Citrus wine, brewing process of citrus brandy and citrus brandy

The technology of brandy and citrus is applied to the brewing process of citrus wine, citrus brandy and citrus brandy. In this field, it can solve problems such as unstable taste and aroma, affect the taste of citrus wine, and unsatisfactory fermentation effect, and achieve the effects of no toxic side effects, increased wine production rate, and remarkable efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

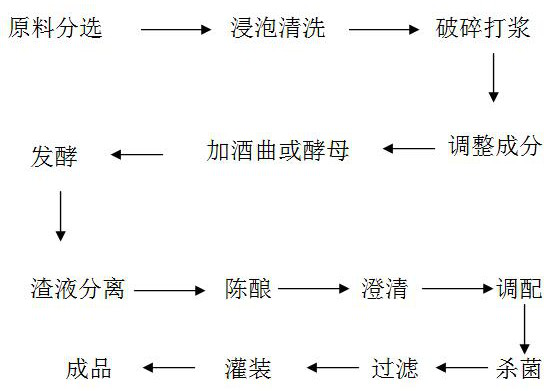

Image

Examples

Embodiment 1

A brewing process of citrus wine, comprising the following steps:

S1 raw material selection: select fully mature fruits as raw materials; select fresh sugar oranges with a maturity of more than 90%, no pests and diseases, and no residues;

S2 immersion cleaning: wash with running water to remove soil, debris and microorganisms attached to the fruit;

S3 crushing and beating: first scald the washed fruit in hot water at 95-100°C for 30-60 seconds, peel off the peel and tangerine network by hand, and remove the core. Put it into a beater for crushing and beating, and then use a screw juicer to extract the juice;

S4 adjustment ingredients: 100 kg of citrus is added with 9, 10 or 11 kg of white sugar, and the acid content of the raw material is adjusted to 0.7% with carbonic acid before fermentation, and the sugar content is increased to 18%; the alcohol content of the brewed wine is about 15 %VOL;

S5 Add koji or yeast: after adding sugar, add fruit koji or yeast, the inocula...

Embodiment 2

A brewing process of citrus wine, comprising the following steps:

S1 selection of raw materials: select fully ripe fruits as raw materials; select fresh citrus with a maturity of more than 90%, no pests and diseases, and no residues, the citrus in the present invention is citrus, and the raw material is selected from citrus;

S2 immersion cleaning: wash with running water to remove soil, debris and microorganisms attached to the fruit;

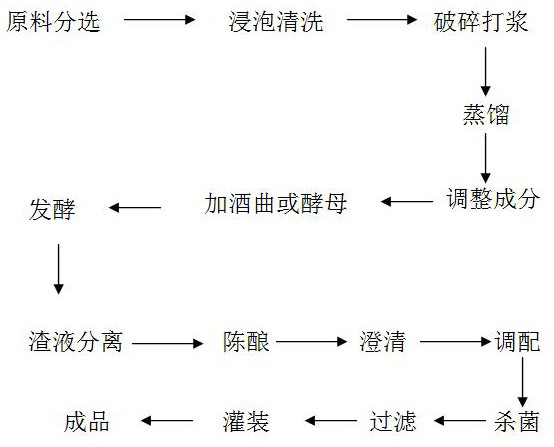

S3 Crushing and beating: First, scald the washed fruit in hot water at 95-100°C for 30 seconds, peel off the peel and tangerine network, and remove the core by hand. Wear sterile gloves during manual processing, and put the citrus in the beating process. Crushing and beating is carried out in the machine, and then the juice is extracted with a screw juicer; the extracted juice is distilled and concentrated, the distillation temperature is controlled at 75-90 ° C, the distillate is collected for use, and when the distillation is concentrated to ...

Embodiment 3

A brewing process of citrus wine, comprising the following steps:

S1 selection of raw materials: select fully mature fruits as raw materials; select fresh citrus with a maturity of more than 90%, no diseases and insect pests, and no residues, the citrus in the present invention is citrus, and the raw materials are selected from sugar tangerine and baba tangerine; select fully mature fruits As the raw material for winemaking, at this time, the sugar content is high, and the higher the sugar content, the better the raw material, the higher the yield of wine, the delicious juice, the fragrance of citrus and the good flavor;

S2 immersion cleaning: wash with running water to remove soil, debris and microorganisms attached to the fruit;

S3 Crushing and beating: first scald the washed fruit in hot water at 95-100 ° C for 30-60 seconds, peel off the peel and tangerine network by hand, remove the core, put the citrus in a beating machine for crushing and beating, and then Use a scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com