Gelling foamed concrete and preparation method thereof

A foamed concrete and rubber modification technology, which is applied in the field of building materials, can solve the problems of low material strength, easy drying shrinkage cracks, and limited reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The preparation method of gelling foamed concrete of the present invention comprises the following steps:

[0078] (1) under normal temperature, 0.03 weight part initiator is dissolved in the water of 20-25 weight part, obtains initiator solution;

[0079] (2) Under normal temperature, 0.1 weight part of resin curing agent, 0.1 weight part of stabilizer, 0.5 weight part of water reducing agent and 0.03 weight part of air-entraining agent are respectively dissolved in 20-25 weight parts of water to prepare resin curing agent solution, stabilizer solution, water reducer solution and air-entraining agent solution;

[0080] (3) Add 0.2 parts by weight of olefin monomer and 1.8 parts by weight of epoxy vinyl ester resin to the initiator solution, stir evenly, send it into the reaction kettle, feed nitrogen, and keep stirring at 70-90 ° C for 5 -6 hours, cooling discharge, to obtain the rubber modified epoxy vinyl ester resin;

[0081] (4) adding 2 parts by weight of foamin...

Embodiment 2

[0101] In this example, except that the olefin monomer is butadiene, other preparation methods and reagent consumption are the same as in Example 1.

Embodiment 3

[0103] In this example, except that the olefin monomer is isoprene, other preparation methods and reagent dosages are the same as in Example 1.

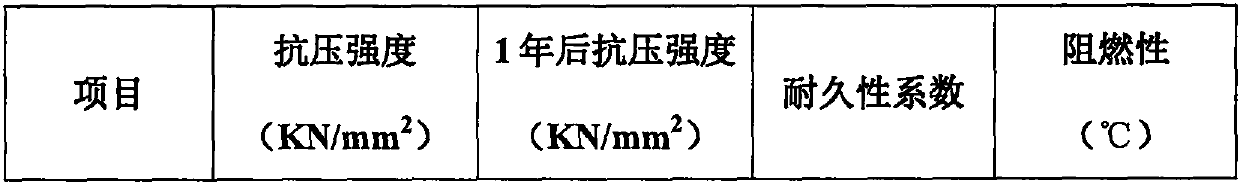

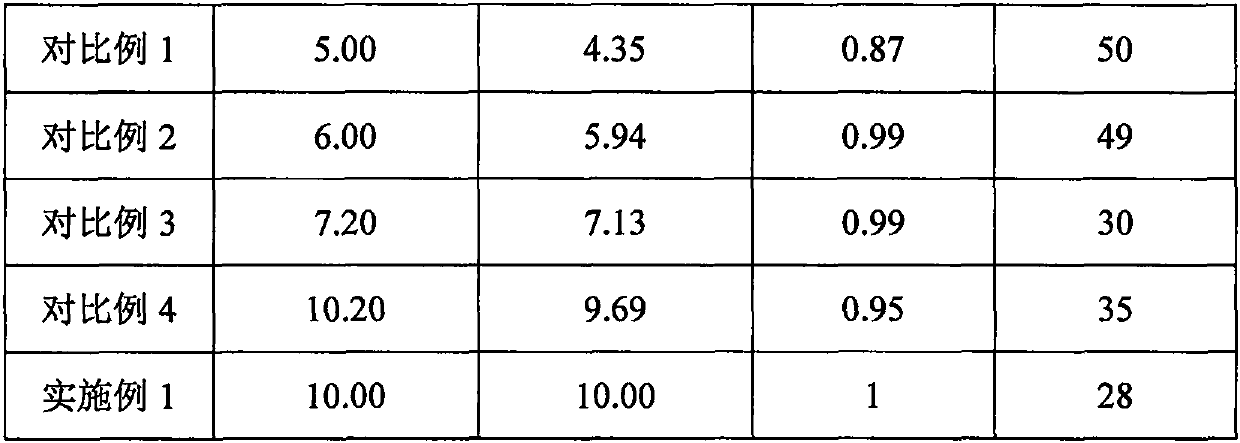

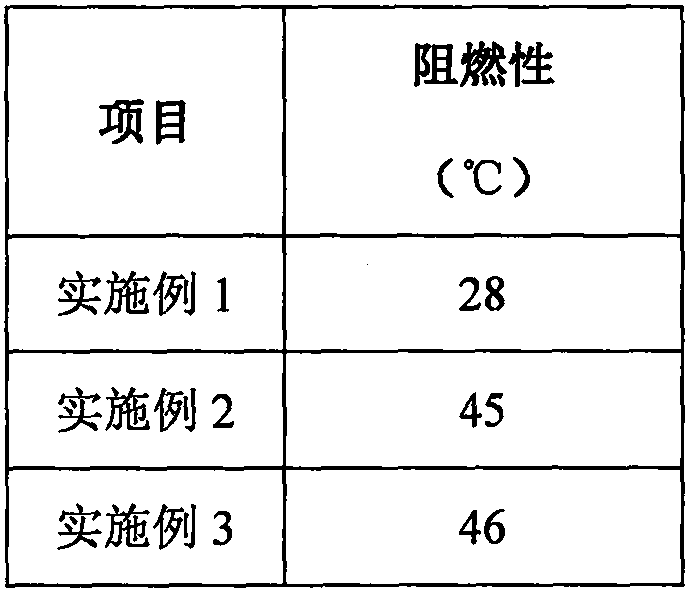

[0104] The flame retardant performance of the gelled foamed concrete of Examples 1-3 was tested using the above flame retardant performance detection method, and the test data are shown in Table 2.

[0105] Table 2 Comparison of the flame retardant performance of the cementitious foamed concrete of Examples 1-3

[0106]

[0107] The results in Table 2 show that the gelling foamed concrete of Example 1 has stronger flame retardancy, and the flame retardancy of Example 2 and Example 3 is at the same level, and is much different than that of Example 1. It can be seen that when the olefin monomer is chloroprene, the flame retardancy of the prepared gelled foamed concrete is the best.

[0108] 3. Performance comparison of the cementitious concrete of the present invention with different rubber-modified epoxy vinyl ester resin dosages....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com