Multi-steam turbine combined power generation type ultra-supercritical unit

A technology for turbogenerators and ultra-supercritical units, which is applied in the direction of machines/engines, steam turbines, mechanical equipment, etc., and can solve problems such as high power consumption, high construction period and cost, and difficulties in meeting construction site requirements. Achieve the effects of increasing power generation revenue, improving cycle thermal efficiency, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

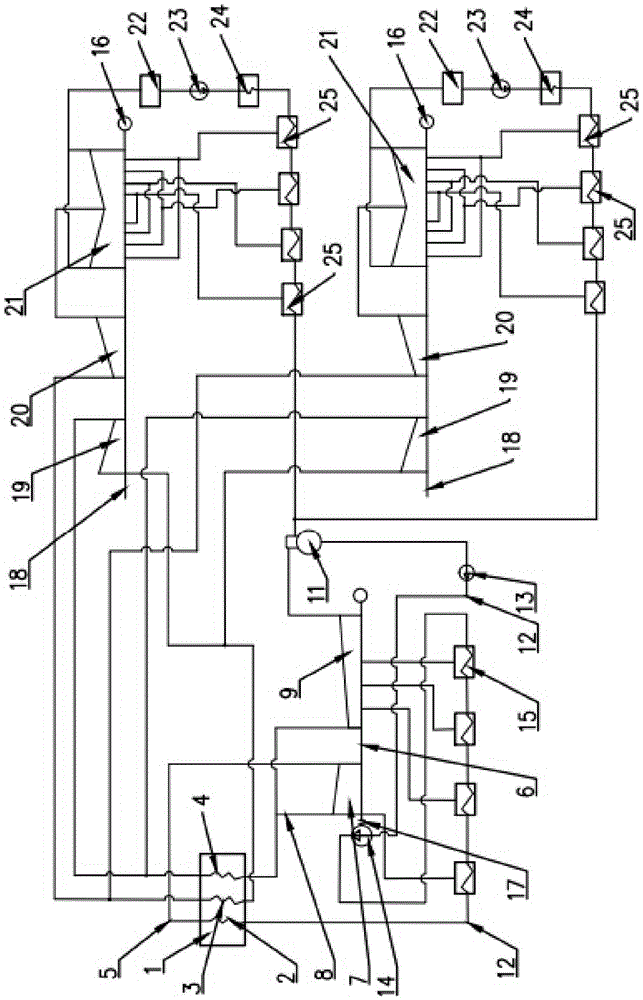

[0027] see figure 1 , the multi-steam turbine combined power generation ultra-supercritical unit of the present invention includes an ultra-supercritical pressure secondary reheat boiler 1, and also includes a plurality of low-parameter turbo-generator sets 18, and each low-parameter turbo-generator set 18 includes a high-pressure cylinder respectively 19. Medium pressure cylinder 20, low pressure cylinder 21 and generator 16;

[0028] The ultra-supercritical pressure secondary reheat boiler 1 is equipped with a heating evaporative superheater 2, a primary reheater 4 and a secondary reheater 3, and the steam outlet of the heating evaporative superheater 2 passes through the pressure steam transmission pipeline 5 and the previous The steam inlet of the ultra-high pressure cylinder 7 of the steam turbine generator set 6 is connected, and the steam outlet of the ultra-high pressure cylinder 7 is respectively connected with the steam inlet of the primary reheater 4 and the extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com