Boiler wet flue gas condensing, water-collecting and fog-clearing system utilizing power station waste heat to refrigerate

A technology of waste heat refrigeration and flue gas treatment system, which is applied in the direction of boiler absorber, refrigerator, refrigeration components, etc. It can solve the problems of low energy utilization rate, poor energy saving and environmental protection effect, and insufficient fog elimination, and achieve condensation effect Reliable, achieve environmental benefits, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

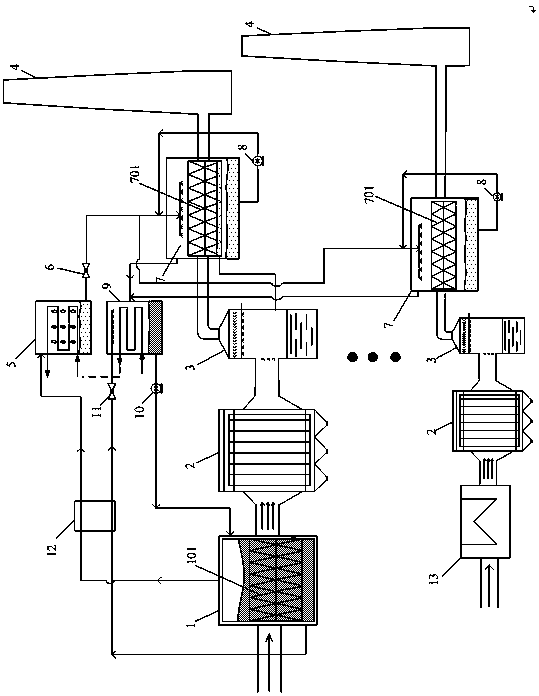

[0032] Such as figure 1 As shown, in this embodiment, a boiler wet flue gas condensation water collection and mist elimination system utilizing waste heat from a power station includes a plurality of boiler unit flue gas treatment systems, and one boiler unit flue gas treatment system is the main boiler unit flue gas treatment system The system includes a waste heat generator 1 , a dust collector 2 , a desulfurization tower 3 , an evaporator 7 and a chimney 4 connected in sequence, and also includes a condenser 5 and an absorber 9 .

[0033] The waste heat generator 1 is provided with a generator heat exchanger 101 through which flue gas passes, and the chamber outside the generator heat exchanger 101 is filled with refrigerant-absorbent solution.

[0034] The evaporator 7 is provided with an evaporator heat exchanger 701 through which flue gas passes, and the top of the evaporator 7 is provided with a spraying device for spraying the evaporator heat exchanger 701 .

[0035] ...

Embodiment 2

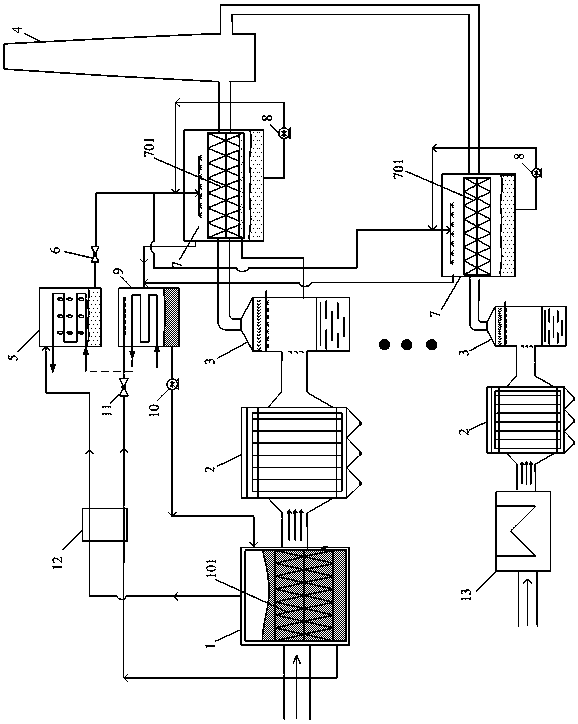

[0058] The difference between this embodiment and the embodiment is: as figure 2 As shown, the flue gas treatment system of the main boiler unit and the flue gas treatment system of the auxiliary boiler unit not only share a refrigeration system, but also share a chimney 4, thereby reducing investment costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com