Bread improver and application thereof in bread making

A bread improver and improver technology, applied in application, dough treatment, pre-baked dough treatment and other directions, can solve the problem of insignificant effect, etc., and achieve the effects of improving flavor, inhibiting aging, and improving operational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

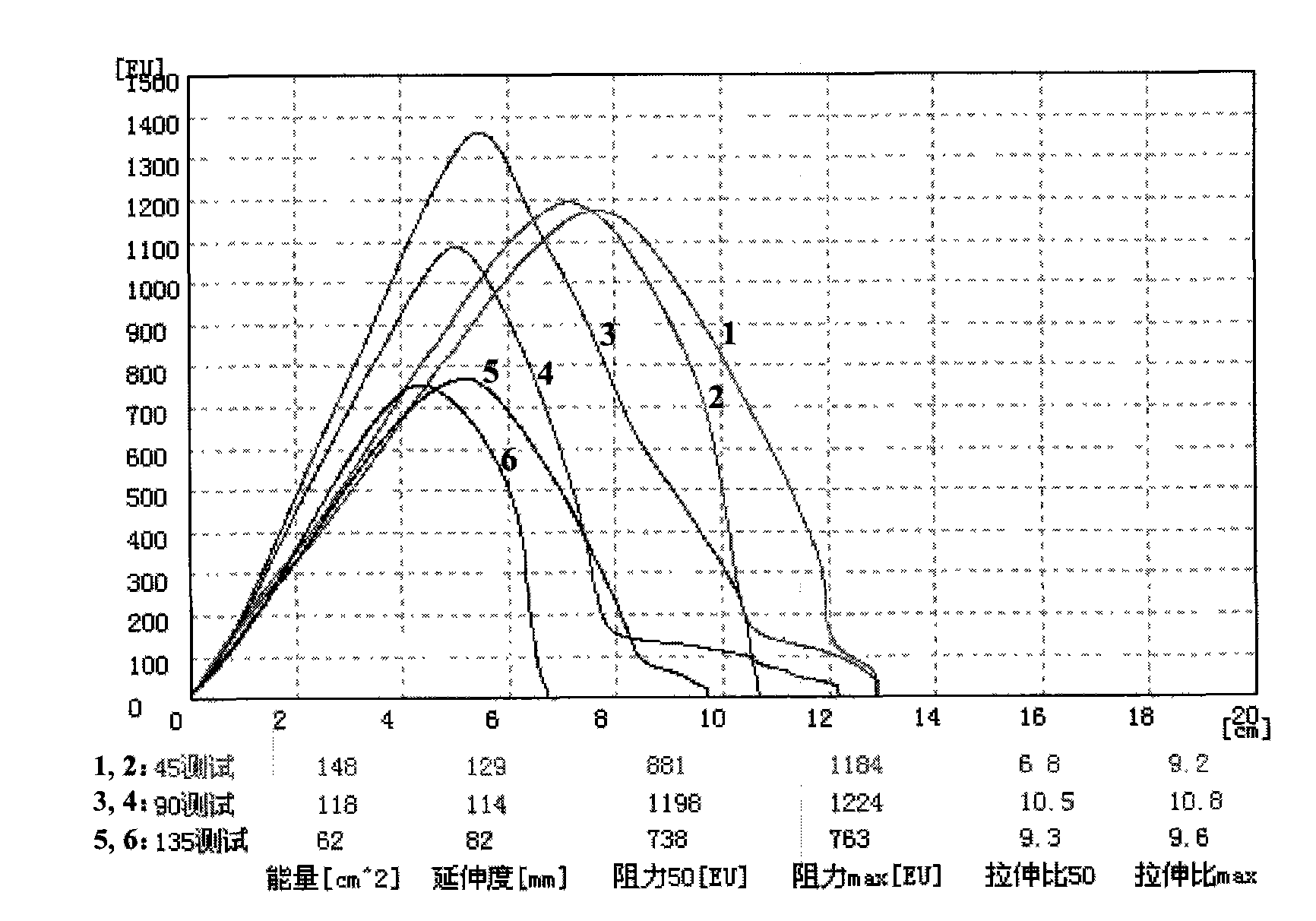

[0036] Embodiment 1 bread experimental data

[0037] First, mix 1000g of bread flour, 5g of bread improver, 12g of salt, 50g of white sugar, 40g of butter, 600g of water, and 2g of calcium propionate, then stir slowly for 3 minutes, then stir quickly 3 minutes. The dough was allowed to relax for 10 minutes, divided, 400g / piece, shaped (made into toast), and fermented at 37°C for 100 minutes. Then bake: heat up to 180°C, lower heat to 190°C for 25 minutes. It is then cooled and packaged. In this example, the bread improver consisted of 0.1% by weight alpha-amylase, 0.5% hemicellulase, 0.3% maltogenic amylase, 0.3% lipase, 20% inactivated dry yeast, 2% ascorbic acid (vitamin C) as an oxidizing agent, 10% diacetyl tartaric acid monoglyceride and 5% calcium / sodium stearoyl lactylate as an emulsifier, and 61.8% corn starch.

[0038] Accordingly, bread with the following characteristics can be obtained: low hardness, good taste and sufficient elasticity.

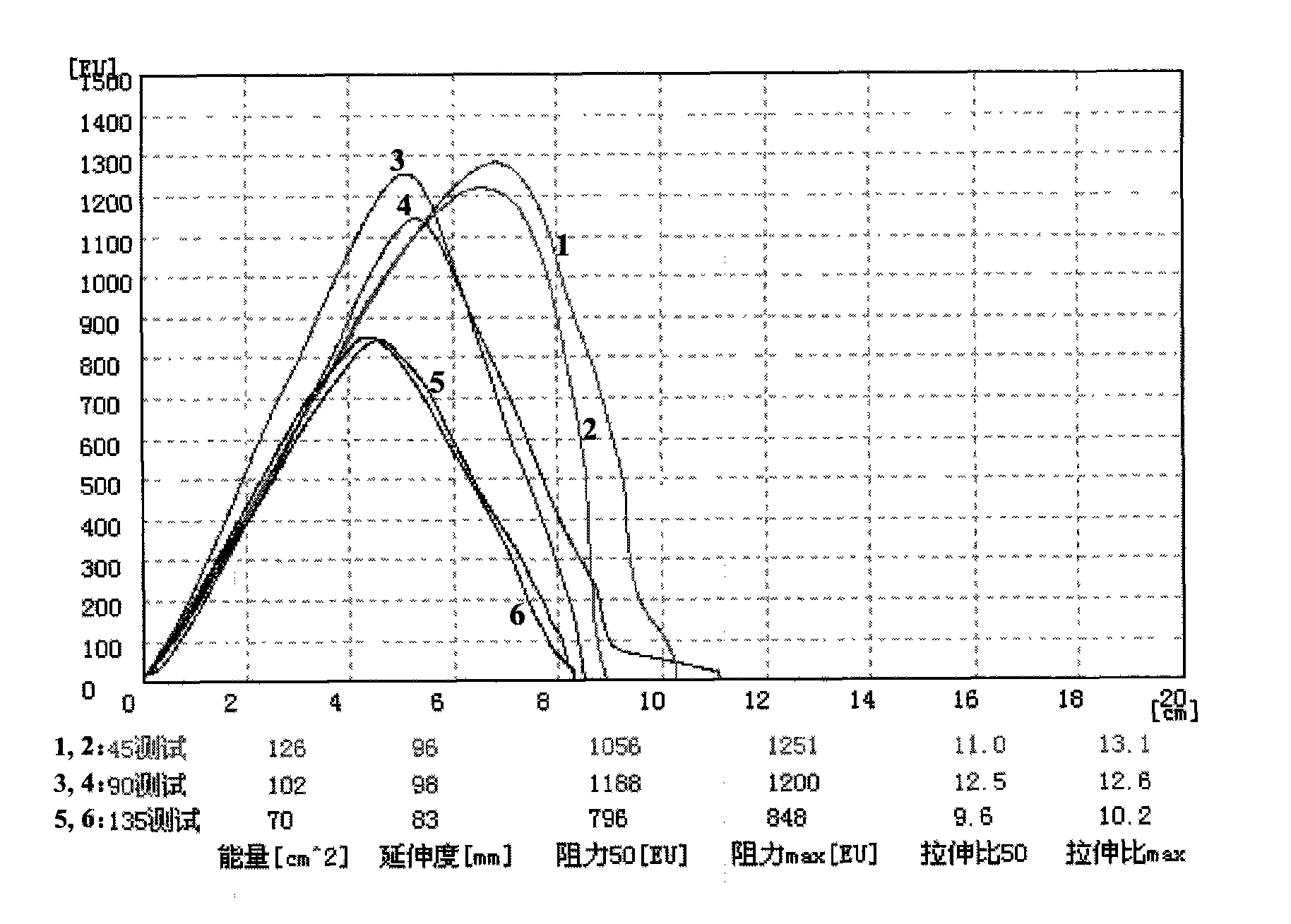

Embodiment 2

[0040] Bread was made in the same manner as in Example 1, except that the content of each ingredient in the bread improving agent in Example 1 was changed, and in Example 2, the bread improving agent was changed from 0.15% α- Amylase, 0.6% hemicellulase, 0.4% maltogenic amylase, 0.2% lipase, 15% inactivated dry yeast, 1% ascorbic acid (vitamin C) as oxidizing agent, 15% as emulsifier Diacetyl tartaric acid monoglyceride and 10% calcium / sodium stearoyl lactylate, and 57.65% corn starch.

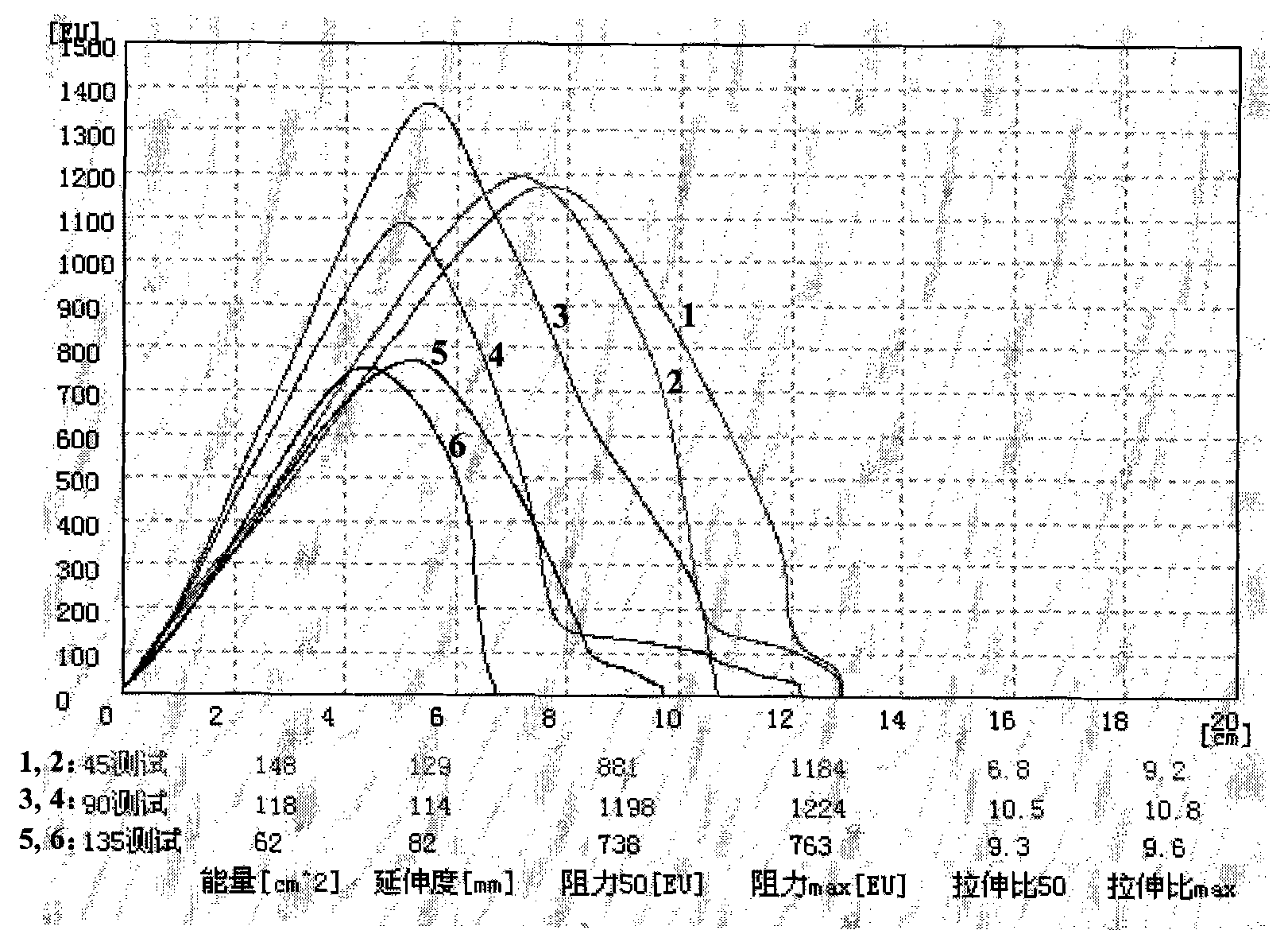

Embodiment 3

[0042] Bread was made in the same manner as in Example 1, except that the content of each ingredient in the bread improver in Example 1 was changed, and in Example 3, the bread improver consisted of 0.2% α- Amylase, 0.7% hemicellulase, 0.5% maltogenic amylase, 0.1% lipase, 30% inactivated dry yeast, 3% ascorbic acid (vitamin C) as oxidizing agent, 15% as emulsifier Diacetyl tartaric acid monoglyceride and 15% calcium / sodium stearoyl lactylate, and 35.5% corn starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com