A water seal drain

A drainer and water seal technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of increasing the ground pipeline or equipment foundation height, no alarm device, messy pipeline, etc., to prevent system pressure Large-scale fluctuations, reduce labor intensity, and avoid the effects of messy venues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

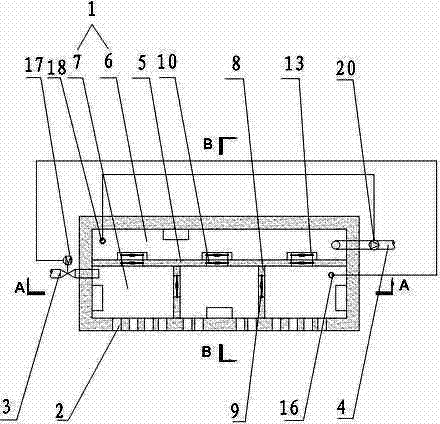

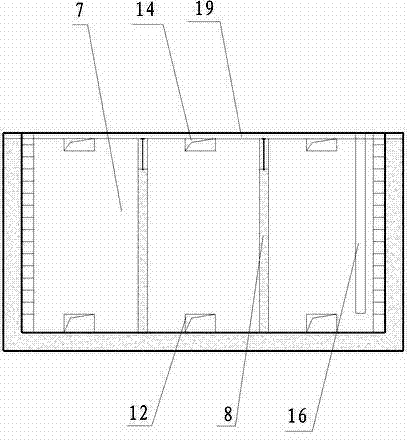

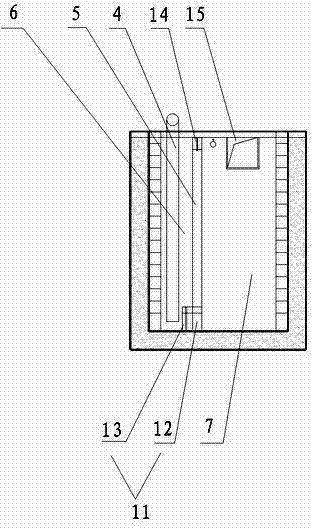

[0033] Such as figure 1 , figure 2 , image 3 As shown, a water-sealed drain includes a pool 1, a water inlet pipe 2, a water supply pipe 3 and a drain pipe 4, and a main partition wall 5 is arranged in the pool 1 to separate the pool 1 into drainage pools that do not communicate with each other. 6 and the water seal body, the replenishment pipe 3 passes through the pool 1 and leads to the water seal body, the drain pipe 4 passes through the pool 1 and leads to the drainage pool 6, the water seal body includes a plurality of water seal pools 7, adjacent water seal The pools 7 are separated into separate independent units by water-sealed partition walls 8, and multiple water inlet pipes 2 pass through the side walls of the pools 1 and lead to each water-sealed pool 7, at the top of each water-sealed partition wall 8 Both overflow devices 9 are provided, and a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com