High-temperature-resistant energy-saving silicon carbide plate and preparation method thereof

A silicon carbide board, energy-saving technology, applied in the field of ceramic materials, can solve the problems of large exhaust gas emissions, environmental pollution, high energy consumption, etc., and achieve the effects of inhibiting oxidation, uniform board surface, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

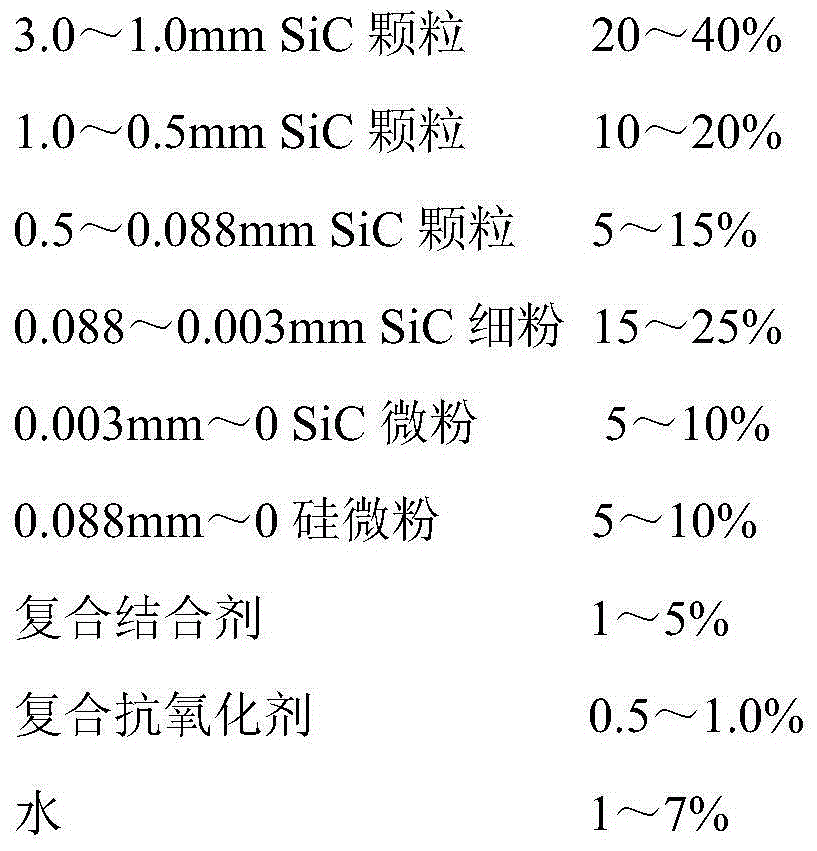

Method used

Image

Examples

Embodiment 1

[0034] 1), select the true density of 3.12g / cm 3 , silicon carbide content (weight percentage) 99.4%, free carbon content 0.3%, Fe 2 o 3 The silicon carbide block raw material with a content of 0.3% is processed into five kinds of silicon carbide particles with different particle size distributions of 3.0-1.0mm, 1.0-0.5mm, 0.5-0.088mm, 0.088-0.003mm, and 0.003mm-0;

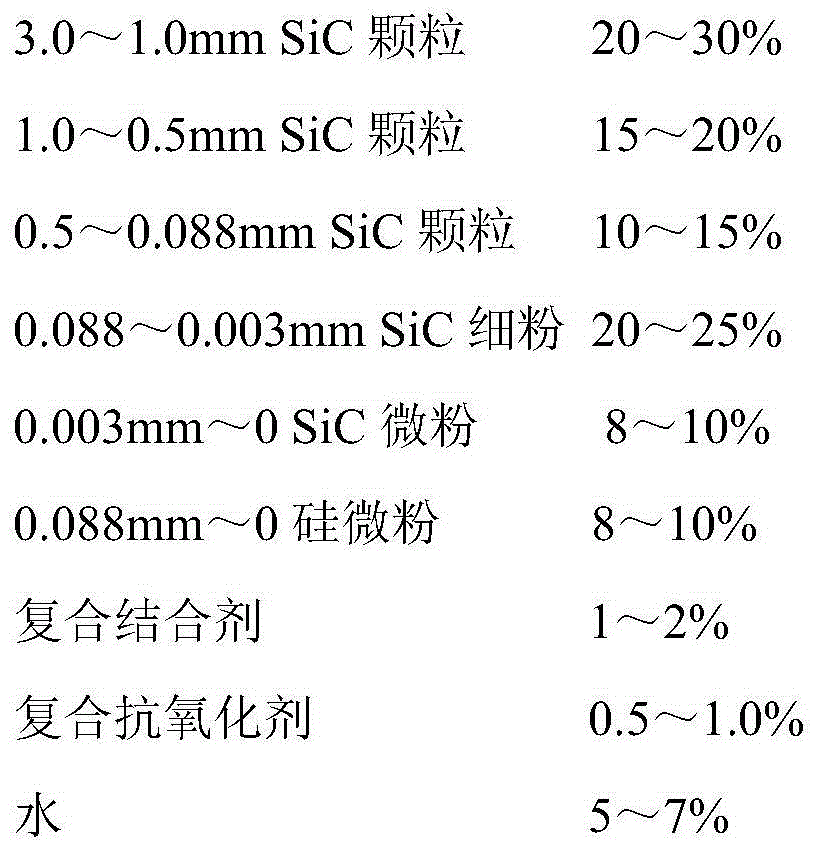

[0035] 2) Weighing and proportioning according to weight percentage: 3.0-1.0mm SiC particles 25%, 1.0-0.5mm SiC particles 15%, 0.5-0.088mm SiC particles 10%, 0.088-0.003mm SiC fine powder 25% , 0.003mm~0SiC micropowder 8%, ≤0.088mm silicon micropowder 8%, composite binder (compounded by weight percentage 60% yttrium oxide and 40% manganese oxide) 3%, composite antioxidant (by weight percentage content of 50% metal silicon powder and 50% graphite carbon compound) 1%, water 5%, put into the 750-type forced planetary mixer to mix and stir, and trap the material in a closed container for 48 hours to make the materia...

Embodiment 2

[0042] 1) Choose a true density of 3.21g / cm 3 , silicon carbide content (weight percentage) 99.5%, free carbon content 0.3%, Fe 2 o 3 The silicon carbide block raw material with a content of 0.2% is processed into five kinds of silicon carbide particles with different particle size distributions of 3.0-1.0mm, 1.0-0.5mm, 0.5-0.088mm, 0.088-0.003mm, and 0.003mm-0;

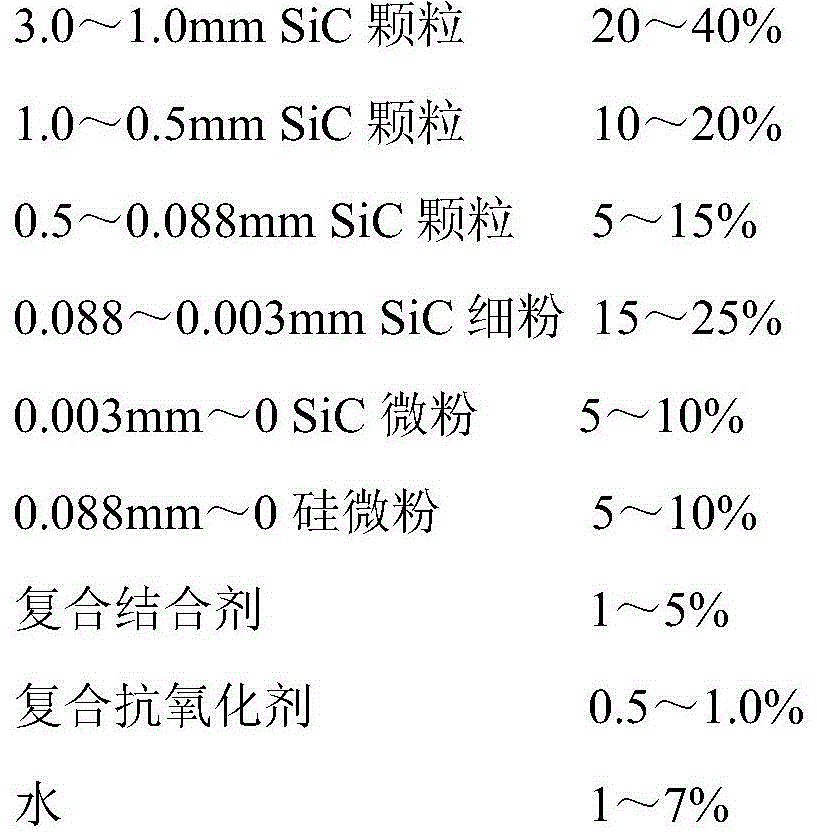

[0043] 2) Weighing and proportioning according to weight percentage: 3.0-1.0mm SiC particles 30%, 1.0-0.5mm SiC particles 10%, 0.5-0.088mm SiC particles 5%, 0.088-0.003mm SiC fine powder 22.5% , 0.003mm~0 SiC micropowder 10%, 0.088mm~0 SiC micropowder 10%, composite binder (compounded by 50% yttrium oxide and 50% zirconia by weight percentage) 5%, composite antioxidant (by weight percent content of 50% metal silicon powder and 50% graphite carbon compound) 0.5%, water 7%, put into 750 type forced planetary mixer after mixing and stirring, trap the material in a closed container for 48 hours, make the material addit...

Embodiment 3

[0050] 1), select the true density of 3.15g / cm 3 , silicon carbide content (weight percentage) 99.6%, free carbon content 0.2%, Fe 2 o 3 The silicon carbide block raw material with a content of 0.2% is processed into five kinds of silicon carbide particles with different particle size distributions of 3.0-1.0mm, 1.0-0.5mm, 0.5-0.088mm, 0.088-0.003mm, and 0.003mm-0;

[0051] 2) Weighing and proportioning according to weight percentage: 3.0-1.0mm SiC particles 31.2%, 1.0-0.5mm SiC particles 17%, 0.5-0.088mm SiC particles 15%, 0.088-0.003mm SiC fine powder 20% , 0.003mm ~ 0 SiC micropowder 5%, 0.088mm ~ 0 SiC powder 5%, composite binder (compounded by weight percentage 33.3% yttrium oxide, 33.3% zirconia and 33.4% manganese oxide) 4%, composite anti- Oxidizing agent (made by weight percentage 50% metal silicon powder and 50% graphite carbon) 0.8%, water 2%, after putting into 750 type forced planetary mixer mixing and stirring, trapped in a closed container for 48 hours, After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com