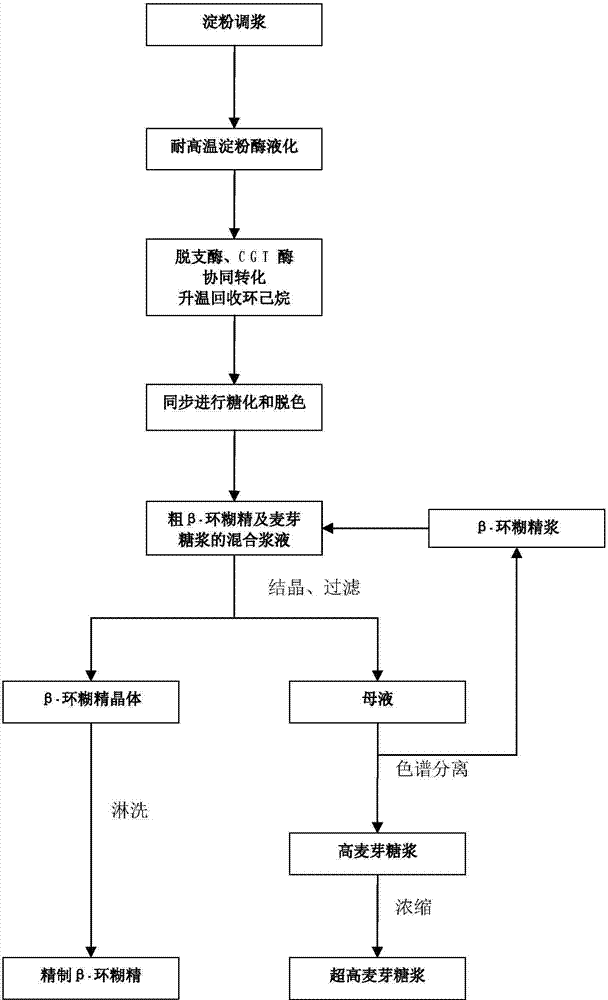

Preparation technology for combined production of beta-cyclodextrin and extremely high maltose syrup

A maltose syrup and preparation process technology, which is applied in the field of β-cyclodextrin and ultra-high maltose syrup co-production preparation technology, can solve the problems of increasing the difficulty of extraction, reducing the utilization rate of starch, increasing the production cost, etc., so as to improve the synthesis of raw materials. Effectiveness of utilization rate, reduction of starch aging, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this example, the co-production process of β-cyclodextrin and ultra-high maltose syrup adopts the above-mentioned specific implementation process, and the specific parameters are as follows:

[0042] In the first step, adopt the tapioca starch 1.2t that pure starch mass content is 84.3%, prepare the starch slurry that mass concentration is 20% by pure starch with warm water in liquefaction injector, the pH value of starch slurry is adjusted to 5.8, high temperature resistance The amount of α-amylase added is 4 units per gram of pure starch; after thorough mixing, the temperature is raised to 108°C for liquefaction, jet cooking, and then flashed to 98°C and laminar flow for 80 minutes.

[0043] In the second step, the slurry obtained in the first step is cooled to 60°C, the amount of pullulanase added is 2.5 units per gram of pure starch, the amount of CGT enzyme added is 2.5 units per gram of pure starch, and the added weight of cyclohexane It is 3% of the dry weight...

Embodiment 2

[0048] In this example, the co-production process of β-cyclodextrin and ultra-high maltose syrup adopts the above-mentioned specific implementation process, and the specific parameters are as follows:

[0049] In the first step, 1.45t of cornstarch with a mass content of 85.9% of pure starch is used, and warm water is used to prepare starch slurry with a mass concentration of 25% based on pure starch in a liquefaction injector. The pH value of the starch slurry is adjusted to 5.6, which is resistant to high temperatures. The amount of α-amylase added is 6 units per gram of pure starch; after thorough mixing, the temperature is raised to 110°C for liquefaction, jet cooking, and then flashed to 96°C and laminar flow for 60 minutes.

[0050] In the second step, the slurry obtained in the first step is cooled to 60° C., the amount of pullulanase added is 3 units per gram of pure starch, the amount of CGT enzyme added is 4 units per gram of pure starch, and the added weight of cyclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com