Waste heat recovery system for environment-friendly coating mechanical equipment

A technology of waste heat recovery system and mechanical equipment, applied in heat exchange equipment, lighting and heating equipment, devices for coating liquid on surfaces, etc., can solve problems such as thermal energy waste, atmospheric environmental pollution, etc. The effect of recycling and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

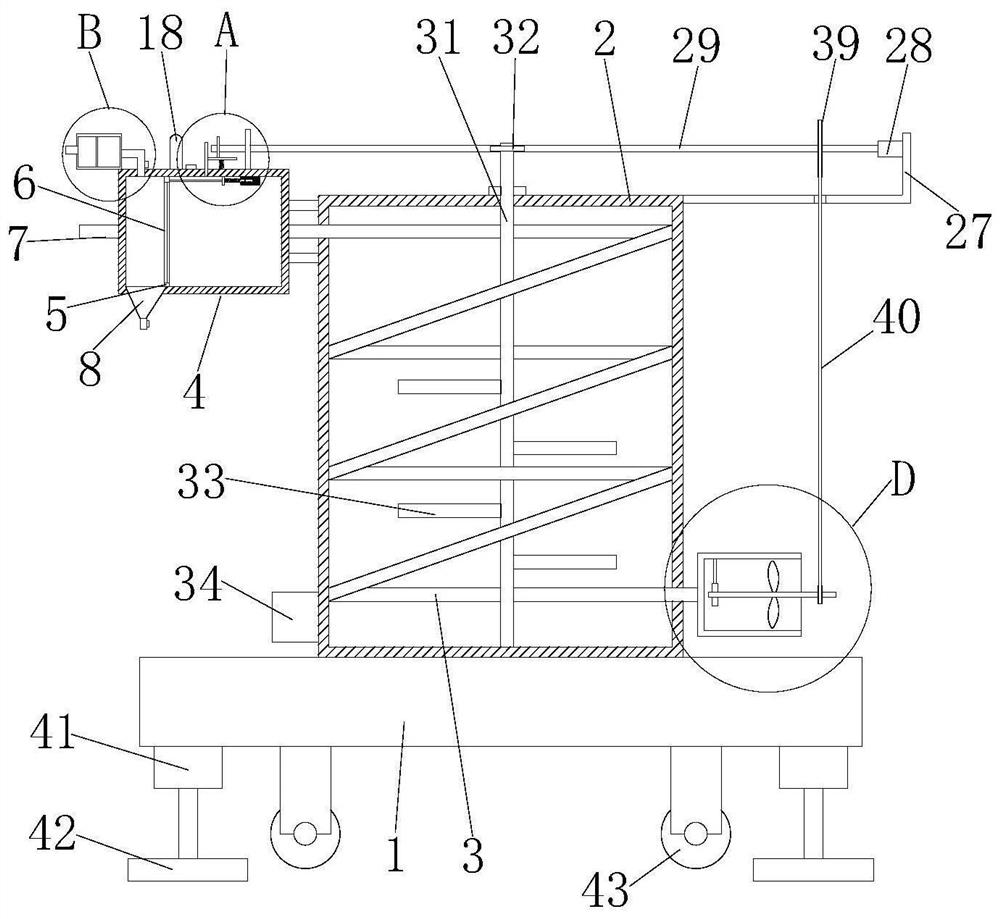

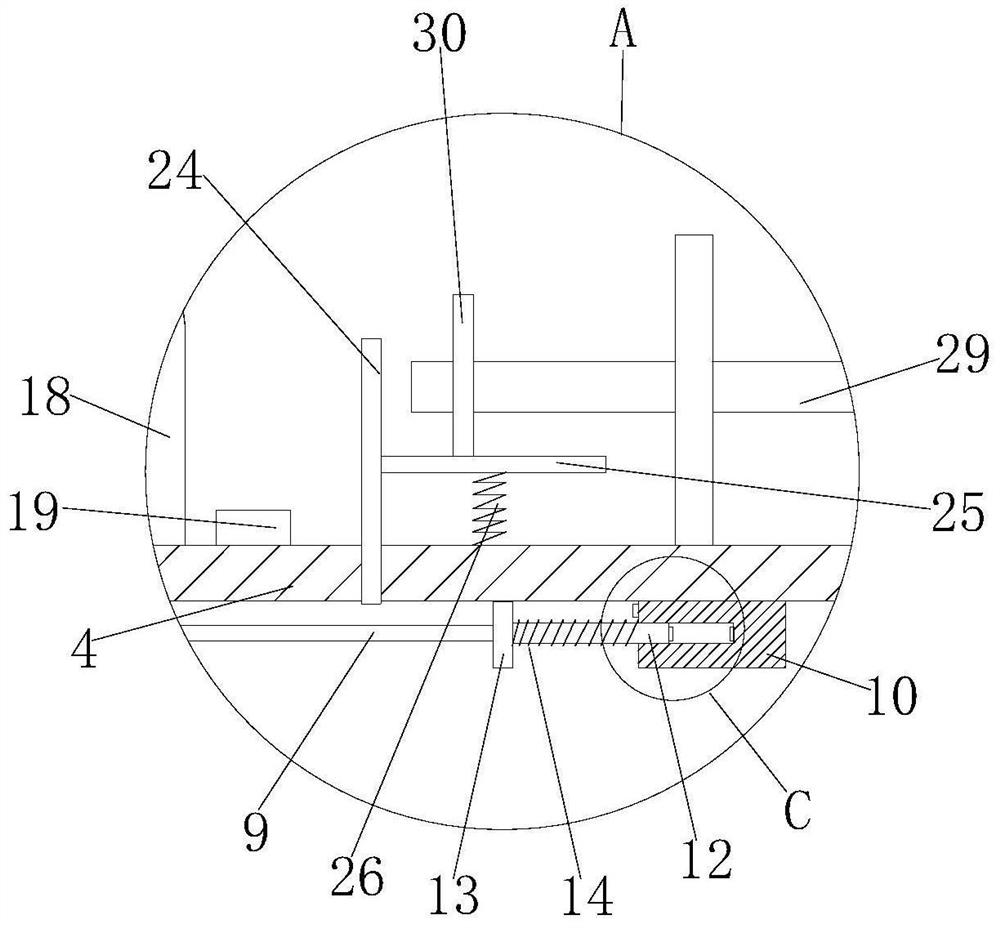

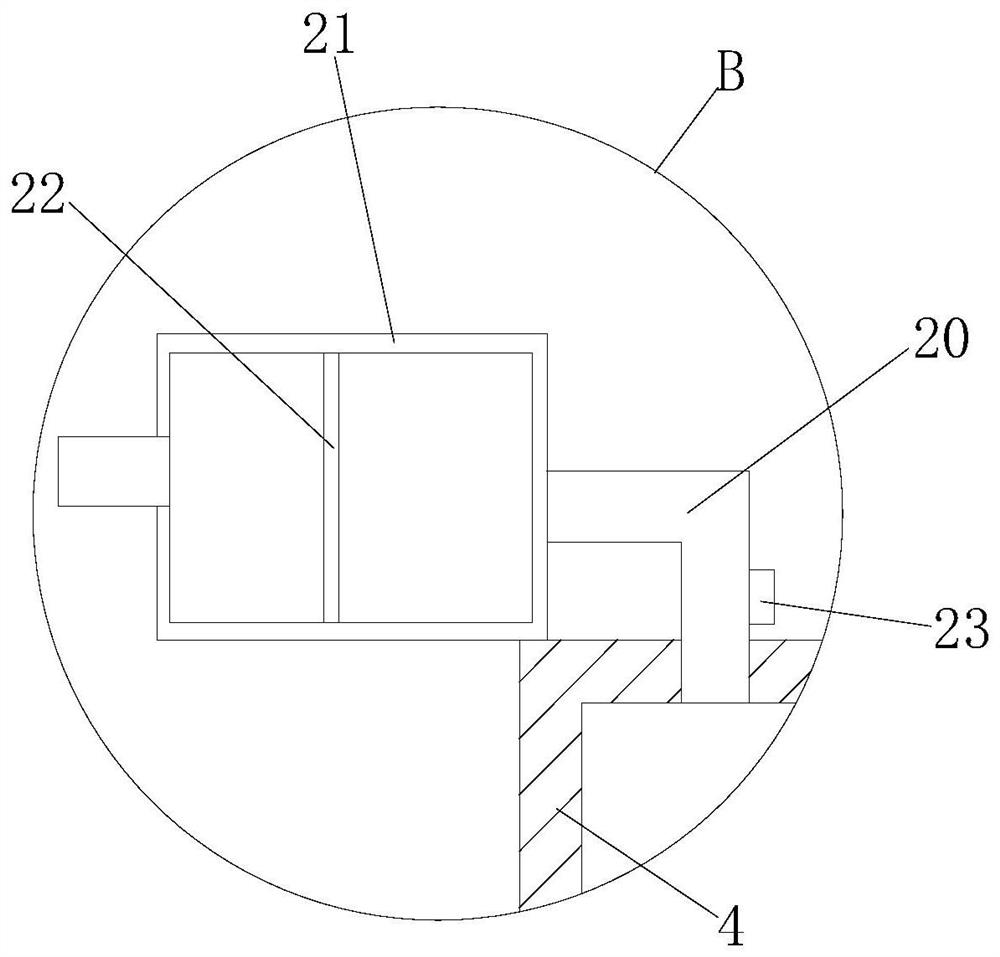

[0031] refer to Figure 1-5 , a waste heat recovery system for coating environmental protection machinery and equipment, including a conveying plate 1, a box 2 is fixedly installed on the top of the conveying plate 1, a spiral coil 3 is arranged on the inner wall of the box 2, and one end of the spiral coil 3 is fixedly installed There is a processing box 4, a sliding frame 5 is slidably installed in the processing box 4, a filter screen 6 is fixedly installed in the sliding frame 5, and a collecting bucket 8 is fixedly connected to the bottom of the processing box 4, and a valve is arranged in the collecting bucket 8, and the processing box 4 One side of the sliding frame 5 is fixedly equipped with an intake pipe 7, one side of the sliding frame 5 is fixedly installed with a side of the contact plate 9, and a fixed seat 10 is fixedly installed on the top inner wall of the processing box 4, and one side of the fixed seat 10 is provided with a chute 11. A slide bar 12 is slidab...

Embodiment 2

[0042] refer to Figure 1-5 , a waste heat recovery system for coating environmental protection machinery and equipment, including a conveying plate 1, a box body 2 is fixed on the top of the conveying plate 1 through bolts, a spiral coil 3 is arranged on the inner wall of the box body 2, and one end of the spiral coil 3 The processing box 4 is fixedly installed by bolts, the sliding frame 5 is slidably installed in the processing box 4, the filter screen 6 is fixedly installed by bolts in the sliding frame 5, and the bottom of the processing box 4 is fixedly communicated with a collecting bucket 8, and the collecting bucket 8 is equipped with There is a valve, one side of the treatment box 4 is fixed with an air inlet pipe 7 by bolts, one side of the sliding frame 5 is fixed with a side of the contact plate 9 by bolts, and the top inner wall of the treatment box 4 is fixed with a fixed seat by bolts 10. One side of the fixed seat 10 is provided with a chute 11, and a slide ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com