Liquid fermentation distilled liquor technique

A technology of liquid fermentation and process method, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of complex wine components, high labor intensity, and low wine production rate, and achieve high product quality controllability, low labor intensity, and high yield. The effect of high alcohol rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

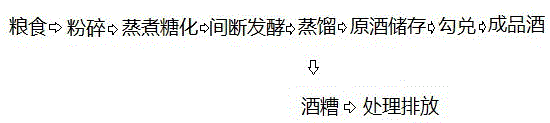

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] A process for distilling wine by liquid fermentation, characterized in that it is produced by the following steps with grain raw materials:

[0025] Step 1: Grinding the grain raw materials, passing the crushed particles through a sieve below 1.8-2.5 mm to obtain powdery raw materials, adding water to the powdery raw materials and stirring them into a powder slurry, the water-adding ratio is 1:2.1-4;

[0026] Step 2: Heating the powder slurry for 30-90 minutes, gelatinizing under the action of liquefaction enzyme at 95-110°C for 60-120 minutes to obtain gelatinized mash, the amount of liquefaction enzyme added is generally 1 gram of raw material 5~20 units;

[0027] Step 3. Cool the gelatinized mash to about 60°C, add glucoamylase for saccharification, the amount of glucoamylase added is 80-200 units per gram of raw material, and the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com