A kind of production preparation technology of trehalose

A preparation process, trehalose technology, applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of limited scope of application, inability to completely remove, etc., achieve consistent process, easy and excellent separation effect, and improve conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

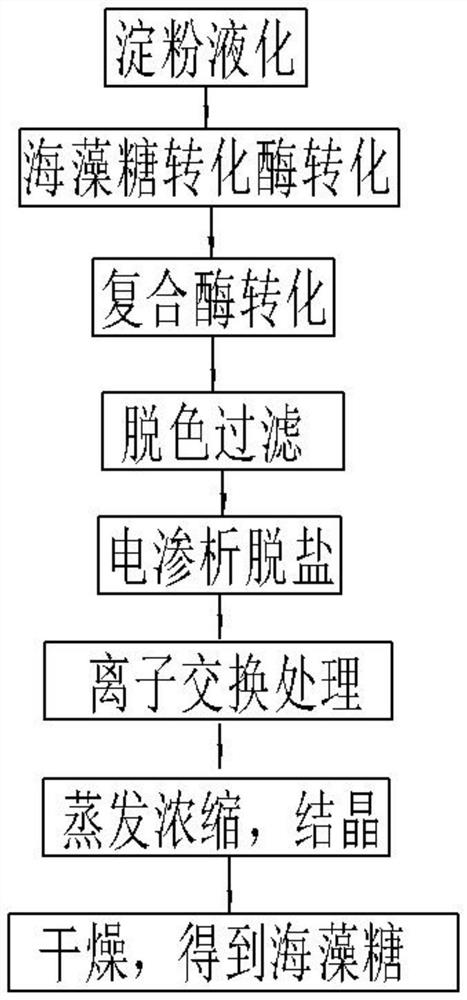

Method used

Image

Examples

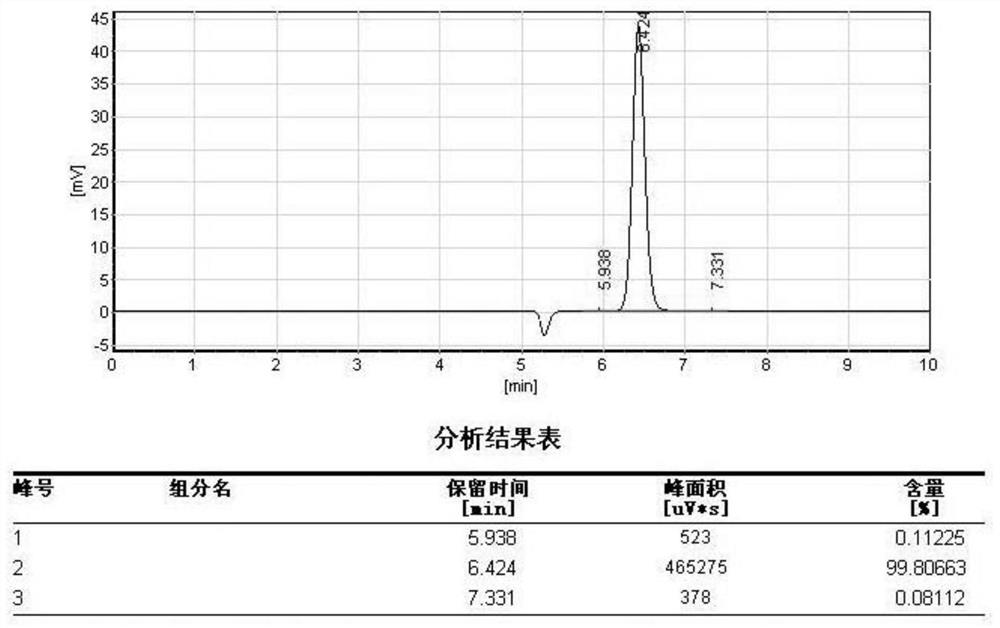

Embodiment 1

[0060] S1: Starch liquefaction: Mix starch and water to prepare starch slurry, then adjust the pH value of the starch slurry to 5.4, add α-amylase, mix well, heat up to 105°C for 5 minutes, and then flash evaporate to 94 DEG C and laminar flow 60min, control DE value 2, inactivate enzyme, obtain liquefaction liquid; The starch is 84.3% cornstarch; The mass concentration of described starch slurry is 20%; The addition amount of α-amylase is starch 0.02% by mass.

[0061] S2: Trehalase conversion: Take the liquefied liquid, add starch debranching enzyme and trehalose converting enzyme, and enzymatically hydrolyze for 24 hours under the conditions of pH 5.5 and temperature 45° C. to obtain trehalose conversion liquid. The trehalose inverting enzyme includes trehalose hydrolase and trehalose synthetase; the mass of the trehalose inverting enzyme is 1% of the starch mass.

[0062] S3: Compound enzyme conversion: take trehalose conversion solution, add glucoamylase and compound enz...

Embodiment 2

[0069] S1: Starch liquefaction: Mix starch and water to prepare starch slurry, then adjust the pH value of the starch slurry to 5.6, add α-amylase, mix well, heat up to 108°C for 6 minutes, and then flash evaporate to 97°C and laminar flow for 75min, control the DE value to 3, and inactivate the enzyme to obtain a liquefied liquid; the starch is 85.9% potato starch; the mass concentration of the starch slurry is 25%; the amount of α-amylase added is the starch mass 0.03%.

[0070] S2: Trehalase conversion: Take the liquefied liquid, add starch debranching enzyme and trehalose converting enzyme, and enzymatically hydrolyze for 36 hours under the conditions of pH 6 and temperature 50° C. to obtain trehalose conversion liquid. The trehalose inverting enzyme includes trehalose hydrolase and trehalose synthetase; the mass of the trehalose inverting enzyme is 2% of the starch mass.

[0071] S3: Compound enzyme conversion: take trehalose conversion solution, add glucoamylase and com...

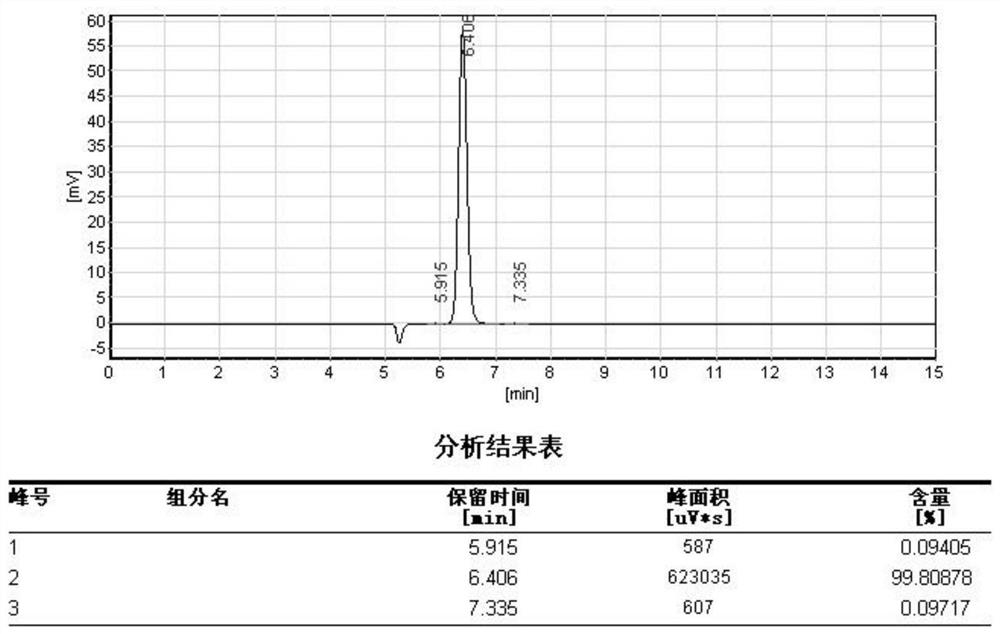

Embodiment 3

[0078] S1: Starch liquefaction: Mix starch and water to prepare starch slurry, then adjust the pH value of the starch slurry to 5.8, add α-amylase, mix well, heat up to 110°C for 8 minutes, and then flash evaporate to 99°C and laminar flow for 90min, control the DE value to 4, and inactivate the enzyme to obtain a liquefied liquid; the starch is tapioca starch; the mass concentration of the starch slurry is 30%; the amount of α-amylase added is 0.04% of the starch mass %.

[0079] S2: Trehalase conversion: take the liquefaction solution, add starch debranching enzyme and trehalose conversion enzyme, and enzymatically hydrolyze for 48 hours under the conditions of pH 6.5 and temperature 55° C. to obtain trehalose conversion solution. The trehalose inverting enzyme includes trehalose hydrolase and trehalose synthetase; the mass of the trehalose inverting enzyme is 3% of the starch mass.

[0080] S3: Compound enzyme conversion: take the trehalose conversion solution, add glucoam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com