Patents

Literature

131 results about "Maltogenic amylase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A unique maltogenic amylase enzyme used to produce large quantities of fermentable maltose sugar.

Methods for producing potato products

The present invention relates to methods for producing consumable products from potatoes, comprising: (a) treating a potato substance with an effective amount of one or more exogenous enzymes selected from the group consisting of an amyloglucosidase, glucose oxidase, laccase, lipase, maltogenic amylase, pectinase, pentosanase, protease, and transglutaminase, and (b) processing the enzyme-treated potato substance to produce a potato product. The invention also relates to consumable products obtained from potatoes by the methods of the present invention.

Owner:NOVO NORDISKBIOTECH INC

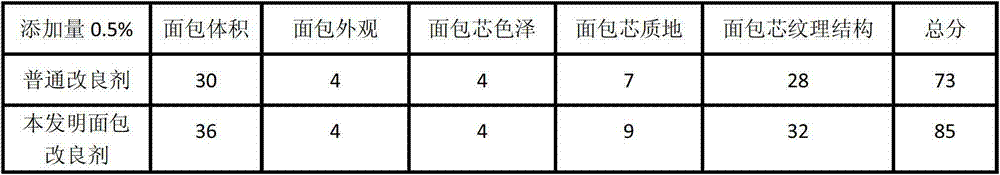

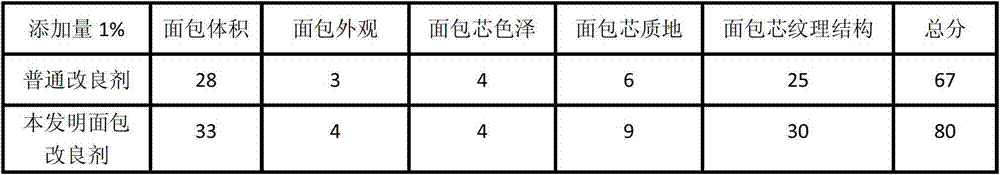

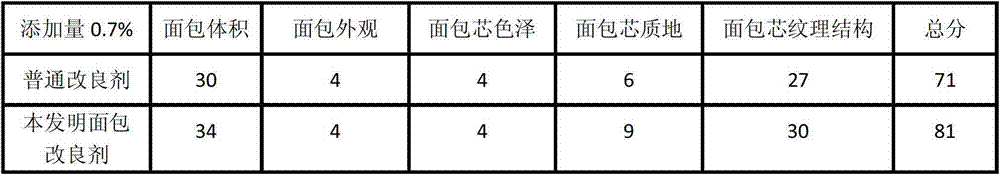

Bread improver and application thereof in bread making

ActiveCN102113530AEasy to operateImprove anti-aging propertiesDough treatmentPre-baking dough treatmentFlavorAntioxidant

The invention relates to a bread improver and application thereof in bread making. The bread improver comprise the following ingredients in terms of the total weight of the improver: 0.9-2.3% of complex enzyme preparation, 0.5-4% of antioxidant, 10-30% of emulsifier, 15-40% of inactivated dried yeast and the balance of starch. The complex enzyme preparation comprises the following ingredients in terms of the total weight of the improver: 0.05-0.3% of alpha-amylase, 0.5-1% of hemicellulase, 0.3-0.7% of maltose amylase, and 0.05-0.3% of lipase. The improver provided by the invention is a composite additive for improving bread quality and can be used for improving the rheological properties and the processability of dough, effectively inhibiting dough aging and improving bread flavor.

Owner:ANGELYEAST CO LTD

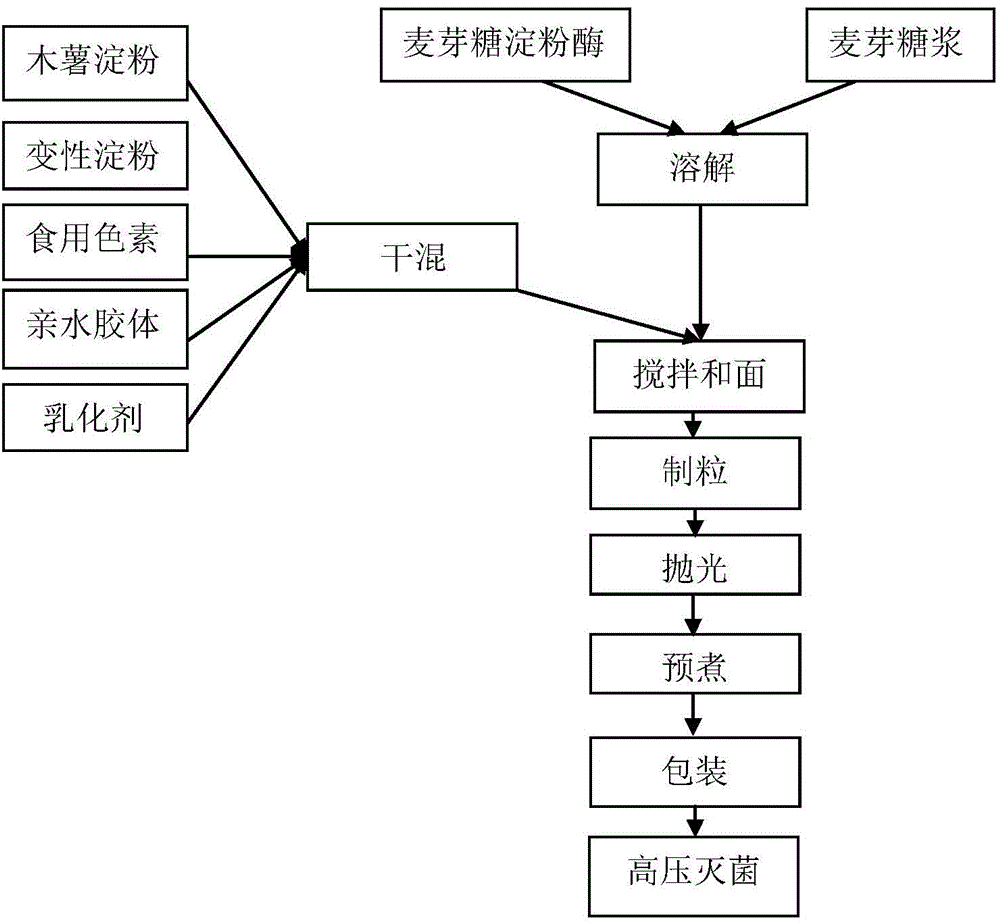

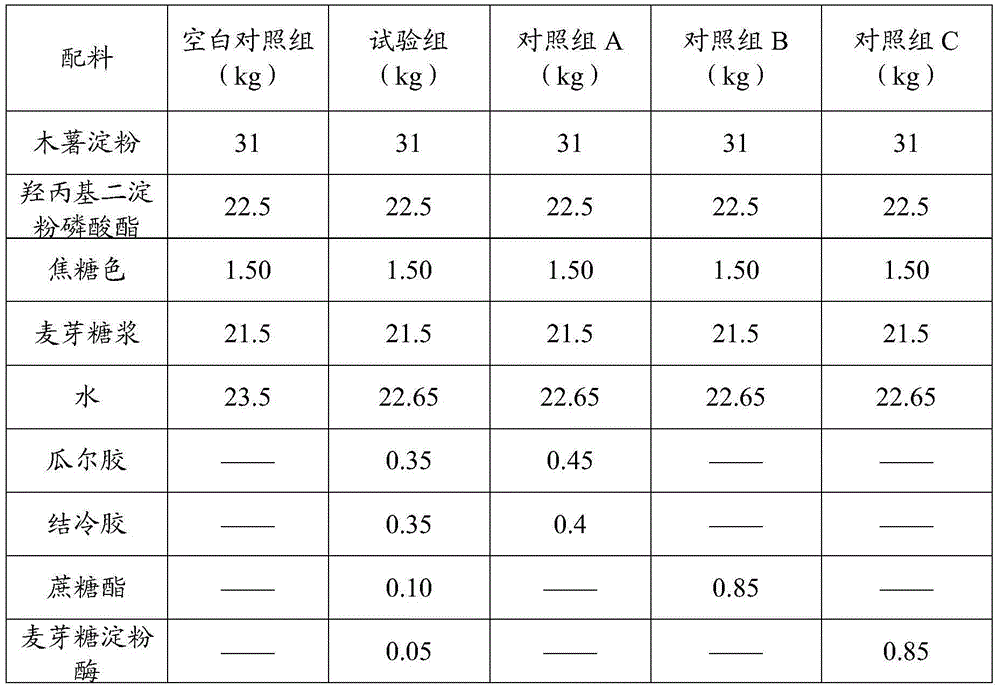

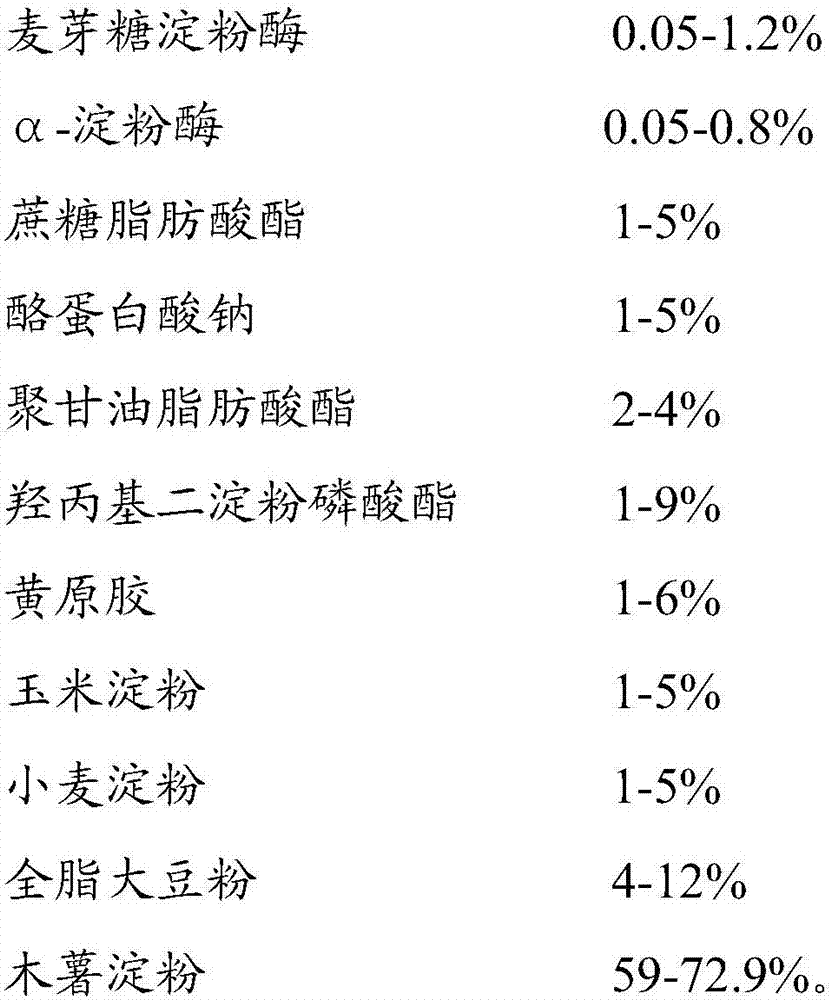

Aging-resistant starch composition, tapioca pearls and preparation method of tapioca pearls

InactiveCN104905086AAnti-aging propertiesElasticFood preparationHigh volume manufacturingResistant starch

The invention relates to the technical field of food and food processing, particularly to an aging-resistant starch composition, tapioca pearls and a preparation method of the tapioca pearls. The aging-resistant starch composition consists of hydrophilic colloid, an emulsifying agent and maltogenic amylase. The hydrophilic colloid, the emulsifying agent and the maltogenic amylase are combined in an appropriate proportion, so that the aging-resistant starch composition has the characteristic of furthest cooperating with starch for aging resistance, and the purposes that the tapioca pearls are still elastic and chewy and are high in safety after long-term storage are achieved. The preparation method of the tapioca pearls, provided by the invention, is simple, so that the tapioca pearls are suitable for mass production.

Owner:I LAN FOODS IND +1

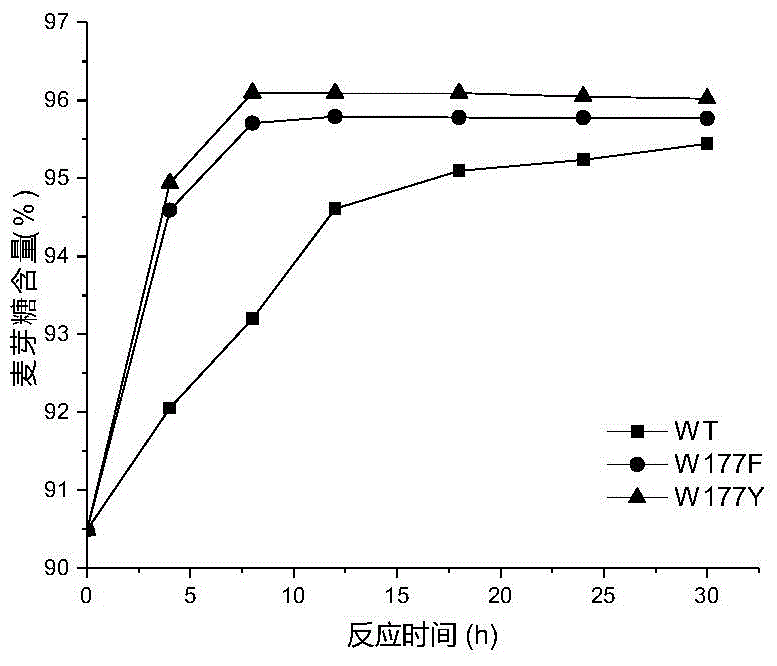

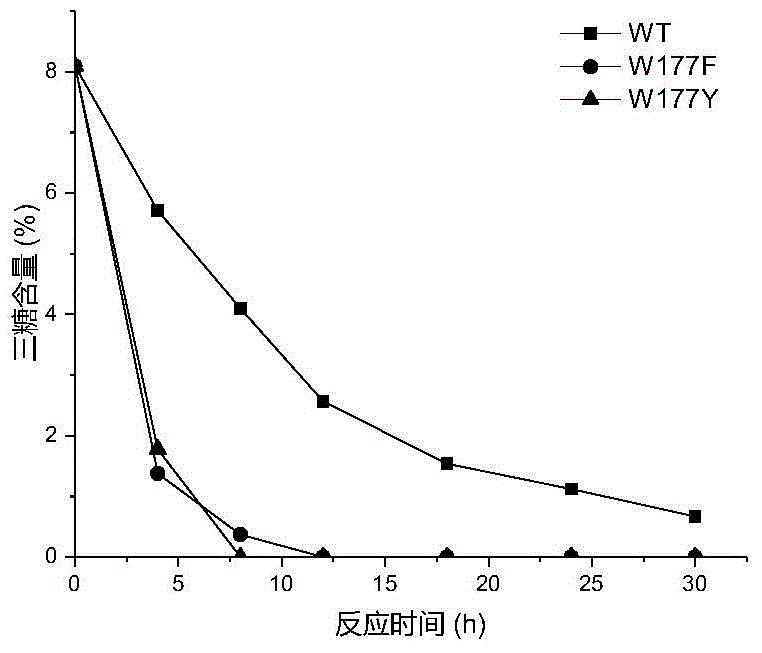

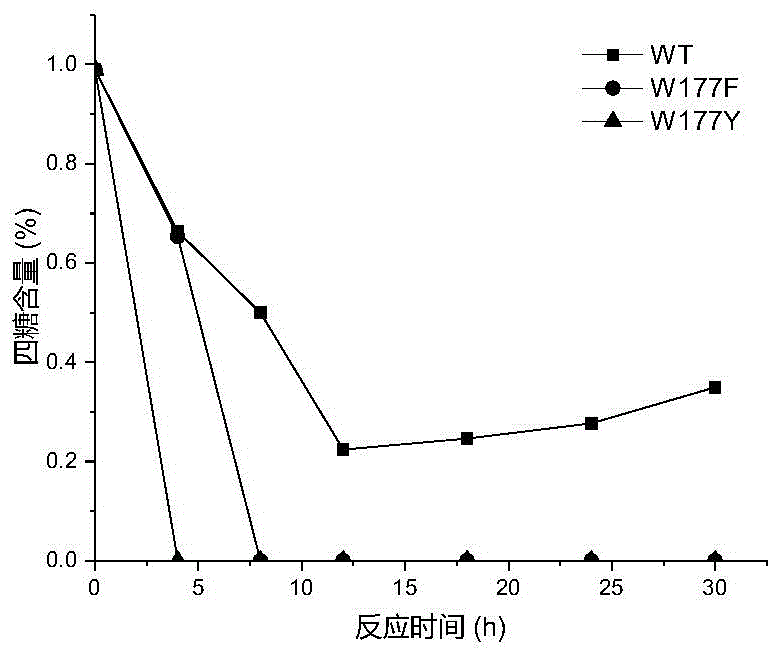

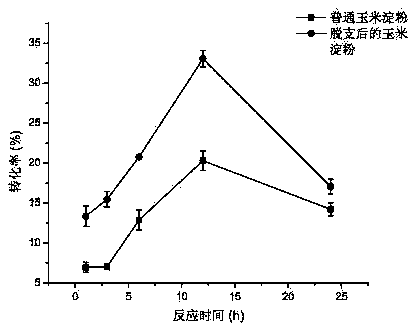

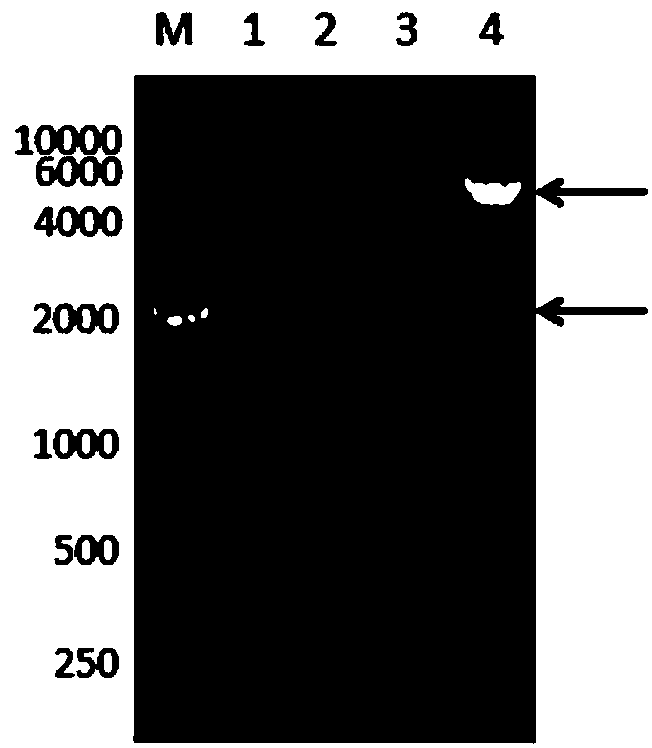

Mutant of maltogenic amylase and preparation method of mutant

ActiveCN104531636AIncrease productivityEasy to separate and purifyMicroorganism based processesFermentationWild typeGenetic engineering

The invention discloses mutant of maltogenic amylase and a preparation method of the mutant, and belongs to fields of genetic engineering and enzyme engineering. According to the mutant, amino acid residues in the glucoside conversion activity center of maltogenic amylase derived from Bacillus stearothermophilus are substituted. Compared with maltogenic amylase of a parental generation, the maltogenic amylase has a relatively high conversion rate to maltose and a relatively small amount of conversion byproducts. At least one of the following properties of B.stearothermophilus maltogenic amylase mutant is changed: 1) the production period is shortened; 2) the product ratio is increased. Compared with wild maltogenic amylase, the mutant is relatively applicable to the production process of maltose.

Owner:JIANGNAN UNIV

Bread improver containing soluble soybean polysaccharide and preparation method and application thereof

InactiveCN103027088AKeep the smell of oilImproved water absorption and water retentionDough treatmentMonoglycerideAlpha-amylase

The invention discloses bread improver containing soluble soybean polysaccharide, which comprises the soluble soybean polysaccharide, oxidant, enzyme preparation, emulsifier and a filler, wherein the oxidant is L-ascorbic acid; the enzyme preparation is alpha-amylase, maltogenic amylase, lipase, pentopan, cellulase and glucose oxidase; the emulsifier is sodium stearyl lactate, calcium stearyl lactylate and diacetyl tartaric acid monoglyceride; and the filler is corn starch. The invention further discloses a preparation method and application of the bread improver. The bread improver can remarkably improve the bread taste, and can prolong the bread quality time.

Owner:EAST CHINA NORMAL UNIV +1

Anti-ageing composition for cakes, cakes and preparation method of cakes

InactiveCN106259601AHigh degree of anti-agingExtended shelf lifeDough treatmentDough/pre-mixesSucroseAnti ageing

The invention discloses an anti-ageing composition for cakes. The anti-ageing composition is prepared from the following components in percentage by weight: 70 percent to 90 percent of hydroxypropyl distarch phosphate, 1 percent to 5 percent of a thickener, 5 percent to 10 percent of sucrose fatty acid ester, 5 percent to 15 percent of an emulsifier, 0.3 percent to 1.5 percent of sodium polyacrylate and 0.1 percent to 1 percent of maltogenic amylase, wherein the sum of the total weight percent of the components is 100 percent. Furthermore, the invention also discloses the cakes containing the anti-ageing composition and a preparation method of the cakes, wherein the use amount of the anti-ageing composition is 10 percent to 20 percent of the use amount of flour. After the anti-ageing composition provided by the invention is added into the cakes, the cakes can have the effects of not dropping dreg, not becoming dry and not becoming hard; the cakes are convenient to use and high in safety.

Owner:东莞市欣荣天丽科技实业有限公司

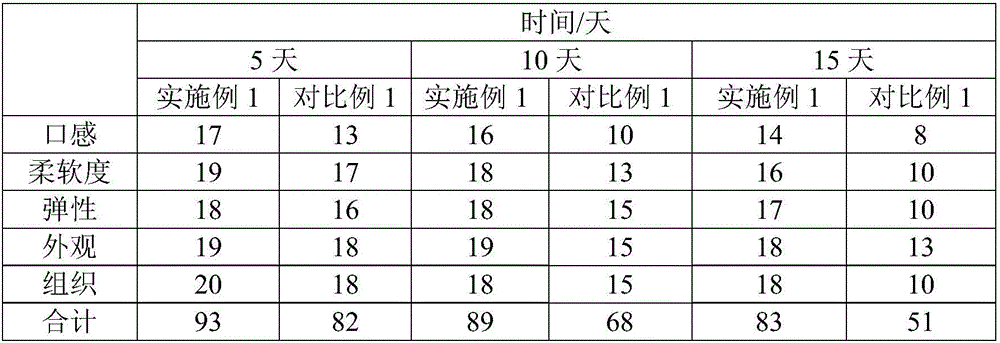

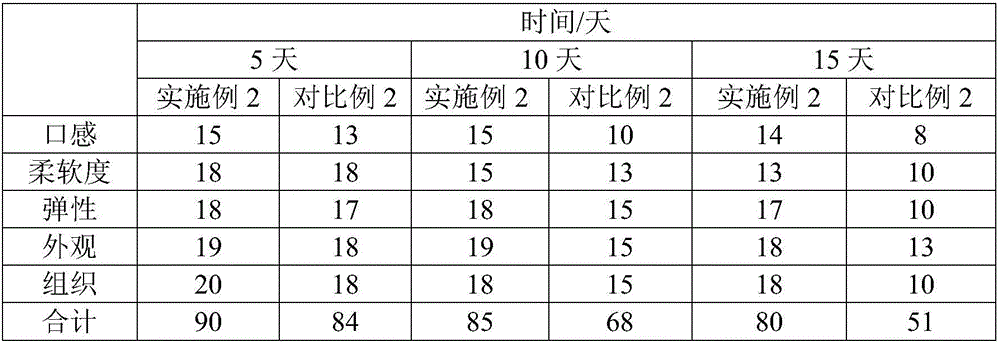

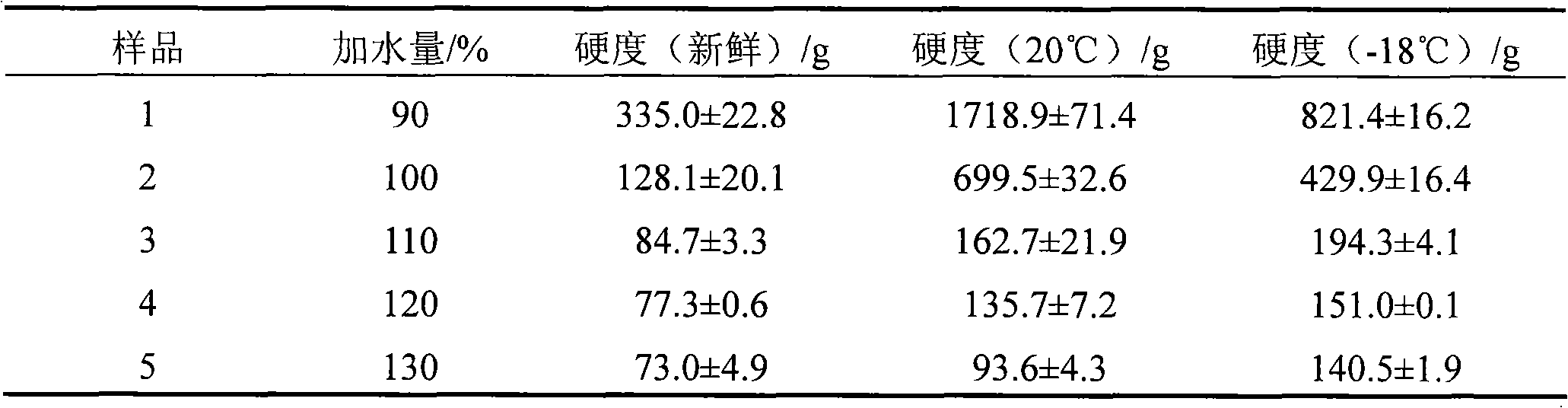

Antiaging method for rice product-mashu

InactiveCN101406311AExtended shelf lifeEasy to storeFood preservationBakery product preservationBiotechnologyFood additive

The invention provides an anti-aging method for deep-fried glutinous rice cake stuffed with bean paste, which belongs to the technical field of agro-product processing and food additive. The invention mainly relates to preparation of an anti-aging compound emulsifying agent and anti-aging application of the compound emulsifying agent and an enzyme agent to the deep-fried glutinous rice cake stuffed with bean paste. In the invention, glutinous rice flour is taken as a main raw material, certain amount of the compound emulsifying agent, the enzyme agent, sugar and water are added, and the product, namely deep-fried glutinous rice cake stuffed with bean paste is produced by stewing and forming processes. The compound emulsifying agent is mainly produced by an extrusion method. A plurality of powder emulsifying agents with good anti-aging effect is evenly distributed on the surface of starch particles. The compound emulsifying agent with good anti-aging effect is obtained by controlling extrusion parameters. The optimal adding amount of the compound emulsifying agent is between 0.2 and 3 percent. The enzyme agent mainly adopts maltose amylase with the adding amount of between 0.02 and 0.15g / kg. The adding amount of the water and the sugar is respectively 110 to 120 percent and 20 to 50 percent of the weight of the glutinous rice flour. Through adding the compound emulsifying agent and the enzyme agent, the deep-fried glutinous rice cake stuffed with bean paste has good anti-aging function, and ensures that the guarantee period is more than 60 months.

Owner:JIANGNAN UNIV

Buckwheat bran dietary fiber containing cake and manufacture method thereof

ActiveCN101889599AImprove nutritional qualityDough treatmentBakery productsPolygonum fagopyrumMonoglyceride

The invention discloses a buckwheat bran dietary fiber containing cake and a manufacture method thereof. The cake comprises the following raw materials in part by weight: 1 to 9 parts of buckwheat bran dietary fiber powder, 5.5 to 8 parts of corn starch, 12 to 18 parts of vegetable oil, 22 to 34 parts of shelled eggs, 21 to 27 parts of white granulated sugar, 0.2 to 0.3 part of edible powdered milk flavor essence, 0.2 to 0.3 part of salt, 0.2 to 0.3 part of maltase-glucoamylase, 0.4 to 0.6 part of monoglyceride, and the balance of progressive self-raising flour. The method comprises the following steps of: degrading a phytic acid of the buckwheat bran; extracting and modifying bran dietary fiber; preparing dietary fiber powder; weighing raw and auxiliary materials of the cake; preparing mixed flour; agitating the mixed flour; preparing paste by using the mixed flour; injecting the paste into a mold; baking the molded paste; and demolding the molded paste and the like to obtain the buckwheat bran dietary fiber containing cake. The cake can promote intestine and stomach peristalsis of human bodies, help digestion, reduce blood fat and cholesterol, and regulate blood sugar due to the containing of the dietary fiber, so that the nutrient quality of the cake is improved.

Owner:HUITOUKE FOOD FUJIAN

Preparation method of Se-enriched nutrient corn beverage

The invention discloses a preparation method of Se-enriched nutrient corn beverage, which is characterized by comprising the following steps of: using fresh sweet corn as raw material, conducting controlled hydrolyzing on fresh sweet corn steep liquor starch liquid by using amylase and maltogenic amylase, then using Lactobacillus acidophilus and Se-enriched beer yeast to carry two-stage fermentation on corn liquid, and obtaining a novel Se-enriched natural corn beverage product with rich health care functional factors and good taste.

Owner:ZHEJIANG UNIV

Preparation method of pulp with high fruit sugar content

InactiveCN101756157AImprove conversion rateGood isomerization effectFood preparationSodium phosphatesPhosphoric acid

The invention provides a preparation method of pulp with high fruit sugar content, which comprises the following steps: (1) soaking dried sweet potatoes or rice corns by water at the room temperature, grinding the dried sweet potatoes or the rice corns into pulp, and filtering the pulp by a filter sieve of more than 70 meshes; (2) regulating the pH value of the pulp to 5.5 to 5.6 by phosphoric acid, adding water to regulate the mass concentration to 30 to 35 percent, adding calcium chloride accessory agents and high-temperature resistance amylase, and uniformly stirring and mixing the mixture; (3) carrying out spraying liquefaction by the mixed pulp at 110 to 113 DEG C, reducing the temperature to 85 to 90 DEG C in 5 to 20 minutes, and then, liquefying the materials for 35 to 45 minutes; (4) carrying out filtration and deslagging; (5) adding maltogenic amylase and debranching enzyme for saccharification for 45 to 55 hours, and then, carrying out enzyme extinguishment and material discharge; (6) carrying out decolourization and filtration; (7) adding sodium phosphate solution into decolourization material liquid for regulating the pH value to 6.0 to 6.7, then, adding glucose isomerase for isomerization for 15 to 20 hours, and next, deactivating the glucose isomerase; (8) carrying out the ion exchange treatment; (9) concentrating obtained materials; and (10) carrying out package. The pulp with high fruit sugar content prepared by adopting the method of the invention has the advantages that the fruit sugar content in dry materials reaches 55 to 58 percent, and the starch conversion rate reaches 90 to 97 percent.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for producing 2,3-butanediol by using starch raw materials

InactiveCN101565721AWide variety of sourcesLow priceMicroorganism based processesFermentationK pneumoniaeAlpha-amylase

The invention discloses a method for producing 2,3-butanediol by using starch raw materials, which comprises the following steps: subjecting the starch raw materials to treatment by alpha-amylase and maltogenic amylase; and producing the 2,3-butanediol by carrying out separate hydrolysis and fermentation or simultaneous sacchrification and fermentation under an aseptic condition, using saccharification liquid or liquefaction liquid as a fermentable substrate and using Klesiella pneumoniae as a fermentable strain. Finally the concentration of the 2,3-butanediol reaches 43 to 112g / L, and the final concentration of acetoin and the final concentration of the 2,3-butanediol reach 45 to 121g / L. The method has the advantages of using the starch raw materials to produce a high-value platform compound by fermentation, reducing the raw material cost of the production of the 2,3-butanediol by the fermentation and establishing the optimal fermentation condition for the production of the 2,3-butanediol by the sacchrification and fermentation of the starch raw materials. The production of the 2,3-butanediol by the simultaneous sacchrification and fermentation of the invention can save energy and equipment investment, reduce fermentation period and improve production efficiency.

Owner:SHANDONG UNIV

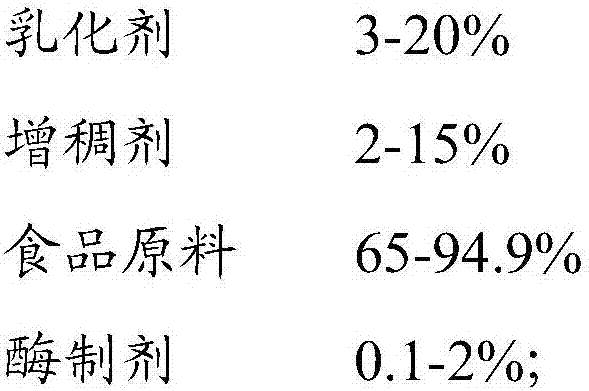

Cake modifying agent

ActiveCN107156220AStay softSoft tasteDough treatmentLeguminous plant bakery productsPhosphateSodium Caseinate

The invention relates to a cake modifying agent. The cake modifying agent comprises, by weight, 3-20% of emulsifying agent, 2-15% of thickening agent, 65-94.9% of food raw materials, and 0.1-2% of enzyme preparation, wherein the emulsifying agent is one or more of single / double-glycerin fatty acid ester, sucrose fatty acid ester, sodium caseinate, and polyglycerin fatty acid ester; the thickening agent is one or more of hydroxypropyl di-starch phosphate and xanthan gum; the enzyme preparation is one or more of maltogenic amylase and alpha-amylase. The cake modifying agent is suitable for being applied to black rice cake manufacturing, the water-prevention and moisture-retaining performance of the black rice cake can be intensified, the ageing problem like product spalling and scaling are postponed, and thus soft, delicate and wet mouthfeel of the cake is maintained.

Owner:GUANGZHOU WELBON BIOLOGICAL TECH

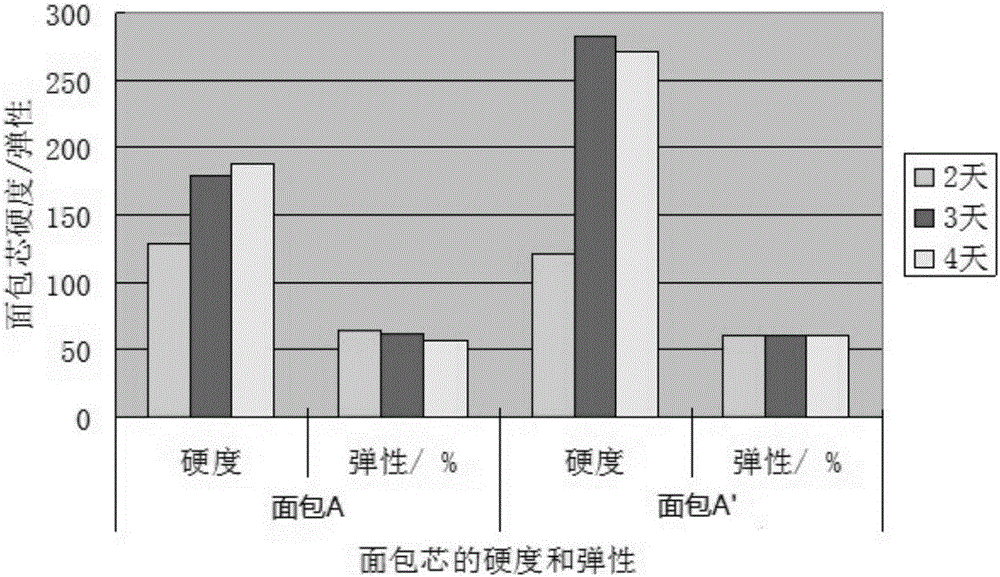

Bread refreshment-retaining enzyme preparations and application thereof

ActiveCN103651662AStable fermentationIncrease in sizeHydrolasesPre-baking dough treatmentAlpha-amylaseXylanase

The invention discloses bread refreshment-retaining enzyme preparations and the application thereof. The bread refreshment-retaining enzyme preparations comprises the components, by weight, of 5%-20% of maltogenic amylase, 0.3%-1.2% of fungus alpha-amylase, 0.2%-0.8% of xylanase and 1%-1.6% of lipase, and the balance starch. During bread making, the adding weight of the bread refreshment-retaining enzyme preparations is 0.08%-0.12% of the weight of flour. According to the bread refreshment-retaining enzyme preparations, during bread making, enzyme adding quantity is small, cost is low, through synergistic effect of various enzymes in the enzyme preparations, the aging speed of bread can be greatly lowered, the freshness of the prepared bread can be kept for a long time, and long-term storage of packaged bread processed in a large-scale mode can be well achieved.

Owner:ANHUI LEVEKING BIOTECH CO LTD

Enzymatic dough conditioner and flavor improver for bakery products

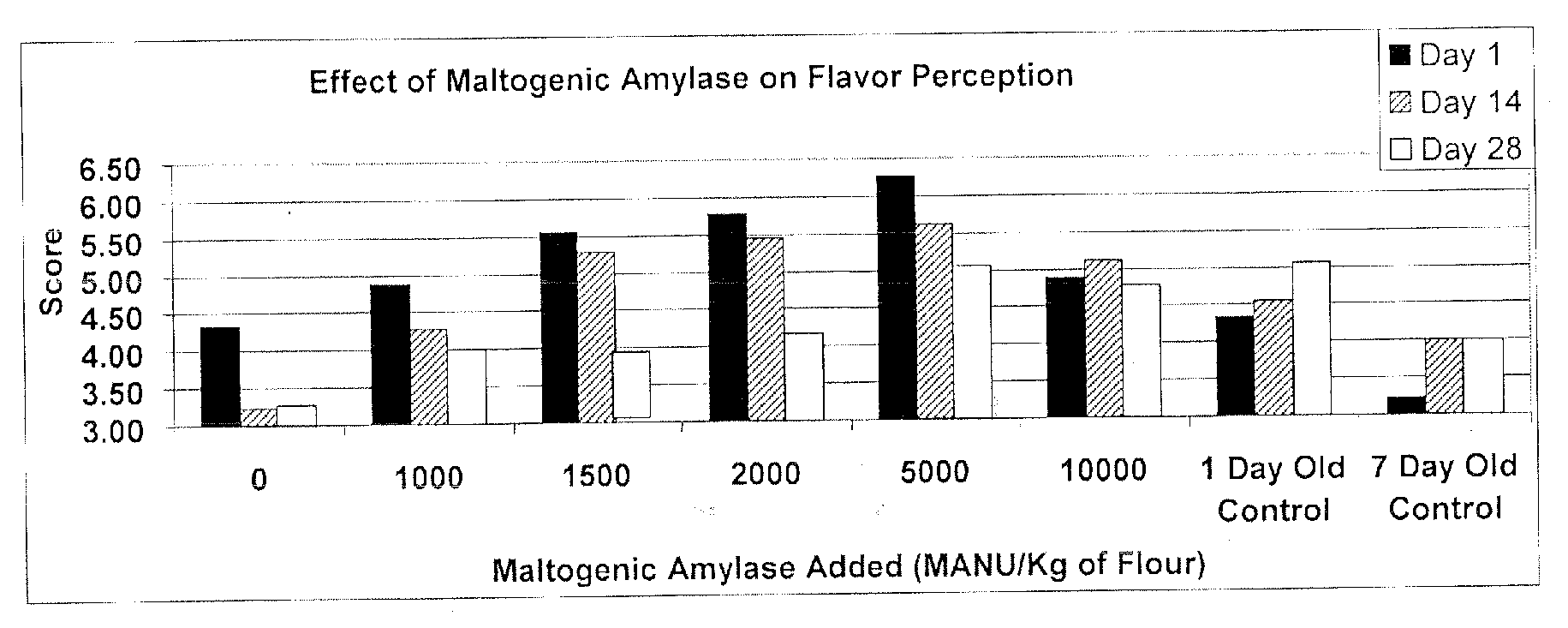

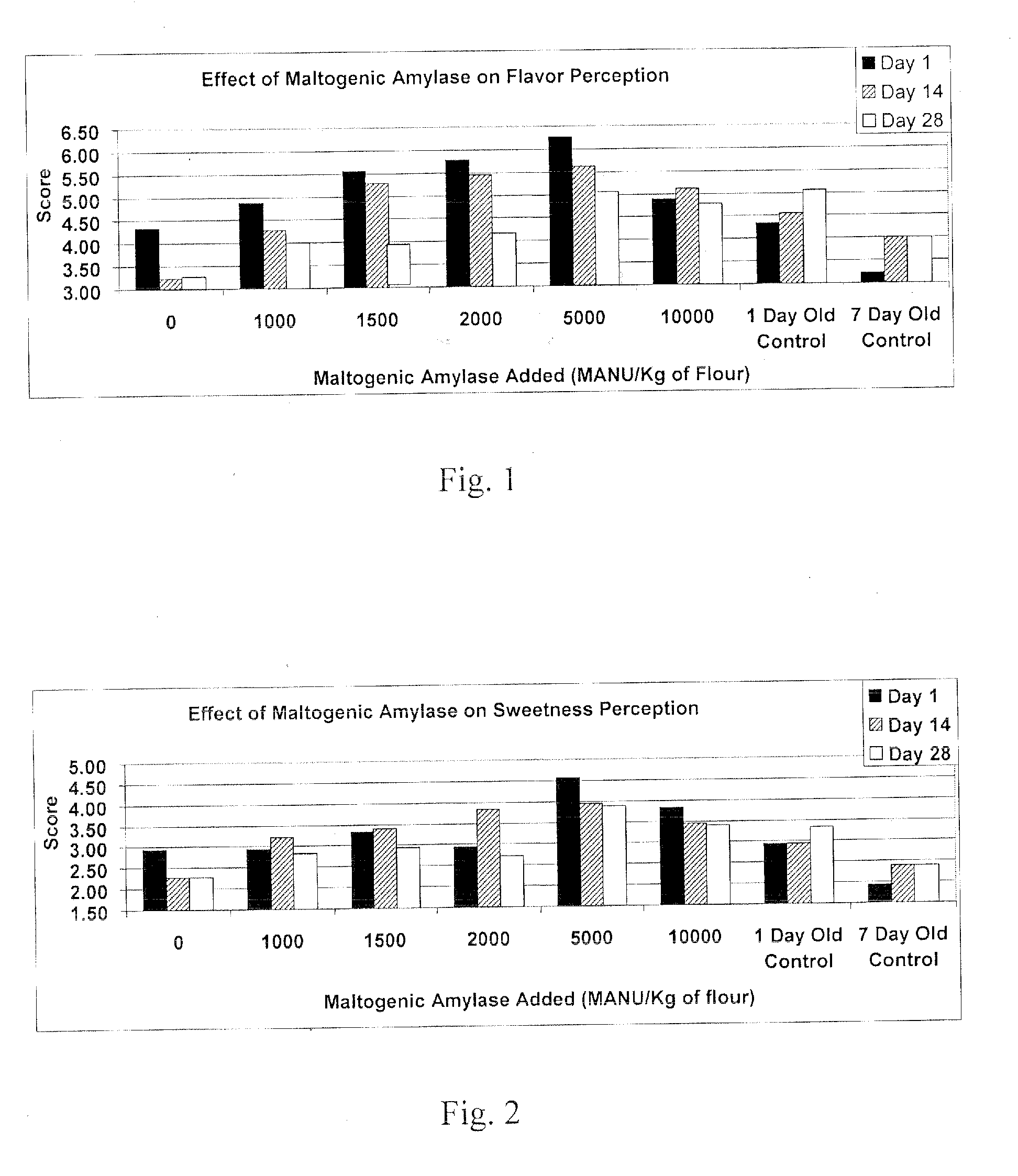

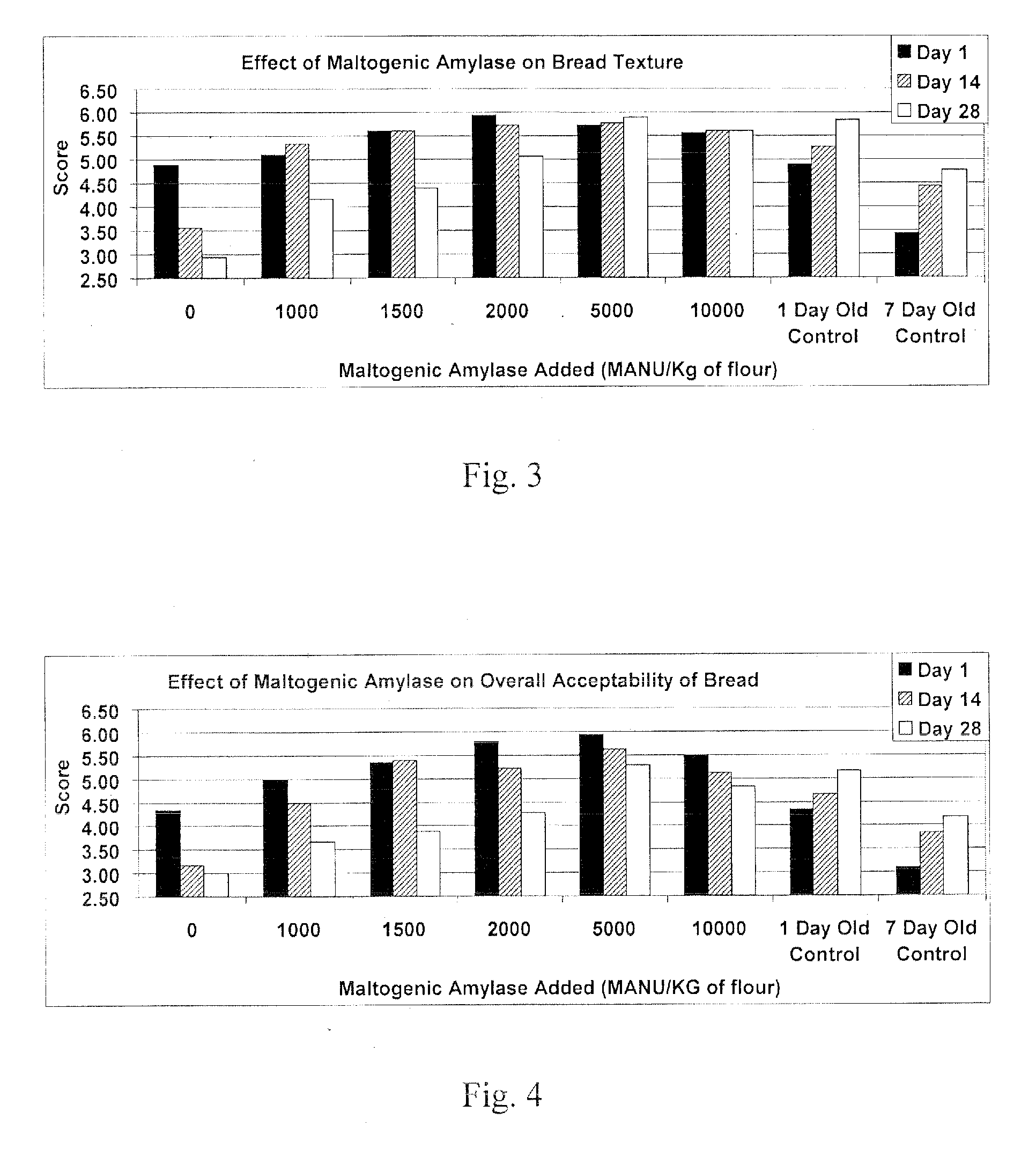

Novel yeast-raised and other bakery products and methods of making those products are provided. The products are formed from dough comprising very high levels of maltogenic amylase. These levels result in improved properties in the final baked product, including improved flavor, longer shelf life, and higher baked volumes. In one embodiment, the level of sugar included in the dough can be substantially reduced compared to prior art quantities, while still achieving a sweet product. The invention also allows certain chemicals such as sodium stearoyl lactylate and azodicarbonamide to be entirely eliminated from the dough.

Owner:CARAVAN INGREDIENTS

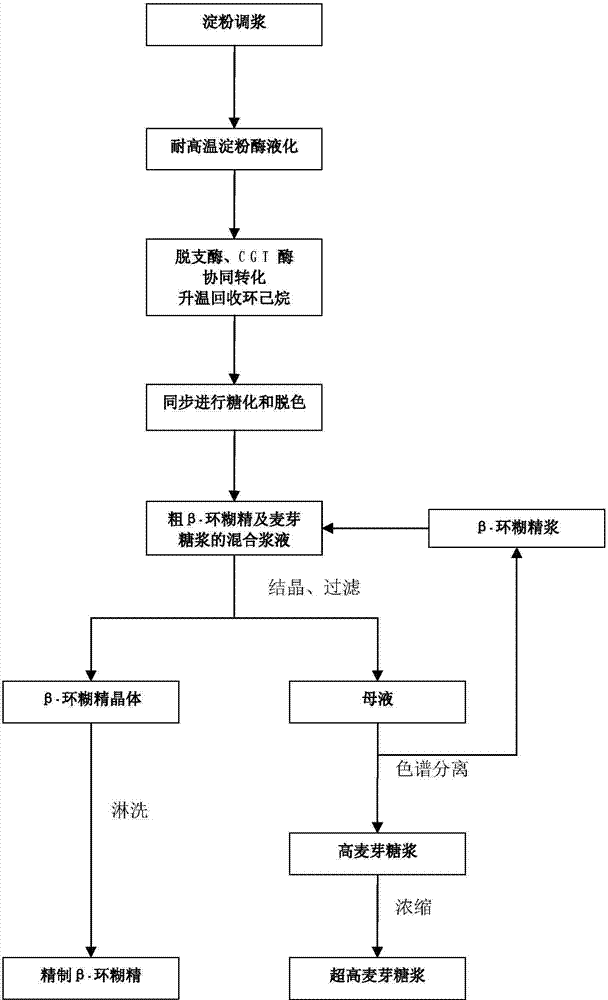

Preparation technology for combined production of beta-cyclodextrin and extremely high maltose syrup

ActiveCN104762346AEffective liquefactionDelay agingFermentationChromatographic separationActivated carbon

The invention relates to a preparation technology for combined production of beta-cyclodextrin and extremely high maltose syrup. The technology comprises the following steps: carrying out starch slurry mixing to resist high temperature alpha-amylase liquefaction; adding debranching enzyme and CGT enzyme for realizing synergism; adding beta-amylase, maltogenic amylase and active carbon to synchronously carry out saccharification and decoloring; and carrying out one time crystallization, filtering, leaching the obtained solid to remove impurities in order to obtain purified beta-cyclodextrin, carrying out chromatographic separation on the obtained mother liquor, and concentrating to obtain the extremely high maltose syrup. The technology has the advantages of high starch conversion rate, one-time decoloring, one-time crystallization, simple steps, preparation of the extremely high maltose syrup, and great improvement of the integral utilization rate of a raw material.

Owner:JIANGSU OGO BIOTECH

Bread improver

ActiveCN105767070ADelay agingImprove Q elasticityDough treatmentPre-baking dough treatmentVitamin CMonoglyceride

The invention discloses a bread improver. The bread improver is prepared from alpha-amylase, xylanase, maltogenic amylase, diacetyl tartaric acid ester of monoglycerides, mono-and diglycerides of fatty acids, sodium stearoyl lactylate, xanthan gum, sodium carboxymethyl cellulose, vitamin C, coarse-grain pre-gelatinized waxy corn starch and vital wheat gluten. The grain size of the coarse-grain pre-gelatinized waxy corn starch meets a condition that a retention rate is smaller than or equal to 40% after the starch is filtered through a 220micrometer screen, and a lactic acid SRC value of the vital wheat gluten is 95.0-130.0%. Due to adoption of the high-fluidity coarse-grain pre-gelatinized waxy corn starch as a carrier, uniformity of components of the bread improver is improved under the conditions of equal time and equal rotation speed; by adoption of the vital wheat gluten with special performances, bread ageing is effectively decelerated to improve resilience of bread.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

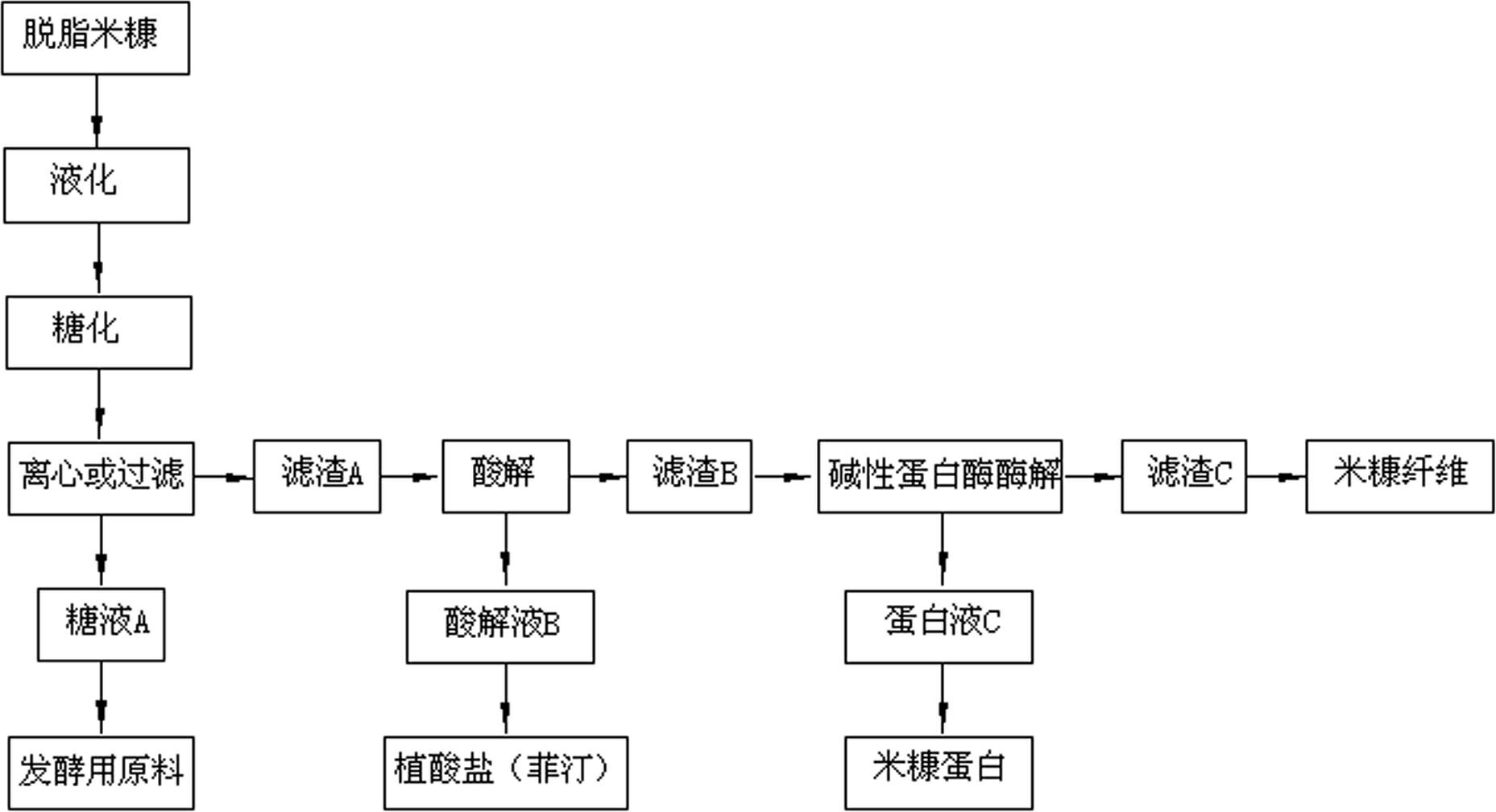

Method for comprehensively utilizing degreased rice bran

InactiveCN102618609AIncrease profitImprove economyGroup 5/15 element organic compoundsFermentationDietary fiberFermentation

The invention the technical field of resource comprehensive utilization, and particularly relates to a method for comprehensively utilizing degreased rice bran. The method comprises the following steps: adding liquefying enzyme in the degreased rice bran for liquification, and carrying out solid-liquid separation to obtain supernate A and residue A, wherein the supernate A is directly used as a raw material for fermentation; adding water into the residue A, mixing to regulate the pH to be acidic, and carrying out solid-liquid separation to obtain supernate B and residue B; regulating the pH of the supernate B to be alkali, filtering, and drying the filter cake to obtain a phytate product; and adding water into the residue B, carrying out reaction between the residue B and basic protease, carrying out solid-liquid separation to obtain supernate C and residue C, carrying out post-processing on the residue C to obtain a dietary fiber (DF) product, and carrying out post-processing on the supernate C to obtain a rice bran protein product. Moreover, maltogenic amylase is added before liquification in the step 1 or enzymolysis in the step 3 for saccharification. According to the method, the comprehensive utilization rate of the degreased rice bran is high; and the generation of rubbish and pollution during the production process is reduced.

Owner:郑州凯乐生物能有限公司

Method for producing fuel ethanol by kudzu root steam explosion pretreatment secondary fermentation

InactiveCN101191134ASave the long cooking processReduce energy consumptionBiofuelsMicroorganism based processesSteam pressureDistillation

The invention relates to a method for production of fuel ethanol through steam explosion pretreatment and secondary fermentation, which comprises the following steps: Kudzu roots are processed by means of steam explosion for 2 to 4 minutes under steam pressure of 0.5 to 1.0MPa; maltogenic amylase is added into the Kudzu roots after steam explosion treatment for saccharification, and (NH4)2SO4, KH2PO4 and yeasts after activation are simultaneously added into the Kudzu roots under aseptic condition for anaerobic fermentation by 48 to 60 hours; ethanol generated by fermentation is distilled and collected; steam explosion technology with short time (2 to 4 minutes) and low pressure (0.5 to 0.8) is adopted for pretreatment of the Kudzu roots, thereby the long-term cooking process (30 to 120 minutes) of starchy materials is left out and energy consumption of fermentation production of the ethanol is reduced. The Kudzu roots after steam explosion treatment are directly fermented after saccharification, and no water is needed to add otherwise, thereby the invention has the advantages of capability of improving ethanol content in beers, reduction of energy consumption of distillation, reduction of treatment of subsequent waste water, reduction of production cost, and favorability for comprehensive utilization of the Kudzu roots.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Special modifying agent for frozen dough containing yeasts as well as manufacturing method and application thereof

InactiveCN105994474AEasy to operateIncrease in sizeDough treatmentPre-baking dough treatmentCooking & bakingVitamin C

The invention relates to the field of foods and particularly relates to a special modifying agent for frozen dough containing yeasts as well as a manufacturing method and application thereof. The special modifying agent for the frozen dough containing the yeasts, provided by the invention, is composed of an emulsifying agent DMG, an emulsifying agent ADMUL DATEM, vitamin C, compound xylanase for baking, xylanase, maltogenic amylase for baking and glucose oxidase. The bread modifying agent provided by the invention is scientific and reasonable in composition and proportion, is high in safety and is simple and convenient to use; and the dough operability can be improved by only utilizing a relatively small dosage of the modifying agent, the size and softness of bread are increased, the anti-ageing effect is remarkable and the guarantee period of the frozen dough is prolonged. The guarantee period of the frozen dough produced by bread chain stores in China is 7-30 days, and the guarantee period of the frozen dough produced by special frozen dough factories also does not exceed 3 months. With the adoption of the special modifying agent provided by the invention, the quality of the product is obviously improved, and the guarantee period can reach 6 months.

Owner:TIANJIN NANQIAO FOOD

Method for brewing kudzu root vinegar

InactiveCN101496600AYellow colorSmell sour and slightly sweetVinegar preparationFood preparationAcetic acidFiltration

The invention relates to a method for brewing kudzuvine root vinegar. The kudzuvine root vinegar is prepared by using powdered kudzuvine root as a basic raw material through the following steps: slicing, drying, breaking and steam boiling the basic raw material; processing the basic raw material with maltogenic amylase; fermenting the basic raw material with acetic acid; performing pressure filtration on the basic raw material; and packaging the finished product. The method uses kudzuvine roots as the raw material to replace foodstuff and fruits to prepare the vinegar, not only successfully makes use of the abundant kudzuvine root resources in China, but also provides a nutrient, medical and delicious health care food.

Owner:余芳

Maize straw core absorbing material and preparing method thereof

InactiveCN101524634ADo not inactivateWide variety of sourcesOther chemical processesNeutral proteaseSlag

The invention discloses a maize straw core absorbing material and a preparing method thereof, which includes the following steps: the maize straw core is crashed to be steamed and boiled in high pressure, sucked, filtered and washed in a mixed solution comprising high boiling-point alcohol and alkali; the filtered slag is oxidized by the oxidizing agent H2O2 and rapidly cooled; the absorbing material is obtained after refrigeration and drying. The preparing method of the invention uses the maize straw core as the raw material for preparing the absorbing material which effectively absorbs neutral protease and maltogenic amylase but does not inactivate the enzyme, sufficiently uses the natural resource, simplifies the preparing method and satisfies the requirements of sustainable development.

Owner:HUAIYIN TEACHERS COLLEGE

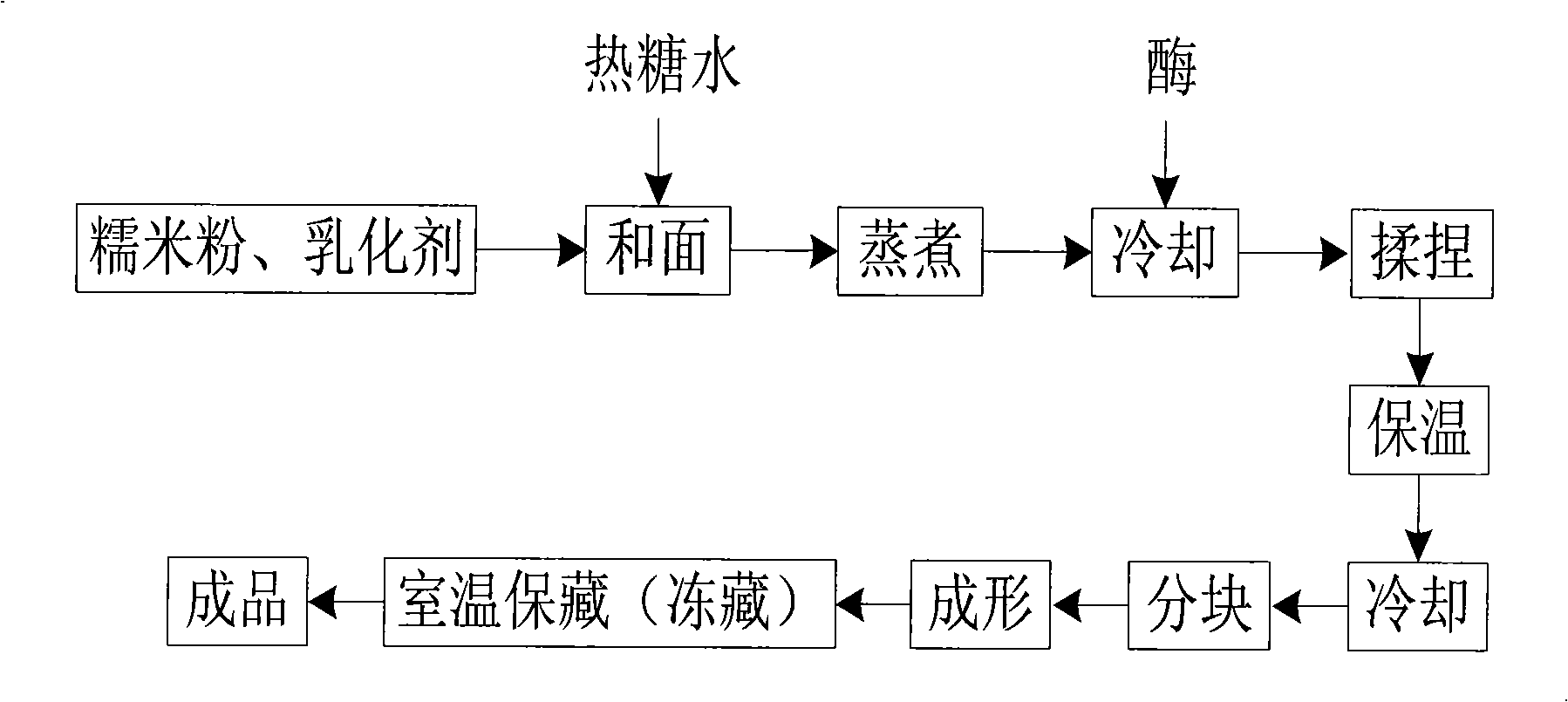

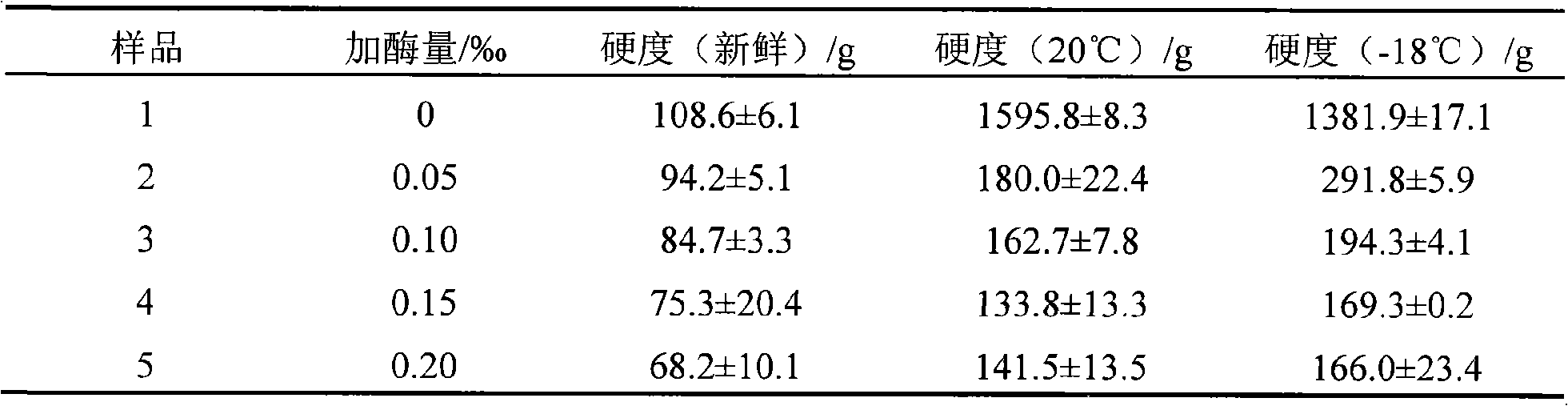

Method for delaying rice retrogradation

The invention relates to a method for making rice with a characteristic of low retrogradation. The method comprises the steps of adding an extremely thermostable maltogenic amylase to a mixture of uncooked rice and water, and then steaming and cooking directly to obtain the rice. The obtained rice has relatively low hardness after being cooled at a room temperature and being stored at a low temperature for some time. The extremely thermostable maltogenic amylase takes effect when the rice is steamed and cooked, treats internal and external starches of the rice uniformly, is in no need of extra enzymolysis time, and can not be polluted easily by microbes. The method is different from the method which comprises the steps of adding uncooked rice and enzyme to room temperature water, immersing or immersing by raising temperature, and then cooking; and is different from the method which comprises the steps of cooking the uncooked rice, cooling, and then treating by adding enzyme.

Owner:CHANGCHUN UNIV +2

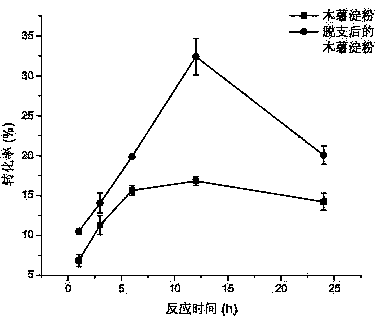

Cycloamylose preparation method based on starch debranching method

The invention discloses a cycloamylose preparation method based on starch debranching method. Starch is taken as an enzyme reaction substrate, and subject to starch debranching, 4-alpha-glycosyl transferase function, maltogenic amylase treatment, ethanol precipitation and freeze-drying to obtain a cycloamylose finish product; the starch is natural starch from different sources and comprises common corn starch and common cassava starch. According to the invention, the low-price natural starch is directly adopted as the substrate to prepare the pure cycloamylose with high conversion rate and high purity, the process is simple and economy and high efficiency are achieved.

Owner:JIANGNAN UNIV

Low carbon hydrate beer and manufacturing method thereof

The invention relates to low carbohydrate beer, which comprises water, alcohol, carbohydrate, protein, carbon dioxide, mineral composition and other compositions, wherein, the carbohydrate is equal to or less than 1.6 percent (m / m), and the heat is equal to or less than 108KJ / 100ml. The manufacturing method of the beer is that: crushing malt, carrying out saccharification and fermentation, filtering and packaging, wherein, the selected raw material is two-rowed malt; the saccharification temperature is 62-65 DEG C and the saccharification time is 60-100 minutes, efficient enzyme preparation is added in the process of saccharification, thereby the fermentation degree of the beer reaches a higher value; maltogenic amylase and pullulanase can be separately selected or selected in a blending way as the efficient enzyme preparation. Compared with the traditional beer, the carbohydrate of the beer is reduced by more than 56 percent, the heat is reduced by more than 36 percent, the rate of dilution can be enlarged to 70 percent, and the main fermentation time is shortened, thereby reducing grain consumption, improving production efficiency, saving production cost and improving product quality.

Owner:TSINGTAO BREWERY

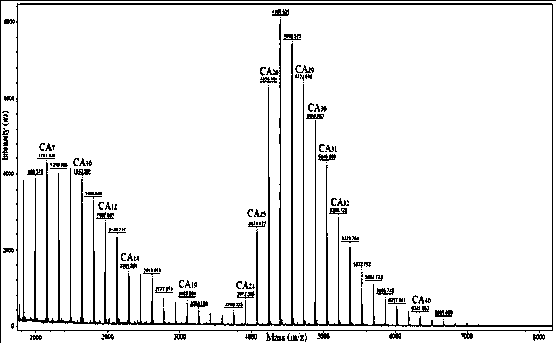

Method for high-efficiency expression of maltogenic amylase in bacillus subtilis

ActiveCN108102996AWide variety of sourcesHigh expressionBacteriaMicroorganism based processesBiotechnologyGenetic engineering

The invention discloses a method for high-efficiency expression of maltogenic amylase in bacillus subtilis, and belongs to the fields of genetic engineering and fermentation engineering. According tothe method provided by the invention, by searching a signal peptide sequence, various signal peptide can be obtained from a bacillus subtilis 168 genome via PCR, recombinant construction is implemented together with target gene maltogenic amylase and a vector pHY300PLK and conversion into bacillus subtilis CCTCC M2016536 is promoted, so that three recombinant bacillus subtilis can be obtained. With the recombinant bacillus subtilis as a strain, the maltogenic amylase is obtained through fermenting production. In addition, the enzyme activity of the recombinant enzyme is improved by confirmingsuch optimized optimum shaker conditions as a nitrogen source, a carbon source, fermentation conditions and the like. The method provided by the invention has the advantages that it conforms that thehigh-efficiency expression of the signal peptide of the maltogenic amylase can be achieved in the bacillus subtilis, and the recombinant expression of the maltogenic amylase is implemented with the food-safety bacillus subtilis as an expression host; enzyme production of the recombinant bacterium undergoes fermentation optimization; a relatively good expression amount is achieved; the enzyme activity of obtained fermentation supernatant is 396U / mL; and the method is broad in source of fermentation raw materials and relatively low in production cost.

Owner:JIANGNAN UNIV

Process for producing ethanol from potato residue

InactiveCN101487028AShorten the timeShort timeBiofuelsMicroorganism based processesAdditive ingredientFiltration

The invention discloses an ethanol production method that utilizes potato pulp and is characterized by comprising the steps: impurity removal of a raw material of potato pulp, addition of a liquefying enzyme, aging and liquefying under microwave heat, dual-enzymatic saccharification, fermentation, vacuum filtration of a fermented fluid, vacuum pressure-reduced distillation and molecular sieve dehydration, thus obtaining 99.5% finished ethanol product, which is then stored at normal temperature. For the raw materials of potato pulp, which contains ingredients of cellulose and starch and the like, firstly the ethanol production method is utilized and microwave is used for aging and liquefying the starch contained in the raw materials of potato pulp, which are added with liquefying enzyme; then maltogenic amylase and cellulose are added for continuing saccharification; immobilized yeast is used for fermenting sugar ingredients; pulp is removed by vacuum filtration; low-concentration ethanol is distillated through pressure-reduced vacuum distillation and the 99.5% ethanol is prepared through molecular sieve dehydration, and finally the ethanol stored at normal temperature in sealed environment. The ethanol production method leads the raw material of potato pulp to be liquefied at the temperature of 70 to 85 DEG C, saccharified by dual enzymes at the temperature of 58 to 62 DEG C,fermented at the temperature of 28 to 32 DEG C, vacuum filtered and distilled in pressure-reduced vacuum, thus maximizing the utilization of the potato pulp ingredients in the ethanol production, andthe ethanol production method is characterized by energy-saving effect, quickness and high yield, and can be widely applied into the ethanol production with various materials of potato pulp that contain cellulose and starch ingredients.

Owner:LANZHOU UNIVERSITY

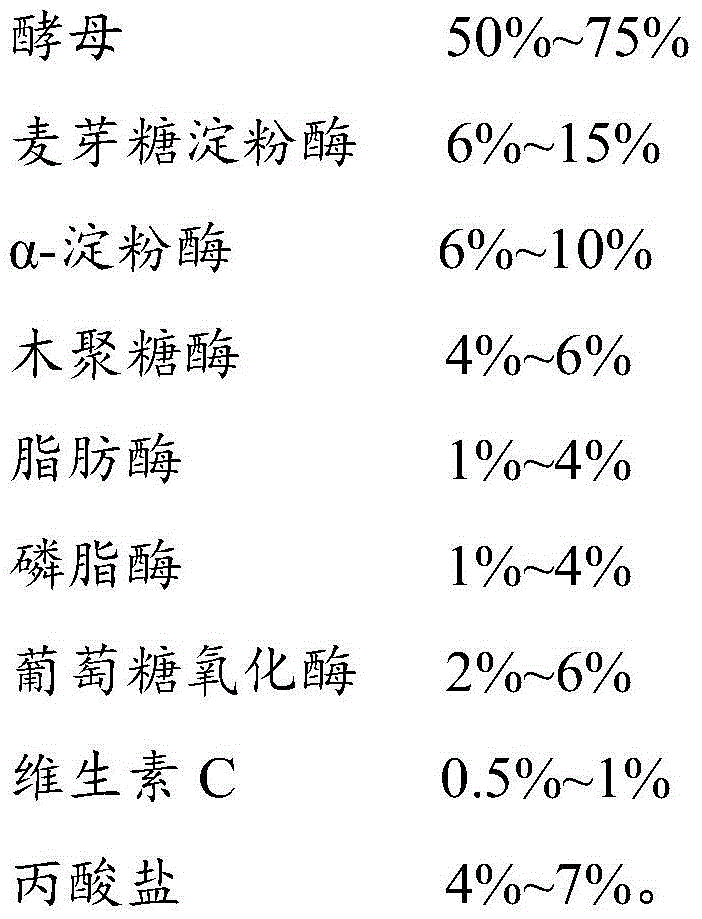

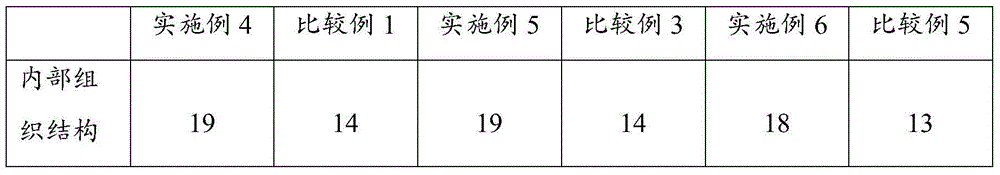

Flour yeast composition and applications thereof

InactiveCN104686611AMaintain structureHas whitening effectPre-baking dough treatmentFood additiveVitamin C

The present invention discloses a flour yeast composition and applications thereof, and belongs to the technical field of flour food additives. The flour yeast composition comprises the following ingredients by weight: 50% to 75% of yeast, 6% to 15% of maltogenic amylase, 6% to 10% of alpha-amylase, 4% to 6% of xylanase, 1% to 4% of lipase, 1% to 4% of phospholipase, 2% to 6% of glucose oxidase, 0.5% to 1% of vitamin C and 4% to 7% of propionate. When the flour yeast composition is added to flour to produce flour products, through the synergetic effects among the ingredients, effects of whitening, anti-aging, shelf life extending and internal organizational structure delicacy improving on flour products are achieved, and the flavor and nutritional value of flour products are retained.

Owner:ANHUI LEVEKING BIOTECH CO LTD

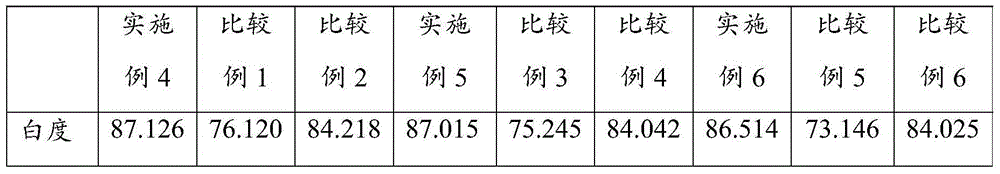

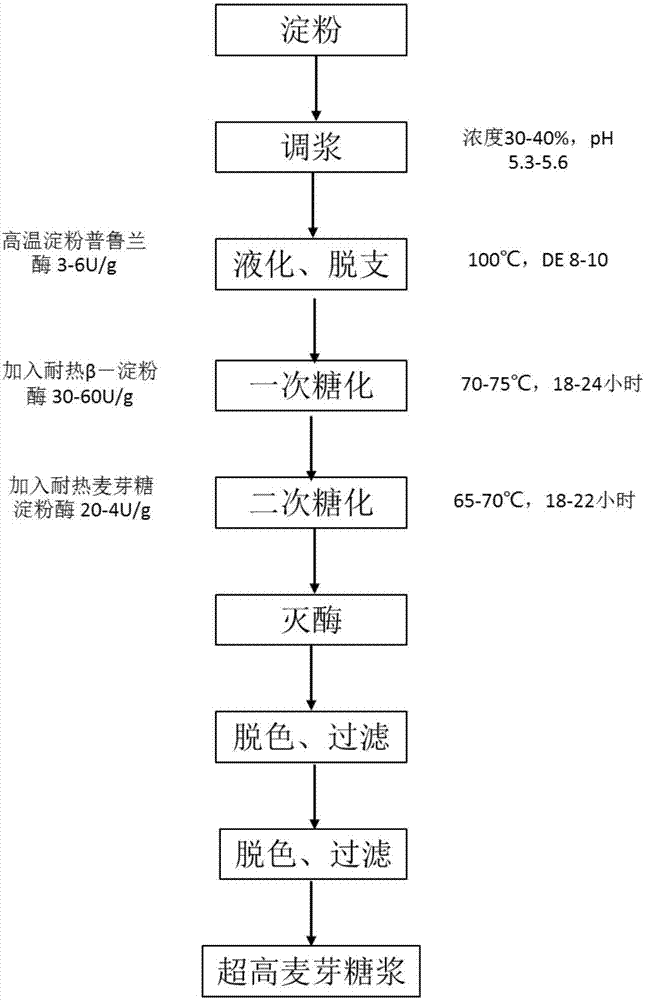

Method for preparing malt syrup

ActiveCN107043796AHigh liquefaction DE valueIncrease concentrationBacteriaMicroorganism based processesLiquid glucoseEvaporation

The invention relates to a method for preparing malt syrup, which belongs to the technical field of the conversion of starch sugar. The method comprises the following steps: by adopting starch as a substrate, performing synchronous liquefaction and debranching reaction by utilizing high-temperature starch pullulanase, then adding heat-resistant beta-amylase and heat-resistant maltogenic amylase step by step or simultaneously, performing saccharification, decoloring, and concentrating, thus obtaining the malt syrup. The process has the advantages of high substrate concentration, low possibility of contaminating infectious microbe and simple process; the liquid glucose evaporation energy consumption in a later period of sugar preparation from starch can be reduced, extraction procedures can be simplified, and the production efficiency of the malt syrup can be favorably increased.

Owner:JIANGSU OGO BIOTECH

Liquid fermentation distilled liquor technique

InactiveCN105132244AIncrease wine yieldHigh product quality controllabilityAlcoholic beverage preparationDistillationEvaporation

The invention discloses a liquid fermentation distilled liquor technique. The liquid fermentation distilled liquor technique is characterized in that a mono-grain or various grains is / are taken as the raw materials, the grain raw material is crushed into a powder syrup, the powder syrup is heated and gelatinized to obtain a gelatinized mash, the gelatinized mash is processed under the action of maltogenic amylase to obtain a saccharified mash, saccharified mash is processed under the action of yeast to produce alcohol so as to obtain a fermented mash, or the gelatinized mash is added with distiller's yeast to be directly fermented to obtain a fermented mash, a distiller consisting of a distillation still, a distillation tower and a condenser is adopted to perform intermittent distillation to obtain a 60-94 percent (v) wine base, the wine base is placed in a wood barrel for storage, and blending, filtering and filling are performed to obtain a liquid fermentation distilled liquor. The liquid fermentation distilled liquor technique has the advantages of being high in liquor yield, low in labor intensity, controllable in production process, highly controllable product quality and the like, and fully conforms to the health concept requirements, discharged vinasse can directly serve as animal food or evaporated and dried to produce a DDGS high-protein feed, and the evaporation wastewater can be subjected to standard emission after simple anaerobic and aerobic treatment, so that the liquid fermentation distilled liquor technique conforms to the national environment-friendly industrial policy.

Owner:威海远航科技发展股份有限公司

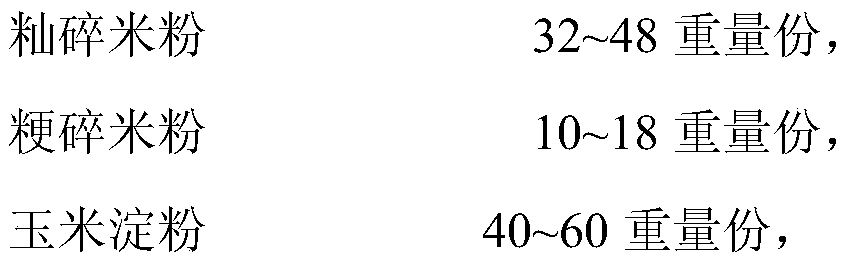

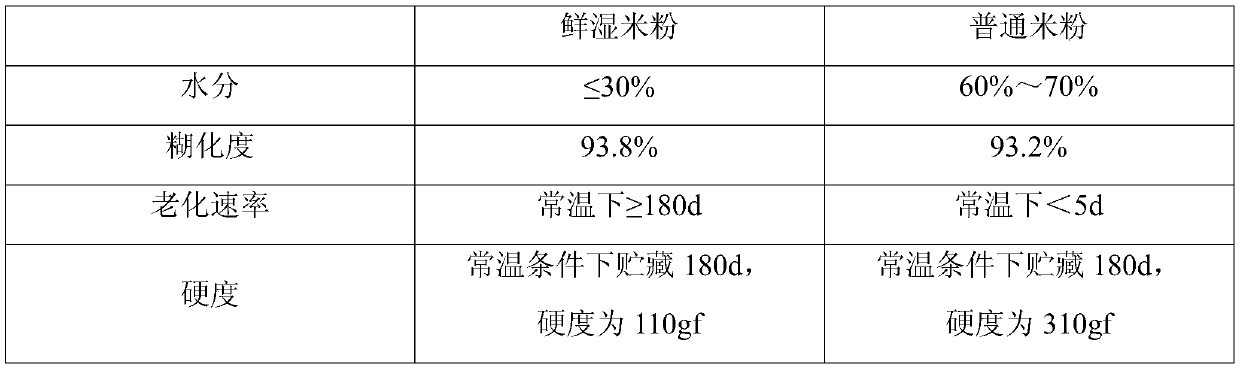

Fresh wet rice noodles and preparation method thereof

InactiveCN110326741ASolve long-term wasteIncrease added valueFood scienceDegree of polymerizationKonjac glucomannan

The invention relates to the technical field of food processing, in particular to fresh wet rice noodles and a preparation method thereof. The fresh wet rice noodles comprise the following raw materials: 32-48 parts by weight of broken polished long-grained nonglutinous rice flour, 10-18 parts by weight of broken polished round-grained rice, 40-60 parts by weight of corn starch, 1-5 parts by weight of cooked rice flour and 0.2-0.8 part by weight of compound quality modifier, wherein the compound quality modifier comprises sodium carboxymethylcellulose, modified soybean phosphatide, konjac glucomannan, beta-amylase and maltogenic amylase. By use of the fresh wet rice noodles, the broken polished long-grained nonglutinous rice flour, the broken polished round-grained rice, the corn starch and the cooked rice flour are taken as main raw materials, and the compound quality modifier is taken as an auxiliary material. Through the synergistic effect of the beta-amylase and the maltogenic amylase in the compound quality modifier, the gelatinization degree of the rice noodles is improved, in addition, the degree of polymerization of amylose in the rice noodles is lowered, the rice noodle aging rate in a rice noodle storage process is greatly delayed, the rice noodles can keep good elasticity and can maintain proper hardness during shelf life, and the quality of the fresh wet rice noodles is guaranteed to be stable.

Owner:四川东方主食产业技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com