Construction waste sand-making equipment

A construction waste and equipment technology, applied in the field of construction waste sand making equipment, can solve the problem of not specifying the use method of construction waste machine-made sand in detail, and achieve the effect of good particle shape and reasonable gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

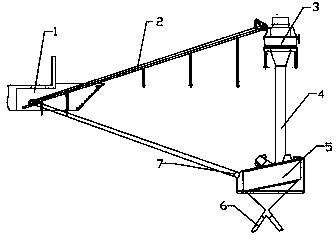

[0020] A construction waste sand making equipment of the present invention will be described in detail below with reference to the accompanying drawings.

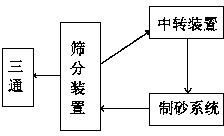

[0021] Such as figure 1 , figure 2 As shown, a construction waste sand making equipment of the present invention has a structure including a transfer device 1, a sand making system 3, a screening device 5 and a tee 6. The transfer device 1 can be a ground bin, a hopper, etc., which are used for storing The amount of construction waste stones and ordinary stones can be adjusted according to the amount of material returned by the sand making machine. The transfer device 1 is connected to the sand making system 3 through the belt conveyor 2, the sand making system 3 is connected to the screening device 5 through the conveying device 4, the screening device 5 is connected to the tee 6, and the screening One side of the sub-device 5 is provided with a material return port, and the material return port is connected with the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com