Energy storage thermal insulation building material

A technology of building materials and energy storage materials, which is applied in the fields of architecture, building structure, climate change adaptation, etc., can solve the problems of few phase change cycles, certain corrosiveness, and low utilization rate of energy storage, so as to avoid solid- Liquid separation, strong corrosion resistance, and large energy storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

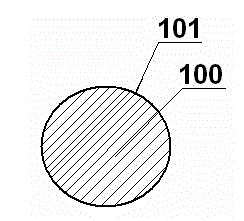

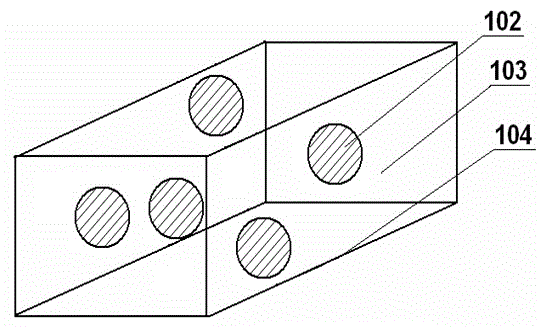

[0016] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the mass ratio is 50-85% sodium sulfate decahydrate, 5-20% sodium chloride, 1-10% sodium hexametaphosphate, 5-30% carboxymethyl cellulose, 1-10 % borax is stirred and mixed evenly in a water bath at 45-50°C and heated until the solution becomes a paste, forming an inorganic phase change material PCM100, whose phase change point is 15-30°C, and the latent heat of phase change is 100-200KJ / Kg. The paste-like inorganic phase change material PCM100 is injected into the coating layer of the hollow spherical or small cube-shaped high thermal conductivity carbon-based functional material 101 to form the energy storage coating body 102 .

[0017] Such as figure 2 As shown, the oil shale waste residue powder with a mass ratio of 40-60%, 10-30% water glass, 10-30% sodium hydroxide solution, and 10-30% cement are uniformly mixed to form a slurry. 103 Add The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com