Hybrid dynamic system with combined cycle of internal combustion engine-stirling engine

A hybrid power system, Stirling engine technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of complex structure, lack of operational reliability, difficulty in layout structure, etc., and increase output power. , the effect of improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

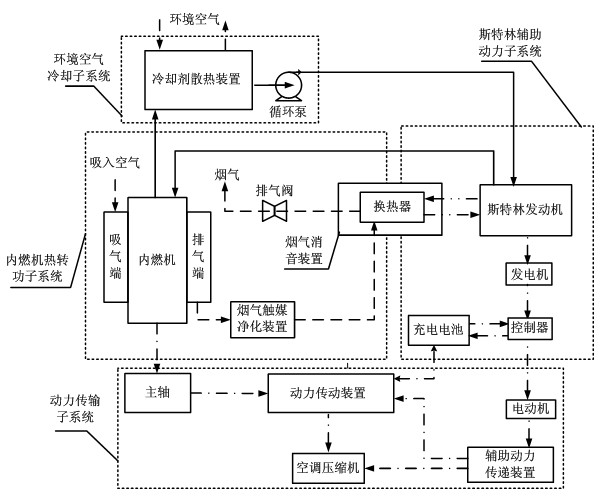

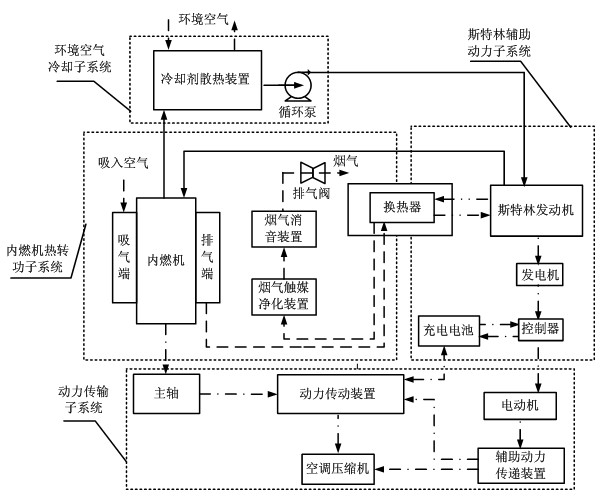

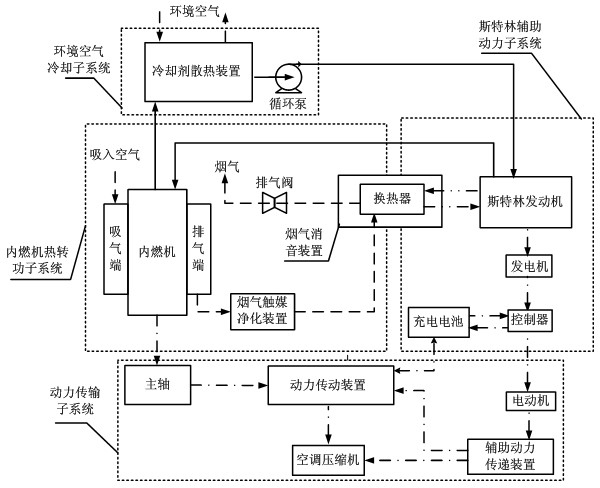

[0014] The hybrid power system of the internal combustion engine-Stirling machine combined cycle that the present invention proposes, such as figure 1 shown. The hybrid power system includes an internal combustion engine heat transfer subsystem, an ambient air cooling subsystem, a power transmission subsystem, and a Stirling auxiliary power subsystem; wherein the internal combustion engine heat transfer subsystem includes an internal combustion engine with an air intake end and an exhaust end, A flue gas catalyst purification device, a flue gas muffler, and an exhaust valve that are sequentially connected to the exhaust end of the internal combustion engine; the engine also has a coolant inlet and a coolant outlet; the ambient air cooling subsystem includes a cooling air inlet, a cooling air outlet, Coolant cooling device and circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com