Method for high-impermeability concrete material by wet grinding process

A wet grinding process and concrete technology, applied in the application field of waste recycling, can solve the problems of high cost, late strength shrinkage, high noise, etc., and achieve the effects of low production cost, good compactness and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

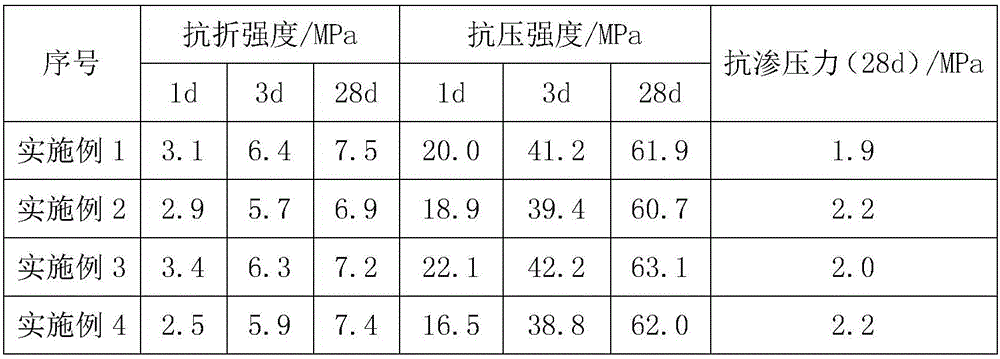

Examples

Embodiment 1

[0029] 1) Weigh 10 parts by weight of fly ash, 30 parts of slag, 0.8 parts of polymerized polyol grinding aid, and 35 parts of water, and place them in a jaw ball mill for ball milling until the specific surface area is 400-1000m 2 / kg, the average diameter of the particles is 1-20 μm, and a slurry is obtained;

[0030] 2) Weigh 5 parts by weight of quartz sand and 5 parts of water and place them in a ball mill for ball milling until the specific surface area is 300-500m 2 / kg, the average diameter of the particles is 10-50 μm, to obtain slurry two;

[0031] 3) Weigh 100 parts by weight of 42.5 parts of ordinary Portland cement, 100 parts of river sand, 200 parts of gravel, 8 parts of rubber powder, 1.0 parts of polycarboxylate water reducer, 1.8 parts of polyol defoamer, 25 parts Parts of water and the first slurry in step 1) and the second slurry in step 2) are placed in a mixer and stirred until they are evenly stirred; a high impermeability concrete material is obtained. ...

Embodiment 2

[0033] 1) Weigh 20 parts by weight of fly ash, 20 parts of slag, 0.5 parts of polymerized polyol grinding aid, and 40 parts of water, and place them in an impact ball mill for ball milling until the specific surface area is 400-1000m 2 / kg, the average diameter of the particles is 1-20 μm, and a slurry is obtained;

[0034] 2) Weigh 10 parts by weight of quartz sand and 5 parts of water and place them in a ball mill for ball milling until the specific surface area is 300-500m 2 / kg, the average diameter of the particles is 10-50 μm, to obtain slurry two;

[0035] 3) Weigh 100 parts by weight of 42.5 Portland cement, 80 parts of river sand, 180 parts of gravel, 3 parts of rubber powder, 0.8 parts of naphthalene-based water reducer, 0.8 parts of polysiloxane defoamer, 25 parts The water and the first slurry in the step 1) and the second slurry in the step 2) are placed in a mixer and stirred until the mixing is uniform; a high impermeability concrete material is obtained.

Embodiment 3

[0037] 1) Weigh 10 parts by weight of fly ash, 10 parts of slag, 0.6 parts of triisopropanolamine grinding aid, and 20 parts of water, and place them in an impact ball mill for ball milling until the specific surface area is 400-1000m 2 / kg, the average diameter of the particles is 1-20 μm, and a slurry is obtained;

[0038] 2) Weigh 8 parts by weight of quartz sand and 5 parts of water and place them in a ball mill for ball milling until the specific surface area is 300-500m 2 / kg, the average diameter of the particles is 10-50 μm, to obtain slurry two;

[0039] 3) Weigh 100 parts by weight of 42.5 parts of ordinary Portland cement, 90 parts of river sand, 160 parts of gravel, 5 parts of rubber powder, 1.0 parts of naphthalene-based water reducer, 1.5 parts of polysiloxane defoamer, 35 parts Parts of water, slurry 1 obtained in step 1) and slurry 2 obtained in step 2) are placed in a mixer and stirred until uniformly stirred; high impermeability concrete material is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com