Cooling and dehumidifying equipment for medical laboratory

A technology for cooling and dehumidification and inspection rooms, which is applied in the field of medical inspections, can solve problems such as being very sensitive to temperature changes, medical accidents, short circuits of electronic components, circuits, etc., achieve high efficiency of liquefaction heat transfer, stable and continuous circuit, and solve low operating costs , The effect of non-attenuation of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

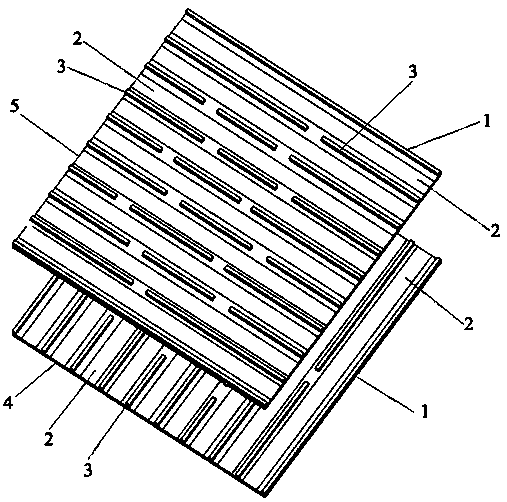

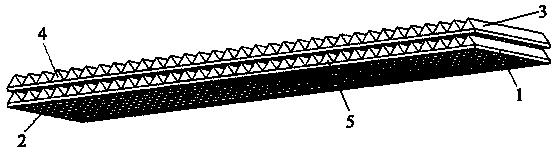

[0029] Such as Figure 1 to Figure 6 As shown, this embodiment provides an absorbing shell plate, including: absorbing shell plate 1, characterized in that the shell plate 1 is matched with channels 2 and refrigeration pipes 3, and a plurality of shell plates 1 are stacked. Refrigerating pipes 3 enclose the first air passage 4 and the second air passage 5, the passages 2 are staggered at intervals to form spaced cooling and liquefaction absorption areas, and the cold source protrudes from the contact line between the surface part of the shell and the plane of the shell A gap is provided at the center, and the air duct gap has been formed for the liquefaction and dry absorption of moisture.

[0030] A cooling and dehumidification device, comprising: an absorption shell plate 1, channels 2 etc. are arranged on the absorption shell plate, there are multiple absorbing shell plates, the absorbing shell plate can cool down and liquefy absorb water vapor, the shell plate 1. The abso...

Embodiment 2

[0038] Such as figure 1 with Image 6 As shown, a cooling and dehumidification equipment includes: an absorption shell plate 1, a second absorption shell plate, etc., there are multiple absorbing shell plates, and the absorbing shell plate can cool down and liquefy absorb water vapor, and the shell plate 1. The second absorbing shell plate and the absorbing shell plate X are stacked in sequence, and a cooling pipe 3 is arranged between any two absorbing shell plates, and the cooling pipe 3 can generate cooling and liquefaction absorption Energy exchange can be performed on the area or the shell plate, and there is a gap at the contact line between the protruding shell surface part of the cold source and the shell plane, which has formed the air duct gap, and the shell plate 1 as a whole It is a metal with low specific heat, the surface of the metal with low specific heat is liquefied substance, the absorbent shell 1 contains absorbent for absorbing water and preventing freezi...

Embodiment 3

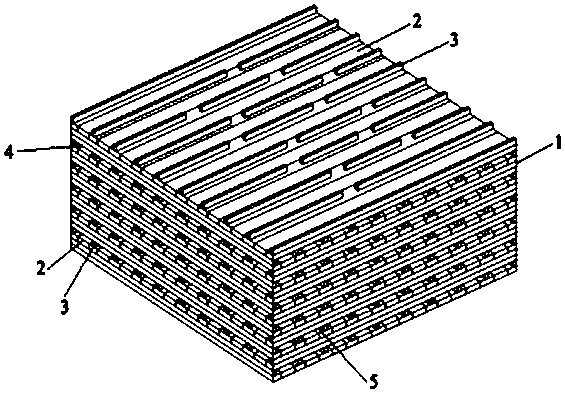

[0048] Based on the basis of embodiment one and two, such as image 3 , 4 As shown in and 5, an absorbing shell plate provided in the third embodiment includes: a shell plate 1, characterized in that, the shell plate 1 is matched with a channel 3 and a heat sink 2, and a plurality of the shell plates 1 Overlapping, there is a gap at the line of contact between the protruding shell surface part of the cold source and the plane of the shell, the air duct gap has been formed, and the first air duct 4 and the second air duct are formed by the cold source 2 5. The cooling and liquefaction absorption zones are formed between all the shells at intervals. When combined with the energy exchange system, the non-moisture medical inspection and dry absorption can be well realized.

[0049] specifically:

[0050] The shell plate 1 includes a refrigeration pipeline plate and a shell plane, and the shell plate and the refrigeration pipeline plate have a hexagonal structure, specifically: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com