Coal gas pressing device and coal gas pressing control method for furnace kiln coal gas

A technology of pressurizing device and converter gas, which is applied to furnace control devices, furnaces, furnace components, etc., can solve the problems of increasing difficulty in pressure regulation, unstable quality of lime production, and great influence on normal calcination and smooth operation. The benefits of energy saving and emission reduction, stable and controlled heat, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

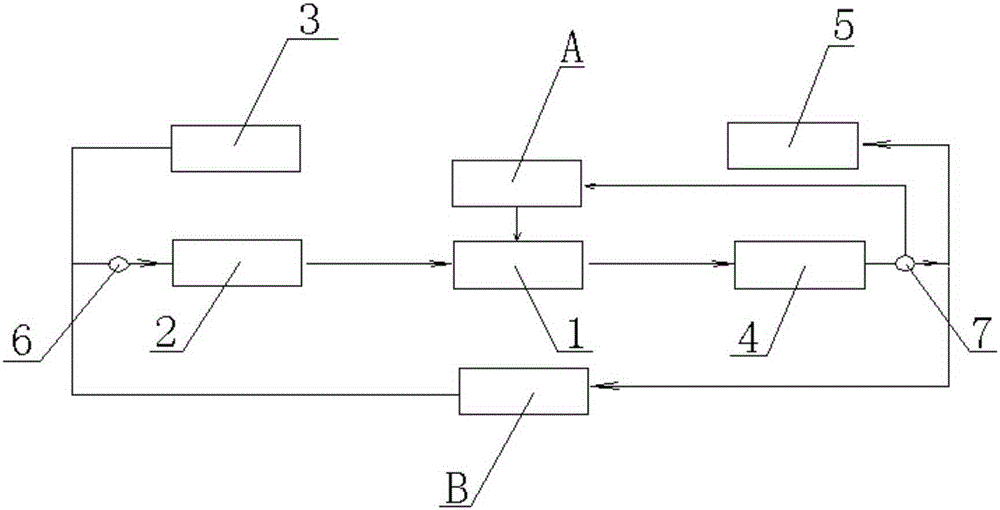

[0044] Such as Figure 1 to Figure 5 As shown, a gas pressurization device for kiln gas includes a gas pressurizer 1, the inlet end of the gas pressurizer is connected with a gas inlet valve 2, and the gas inlet valve is connected with a converter gas supply gas bag 3 The gas path is connected, and the gas outlet end of the gas pressurizer is connected with a gas outlet valve 4, and the gas outlet valve is connected with the gas path of the subsequent furnace system 5;

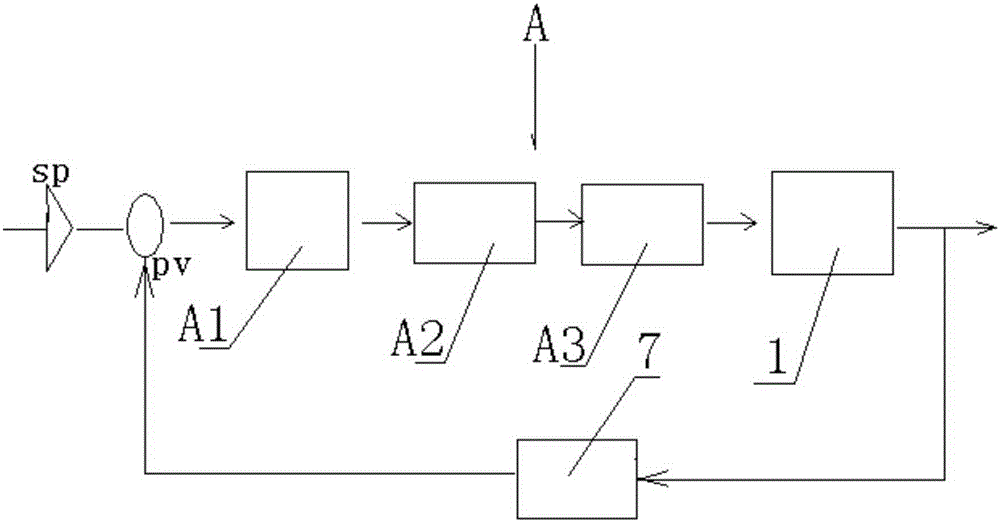

[0045] The gas pressurizer 1 is provided with a frequency converter component A, and the pressure of the gas pressurizer is kept stable through the frequency conversion and speed regulation of the frequency converter component;

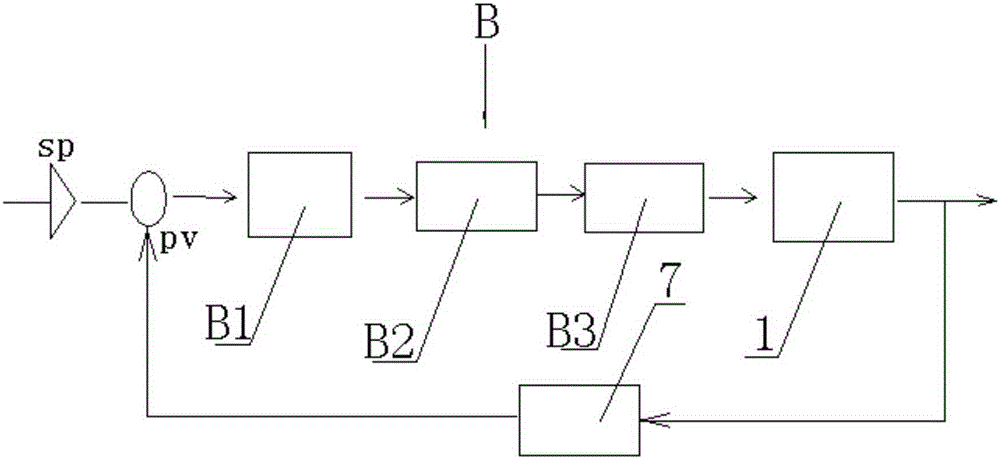

[0046] One end of the backflow valve assembly B is connected to the gas path between the gas inlet valve 2 and the converter gas supply bag 3, and the other end of the backflow valve assembly is connected to the gas path between the gas outlet valve 4 and the furnace system 5 ;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com