Method for preparing cement-based grouting material from phosphorus solid wastes through wet grinding technology

A wet grinding process and grouting material technology, applied in the field of building materials, can solve the problems of poor structure compactness and high cost, and achieve the effects of good compactness, low production cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Weigh 100 parts by weight of phosphorous tailings, carry out 4.75mm, 2.36mm, 1.18mm, 600μm, 300μm, 150μm graded crushing, and the cumulative sieve residues of the square sieve holes are: 0%, 0-25% , 10-50%, 41-70%, 70-92%, 80-100%, to get phosphorus tailings powder;

[0034] 2) taking by weight 70 parts of phosphorus slag, crushing it with a crusher to an average particle size of 2-10 mm to obtain phosphorus slag powder;

[0035] 3) Weigh 8 parts by weight of phosphogypsum, 0.6 parts of polymerized polyol grinding aid, and add 7 parts of water glass into the obtained phosphorus slag powder in step 2) and place 54 parts by weight of water in a ball mill Ball milling until the specific surface area is 300-1100m 2 / kg, the average diameter of the particles is 1-50 μm, and aged for 2-5h to obtain the slurry;

[0036] 4) Weigh 100 parts by weight of cement, 0.8 parts of melamine-based water reducer, 7 parts of HCSA expansion agent, and 1.2 parts of polyol defoamer and a...

Embodiment 2

[0041] Embodiment 2: with embodiment 1, the difference is,

[0042] 1) taking 125 parts by weight of phosphorous tailings for classification and crushing, and sieving to obtain phosphorous tailings powder;

[0043] 2) taking by weight is 90 parts of phosphorus slag, and the crusher is crushed to obtain phosphorus slag powder;

[0044]3) Weigh 12 parts by weight of phosphogypsum, 0.8 part of triethanolamine grinding aid, add 10 parts of lime into the phosphorous slag powder obtained in step 2), and place 63 parts by weight of water in a ball mill for ball milling, aging 2-5h, get slurry;

[0045] 4) Weigh 100 parts by weight of cement, 1.2 parts of polycarboxylate water reducer, 5 parts of CEA composite expansion agent, and 1.0 part of polysiloxane defoamer to add the phosphorus tail obtained in step 1). The mineral powder and the slurry obtained in step 3) are placed in a mixer and stirred until they are evenly stirred to obtain a cement-based grouting material.

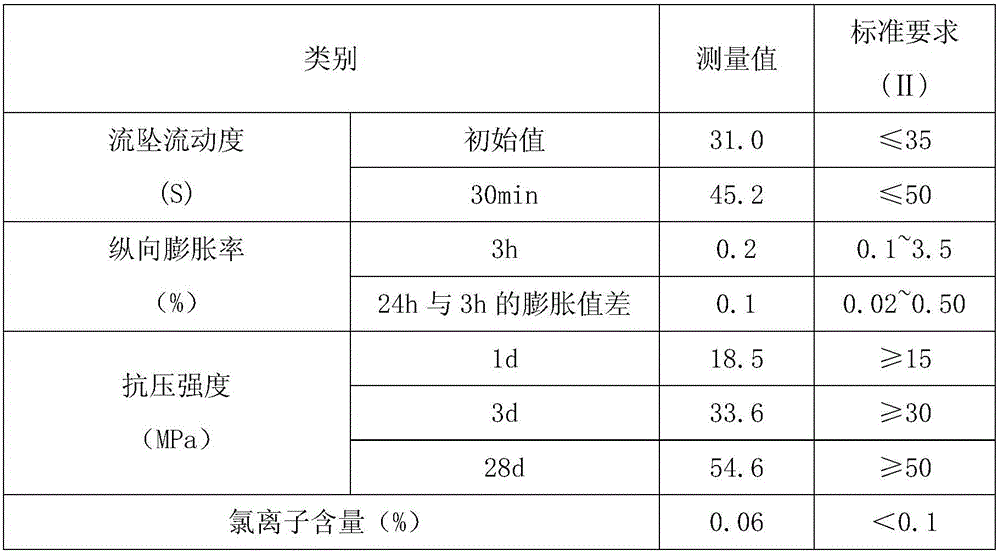

[0046] Th...

Embodiment 3

[0049] Embodiment 3: with embodiment 1, the difference is,

[0050] 1) taking 150 parts by weight of phosphorous tailings for classification and crushing, and sieving to obtain phosphorous tailings powder;

[0051] 2) taking by weight is 50 parts of phosphorus slag, and the crusher is crushed to obtain phosphorus slag powder;

[0052] 3) Weigh 6 parts by weight of phosphogypsum, 0.8 parts of triisopropanolamine grinding aid, add 5 parts of Glauber's salt to the phosphorus slag powder obtained in step 2), and place 50 parts by weight of water in a ball mill for ball milling , aged for 2-5h to obtain slurry;

[0053] 4) Weigh 100 parts by weight of cement, 1.5 parts of naphthalene-based water reducer, 6 parts of FEA expansion agent, and 1.5 parts of polysiloxane defoamer and add the phosphorous tailings powder obtained in step 1) and the step 3) The obtained slurry is placed in a mixer and stirred until it is evenly stirred to obtain a cement-based grouting material.

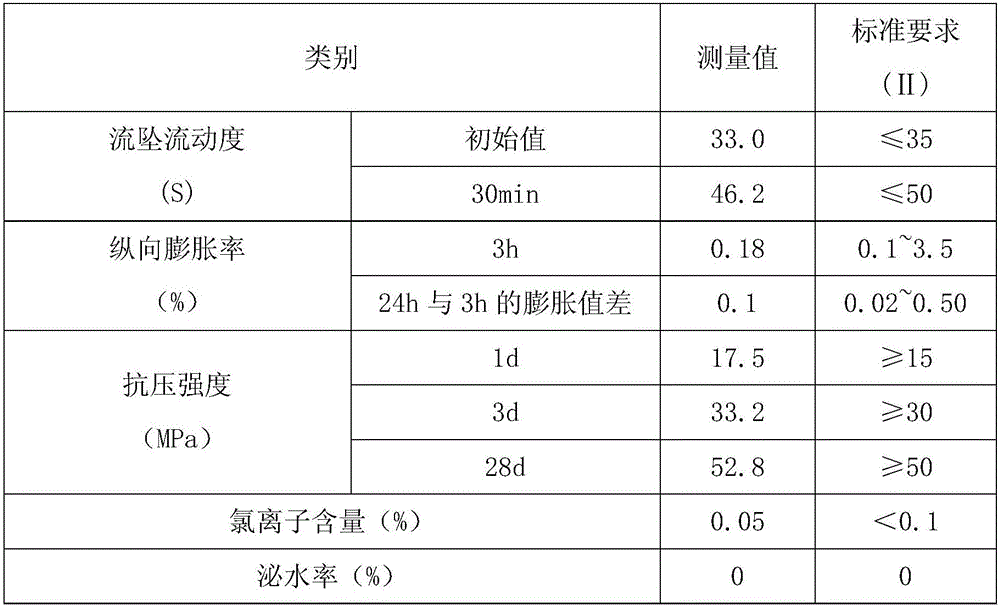

[0054]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com