Aminosilane-modified ecological nano cementing material and preparation method thereof

A technology of aminosilane and nanomaterials, which is applied in the field of building materials, can solve the problems such as the inability to disperse silica fume, and achieve the effect of improving dispersibility and microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

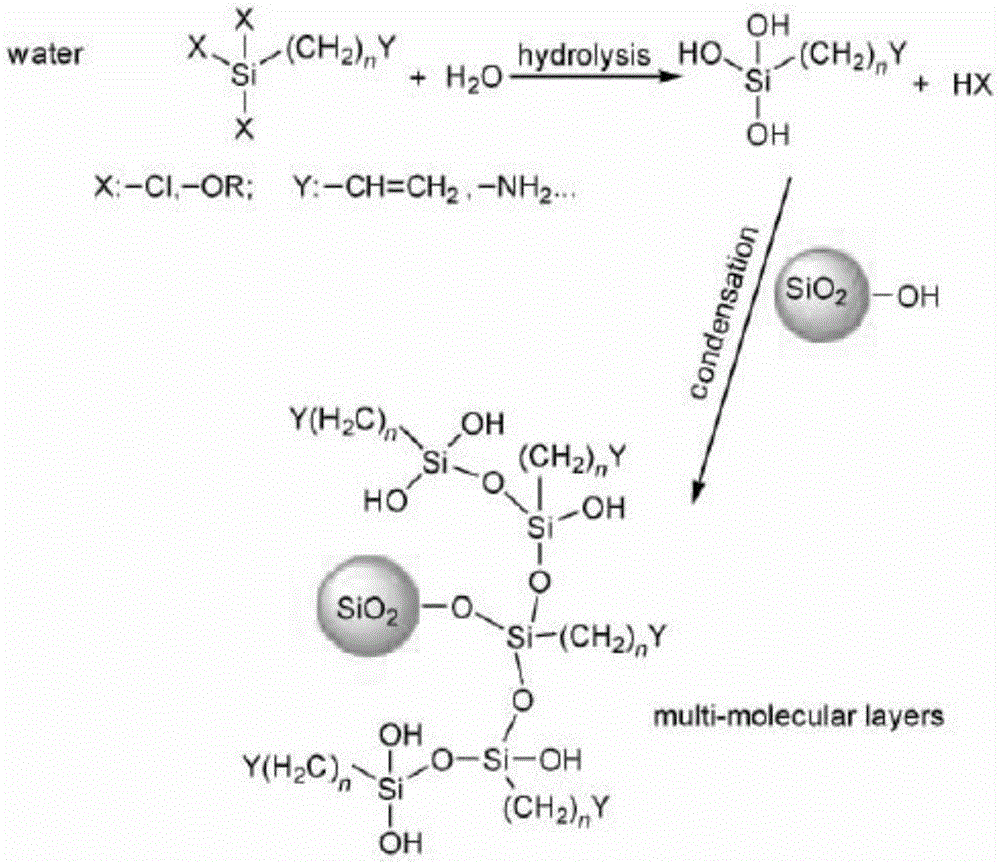

Method used

Image

Examples

Embodiment 1

[0026] An aminosilane modified ecological nano-gelling material, by weight, the water-cement ratio is 0.15, other components except water and the mass percentage are as follows: cement is 35%, ecological nano-material is 3%, limestone powder 19.987%, high-quality Class I low-calcium fly ash is 40%, aminosilane modifier is 0.013%, and polycarboxylate superplasticizer is 2%.

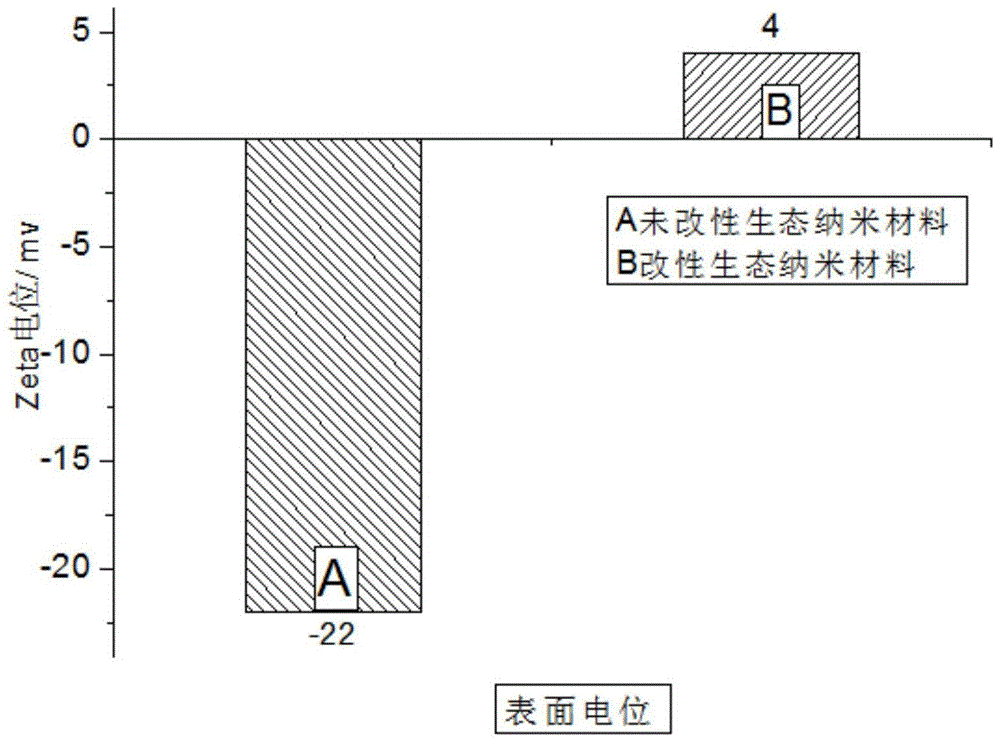

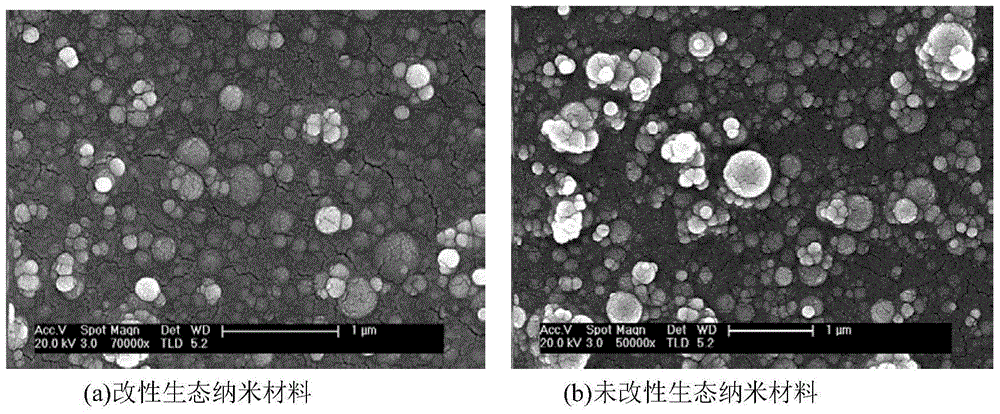

[0027] Surface potential diagrams of silica fume particles before and after modification figure 1 As shown, the picture shows that the potential of the modified silica fume particles is converted into a positive potential; the microscopic morphology comparison of the silica fume particles before and after modification combined with the water reducer is shown in figure 2 As shown in the picture, the dispersibility of silica fume after modification is obviously improved.

Embodiment 2

[0029] An aminosilane modified ecological nano-gelling material, by weight, the water-cement ratio is 0.20, and the other components and mass percentages except water are as follows: 38.5% for cement, 5% for ecological nano-materials, limestone powder 17%, high-quality Class I low-calcium fly ash is 38%, aminosilane modifier is 0.017%, and high-efficiency water reducer is 1.483%.

Embodiment 3

[0031] An aminosilane modified ecological nano-gelling material, by weight, the water-cement ratio is 0.25, and the other components and mass percentages except water are as follows: 42% for cement, 11% for ecological nano-materials, limestone powder 14%, high-quality Class I low-calcium fly ash is 32%, aminosilane modifier is 0.024%, and high-efficiency water reducer is 0.976%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com