Fresh wet rice noodles and preparation method thereof

A rice noodle and fresh wet technology, which is applied in the field of fresh wet rice noodle and its preparation, can solve the problems of fresh wet rice noodle without rice flavor, long exposure time of production raw materials, and low amount of rice added, so as to delay the aging rate and save processing energy consumption , full of rice fragrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

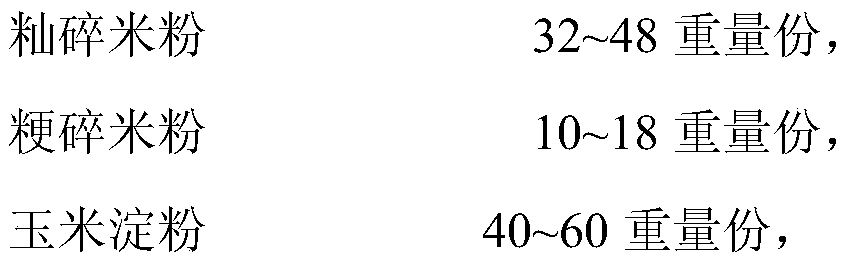

[0023] A preparation method of fresh wet rice noodles, raw materials comprising:

[0024] The indica broken rice flour of 45 weight parts, the japonica broken rice flour of 10 weight parts, the cornstarch of 50 weight parts, the cake flour of 3 weight parts, the compound quality improver of 0.65 weight part; Described compound quality improver comprises a mass ratio of 0.4 : 0.2: 0.5: 0.04: 0.03 sodium carboxymethylcellulose, modified soybean lecithin, konjac glucomannan, β-amylase, maltose amylase, the particle size of the indica broken rice flour and japonica broken rice flour is 80 ~120 meshes, the cake flour is cooked indica broken rice flour;

[0025] During the preparation process, weigh the raw materials according to the above ratio, mix them evenly, and then add water to mix evenly. The mass ratio of the material to water in the process of adding water is 0.3:1, and in the process of adding water to the material, mix the material until the material is loose. Small par...

Embodiment 2

[0030] A preparation method of fresh wet rice noodles, raw materials comprising:

[0031] The indica broken rice flour of 44 weight parts, the japonica broken rice flour of 18 weight parts, the cornstarch of 48 weight parts, the cake powder of 5 weight parts, the compound quality improver of 0.55 weight part; Described compound quality improver comprises a mass ratio of 1 : 0.3: 0.8: 0.05: 0.02 sodium carboxymethyl cellulose, modified soybean lecithin, konjac glucomannan, β-amylase, maltose amylase, the particle size of the indica broken rice flour and japonica broken rice flour is 80 ~120 meshes, the cake flour is cooked indica broken rice flour;

[0032] During the preparation process, weigh the raw materials according to the above ratio, mix evenly, and then add water to mix evenly. The mass ratio of the material to water during the water addition process is 0.4:1, and in the process of adding water to the material, mix the material until the material is loose. Small parti...

Embodiment 3

[0035] A preparation method of fresh wet rice noodles, raw materials comprising:

[0036] The indica broken rice flour of 48 weight parts, the japonica broken rice flour of 16 weight parts, the cornstarch of 60 weight parts, the cake flour of 1 weight part, the compound quality improver of 0.8 weight part; Described compound quality improver comprises a mass ratio of 0.8 : 0.4: 0.5: 0.03: 0.06 sodium carboxymethylcellulose, modified soybean lecithin, konjac glucomannan, β-amylase, maltose amylase, the particle size of the indica broken rice flour and japonica broken rice flour is 80 ~120 meshes, the cake flour is cooked indica broken rice flour;

[0037] During the preparation process, weigh the raw materials according to the above ratio, mix them evenly, and then add water to mix evenly. The mass ratio of the material to water during the water addition process is 0.35:1, and in the process of adding water to the materials, mix the materials until the materials are loose Smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com