Modified ecological cementing nano-material and preparation method therefor

A nano-modified and gelled material technology, applied in the field of building materials, can solve the problems of micro-nano silica fume loss, surface activity decline, thermodynamic instability, etc., to optimize particle gradation, improve compactness, and improve later strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An ecological nano-modified cementitious material, by weight, the water-cement ratio is 0.15, other components and mass percentages are as follows: 35% of cement, 3% of ecological nano-materials, 20% of limestone powder, high-quality grade I Low calcium fly ash is 40%, polycarboxylate superplasticizer is 2%.

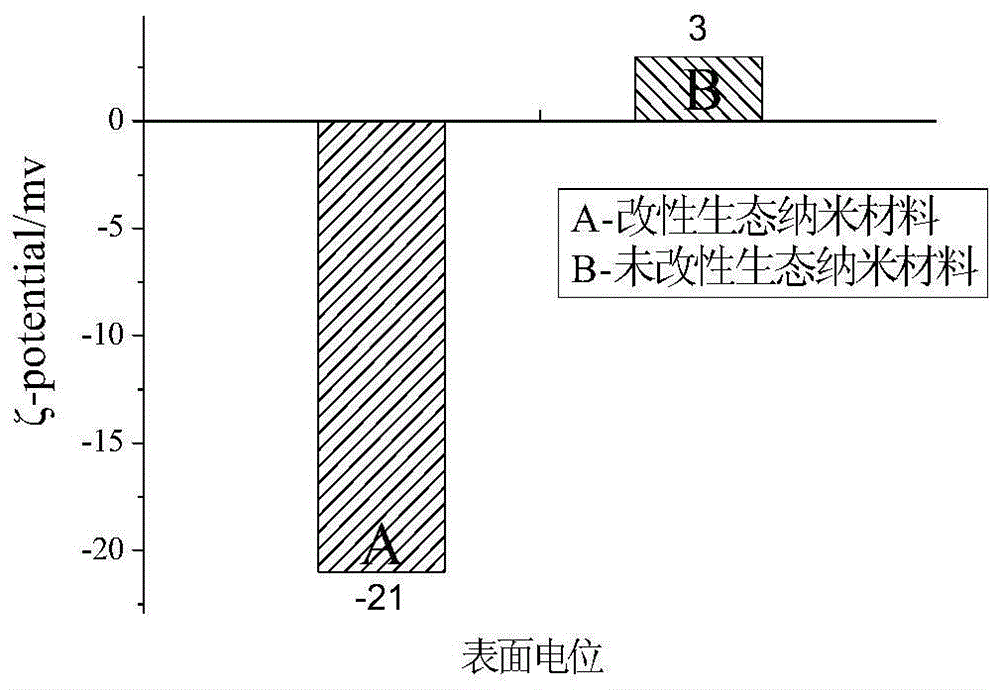

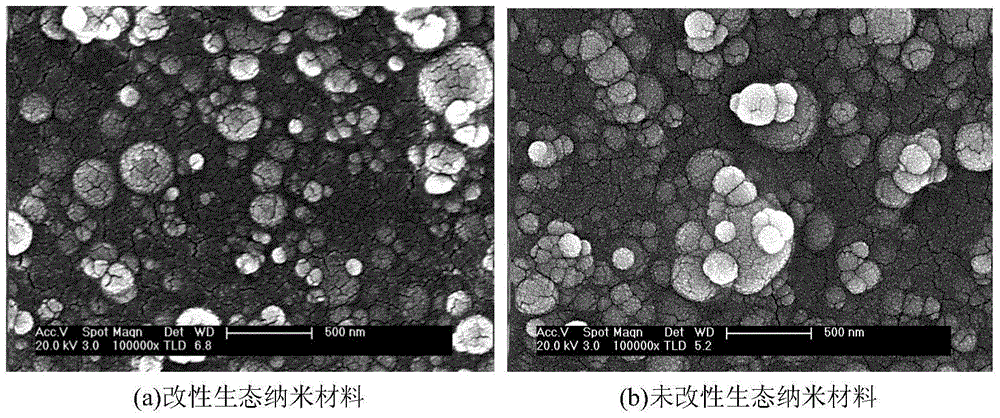

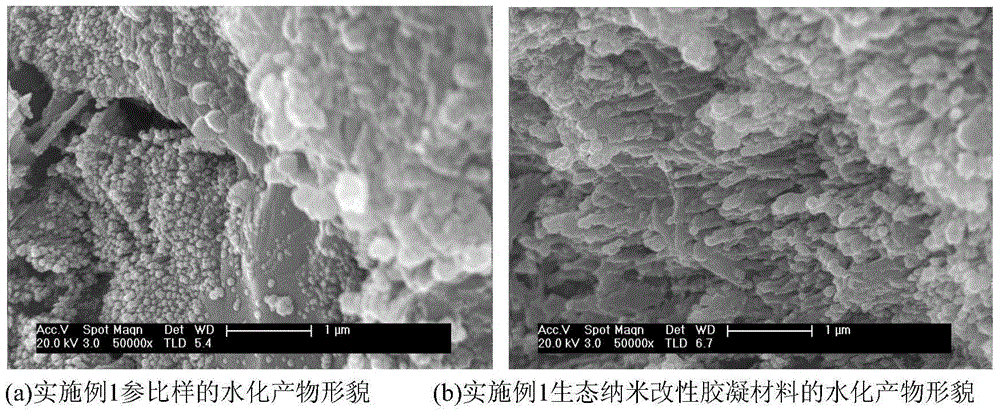

[0026] Surface potential diagrams of silica fume particles before and after modification figure 1 As shown, the picture shows that the potential of the modified silica fume particles is converted into a positive potential; the microscopic morphology comparison of the silica fume particles before and after modification combined with the water reducer is shown in figure 2 As shown, the picture shows that the dispersion of silica fume after modification is significantly improved; the microscopic morphology of the hardened ecological nano-modified gel material and the corresponding reference sample image 3 As shown in the picture, the surface of silica fume in the ...

Embodiment 2

[0028] An ecological nano-modified cementitious material, by weight, the water-cement ratio is 0.20, and other components and mass percentages are as follows: 38.5% of cement, 5% of ecological nano-materials, 17% of limestone powder, high-quality grade I Low-calcium fly ash is 38%, and high-efficiency water reducer is 1.5%.

Embodiment 3

[0030] An ecological nano-modified cementitious material, by weight, the water-cement ratio is 0.25, other components and mass percentages are as follows: 42% of cement, 7% of ecological nano-materials, 15% of limestone powder, high-quality grade I Low-calcium fly ash is 35%, and high-efficiency water reducer is 1.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com