Autoclaved aerated concrete block and preparation method thereof

A concrete block, autoclaved gas filling technology, applied in the field of building materials, can solve the problems of large drying shrinkage deformation, wall cracking, etc., and achieve the effects of improving performance, protecting the environment, and excellent performance of block products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

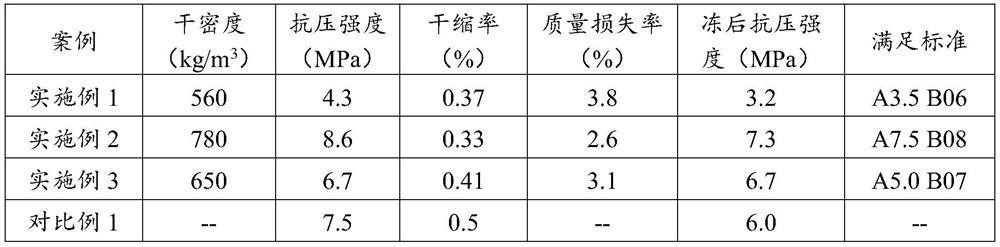

Examples

preparation example Construction

[0013] The raw materials for preparing the autoclaved aerated concrete block provided by the invention include dry materials. In parts by mass, the dry material of the autoclaved aerated concrete block provided by the present invention includes 15-25 parts of cement, more preferably 17-23 parts. In the present invention, the cement preferably includes P·O42.5 cement, P·I42.5 cement or P·II42.5 cement, more preferably P·O42.5 cement.

[0014] Based on the mass fraction of the cement, the dry material of the autoclaved aerated concrete block provided by the present invention includes 25-35 parts of quicklime powder, more preferably 27-33 parts. In the present invention, the quicklime powder is preferably ground calcareous quicklime powder, the effective content of CaO and MgO in the quicklime powder is preferably ≥ 85wt.%, and the particle size of the quicklime powder is preferably 1-200 μm, more preferably 1 to 100 μm. The quicklime powder used in the present invention has a ...

Embodiment 1

[0041] Cut the waste wind power blades to obtain a large piece of material with a width of 40cm and a length of 150cm; put the large piece of material into a shredder and shred it under 100kw to obtain a small piece of material with a size of 8cm; The small pieces of material are put into a pulverizer and crushed at 50kw to obtain irregular crushed materials, and then sorted by a fan at 8kw to obtain waste wind power blade fibers with a length of 0.45mm and waste wind power blades with a particle size of ≤0.05mm. Leaf powder is sent to a special storage bin for standby;

[0042] Weigh 15 parts of P·O42.5 cement, 35 parts of quicklime powder (particle size 1-100 μm, effective content of CaO and MgO is 85wt.%), 40 parts of waste wind power blade powder (particle size ≤ 0.05mm, ratio The surface area value is 700m 2 / kg), 6 parts of waste wind power blade fiber (diameter is 20 μm, length is 0.45 mm, aspect ratio is 30) and 4 parts of natural dihydrate gypsum (total content of di...

Embodiment 2

[0044] The difference with Example 1 is that the dry material in the raw materials for the preparation of the autoclaved aerated concrete block includes 20 parts of P.O42.5 cement, 28 parts of quicklime powder (with a particle size of 1 to 100 μm, the effective content of CaO and MgO content of 85wt.%), 45 parts of waste wind power blade powder (particle size ≤ 0.05mm, specific surface area value 700m 2 / kg), 4 parts of waste wind power blade fiber (diameter is 20 μm, length is 0.45 mm, aspect ratio is 30) and 3 parts of natural dihydrate gypsum (total content of dihydrate gypsum and anhydrite ≥75wt.%), 60 The water of % dry matter quality and the aluminum powder (purity is 95%) of 0.07% dry matter quality, all the other contents are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com