Flour yeast composition and applications thereof

A composition and yeast technology, which are applied to the yeast composition for noodles and the application field in the production of noodle food, can solve the problems of destroying, reducing the flavor of noodle products, reducing the nutritional value of noodle products, etc. The effect of maintaining the flavor and nutritional value, and improving the fineness of the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

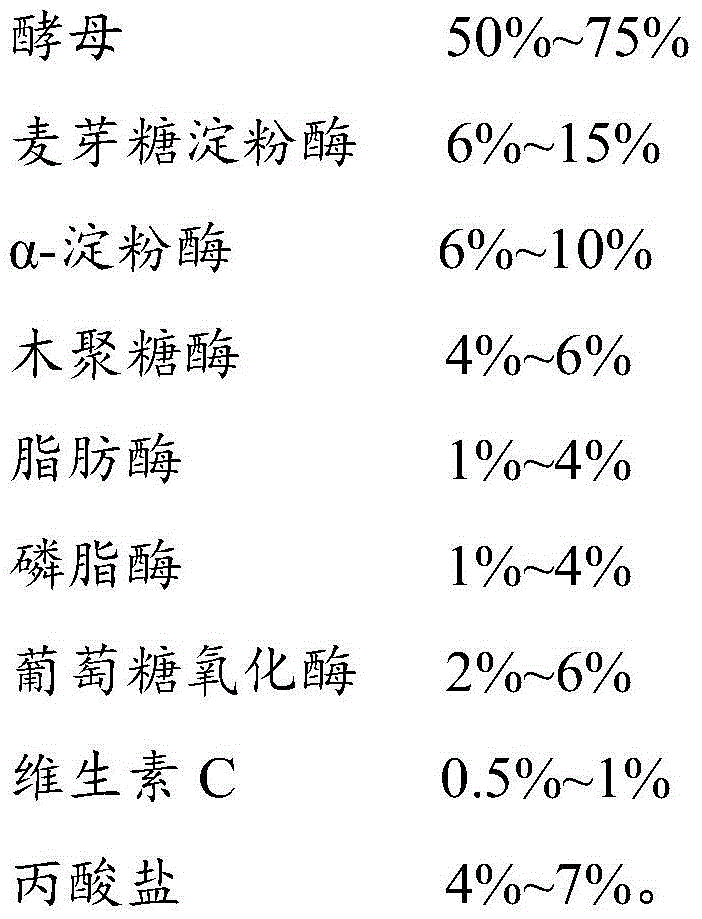

[0030] Prepare 1Kg of dough yeast composition of the present invention, its formula is as follows:

[0031] Yeast 500g, maltose amylase 150g, α-amylase 100g, xylanase 60g, lipase 40g, phospholipase 40g, glucose oxidase 60g, vitamin C 10g, calcium propionate 40g. The above-mentioned components are weighed and mixed uniformly to obtain the noodle yeast composition of the present invention.

example 2

[0033] Prepare 1Kg of dough yeast composition of the present invention, its formula is as follows:

[0034] Yeast 602g, maltose amylase 100g, α-amylase 80g, xylanase 50g, lipase 25g, phospholipase 25g, glucose oxidase 40g, vitamin C 8g, calcium propionate 70g. The above-mentioned components are weighed and mixed uniformly to obtain the noodle yeast composition of the present invention.

example 3

[0036] Prepare 1Kg of dough yeast composition of the present invention, its formula is as follows:

[0037]Yeast 750g, maltose amylase 60g, α-amylase 60g, xylanase 40g, lipase 10g, phospholipase 10g, glucose oxidase 20g, vitamin C 5g, calcium propionate 45g. The above-mentioned components are weighed and mixed uniformly to obtain the noodle yeast composition of the present invention.

[0038] The calcium propionate in embodiment 1~3 adopts microbial fermentation method to make, and preparation method is as follows:

[0039] 1. Culture medium (by weight to volume ratio):

[0040] 1. Seed medium: 1.0% glycerin, 2% yeast extract, 1% bean cake powder, 0.3% dipotassium hydrogen phosphate, 0.3% potassium dihydrogen phosphate, and the balance is water;

[0041] 2. Basic fermentation medium: 3% glycerin, 2% yeast extract, 1% bean cake powder, 0.8% calcium carbonate, 0.3% dipotassium hydrogen phosphate, 0.3% potassium dihydrogen phosphate, and the balance is water.

[0042] Prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com