Blast furnace cinder flushing exhaust steam white smoke elimination and waste heat recovery system

A waste heat recovery system and blast furnace slag flushing technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as corrosion of surrounding buildings, waste of energy and water resources, and waste heat recovery in the scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

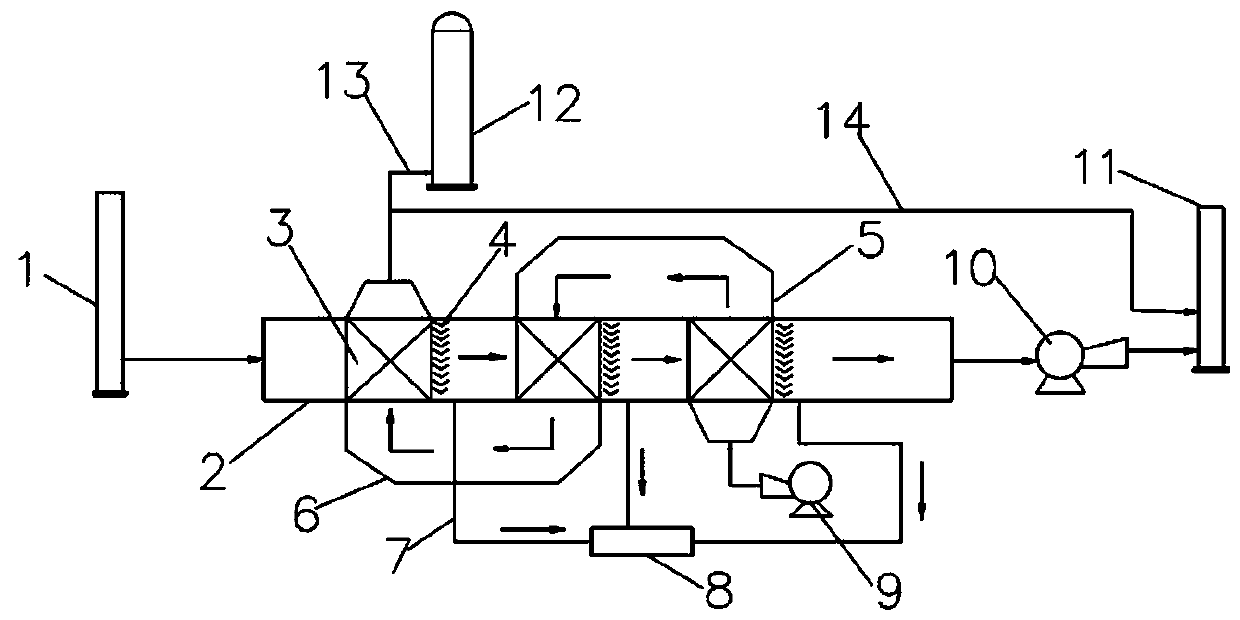

[0019] Such as figure 1 As shown, a blast furnace slag flushing waste steam whitening and waste heat recovery system includes but not limited to slag flushing water exhaust steam release tower 1, exhaust steam channel 2 and air channel.

[0020] The slag flushing water exhaust steam release tower 1 is used to discharge exhaust steam. The exhaust steam channel 2 includes an input end and an output end, and the input end is connected to the exhaust port of the exhaust steam release tower 1 for flushing slag water, and a exhaust steam induced draft fan 10 is installed at the output end. The exhaust steam induced draft fan 10 is used to provide steam extraction power for the exhaust steam. One end of the air passage is connected to an external air source, and the other end is connected to a hot air pipeline. The air passage is connected to the exhaust steam passage 2 meanderingly and multiple times, and the position where the air passage and the exhaust steam passage 2 meet A he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com