Thermoelectric generation device using steel ladle surface waste heat

A thermoelectric power generation, ladle technology, applied in the directions of generators/motors, electrical components, etc., can solve the problem of inability to use waste heat, and achieve the effect of solving the problem of unavailability of waste heat, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

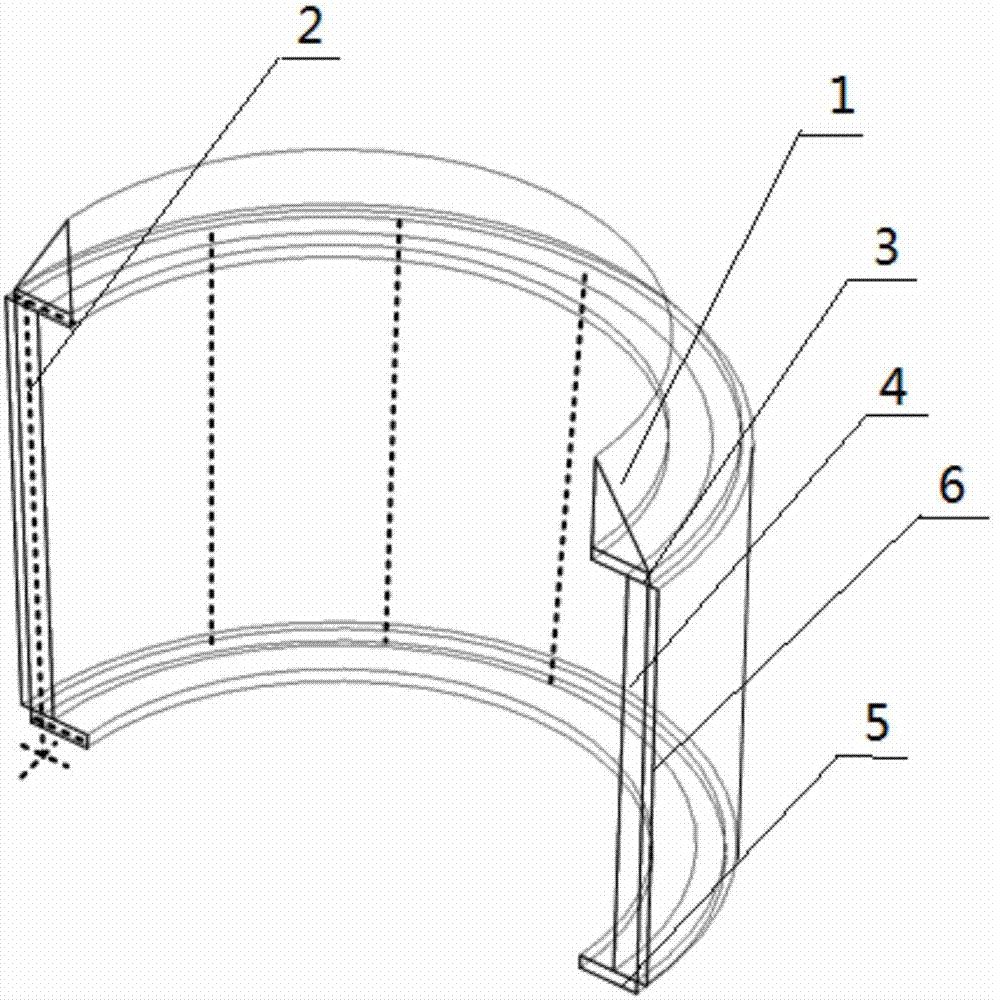

[0031] Such as Figure 1-Figure 4 Shown is a thermoelectric power generation device using waste heat on the surface of a ladle, which is characterized in that the device includes a protective cover 1, a skeleton 2, an upper heat insulation board 3, a thermoelectric system 4, a lower heat insulation board 5 and a cooling system 6;

[0032] The skeleton 2 is a semi-cylindrical bracket;

[0033] The protective cover 1 is welded on the frame 2;

[0034] The upper insulation board 3, the thermoelectric system 4 and the lower insulation board 5 are all fixed on the framework 2 by bolts, forming a semi-cylindrical shape;

[0035] The cooling system 6 is placed outside the thermoelectric system 4;

[0036] The device is composed of two semi-cylindrical shapes.

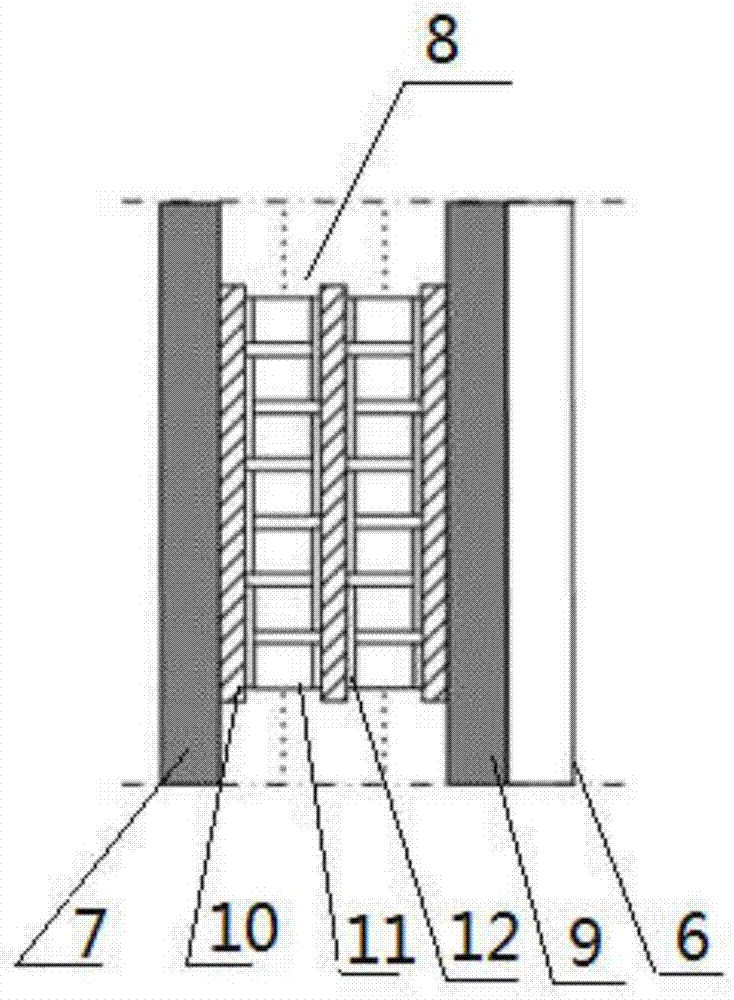

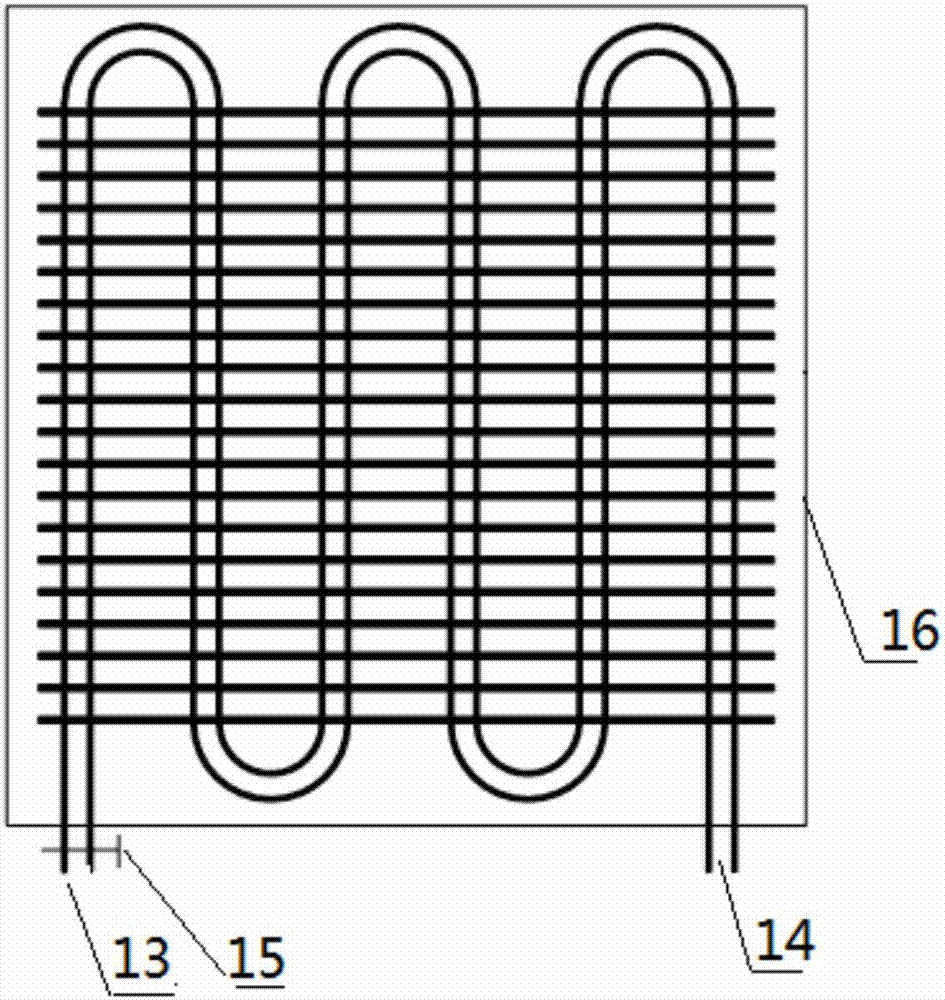

[0037] The thermoelectric system 4 includes an inner receiving thermal copper plate 7, a double-layer thermoelectric module 8, and an outer heat dissipation copper plate 9;

[0038] The thermoelectric system 4 is compresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com