Compressed air purification system and using method thereof

A compressed air and purification system technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of raw materials and products and production process pollution, unstable drying effect, low filtration efficiency, etc., to achieve high practicality Sex and market value, stable and reliable purification effect, low cost of use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

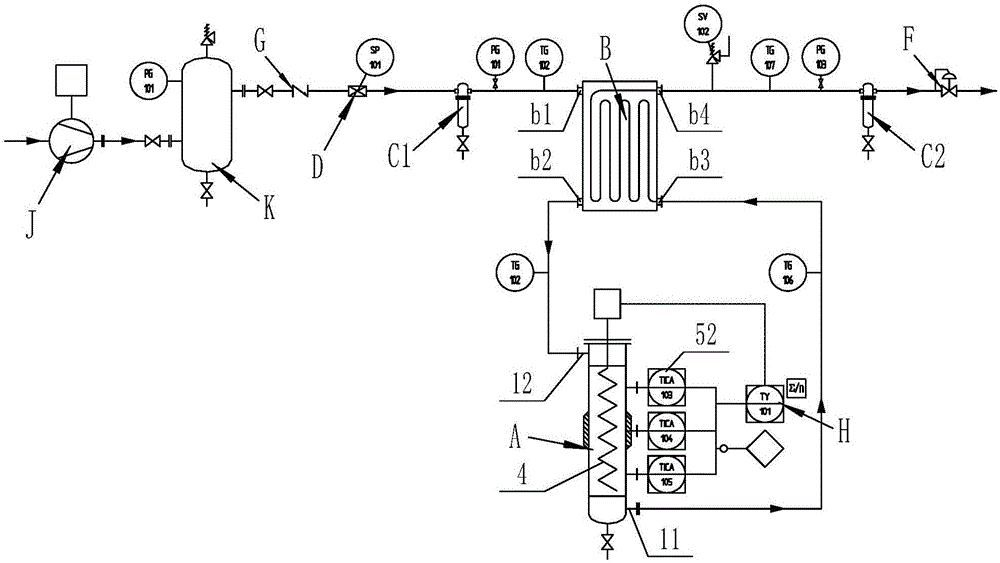

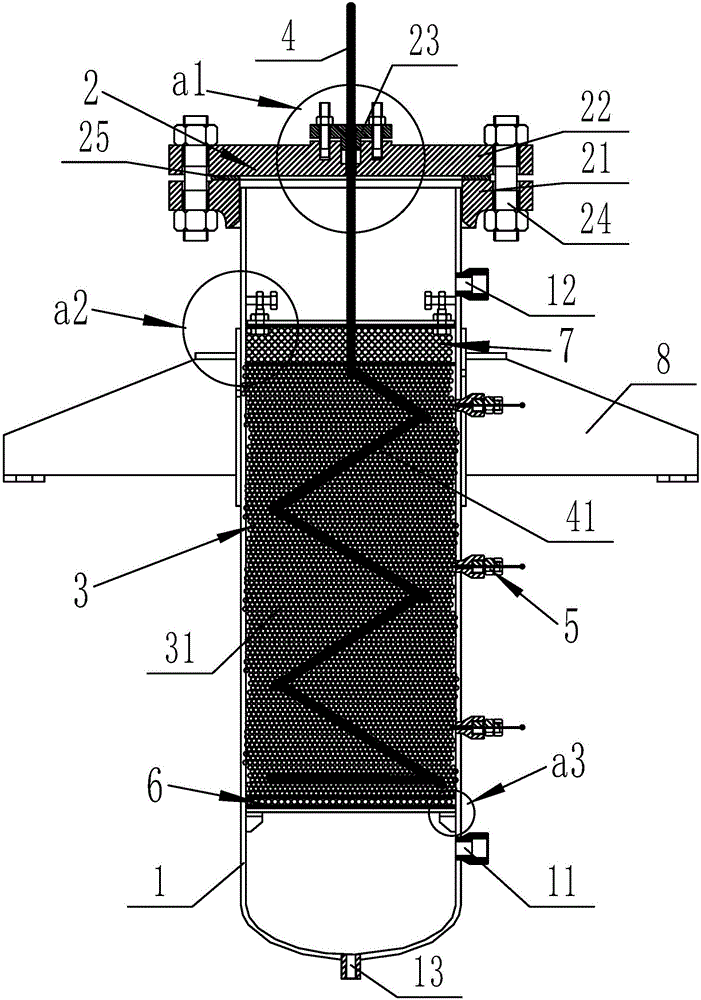

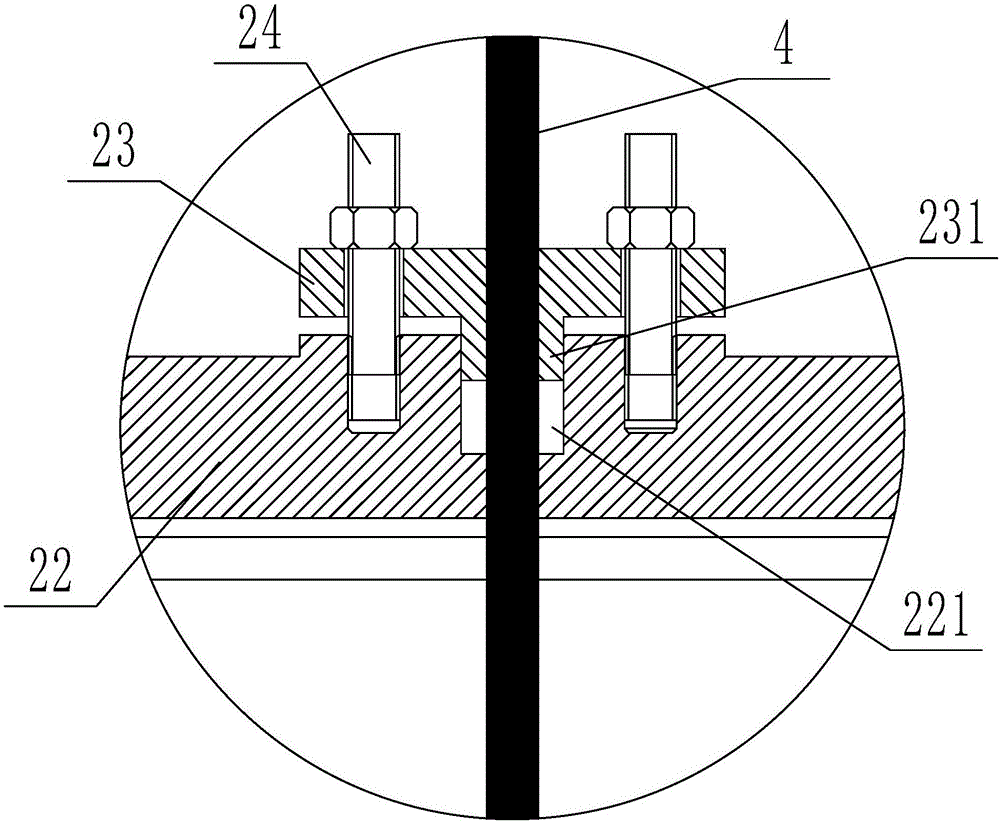

[0036] Such as figure 1 and figure 2 As shown, a compressed air purification system includes a buffer tank K connected to the air compressor J through pipelines, and after the buffer tank K, a check valve G, a flame arrester D, and a first precision filter C1 are sequentially connected through pipelines , Preheating heat exchanger B, reactor A, second precision filter C2 and minimum pressure valve F. The preheating heat exchanger B is provided with a preheating air inlet b1, a preheating air outlet b2, a heat exchange air inlet b3 and a heat exchange air outlet b4. The reactor A includes a cylinder body 1 and a bung assembly 2 fastened on the cylinder body 1. The middle section inside the cylinder body 1 is a reaction zone 3 for filling catalyst packing 31. In the reaction zone 3 The upper cylinder 1 is provided with a reactor air inlet 12, the lower cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com