Aging-resistant starch composition, tapioca pearls and preparation method of tapioca pearls

An anti-aging and composition technology, which is applied in food preparation, food science, application, etc., can solve the problems of hardening the taste of the powder balls, affecting the eating pleasure of the powder balls, and not being easy to break, so that the preparation method is simple and suitable for large The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

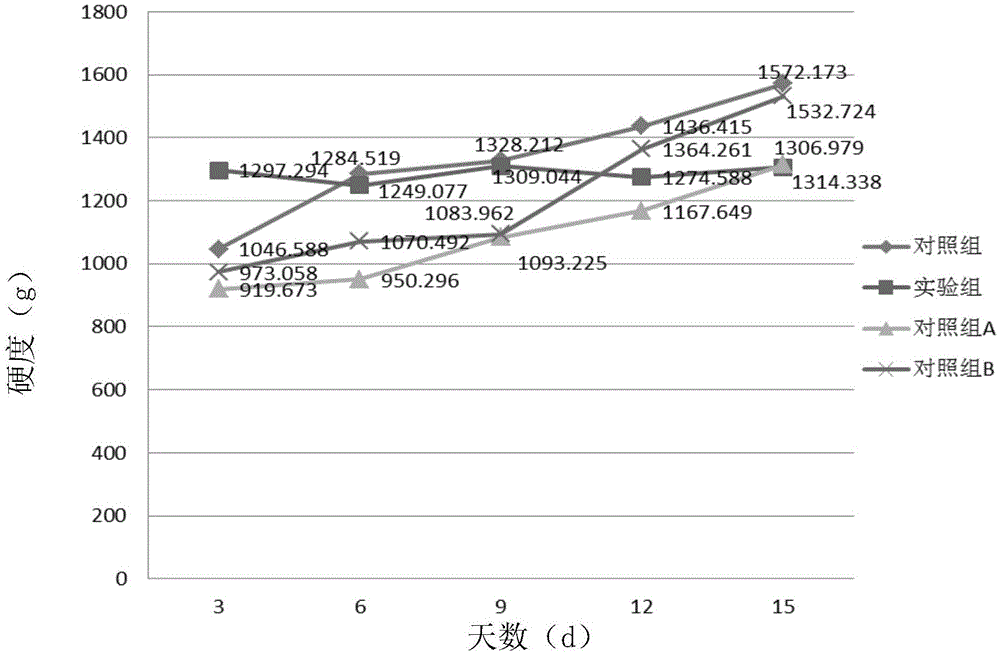

Problems solved by technology

Method used

Image

Examples

Embodiment 1

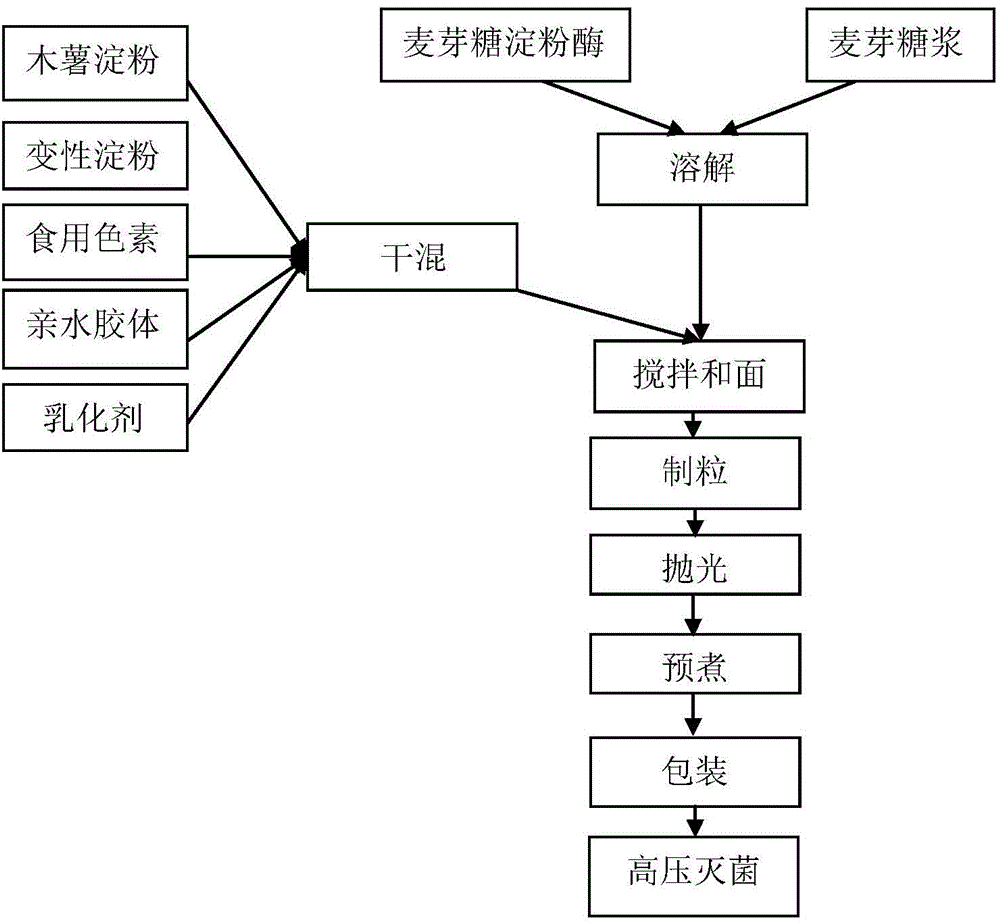

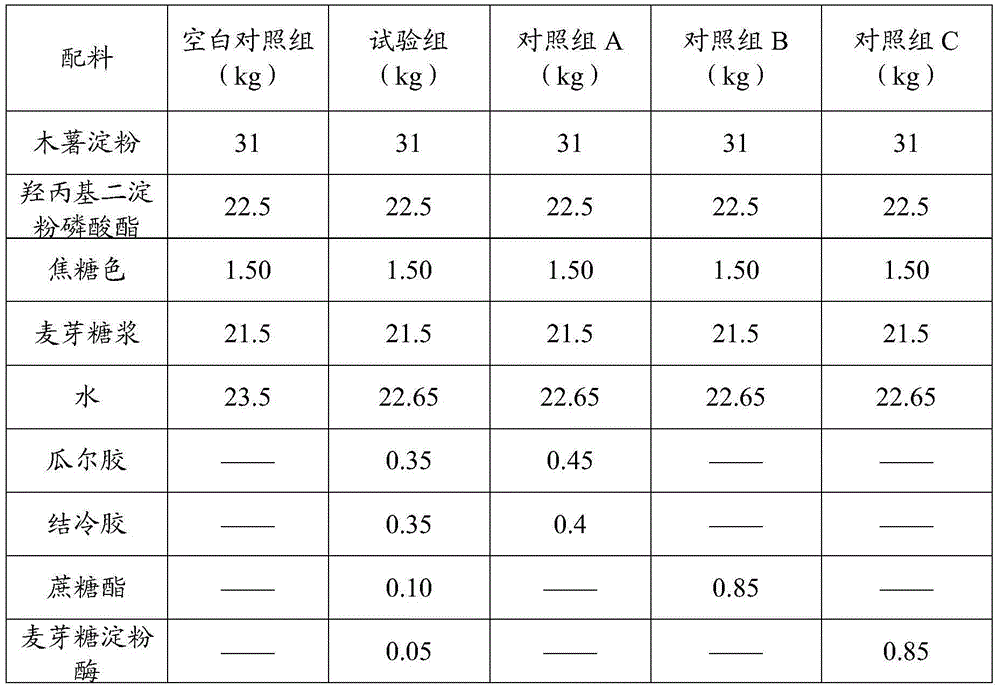

[0050] The preparation of embodiment 1 powder circle

[0051] 31kg of tapioca starch, 22kg of hydroxypropyl distarch phosphate, 1.5kg of caramel pigment, 0.35kg of guar gum, 0.35kg of gellan gum, and 0.1kg of sucrose ester were dry mixed in a V-type mixer, and the time was set correctly. Rotate for 20 minutes, invert for 20 minutes to obtain mixed powder.

[0052] Dissolve 21.5kg of maltose syrup in 23.15kg of hot water at a temperature of 75°C, and then add 0.05kg of maltose amylase to obtain an enzyme solution.

[0053] The mixed powder obtained above is first poured into a horizontal mixer, and then the enzyme solution is poured into the horizontal mixer and immediately starts stirring and kneading. After the dough is evenly stirred, the dough is immediately granulated and shaped by a non-stuffed glutinous rice ball machine while it is still hot. Turn on the round spheronizer, adjust the speed, and put the finished particles into the spheroid for polishing. After polishi...

Embodiment 2

[0054] The preparation of embodiment 2 powder circle

[0055] 18kg tapioca starch, 40kg hydroxypropyl distarch phosphate, 1kg caramel pigment, 0.5kg guar gum, 0.5kg carrageenan, and 0.05kg glycerol monostearate were dry mixed in a V-type mixer, and the time was set Rotate forward for 20 minutes and reverse for 20 minutes to obtain mixed powder.

[0056] Dissolve 10kg of maltose syrup in 29.45kg of hot water at a temperature of 50°C, and then add 0.5kg of maltose amylase to obtain an enzyme solution.

[0057] The mixed powder obtained above is first poured into a horizontal mixer, and then the enzyme solution is poured into the horizontal mixer and immediately starts stirring and kneading. After the dough is evenly stirred, the dough is immediately granulated and shaped by a non-stuffed glutinous rice ball machine while it is still hot. Turn on the round spheronizer, adjust the speed, and put the finished particles into the spheroid for polishing. After polishing, the powder...

Embodiment 3

[0058] Example 3 Preparation of powder balls

[0059] 40kg tapioca starch, 18kg hydroxypropyl distarch phosphate, 3kg caramel pigment, 0.25kg guar gum, 0.25kg konjac gum, 0.5kg diacetyl tartrate monoglyceride are dry mixed in a V-type mixer, and the time is set Rotate forward for 20 minutes and reverse for 20 minutes to obtain mixed powder.

[0060] Dissolve 30kg of maltose syrup in 7.99kg of hot water at a temperature of 85°C, and then add 0.01kg of maltose amylase to obtain an enzyme solution.

[0061] The mixed powder obtained above is first poured into a horizontal mixer, and then the enzyme solution is poured into the horizontal mixer and immediately starts stirring and kneading. After the dough is evenly stirred, the dough is immediately granulated and shaped by a non-stuffed glutinous rice ball machine while it is still hot. Turn on the round spheronizer, adjust the speed, and put the finished particles into the spheroid for polishing. After polishing, the powder bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com