System for resource utilization and disposal of building wastes

A technology for disposal system and construction waste, applied in the direction of sustainable waste treatment, climate sustainability, solid waste management, etc., can solve the problems of high cost, large floor area, high moisture content, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

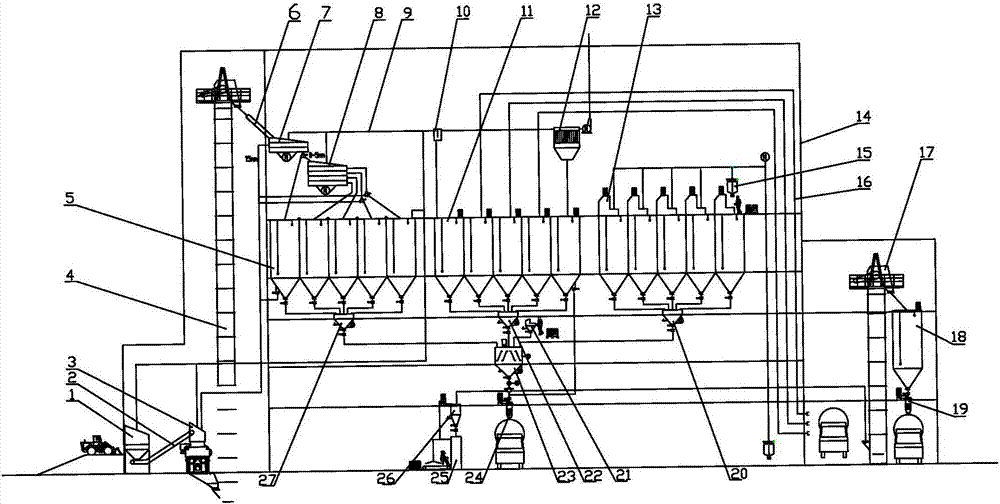

[0010] Embodiment 1: see attached figure 1, Construction waste resource utilization and disposal system, including silo 1, belt conveyor 2, sand making machine 3, hoist 4, sand bin assembly 5, spreader 6, vibrating screen Ⅰ7, vibrating screen Ⅱ8, dust removal pipeline 9 , primary air separator 10, powder bin assembly 11, dust collector 12, additive bin assembly 13, closed main building 14, ton package elevator 15, powder feeding pipeline 16, finished product elevator 17, finished product bin assembly 18 , finished product bulk machine 19, additive scale 20, micro material additive feeding hopper 21, powder scale 22, mixer 23, building bulk machine 24, packaging machine 25, packaging hopper 26, sand scale 27; the upper part of the silo is provided with suction The motor drive of the dust cover and the belt conveyor adopts frequency conversion control. The belt conveyor is equipped with alarm devices such as material flow detection and pull switch; Sand shaping. The motor of t...

Embodiment 2

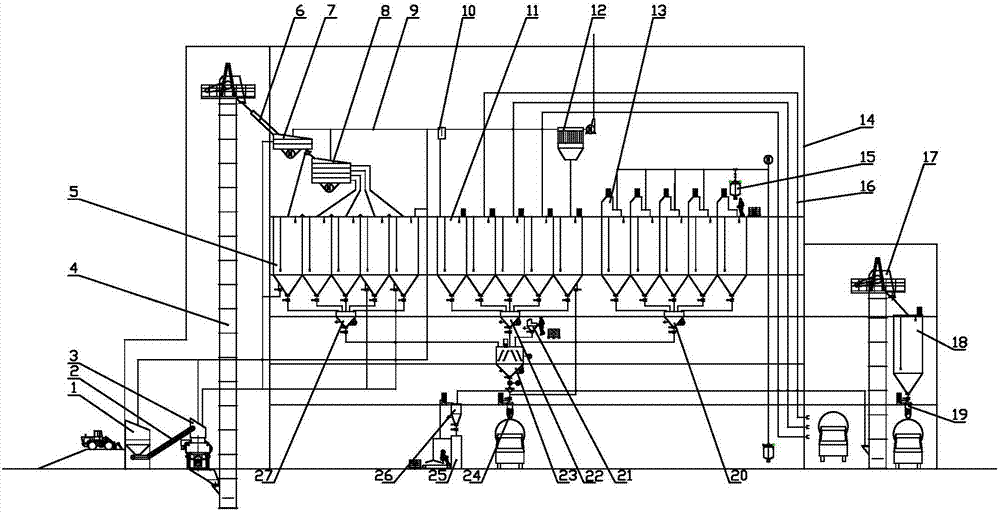

[0011] Embodiment 2: see attached figure 2 , the two three-way valves in the 1.2-2.4mm and 2.4-5mm pipelines of the vibrating screen II discharge port are cancelled; the original 1.2-2.4mm and 2.4-5mm two pipelines return to the serial number 3 sand making through the system return main pipeline The return material of closed-loop sand making in the machine is realized by moving to the bottom of the silo; the rest is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com