Method for preparing malt syrup

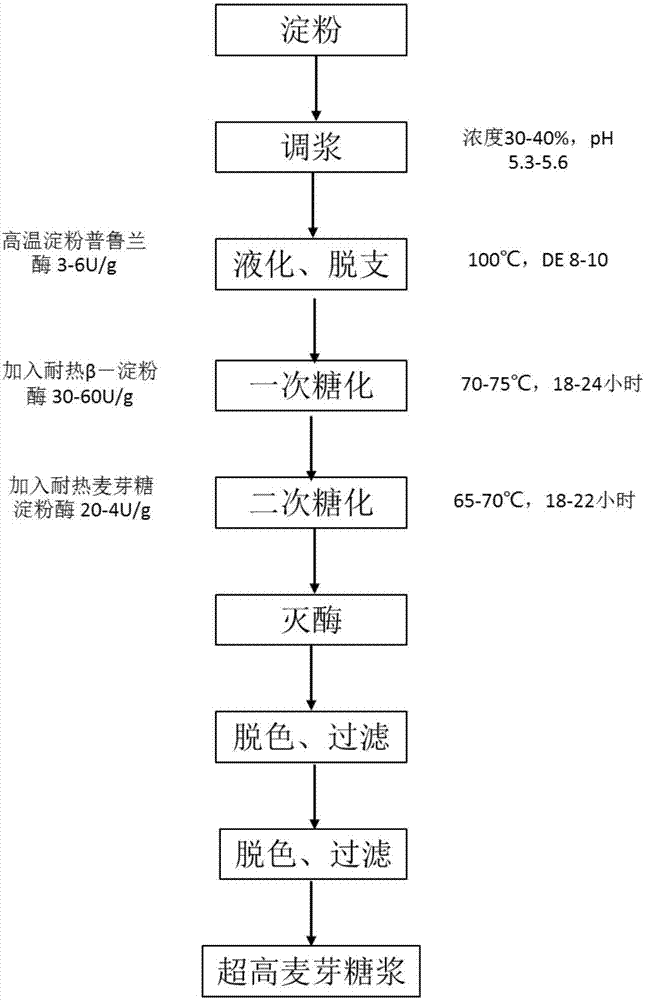

A maltose syrup and maltose amylase technology, which is applied in the field of starch sugar conversion, can solve the problems of high probability of contamination, repeated addition of acid and alkali, large temperature and temperature rise, etc., and achieves the effects of increasing maltose concentration, reducing consumption and reducing burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of high temperature starch pullulanase

[0032] Purchase and obtain Thermococcus litoralis DSM5473 from ATCC, take the genome of this bacterium as template, PCR obtains sequence such as the sequence that GeneID is 16549640 in NCBI database, connects in the expression vector pET20b, transforms host bacterial strain BL21 (DE3) again; TB medium (glycerol 5g / L, peptone 12g / L, yeast extract 24g / L, dipotassium hydrogen phosphate 12.54g / L, potassium dihydrogen phosphate 2.31g / L, kanamycin 30μg / mL) culture, and adopt The expression was induced by IPTG, and the recombinant high-temperature starch pullulanase was obtained after centrifugation. The enzyme activity assay showed that the pullulanase activity in the fermentation supernatant was 36.8U / mL, and the α-amylase activity was 103.6U / mL.

[0033] The starch pullulanase has dual activities of pullulanase and α-amylase, and can simultaneously hydrolyze α-1,6 glucosidic bonds and α-1,4 glycosidic bonds in starch...

Embodiment 2

[0047] Weigh 500 grams of cornstarch, add appropriate amount of water to prepare starch milk with a mass concentration (based on pure starch dry basis) of 30%, add 0.2% calcium chloride, adjust the pH value of the starch milk to 5.5, and then add high-temperature starch Pullulanase, the amount of the enzyme added is 5U (calculated as α-amylase activity) per gram of starch (calculated as pure starch dry basis), fully stirred and mixed evenly, gradually warming up to 95°C, and controlling the stirring speed to 100 rpm / min, liquefied for 80 minutes, and the DE value of the liquefied system was determined to be 8.1.

[0048] Lower the temperature of the starch liquefaction liquid system to 70°C, and add heat-resistant β-amylase and heat-resistant maltose amylase to it, the addition amount is 30U and 40U per gram of pure starch, control the stirring speed to 150 rpm, continue React for 20 hours.

[0049] When sampling with absolute alcohol to check that there is no dextrin in the...

Embodiment 3

[0052] Take by weighing 500 grams of tapioca starch, add an appropriate amount of water to prepare a starch milk with a mass concentration (in terms of pure starch dry basis) of 30%, add 0.1% calcium chloride, adjust the pH value of the starch milk to 5.6, and then add high-temperature starch Pullulanase, the amount of the enzyme added is 5U (calculated as α-amylase activity) per gram of starch (calculated as pure starch dry basis), fully stirred and mixed evenly, gradually heated to 100 °C, and the stirring speed was controlled to 100 rpm / min, liquefied for 80 minutes, and the DE value of the measured liquefied system was 9.0.

[0053] Lower the temperature of the starch liquefaction liquid system to 70°C, and add heat-resistant β-amylase and heat-resistant maltose amylase to it, the addition amount is 60U and 30U per gram of pure starch, control the stirring speed to 150 rpm, continue React for 20 hours.

[0054] When sampling with absolute alcohol to check that there is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com