Grading method of ore ball mill

A ball mill and grading technology, which is applied in the field of mining equipment, can solve the problems that the comprehensive grinding efficiency is difficult to meet expectations, the grinding ball gradation is difficult to achieve balance, and the grinding efficiency is high, so as to improve the comprehensive grinding efficiency and avoid insufficient production capacity. The effect of improving the average and comprehensive production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

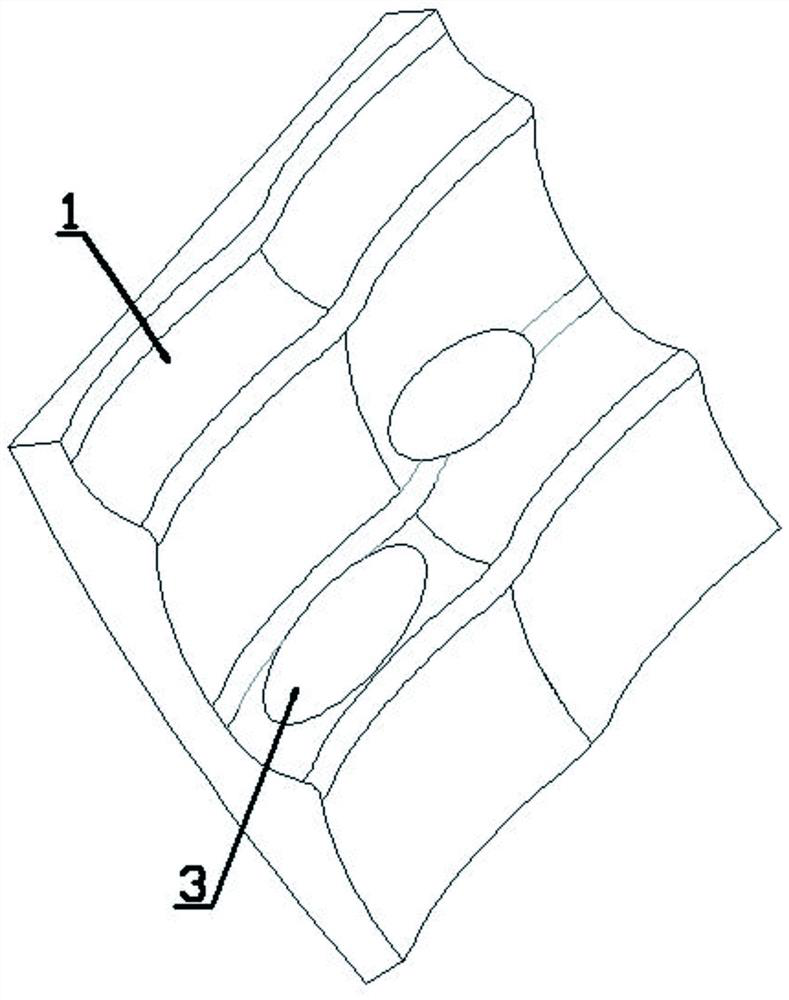

[0048] The utility model relates to a ball mill, the drum of which is a through chamber without a partition chamber. A liner 1 is laid on the inner wall of the drum, and two kinds of grinding balls are filled in the drum, the two kinds of grinding balls are ellipsoid 3 and concave ellipsoid 2 respectively.

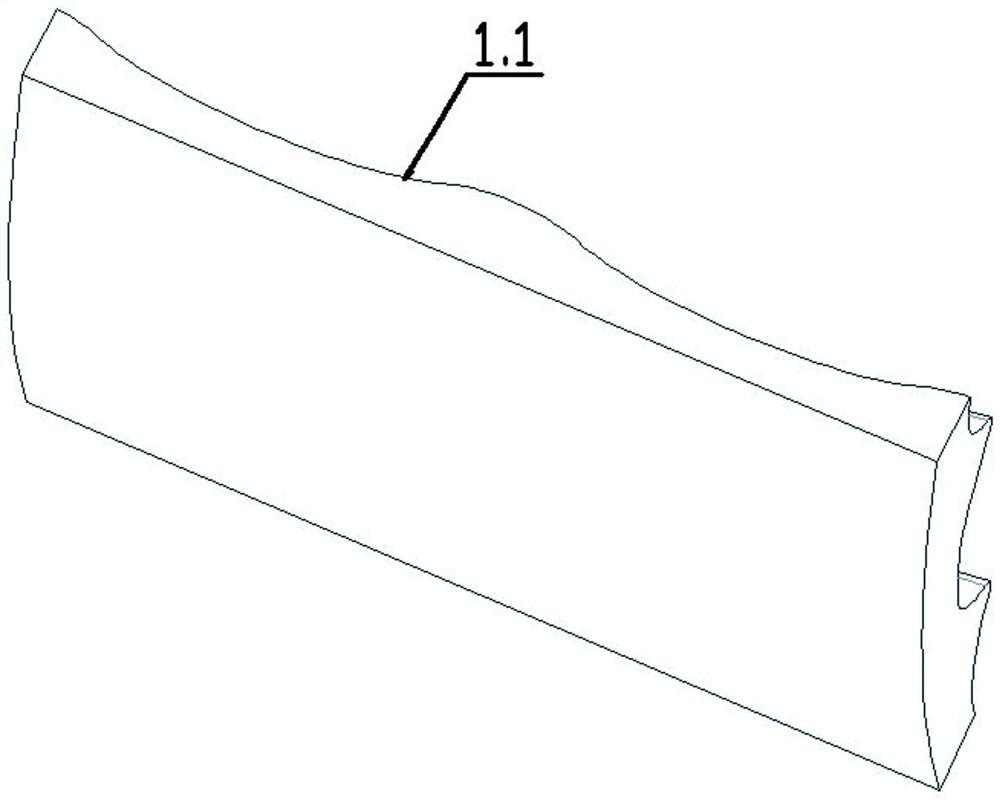

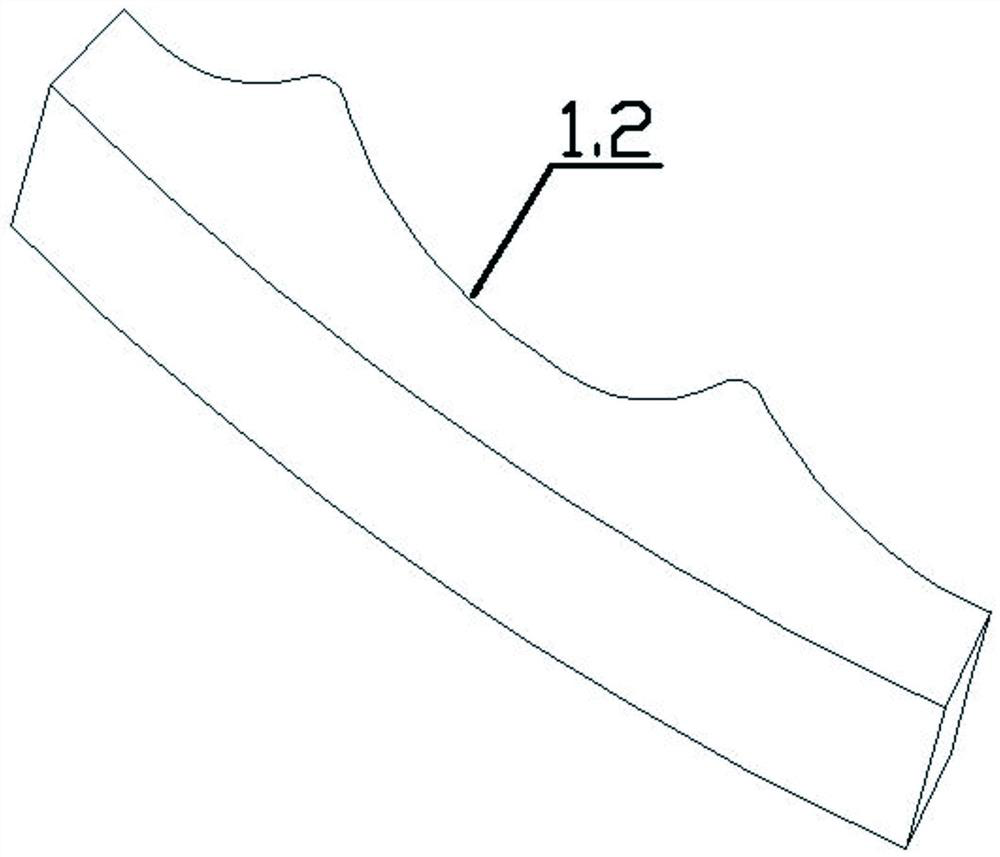

[0049] Such as figure 1As shown, an axial corrugated structure undulating along the axial direction is provided on the working surface of the liner 1, and the corrugated lines 1.1 of the axial corrugated structure are formed by smoothly connecting crest lines and trough lines, wherein the crest lines and trough lines are both is an elliptical arc. In this embodiment, the axial corrugated structure includes two peak lines and two valley lines, the length of the valley lines is 155 mm, the length of the peak lines is 45 mm, and the length of the wave amplitude is 27 mm. The trough surface of the axial corrugated structure constitutes the circumferential raceway of the gri...

Embodiment 2

[0083] The difference from Example 1 is that according to the distribution of ore particle size, there are three groups of particle size intervals with relatively large proportions, which are 4-6mm, 8-10mm and 1-2mm respectively, among which, the particle size interval of 4-6mm and the particle size interval of 8-10mm The proportion is the largest, and the proportion of the 4-6mm granularity interval is twice that of the 1-2mm granularity interval. The convex area of the working surface of the liner of the ball mill accounts for 20% of the total surface area, and the concave area accounts for 80% of the total surface area.

[0084] The grading method comprises the following steps:

[0085] S1: According to the above three groups of ore feeding granularity, select ellipsoids and concave ellipsoids with suitable single weight. Among them, the large ellipsoid corresponds to the particle size range of 4-6mm, the major axis of the large ellipsoid is 10 cm, and the minor axis is 6...

Embodiment 3

[0101] The difference from Example 2 is that according to the distribution of ore particle size, there are four groups of particle size intervals with relatively large proportions, which are 4-6mm, 8-10mm, 2-4mm and 1-2mm respectively. Among them, the 4-6mm particle size interval, The proportion of the 8-10mm granularity interval is the largest, the proportion of the 4-6mm granularity interval is twice that of the 1-2mm granularity interval, and the proportion of the 8-10mm granularity interval is 2 times that of the 2-4mm granularity interval. times.

[0102] The grading method comprises the following steps:

[0103] S1: According to the above four groups of ore feeding granularity, select ellipsoids and concave ellipsoids suitable for single weight. Among them, the large ellipsoid corresponds to the particle size range of 4-6mm, the major axis of the large ellipsoid is 10 cm, and the minor axis is 6 cm. Its convex surface area is 1.66 square decimeters and its weight is 1.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com