Ecological self-compact concrete

A self-compacting concrete and ecological technology, applied in the field of building materials, can solve problems such as large amount of cementitious materials, large formwork pressure, aggregate settlement, etc., achieve high fluidity and anti-segregation, improve adhesion, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

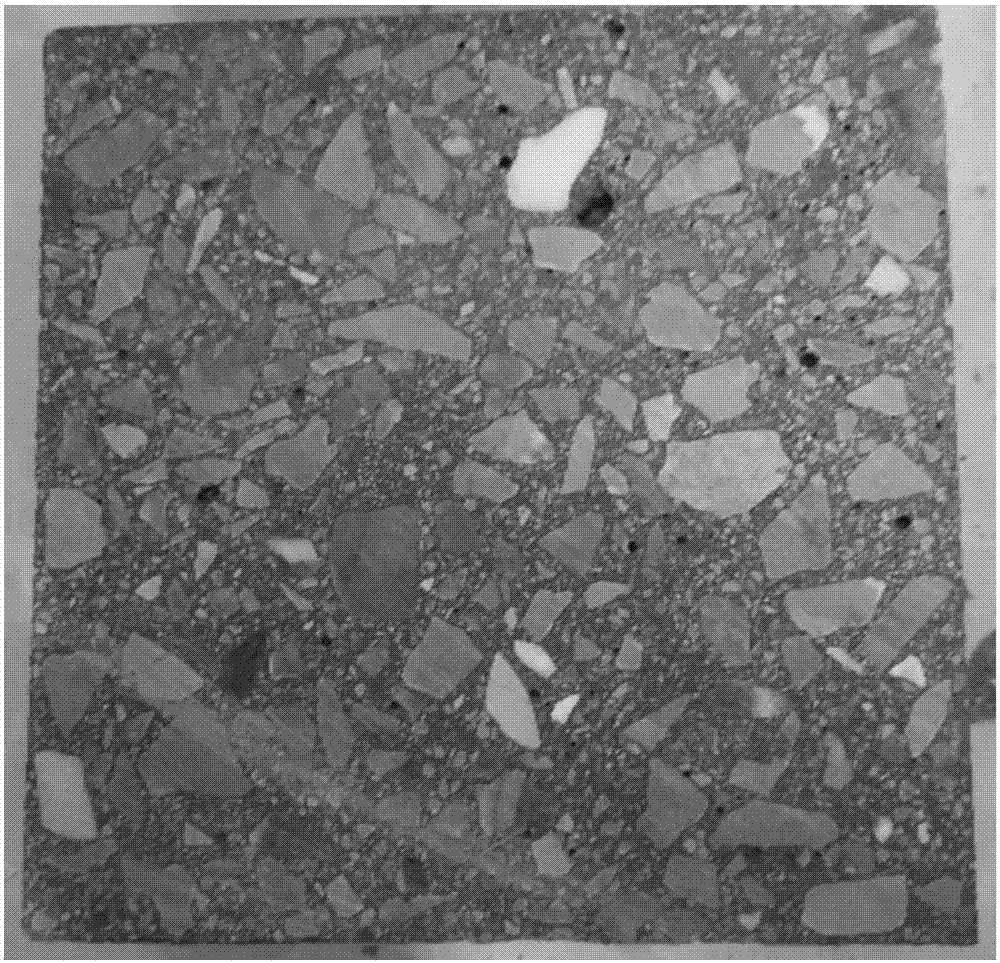

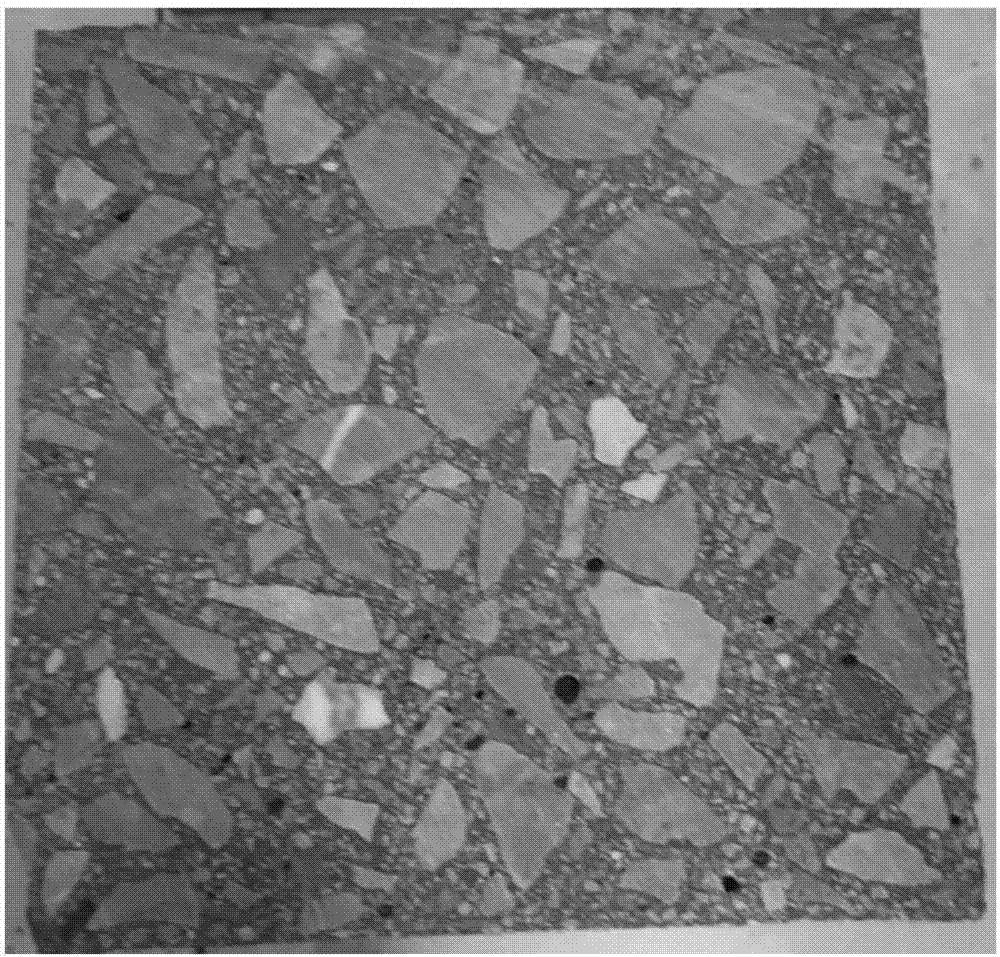

Image

Examples

Embodiment 1

[0024] In this embodiment, the specific C50 ecological self-compacting concrete mixture material composition and mix ratio parameters are taken as an example, which includes the following steps:

[0025] The volume ratio of coarse aggregate of C50 ecological self-compacting concrete prepared in this test is 0.37, the volume sand ratio of fine aggregate is 0.42 (volume ratio refers to the volume fraction of mortar in concrete), the volume ratio of limestone powder is 0.01; the water-binder ratio is 0.32 , the total amount of cementitious material is 530kg / m 3 , of which the amount of cement is 371kg / m 3 , the amount of fly ash is 59kg / m 3 , slag fine powder 100kg / m 3 , the amount of superplasticizer is its saturated amount, which is 2% of the amount of gelling material; Wenlun glue is 0.01%. Compared with C50 ordinary self-compacting concrete, while ensuring its excellent working performance, it reduces the total amount of cementitious materials, is more ecological and envir...

Embodiment 2

[0028] This embodiment takes the specific C40 ecological self-compacting concrete mixture material composition and mix ratio parameters as an example, which includes the following steps:

[0029] The C40 ecological self-compacting concrete prepared in this test has a coarse aggregate volume ratio of 0.37, a fine aggregate volume sand ratio of 0.41, a tailings volume ratio of 0.03, a water-binder ratio of 0.37, and a total amount of cementitious materials of 485kg / m 3 , of which the amount of cement is 340kg / m 3 , the amount of fly ash is 145kg / m 3 . The amount of superplasticizer is 1.8% of the amount of cementitious material, and that of montmorillonite is 0.5%. Compared with C40 ordinary self-compacting concrete, while ensuring its excellent working performance, it reduces the total amount of cementitious materials, is more ecological and environmentally friendly, and improves economic benefits. Excellent working performance, the performance level of slump expansion reach...

Embodiment 3

[0032] This embodiment takes the specific C30 ecological self-compacting concrete mixture material composition and mix ratio parameters as an example, which includes the following steps:

[0033] The C30 ecological self-compacting concrete prepared in this test has a coarse aggregate volume ratio of 0.37, a fine aggregate volume sand ratio of 0.38, a limestone powder volume ratio of 0.06, a water-binder ratio of 0.41, and a total amount of cementitious materials of 452kg / m 3 , of which the amount of cement is 317kg / m 3 , the amount of fly ash is 135kg / m 3 , the amount of superplasticizer is 1.6% of the amount of gelling material, and xanthan gum is 0.005%. Compared with C30 ordinary self-compacting concrete, while ensuring its excellent working performance, it reduces the total amount of cementitious materials, is more ecological and environmentally friendly, and improves economic benefits. Excellent working performance, the performance level of slump expansion reaches SF2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com