Automatic shaping device for paper pouring gate pipe

A technology of shaping device and sprue pipe, applied in textile and papermaking, dry gas arrangement, mechanical processing/deformation, etc., can solve the problems of increased outer surface finish, uneven thickness of pipe wall, etc., and achieves improved strength, high hardness, Uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

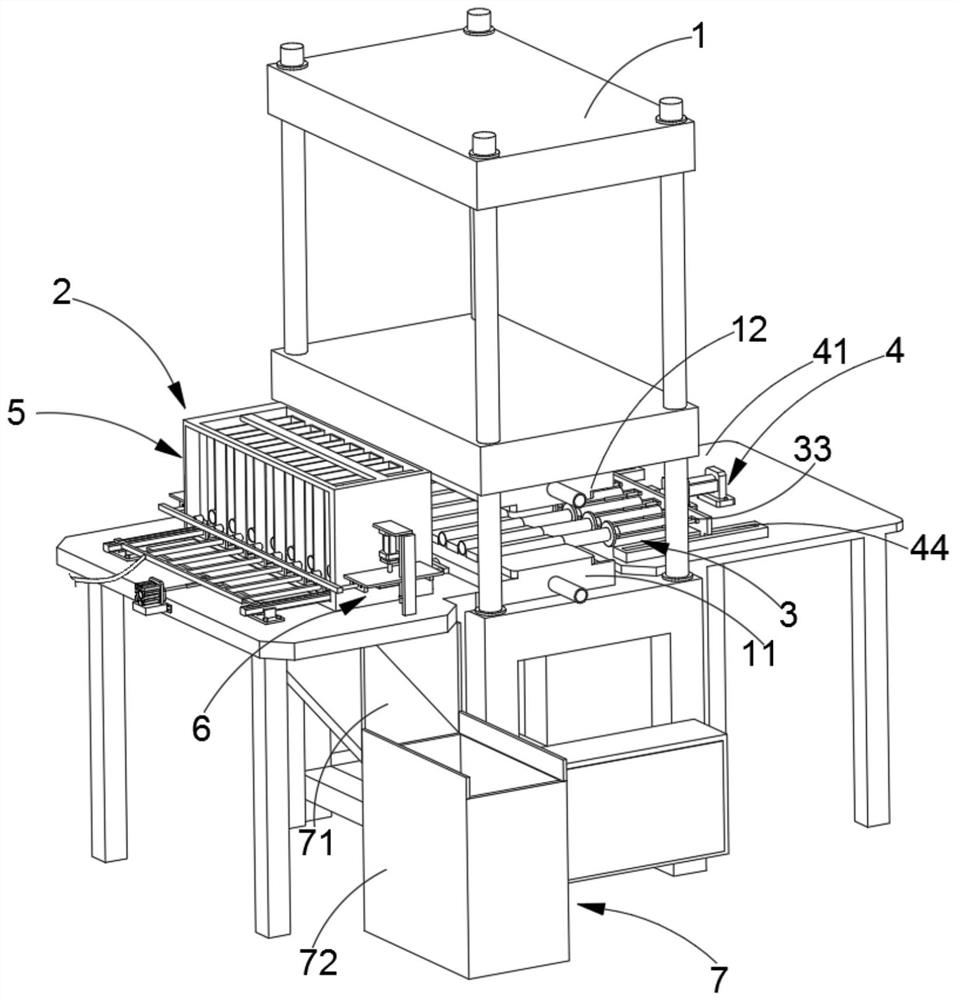

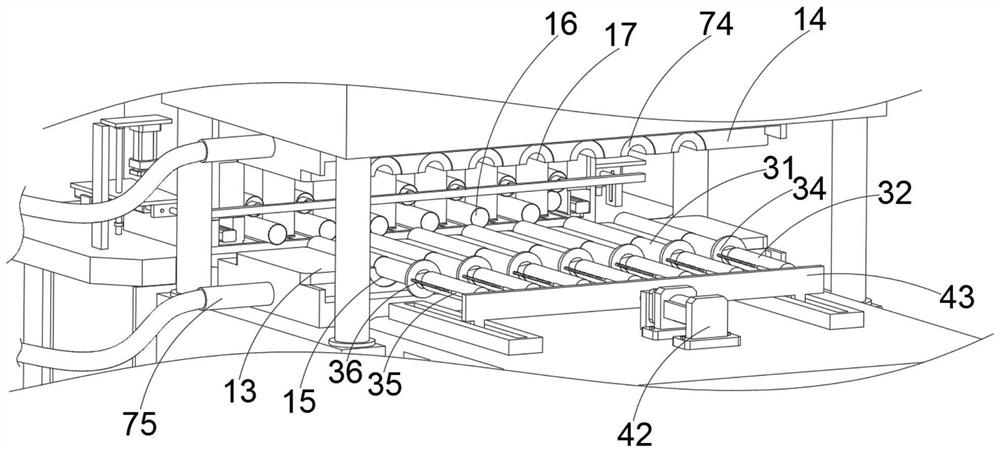

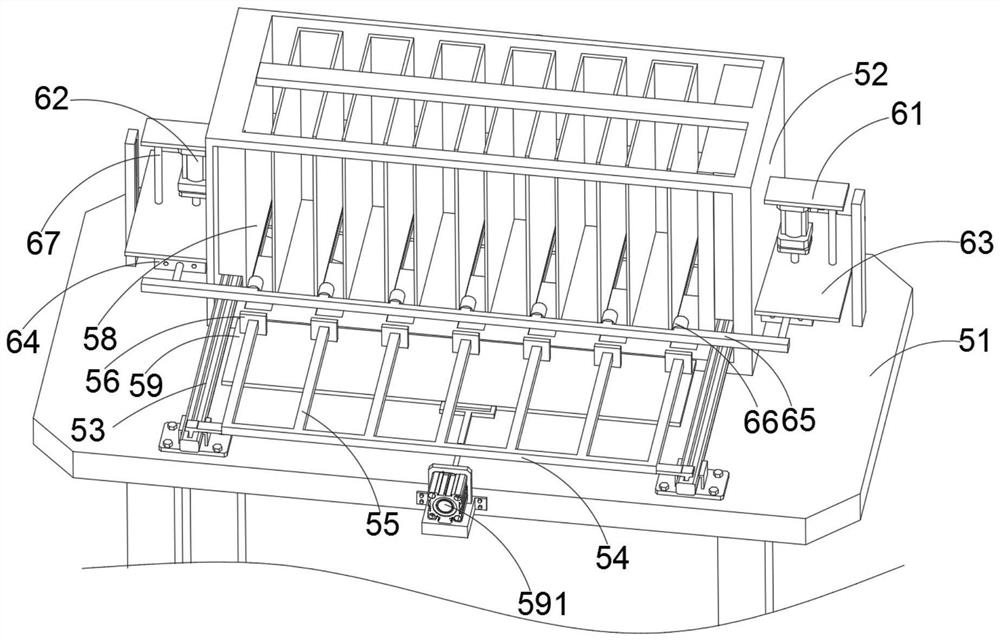

[0032] Such as Figure 1 to Figure 8 As shown, a kind of automatic shaping device of paper sprue tube, comprises frame 1, the lower mold base 11 that is fixedly arranged on the frame 1 and the upper mold base 12, the lower mold base 11 is provided with lower mold 13, upper The mold base 12 is provided with an upper mold 14, the front of the frame 1 is provided with a feeding mechanism 2, and the rear of the frame 1 is provided with a shaping assembly 3, which includes a shaping capsule 31 and a shaping rod 32, and the rear of the...

Embodiment 2

[0043] Such as Figure 8 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The advantage is that several air holes 8 are provided on the inner walls of the plastic cavity a15 and the plastic cavity b17.

[0044] Here, in this embodiment, a number of vent holes 8 are provided on the inner walls of the shaping cavity a15 and the shaping cavity b17, and the heating device heats the pipe material 17 so that the generated water vapor can be discharged through the vent holes 8 to avoid water vapor. The steam stays in the upper mold 14 and the lower mold 13 to cause damage to the upper mold 14 and the lower mold 13, while preventing the pipe material from getting wet again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com