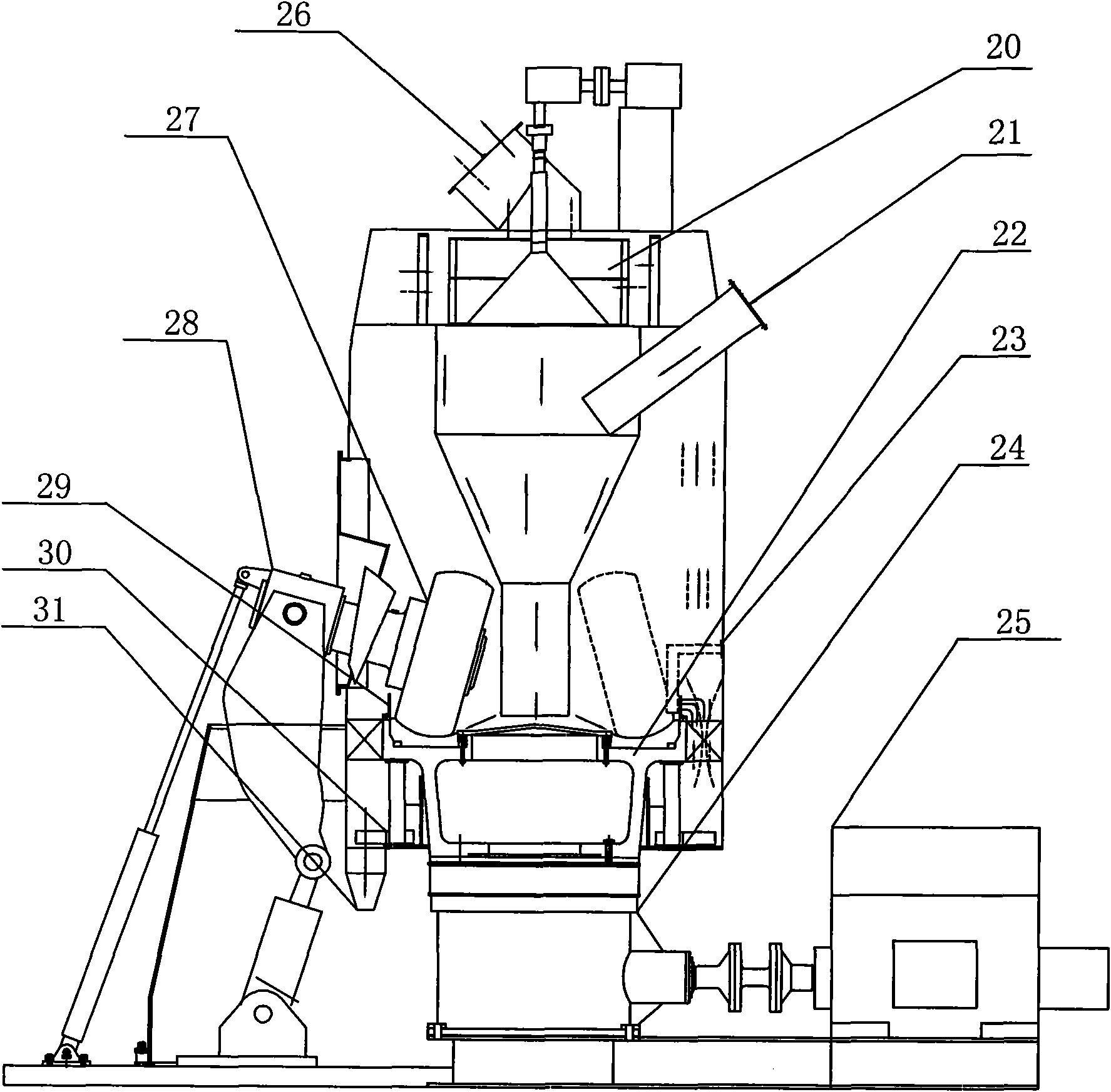

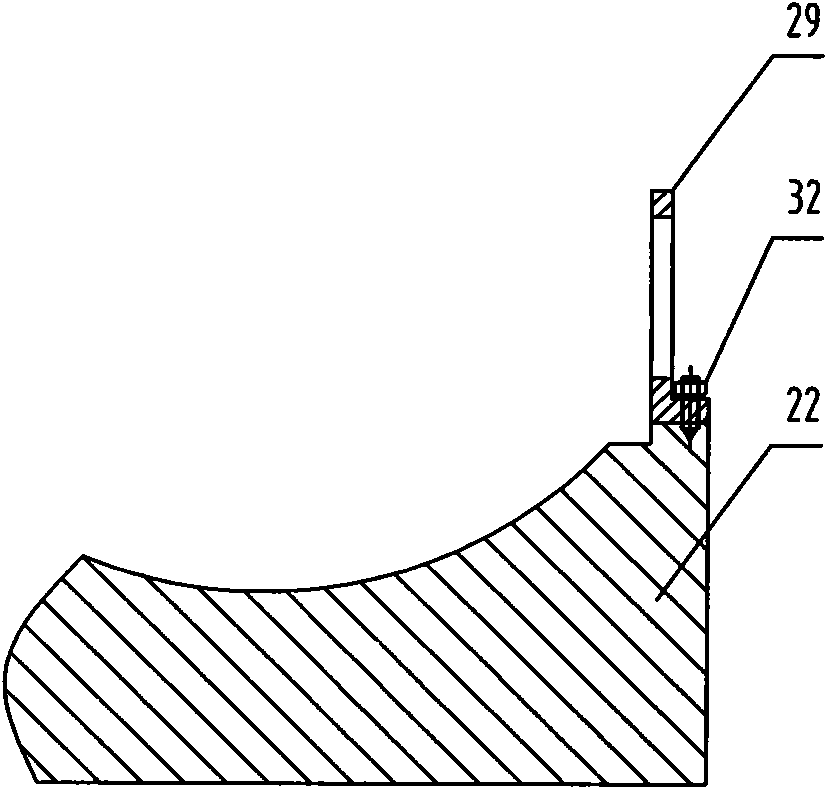

[0022] This embodiment is a semi-final pre-grinding vertical mill and ball mill combined grinding device, the structure is as follows figure 1 As shown, it includes a semi-final pre-grinding vertical mill 5 and a ball mill 11. The structure of the semi-final pre-grinding vertical mill 5 is as follows figure 2 As shown, it includes powder separator 20, material inlet 21, grinding disc 22, upper scraper 23, reducer 24, main motor 25, air outlet 26, grinding roller 27, rocker arm 28, lower scraper 30 and semi-finished product discharge Mouth 31, grinding disc 22 is installed on the transmission device that is made up of main motor 25 and reduction mobility 4, and grinding roller 27 is installed on the rocking arm 28. The material enters the semi-final pre-grinding vertical mill through the material inlet 21. The outer edge of the grinding disc 22 is provided with a grid ring 29, and the connection between the grinding disc and the grid ring is as follows: image 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com