Self-compaction mortar and deep hole curtain pouring construction method

A construction method and self-compacting technology, which is applied in water conservancy projects, sea area projects, infrastructure projects, etc., can solve problems such as the lack of suitable self-compacting mortar, and achieve construction quality and stability, which are easy to guarantee, and have obvious benefits in energy saving and emission reduction. highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

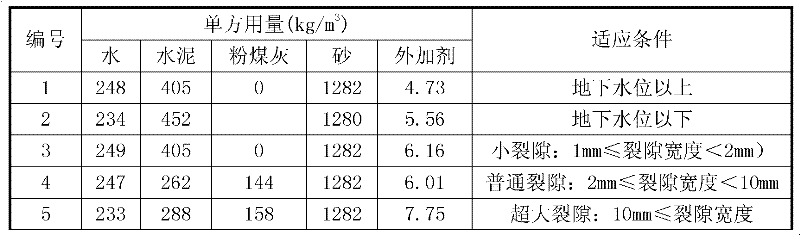

[0046] Self-compacting mortar preparation: prepared according to different self-compacting mortar ratio requirements, the self-compacting mortar production process includes: (1) Preparations before production: ① Select the self-compacting mortar ratio and prepare corresponding raw materials; ② Before the production of self-compacting mortar, the raw materials should be tested to understand the moisture content and fineness modulus of the sand. ③ Make sure that the water in the transport tanker has been drained, and pay attention to stirring during transportation. (2) Matters needing attention in the production process: ① The mixing sequence of the self-compacting mortar is: put the weighed sand and cementitious materials into the mixer for dry mixing, and the dry mixing time of the mixer should not be less than 10 seconds, then add water and admixture Then continue to stir for more than 60 seconds. When the temperature is lower than 15°C, the stirring time should not be less t...

Embodiment 2

[0057] Carry out self-compacting mortar deep hole curtain grouting construction according to the following steps:

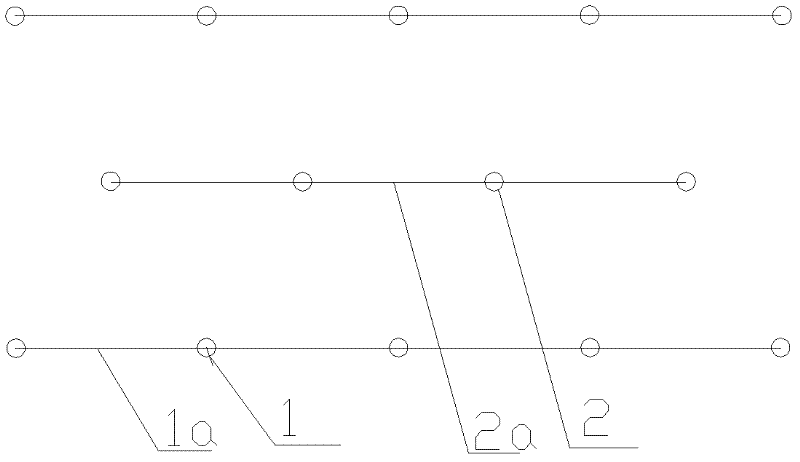

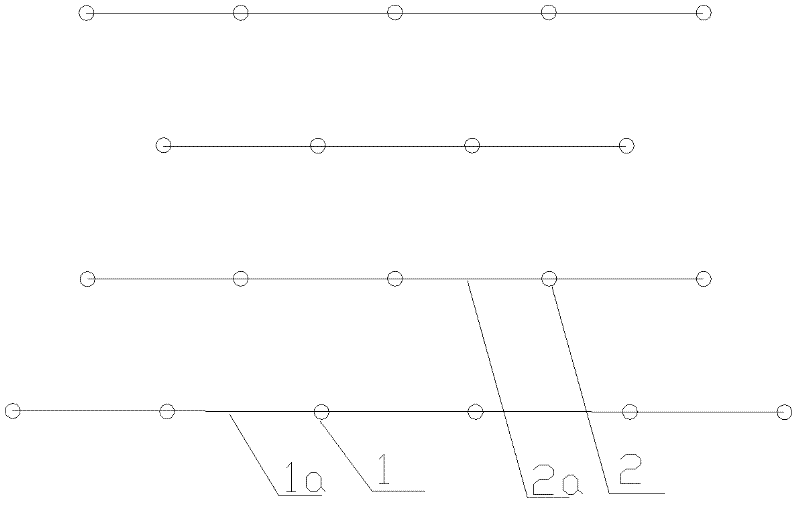

[0058] a. Construction preparation: including erection of construction bent structures, layout of wind and water power systems, layout of sewage system, layout of grouting pipelines, etc. Including accurate hole stakeout according to curtain grouting hole position parameters; hole stakeout can be arranged in two ways, such as figure 2 As shown, first, the row spacing of the door closing holes is 3.0m, and the hole spacing is 0.75m; the middle curtain hole has double rows, the row spacing is 1.0m, and the hole spacing is 1.5m; Hole spacing 1.0m; figure 1 As shown, another arrangement is that the row spacing of the door closing holes is 3.0m, and the hole spacing is 0.75m; the middle curtain hole is single row, and the hole spacing is 1.5m; 1.5m.

[0059] b. Drilling construction: advanced concentric drilling is adopted, drilling in sections from top to bottom,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com